Exam Code: 700-821

Exam Name: Cisco IoT Essentials for System Engineers

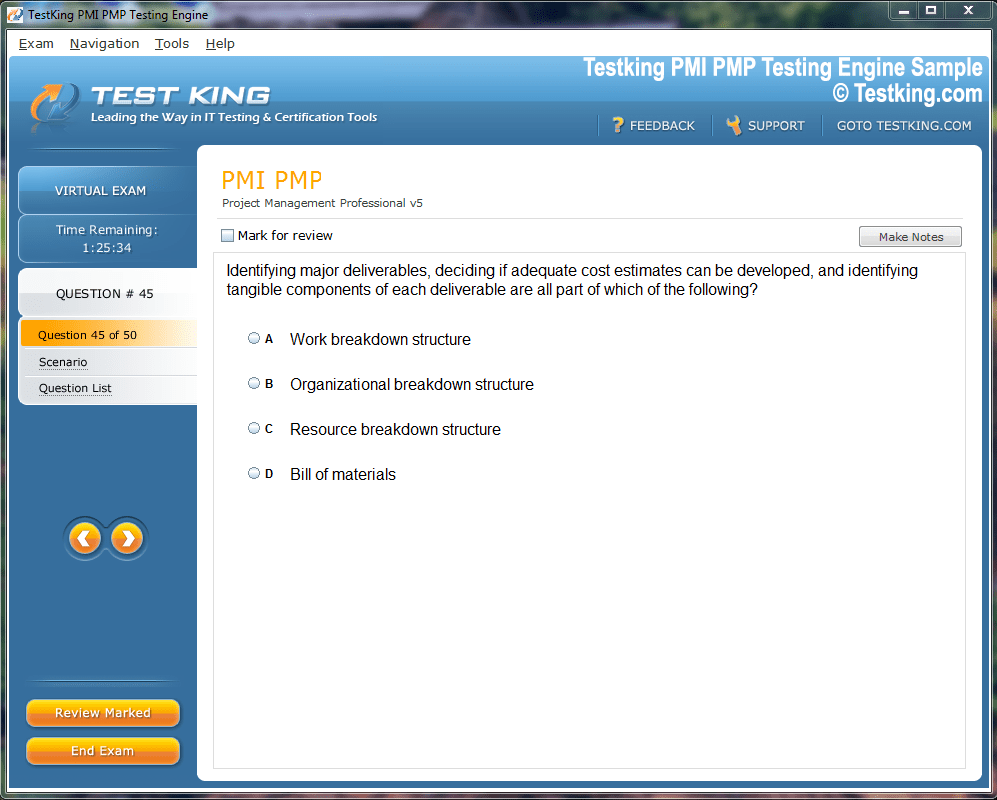

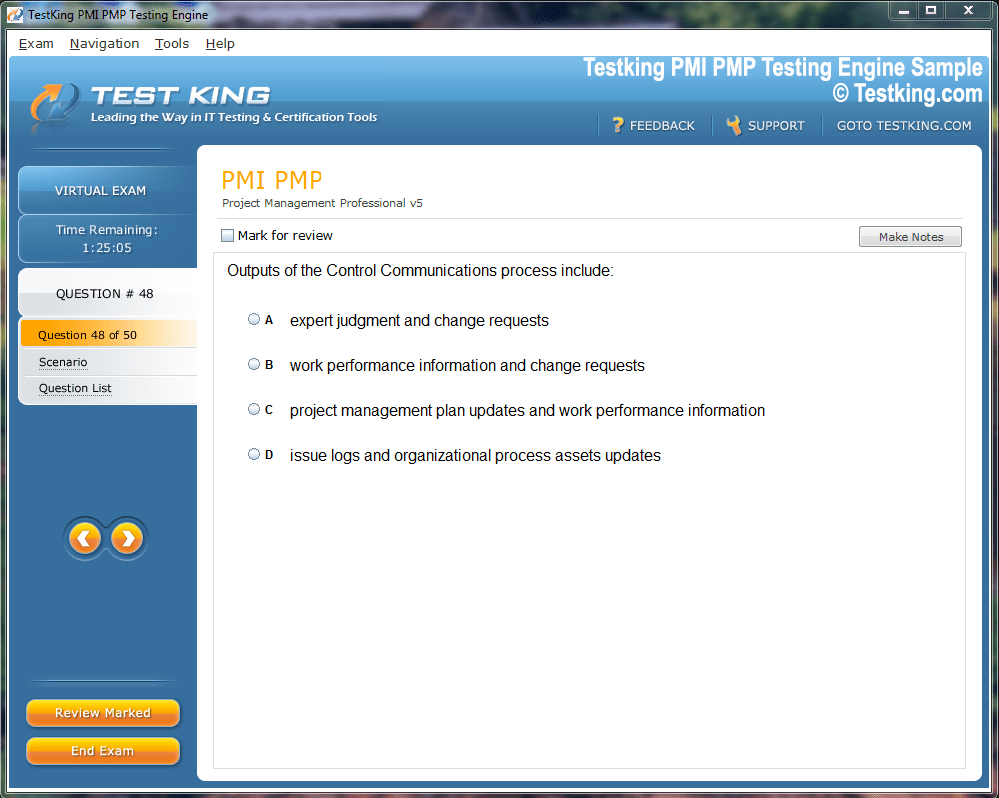

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our 700-821 testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top Cisco Exams

- 200-301 - Cisco Certified Network Associate (CCNA)

- 350-401 - Implementing Cisco Enterprise Network Core Technologies (ENCOR)

- 350-701 - Implementing and Operating Cisco Security Core Technologies

- 300-410 - Implementing Cisco Enterprise Advanced Routing and Services (ENARSI)

- 300-715 - Implementing and Configuring Cisco Identity Services Engine (300-715 SISE)

- 350-801 - Implementing Cisco Collaboration Core Technologies (CLCOR)

- 300-420 - Designing Cisco Enterprise Networks (ENSLD)

- 350-601 - Implementing and Operating Cisco Data Center Core Technologies (DCCOR)

- 300-425 - Designing Cisco Enterprise Wireless Networks (300-425 ENWLSD)

- 300-415 - Implementing Cisco SD-WAN Solutions (ENSDWI)

- 300-710 - Securing Networks with Cisco Firewalls

- 200-901 - DevNet Associate (DEVASC)

- 200-201 - Understanding Cisco Cybersecurity Operations Fundamentals (CBROPS)

- 350-501 - Implementing and Operating Cisco Service Provider Network Core Technologies (SPCOR)

- 350-901 - Developing Applications using Cisco Core Platforms and APIs (DEVCOR)

- 400-007 - Cisco Certified Design Expert

- 820-605 - Cisco Customer Success Manager (CSM)

- 300-620 - Implementing Cisco Application Centric Infrastructure (DCACI)

- 300-430 - Implementing Cisco Enterprise Wireless Networks (300-430 ENWLSI)

- 300-435 - Automating Cisco Enterprise Solutions (ENAUTO)

- 500-220 - Cisco Meraki Solutions Specialist

- 300-730 - Implementing Secure Solutions with Virtual Private Networks (SVPN 300-730)

- 100-150 - Cisco Certified Support Technician (CCST) Networking

- 350-201 - Performing CyberOps Using Core Security Technologies (CBRCOR)

- 300-820 - Implementing Cisco Collaboration Cloud and Edge Solutions

- 300-735 - Automating Cisco Security Solutions (SAUTO)

- 300-815 - Implementing Cisco Advanced Call Control and Mobility Services (CLASSM)

- 300-745 - Designing Cisco Security Infrastructure

- 700-805 - Cisco Renewals Manager (CRM)

- 300-810 - Implementing Cisco Collaboration Applications (CLICA)

- 300-610 - Designing Cisco Data Center Infrastructure for Traditional and AI Workloads

- 300-510 - Implementing Cisco Service Provider Advanced Routing Solutions (SPRI)

- 300-440 - Designing and Implementing Cloud Connectivity (ENCC)

- 300-720 - Securing Email with Cisco Email Security Appliance (300-720 SESA)

- 300-535 - Automating Cisco Service Provider Solutions (SPAUTO)

- 300-445 - Designing and Implementing Enterprise Network Assurance

- 300-515 - Implementing Cisco Service Provider VPN Services (SPVI)

- 300-835 - Automating Cisco Collaboration Solutions (CLAUTO)

- 500-442 - Administering Cisco Contact Center Enterprise

- 100-140 - Cisco Certified Support Technician (CCST) IT Support

- 100-490 - Cisco Certified Technician Routing & Switching (RSTECH)

- 300-725 - Securing the Web with Cisco Web Security Appliance (300-725 SWSA)

- 300-215 - Conducting Forensic Analysis and Incident Response Using Cisco CyberOps Technologies (CBRFIR)

- 300-615 - Troubleshooting Cisco Data Center Infrastructure (DCIT)

- 300-635 - Automating Cisco Data Center Solutions (DCAUTO)

- 300-910 - Implementing DevOps Solutions and Practices using Cisco Platforms (DEVOPS)

- 700-240 - Cisco Environmental Sustainability Overview

- 700-245 - Environmental Sustainability Practice-Building

- 700-150 - Introduction to Cisco Sales (ICS)

- 800-150 - Supporting Cisco Devices for Field Technicians

- 300-630 - Implementing Cisco Application Centric Infrastructure - Advanced

- 500-560 - Cisco Networking: On-Premise and Cloud Solutions (OCSE)

- 500-444 - Cisco Contact Center Enterprise Implementation and Troubleshooting (CCEIT)

- 700-750 - Cisco Small and Medium Business Engineer

- 700-250 - Cisco Small and Medium Business Sales

Cisco 700-821 Exam Pathway to Professional IoT Excellence

In the contemporary technological realm, the Internet of Things has become a formidable force that shapes industries, redefines workflows, and connects devices in ways that were unimaginable only a few years ago. Industrial networks, sensors, smart devices, and data-driven applications work together to create ecosystems where efficiency and automation are paramount. The acceleration of IoT adoption across manufacturing, healthcare, energy, transportation, and smart cities has intensified the need for engineers who can design and administer robust systems.

Within this context, the Cisco 700-821 IoT Essentials exam emerges as a rigorous evaluation tool. It not only measures an individual’s grasp of specific networking technologies but also affirms the ability to apply theoretical principles to tangible industrial use cases. The role of the system engineer is at the epicenter of this transformation, as these professionals serve as the bridge between intricate devices and the larger network infrastructure that keeps data flowing securely.

Exam Structure and Its Real-World Implications

The exam encompasses a range of subjects deliberately chosen to reflect the multifaceted responsibilities of system engineers. The questions are designed to emulate real-world dilemmas where decisions about device connectivity, security, and efficiency must be made quickly and accurately. This structure helps ensure that passing the exam is not merely about memorization but about demonstrating applied knowledge.

Candidates face between fifty-five and sixty-five questions, with a limited window of one hundred and twenty minutes. This compressed timeframe compels examinees to develop not only mastery of the subject matter but also agility in managing time effectively. Such conditions resemble the high-pressure environments in which engineers frequently operate, where troubleshooting or configuring a network cannot be prolonged indefinitely.

The score range required to succeed, between seven hundred fifty and eight hundred fifty out of one thousand, illustrates the exam’s stringent standards. Achieving such a score confirms that the candidate has surpassed baseline knowledge and is capable of addressing the intricate nuances of IoT systems.

Domains of Knowledge Tested in the 700-821 Exam

Several thematic pillars form the backbone of this examination, each representing a crucial element of industrial and enterprise IoT networks.

Industrial Ethernet Switching

One of the primary focuses is the understanding of Cisco’s Industrial Ethernet switching portfolio. Switches are the conduits through which vast volumes of industrial data flow. Knowing the characteristics, power options, and management capabilities of these switches is vital. Engineers must distinguish between models, determine suitable power supply alternatives, and comprehend leadership options in managing the switches efficiently. Mastery here ensures that the right switch is deployed in the right context, providing stability and scalability.

Industrial Wireless

Wireless solutions serve as the arteries of mobility within IoT ecosystems. The exam requires familiarity with devices like the IW6300 and IW9167, which deliver dependable connectivity in rugged environments. Beyond individual products, understanding the ultra-reliable wireless transport solutions is crucial. This ensures engineers are able to guarantee seamless connections even in environments riddled with interference or demanding reliability.

Industrial Routing

Routing knowledge is indispensable for system engineers who must design networks capable of spanning large distances, integrating disparate systems, and managing data securely. Candidates must demonstrate a nuanced understanding of Cisco’s routing and gateway portfolio, the inner workings of industrial routers, and the implications of SD-WAN support within these devices. The ability to design routing solutions ensures that IoT deployments remain interconnected without bottlenecks or vulnerabilities.

IoT Operations Dashboard

The ability to visualize, manage, and secure devices from a centralized platform is another area of emphasis. The exam explores the IoT Operations Dashboard, which provides a cohesive framework for monitoring and administering edge devices. Knowing how to configure the Edge Device Manager, how Secure Equipment Access functions, and how to design effective monitoring solutions ensures candidates can maintain the delicate equilibrium between convenience and security.

Why This Certification Matters

The Cisco 700-821 IoT Essentials certification signifies more than just the ability to pass an exam; it serves as a professional validation of increasingly indispensable skills. As industries integrate more connected devices, the complexity of their networks grows. With complexity comes the risk of misconfigurations, downtime, and vulnerabilities. System engineers must therefore be prepared to design infrastructures that are not only efficient but also resilient.

Employers value certifications because they represent a standardized measure of competence. In an environment where theoretical knowledge must be translated into real solutions, the certification stands as a seal of credibility. Engineers who hold this certification are perceived as individuals who can be trusted with mission-critical responsibilities, whether that involves maintaining continuous uptime in an energy plant or ensuring secure data transmission in a healthcare environment.

The Evolution of IoT and Its Impact on the Exam

The evolution of IoT is rapid and relentless. Devices have become smaller yet more powerful, data has grown in both volume and velocity, and networks are tasked with managing unprecedented workloads. The exam reflects this evolution by including modernized topics that align with the most recent advancements.

For example, the focus on SD-WAN within industrial routing illustrates the trend toward software-defined infrastructure, where agility and centralized control dominate. Similarly, the emphasis on ultra-reliable wireless transport mirrors the necessity for uninterrupted connectivity in mission-critical applications. The inclusion of secure equipment access in the syllabus underscores the growing concerns around cyber threats in IoT ecosystems.

Candidates must therefore recognize that the exam is not static. It changes to reflect the technologies shaping today’s networks and tomorrow’s innovations. Staying abreast of these changes is vital for both exam success and professional growth.

Essential Preparation Techniques

Preparing for an exam of this magnitude requires deliberate planning and a multifaceted strategy. Rote memorization alone is insufficient. Instead, candidates must engage with the material deeply, seeking to understand the rationale behind networking decisions and the implications of various technologies.

A practical approach begins with dissecting the syllabus into digestible components. Breaking down industrial switching, wireless, routing, and operations management into manageable segments makes studying less overwhelming. Allocating time to review and revisit each segment ensures retention.

Simulating exam conditions is equally important. Practicing with questions under timed constraints trains the mind to think clearly under pressure. This method also highlights weak areas where additional study is necessary. Candidates should create a structured timetable that allocates time not only for initial study but also for periodic review. Regular revision enhances memory retention and builds familiarity with complex topics.

Another effective method is joining collaborative study groups. Discussing concepts with peers can reveal insights that solitary study may overlook. Articulating ideas aloud and debating possible solutions deepens understanding. It is through these intellectual exchanges that abstract concepts become tangible.

The Role of Real-World Application

What sets the 700-821 exam apart from more theoretical assessments is its insistence on practical application. Candidates are not only asked what technologies exist but also how they should be deployed in specific scenarios. Real-world application is, therefore, central to preparation.

System engineers should take time to explore how Cisco’s industrial devices function within actual deployments. Understanding use cases in energy grids, manufacturing plants, and transportation systems provides context that transforms abstract concepts into concrete solutions. Studying the interplay between routing, switching, wireless connectivity, and monitoring platforms reveals how the components fit into a cohesive system.

By immersing themselves in real-world examples, candidates enhance their ability to interpret questions correctly and apply the most suitable solutions. This pragmatic perspective is invaluable not only for exam success but also for future roles where engineers must make decisions in dynamic, unpredictable environments.

Building the Right Mindset for Success

Beyond technical knowledge, the right mindset is crucial. Approaching the exam with resilience, patience, and curiosity increases the chances of success. IoT technologies are intricate, and studying them can occasionally feel daunting. Developing discipline and avoiding procrastination ensures consistent progress.

It is also essential to maintain balance during preparation. Overworking without breaks can lead to exhaustion, which diminishes productivity. Strategic rest periods keep the mind sharp. Candidates who cultivate both diligence and equilibrium position themselves well for sustained focus.

The Centrality of Switching in IoT Systems

In the architecture of modern IoT deployments, switching technologies form the essential foundation upon which connectivity is built. Industrial Ethernet switches are the pivotal devices that guide, regulate, and secure data flows between countless connected elements. In environments where thousands of devices interact—whether in automated factories, energy grids, or remote facilities—the switches act as the custodians of reliability and performance.

The Cisco 700-821 IoT Essentials exam dedicates a significant portion of its evaluation to industrial switching, acknowledging its indispensability. Mastery of this subject extends far beyond knowing product names. It requires an engineer to recognize which switch belongs in which environment, how power options influence deployment, and how management strategies ensure continuous uptime in harsh conditions.

Understanding the Industrial Ethernet Switching Portfolio

The industrial Ethernet switching portfolio encompasses a spectrum of devices designed to endure environments where traditional enterprise switches would falter. Unlike office settings, industrial spaces may expose equipment to temperature extremes, vibration, electromagnetic interference, or moisture. These realities necessitate devices built with ruggedized enclosures, specialized cooling systems, and durable components.

The exam expects candidates to differentiate between the varied switch models available, understanding their roles in distinct contexts. Some switches are designed for compact spaces where footprint is restricted, while others are engineered for expansive installations where numerous ports are required. The engineer must discern how these devices balance performance with adaptability, ensuring the right tool is matched with the right task.

Exploring Capabilities of Industrial Switches

The capabilities of industrial switches extend beyond simple packet forwarding. They include advanced functionalities that address the complexities of IoT environments.

One such capability is redundancy. In systems where downtime is intolerable, redundancy mechanisms like ring protocols guarantee continued operation even if one path fails. Engineers must know how to configure and manage these redundancy features effectively, as uninterrupted connectivity is often tied directly to revenue and safety.

Another crucial capability is quality of service. IoT systems generate diverse types of traffic, from mission-critical control signals to less urgent monitoring data. Switches must prioritize certain types of traffic over others to avoid delays. Engineers must be adept at configuring quality of service policies to ensure that latency-sensitive data travels without obstruction.

Security features also play a central role. In a world where connected devices are frequent targets of cyber threats, switches must offer access control lists, port security, and segmentation capabilities. The engineer’s responsibility lies in implementing these protections, ensuring that the network remains resilient against malicious incursions.

Power Supply Alternatives for Industrial Switches

The choice of power supply is far from trivial in industrial environments. Unlike office settings where stable electricity is presumed, industrial locations may present fluctuating voltages, long cable runs, or limited power availability.

Industrial switches address these challenges through a variety of power supply alternatives. Power over Ethernet (PoE) is a key feature, enabling devices such as sensors, cameras, or wireless access points to receive both data and power through a single cable. Engineers must evaluate scenarios where PoE offers advantages, reducing cabling complexity and deployment costs.

At the same time, some industrial switches support dual power supplies, enhancing redundancy. If one source fails, the other immediately assumes responsibility, preventing downtime. This feature becomes critical in mission-critical infrastructures like energy production or transportation systems, where even a brief interruption can have catastrophic consequences.

The exam tests not just recognition of these alternatives but also the ability to decide which power option fits a particular environment. For instance, in remote areas with unstable electrical infrastructure, dual redundancy may be indispensable, whereas in compact deployments, PoE may represent the most pragmatic choice.

Leadership and Management Options for Industrial Switches

Beyond hardware, the management of industrial switches requires careful planning. Engineers must be proficient in configuring switches through a range of administrative options.

Some scenarios demand local management through a command-line interface, where direct control ensures precise adjustments. Others call for centralized management platforms, where multiple switches across a distributed environment can be configured and monitored cohesively.

The exam evaluates familiarity with these options, requiring engineers to distinguish the scenarios in which each management style is advantageous. Centralized management often proves indispensable for large-scale IoT deployments where hundreds of switches need consistent configuration. Local management, meanwhile, remains essential in isolated environments where central control is impractical or unnecessary.

Understanding these leadership options reflects a deeper awareness of how administrative practices influence efficiency, scalability, and security.

The Practical Realities of Industrial Switching

While technical specifications are important, what truly distinguishes effective system engineers is their ability to contextualize those specifications in real-world settings.

Consider a manufacturing plant where robotic arms and conveyor systems depend on uninterrupted connectivity. A misconfigured switch could stall operations, halting production and causing financial loss. Engineers must therefore plan switching infrastructure with meticulous attention to detail, ensuring redundancy, quality of service, and secure segmentation.

In another scenario, an energy grid may span vast geographic areas, requiring switches that can withstand outdoor conditions while enabling long-distance communication. Here, durability and redundancy outweigh compact design. The engineer must assess not only the devices themselves but also the environment in which they are deployed.

The exam challenges candidates to think with this level of pragmatism, presenting situations where theoretical knowledge must be applied judiciously.

Preparing for the Switching Section of the Exam

Preparation for the switching domain requires a systematic approach. Candidates should immerse themselves in the specific capabilities of Cisco’s industrial switches, understanding the portfolio’s breadth and the contexts where each model excels. Reading technical documentation, studying diagrams, and practicing configurations in lab environments enhances comprehension.

It is also vital to rehearse redundancy and security features. Knowing how to implement ring topologies or configure port security not only ensures exam readiness but also builds confidence in real-world scenarios. Engineers should also practice setting up quality of service policies, balancing competing traffic streams to ensure efficiency.

Another critical element is developing fluency in power supply options. Reviewing examples of PoE-enabled deployments and redundancy strategies builds the ability to evaluate trade-offs effectively.

The Role of Switching in Securing IoT Deployments

The emphasis on security cannot be overstated. Industrial switches serve as gatekeepers, and their configurations directly influence the network’s exposure to risks. Misconfigured ports, unsecured VLANs, or weak access controls can become vulnerabilities exploited by malicious actors.

For IoT systems, where devices often lack built-in security, the responsibility shifts to the network infrastructure. Engineers must leverage switch-based protections to safeguard the environment. The exam evaluates understanding of these principles, underscoring the expectation that certified professionals will uphold security best practices in every deployment.

Future Trends in Industrial Switching

Switching technologies is not static; they evolve as IoT systems expand and adapt. Emerging trends such as edge computing, where processing occurs closer to devices, influence the demands placed on switches. These devices must now support not just connectivity but also integration with edge analytics platforms.

Additionally, the rise of intent-based networking, where automation and artificial intelligence guide configurations, is transforming switch management. Engineers must prepare for a future where switches become more autonomous, yet still demand oversight from human experts.

The exam reflects these trends by embedding forward-looking content, ensuring that certified professionals are not merely competent in present technologies but prepared for imminent innovations.

The Vital Role of Switching in Industrial Networks

Switching is the beating heart of industrial IoT networks. Without reliable Ethernet switching, the intricate dance of connected devices, sensors, gateways, and controllers would collapse into chaos. Industrial environments demand switching solutions that do not simply transfer data but preserve integrity, prioritize critical information, and survive punishing conditions where enterprise-grade devices would quickly falter.

The Cisco 700-821 IoT Essentials exam dedicates significant weight to industrial switching for this reason. A professional pursuing this certification must grasp the strategic placement of switches, the specific capabilities that differentiate them from standard enterprise devices, and how they support continuous, resilient operations across IoT systems.

Characteristics of Industrial Ethernet Switching

Industrial Ethernet switches differ substantially from their enterprise counterparts. They are engineered for environments rife with dust, vibrations, moisture, and extreme temperatures. Rugged enclosures protect circuitry from corrosive atmospheres, while extended operating ranges ensure dependable performance in settings ranging from scorching factory floors to frigid outdoor installations.

These devices also support specialized protocols tailored for operational technology. Time-Sensitive Networking is one example, enabling deterministic delivery of data where even microseconds of delay could disrupt production. Engineers who study for the 700-821 must understand not only the ruggedness of these switches but the sophisticated features that sustain mission-critical systems.

Redundancy Mechanisms and High Availability

Industrial facilities operate on the principle that downtime is intolerable. A single failure can halt an assembly line, freeze a logistics hub, or disrupt an energy distribution network. For this reason, redundancy mechanisms form a cornerstone of industrial Ethernet switching.

Switches are often configured in ring or mesh topologies where multiple pathways exist for data. If one link fails, traffic reroutes automatically with minimal interruption. Protocols such as Resilient Ethernet Protocol and Parallel Redundancy Protocol are frequently employed to guarantee uninterrupted communication. A system engineer must be adept at selecting and configuring these methods to ensure that critical operations never stall.

The exam evaluates this knowledge by probing how candidates would design resilient topologies, how failover timing affects system performance, and how redundancy strategies should align with specific IoT applications.

Quality of Service and Traffic Prioritization

Not all data is equal in an industrial network. A status update from a temperature sensor is far less time-sensitive than a control command instructing a robotic arm to stop. Quality of Service mechanisms embedded within industrial switches enable differentiation between traffic types, ensuring that latency-sensitive packets are always delivered first.

Candidates preparing for the 700-821 exam must be fluent in traffic classification techniques, queue management, and bandwidth allocation policies. Engineers who master these practices can guarantee that operational technology receives the precedence it requires while still accommodating less critical traffic, such as logs or video streams.

Power Supply Options and Flexibility

Powering devices across sprawling industrial landscapes presents unique challenges. Switches must often provide energy not only to themselves but also to the multitude of sensors, access points, and surveillance cameras connected to them.

Power over Ethernet (PoE) capabilities allow a single cable to deliver both electricity and data, reducing cabling complexity and facilitating deployment in locations where outlets are scarce. Some switches extend this further with support for PoE+, enabling higher wattages to power devices such as pan-tilt-zoom cameras or industrial controllers.

Redundant power supply inputs represent another layer of resilience. By connecting to two independent sources, a switch continues to operate even if one supply fails. This capability is indispensable in industries where interruptions are unacceptable, such as in energy grids or automated manufacturing systems.

Management and Administration of Switches

Managing industrial switches requires versatility. In small deployments, local management through a console or web interface may suffice. In larger installations spanning hundreds of devices, centralized administration becomes essential to maintain consistency and reduce operational overhead.

Cisco industrial switches integrate with platforms that provide visibility, configuration templates, and automated monitoring. Engineers must understand how to balance local control with centralized oversight. The exam assesses whether candidates can identify when a hands-on configuration is preferable and when broader orchestration should take precedence.

Security in Industrial Switching

Industrial switches are not merely conduits of data; they are guardians of critical systems. Cyber threats targeting IoT infrastructure have become increasingly sophisticated, making switch-level security paramount.

Features such as access control lists, port-based authentication, and network segmentation allow engineers to enforce strict boundaries between devices. Switches can block unauthorized traffic, isolate suspicious activity, and prevent lateral movement of threats across the network.

For exam preparation, candidates must familiarize themselves with these protective measures and understand how they align with broader security architectures. A misstep in switch configuration could expose entire systems to compromise, underscoring the weight of responsibility carried by system engineers.

Practical Applications of Industrial Ethernet Switching

Real-world examples illustrate why the exam places such emphasis on switching. In a refinery, for instance, industrial switches connect sensors monitoring pressure, temperature, and flow rates. If a switch fails without redundancy, operators could lose visibility, increasing the risk of catastrophic incidents.

In logistics hubs, Ethernet switches ensure seamless coordination between conveyor belts, barcode scanners, and automated vehicles. Here, Quality of Service ensures that control commands are executed instantly, avoiding collisions or disruptions.

In smart cities, switches provide connectivity to traffic management systems, surveillance networks, and environmental sensors. Power over Ethernet simplifies deployment across expansive urban landscapes where providing separate power lines would be prohibitive.

Each scenario highlights how switching decisions directly influence safety, efficiency, and cost-effectiveness.

Study Strategies for the Switching Section

Preparing for the switching portion of the Cisco 700-821 exam demands both conceptual mastery and practical familiarity. Candidates should adopt the following strategies:

Break down the subject into manageable sections: portfolio knowledge, redundancy, power options, management, and security.

Create visual diagrams of network topologies, illustrating how redundancy protocols maintain connectivity.

Practice configuring Quality of Service rules, experimenting with prioritization techniques.

Review case studies of PoE deployments to understand how power and data integration work in practice.

Simulate centralized versus local management environments to gain hands-on insight.

By rotating between theory and practice, candidates reinforce knowledge and cultivate the intuition needed to respond to scenario-based questions.

The Evolution of Switching in IoT Contexts

The future of industrial switching is shaped by emerging technologies. Edge computing, for example, pushes data processing closer to devices, meaning switches must accommodate not only traffic but also integration with localized analytics engines.

Intent-based networking introduces automation, where switches adjust configurations dynamically based on overarching policies. Artificial intelligence further enhances monitoring, enabling predictive analysis of potential failures before they occur.

The exam, while rooted in current technology, acknowledges these trends. Engineers who prepare with an eye toward innovation will not only succeed in the exam but also remain relevant as industrial networking evolves.

The Human Element in Switching

Though switches are technological artifacts, their deployment and configuration remain deeply human endeavors. System engineers must interpret business needs, evaluate environmental conditions, and balance cost against reliability.

Decision-making in switching infrastructure reflects both technical competence and judgment. For instance, an engineer may decide to invest in redundant power supplies not simply because the technology exists but because the risk of downtime in that particular facility is unacceptable.

The 700-821 exam assesses this balance of technical mastery and situational awareness, ensuring that certified professionals are capable of applying knowledge with discernment.

The Expanding Role of Wireless in IoT

Wireless connectivity has transformed the fabric of IoT, enabling devices to communicate across distances without the restrictions of cables. In industrial environments, this flexibility is not a luxury but a necessity. Wireless technologies provide mobility, adaptability, and scalability in contexts where physical cabling would be impractical, costly, or impossible.

The Cisco 700-821 IoT Essentials exam emphasizes industrial wireless for this reason. Professionals pursuing this certification must understand not only the fundamentals of wireless communication but also the unique characteristics of industrial-grade wireless solutions engineered for harsh environments and mission-critical applications.

Why Industrial Wireless Differs from Enterprise Wireless

Enterprise wireless networks are designed for office spaces, campuses, or hospitality environments where environmental conditions are relatively controlled. Industrial wireless, however, operates under entirely different parameters. Factories, mines, oil refineries, power plants, and outdoor transit systems present conditions where dust, humidity, temperature swings, and interference from machinery can undermine traditional wireless systems.

Industrial wireless devices are ruggedized, optimized for stability, and capable of withstanding electromagnetic noise. They must deliver consistent performance in locations where latency could jeopardize operations, such as controlling robotic arms or managing automated guided vehicles. The Cisco 700-821 exam ensures that engineers grasp this distinction, evaluating their ability to select and configure solutions tailored to the rigors of industrial settings.

Cisco IW6300: Capabilities and Use Cases

The IW6300 is a cornerstone of Cisco’s industrial wireless portfolio. Designed for outdoor and industrial applications, it combines rugged durability with advanced wireless features. Candidates preparing for the exam must become familiar with its capabilities and scenarios where it excels.

One of its defining traits is support for multiple radio frequencies, enabling it to deliver reliable coverage across different bands. This versatility ensures connectivity in environments where interference varies or where regulations dictate specific frequency usage.

The IW6300 also supports high throughput, enabling bandwidth-intensive applications such as video surveillance or real-time analytics. In environments like transportation hubs or large manufacturing floors, the ability to sustain heavy data traffic is critical.

Another strength is its environmental resilience. The IW6300 can withstand extreme heat, cold, dust, and moisture, making it suitable for deployment in mines, tunnels, and open-air facilities.

Understanding these features helps candidates determine when and why to deploy this device, ensuring alignment with the operational requirements of complex IoT ecosystems.

Cisco IW9167: Advancing Industrial Wireless

The IW9167 represents another advanced offering in Cisco’s industrial wireless suite. Where the IW6300 emphasizes ruggedness and flexibility, the IW9167 advances capabilities with next-generation features.

This device integrates cutting-edge wireless standards that enable ultra-reliable connectivity. It is particularly relevant for environments where even momentary disruption is intolerable. For instance, in automated manufacturing plants, machines must exchange commands with near-instantaneous response times. The IW9167 provides the assurance that these communications occur seamlessly.

It also offers enhanced support for mobility. As autonomous vehicles, drones, or mobile equipment move throughout industrial spaces, the IW9167 maintains connectivity without handoff delays or drops. Such capabilities are central to the evolution of mobile industrial ecosystems.

The exam tests familiarity with this device, ensuring engineers know how to differentiate its capabilities from other wireless products and deploy it strategically in environments requiring uninterrupted, high-quality communication.

Ultra-Reliable Wireless Transport Solutions

In certain scenarios, ordinary wireless performance is inadequate. Mission-critical applications demand not just reliability but ultra-reliability, where packet loss or latency is virtually nonexistent. Cisco’s ultra-reliable wireless transport solutions address these needs, providing deterministic connectivity for environments where failure is not an option.

These solutions employ advanced redundancy, multiple frequency utilization, and intelligent routing to guarantee continuous communication. Consider railway signaling systems, where wireless connections coordinate train movements across vast geographies. A dropped packet could result in delays or even safety hazards. Ultra-reliable transport solutions mitigate such risks by ensuring constant, stable connections.

The exam requires candidates to understand these solutions, their design principles, and the types of industrial environments where they are indispensable.

Challenges of Wireless in Industrial Settings

While wireless offers flexibility, it introduces challenges that engineers must confront. Interference from machinery, structural obstacles like thick concrete walls, and environmental factors such as rain or fog can degrade signals.

Security also becomes a pressing concern. Wireless networks, by their nature, are more accessible to interception. Without robust encryption, authentication, and segmentation, they can expose systems to unauthorized access or attacks.

Another challenge is scalability. As IoT deployments expand, networks must support thousands of devices transmitting simultaneously. Engineers must ensure that wireless infrastructure accommodates this density without sacrificing performance.

The Cisco 700-821 exam reflects these realities, probing whether candidates can not only identify challenges but also propose viable strategies to overcome them.

Wireless and Mobility in Industrial IoT

Mobility represents one of the defining advantages of wireless. In many industries, assets are not static but move constantly. Automated guided vehicles transport goods across warehouses, drones survey infrastructure, and workers carry handheld devices to monitor systems.

Industrial wireless must ensure seamless connectivity for these mobile assets. Roaming between access points should occur without disruption, maintaining active sessions and preserving data integrity. In safety-critical environments, even a brief drop in connectivity could compromise operations.

Engineers must understand how to configure wireless networks for such mobility, optimizing handoff performance and ensuring coverage across every corner of the operational space. The exam evaluates proficiency in designing networks that sustain high mobility without compromising reliability.

Integration of Wireless with Wired Infrastructure

Wireless does not operate in isolation. In most deployments, it integrates with wired Ethernet backbones. Switches, routers, and gateways form the foundation, while wireless extends connectivity to devices beyond the reach of cables.

System engineers must design architectures where wireless complements wired infrastructure. This involves ensuring sufficient backhaul capacity, configuring redundancy between wired and wireless links, and synchronizing security policies across both domains.

The exam assesses whether candidates can view wireless as part of the larger ecosystem rather than as a standalone element. Success requires recognizing interdependencies and designing cohesive infrastructures.

Security in Industrial Wireless Networks

The vulnerability of wireless networks necessitates rigorous security practices. Encryption standards such as WPA3 provide a foundation, but industrial environments often require additional layers.

Access control ensures that only authorized devices connect, while segmentation isolates traffic to minimize the spread of threats. Monitoring tools detect anomalies, alerting engineers to unusual behavior that could signify compromise.

System engineers must balance usability with security. Overly rigid restrictions can impede operations, while lax configurations expose systems to risk. The exam measures candidates’ ability to strike this balance, implementing protections that are both practical and robust.

Study Strategies for Industrial Wireless

Preparing for the wireless portion of the Cisco 700-821 exam requires immersion in both conceptual knowledge and real-world practice. Candidates should adopt the following strategies:

Study the specifications of the IW6300 and IW9167, understanding their unique features and appropriate use cases.

Review the principles of ultra-reliable wireless transport, focusing on redundancy and deterministic connectivity.

Familiarize themselves with the environmental challenges of industrial deployments and strategies to mitigate interference.

Practice configuring wireless security settings, ensuring mastery of encryption, access control, and segmentation.

Explore mobility scenarios, analyzing how networks maintain seamless handoffs for moving devices.

By combining theoretical review with hands-on experimentation, candidates gain the depth of understanding required to navigate complex exam questions.

Practical Scenarios of Wireless Deployment

Examining real scenarios illuminates the importance of wireless. In a mining operation, wireless devices provide communication deep underground, where cabling is impractical. The IW6300’s ruggedness ensures operation despite dust and vibration.

In a port terminal, the IW9167 delivers high-speed connectivity to cranes, vehicles, and handheld devices, ensuring coordination of cargo movements. Its mobility features allow seamless operation as assets move across expansive areas.

In a smart rail system, ultra-reliable wireless transport ensures continuous communication between trains and signaling infrastructure. Reliability here directly impacts safety and efficiency.

Each example demonstrates how industrial wireless is not a convenience but a necessity, enabling operations that cannot be realized through wired connections alone.

The Future of Industrial Wireless

Industrial wireless continues to evolve rapidly. The rise of 5G promises unprecedented speed and ultra-low latency, enabling applications that were previously impossible. Integration of private 5G networks into industrial settings is already underway, complementing traditional Wi-Fi and specialized wireless solutions.

Edge computing further influences wireless design. By processing data closer to devices, edge architectures reduce latency and bandwidth demands. Wireless devices must integrate seamlessly with these edge nodes, creating localized intelligence.

Artificial intelligence also shapes the future, with predictive analytics optimizing wireless performance, identifying interference sources, and dynamically adjusting configurations.

The Cisco 700-821 exam reflects these trajectories, preparing candidates not only for present technologies but also for the innovations shaping tomorrow’s IoT environments.

The Central Role of Routing in Industrial IoT

Routing is the backbone of all large-scale networks, ensuring that data finds its way across complex infrastructures. In industrial IoT, routing extends beyond conventional enterprise environments to highly diverse and challenging landscapes. Oil fields, transportation systems, utility grids, and manufacturing facilities all depend on reliable routing to connect machines, sensors, and platforms spread across local and global domains.

The Cisco 700-821 IoT Essentials exam dedicates significant emphasis to industrial routing because it is the glue that binds the distributed components of IoT ecosystems. Engineers are expected to not only understand the functions of routers and gateways but also to design architectures that accommodate scalability, resilience, and security under demanding operational circumstances.

How Industrial Routing Differs from Traditional Routing

Routing within industrial environments introduces a host of complexities absent from enterprise contexts. In offices or campuses, routing typically operates in climate-controlled environments with stable infrastructure. Industrial settings, by contrast, are dynamic and often hostile to equipment.

Dust, vibration, temperature fluctuations, and electrical noise can impact performance. Routers and gateways must be ruggedized and capable of sustaining operations under duress. They must also operate with minimal downtime, as interruptions can halt critical processes such as energy distribution or production lines.

Another critical difference is the need to support a wider range of protocols and interfaces. Industrial devices may communicate using Modbus, DNP3, or proprietary protocols alongside IP-based traffic. Routers and gateways serve as translation points, ensuring interoperability across heterogeneous systems.

The Cisco 700-821 exam evaluates candidates’ grasp of these distinctions, testing their ability to configure and manage industrial routing solutions that meet both operational and environmental demands.

Cisco Industrial Routing and Gateway Portfolio

Cisco offers a comprehensive portfolio of industrial routers and gateways tailored for diverse IoT scenarios. Candidates must familiarize themselves with this portfolio, understanding not just technical specifications but also the practical contexts where each device thrives.

These routers provide high-performance connectivity, built-in security, and support for both wired and wireless communications. They enable edge intelligence, allowing localized decision-making and reducing dependency on central systems. In remote oil rigs or solar farms, this edge capability ensures continuous operations even when central connectivity falters.

Gateways within the portfolio play a crucial role in protocol translation and data aggregation. They enable legacy equipment to integrate with modern IoT platforms, preserving existing investments while extending capabilities.

Mastery of this portfolio is indispensable for success in the exam, as questions often present real-world scenarios requiring candidates to identify the optimal device or configuration.

Functions of Industrial Routers and Gateways

At their core, industrial routers and gateways share the fundamental responsibility of directing data packets across networks. However, their industrial roles expand into additional functions critical for IoT environments.

Routers manage communication between different network segments, enforce security policies, and ensure quality of service for critical traffic. In industrial contexts, they often provide redundant paths to maintain connectivity in case of link failures.

Gateways, on the other hand, act as bridges between incompatible systems. They translate data between industrial protocols and IP-based standards, enabling seamless integration across diverse devices. This translation is particularly vital in industries with significant legacy infrastructure, where replacing every device with IP-capable alternatives is neither practical nor economical.

The exam challenges candidates to understand these distinctions, recognizing when a router suffices, when a gateway is required, and when both must work in tandem.

The Importance of SD-WAN Support in Industrial Routers

Software-Defined Wide Area Networking (SD-WAN) represents a paradigm shift in how networks are managed and optimized. In industrial IoT, SD-WAN provides dynamic control over routing paths, prioritizing traffic based on application needs, network conditions, and security requirements.

For example, a factory may generate streams of sensor data, video feeds, and control commands. SD-WAN enables routers to differentiate between these types of traffic, ensuring that time-sensitive control commands always receive priority over less critical data.

Additionally, SD-WAN enhances resilience by automatically rerouting traffic when links degrade or fail. This capability is crucial in industries where connectivity is unpredictable, such as remote mining operations or ships at sea.

The Cisco 700-821 exam includes SD-WAN in its industrial routing section to ensure that candidates appreciate its transformative role. Engineers must understand how to deploy and manage SD-WAN-enabled routers to deliver optimized, secure, and reliable connectivity across industrial environments.

Routing Protocols in Industrial Environments

Routing protocols form the foundation of network communication, and industrial environments require familiarity with both traditional and specialized protocols.

Protocols such as OSPF and BGP remain central, enabling scalable routing across expansive networks. However, industrial environments also introduce unique challenges that necessitate specialized configurations. For instance, deterministic routing paths may be needed to ensure predictable latency in time-sensitive applications.

Static routing may also find greater use in industrial contexts, where simplicity and predictability are prioritized over dynamic adaptability. In highly controlled systems, fixed routes eliminate variability and reduce the potential for misconfiguration.

The exam assesses whether candidates can select and configure the right protocols for different scenarios, balancing the trade-offs between flexibility, predictability, and complexity.

Security in Industrial Routing

Routing in industrial IoT carries heightened security stakes. Attacks on routers or gateways can compromise entire infrastructures, leading to operational downtime, financial loss, or even safety hazards.

Industrial routers must incorporate advanced security features, such as encryption, firewall capabilities, intrusion prevention, and VPN support. Gateways must ensure that translated data maintains its integrity and cannot be intercepted or manipulated.

Segmentation is another crucial practice. By isolating traffic flows, engineers can prevent threats from spreading across networks. For example, separating sensor traffic from administrative traffic limits the potential impact of breaches.

The Cisco 700-821 exam expects candidates to demonstrate competence in implementing these protections, ensuring secure routing across diverse industrial landscapes.

Scalability and Resilience in Industrial Routing

Industrial IoT deployments rarely remain static. Networks must scale as new devices and applications emerge. Routers and gateways must accommodate this growth without sacrificing performance or security.

Resilience is equally vital. Redundancy in hardware, links, and protocols ensures continuity during failures. Load balancing distributes traffic to prevent bottlenecks. Failover mechanisms guarantee that even if one path collapses, another takes its place instantly.

Engineers must design networks that anticipate expansion and withstand adversity. The exam probes this capability, presenting scenarios where candidates must apply strategies to achieve both scalability and resilience.

Real-World Applications of Industrial Routing

Practical examples highlight the significance of routing in industrial IoT.

In an energy grid, routers connect substations to central monitoring systems, enabling real-time visibility and control. The resilience of these routers ensures continuity even during outages or cyberattacks.

In logistics, gateways integrate tracking devices on vehicles with central systems, providing continuous visibility into shipments. Protocol translation allows legacy sensors to communicate with modern platforms.

In manufacturing, SD-WAN-enabled routers optimize traffic between multiple plants and headquarters, ensuring that production data flows securely and efficiently.

Each scenario demonstrates how routing enables the seamless functioning of industrial ecosystems, validating its prominence in the exam.

Challenges in Deploying Industrial Routers and Gateways

Deploying routers and gateways in industrial environments is not without challenges. Harsh conditions can strain equipment, requiring ruggedized designs that increase cost. Configurations may be complex, especially when integrating legacy devices with modern systems.

Network visibility can also be limited in remote environments, complicating monitoring and troubleshooting. Engineers must rely on advanced tools to maintain oversight.

Another challenge is balancing innovation with reliability. While SD-WAN and edge intelligence offer powerful capabilities, adopting them prematurely can introduce instability. Engineers must assess readiness carefully.

The exam assesses not only technical knowledge but also problem-solving ability, ensuring that candidates can navigate these challenges effectively.

Study Approaches for Industrial Routing

To prepare for the routing section of the exam, candidates should:

Explore the Cisco industrial routing and gateway portfolio, noting the strengths of each device.

Review the principles and configurations of SD-WAN, focusing on industrial applications.

Study routing protocols in both enterprise and industrial contexts, emphasizing their trade-offs.

Practice designing secure, scalable, and resilient routing architectures.

Analyze case studies of industrial routing deployments to understand practical challenges and solutions.

By combining theoretical study with applied exploration, candidates can build the competence required to excel.

The Evolution of Industrial Routing

Industrial routing is not static. As IoT continues to expand, routing solutions evolve to support emerging needs. Private 5G networks, for instance, are introducing new paradigms for wide-area industrial connectivity. Routers must adapt to integrate with these networks seamlessly.

Artificial intelligence is also reshaping routing. Machine learning algorithms analyze traffic patterns, predicting congestion and dynamically adjusting routes. In industrial contexts, such intelligence minimizes downtime and optimizes performance.

Cloud integration further transforms routing, with hybrid models combining on-premises control with cloud-based orchestration. This convergence enhances visibility and management but requires engineers to adapt their approaches.

The Cisco 700-821 exam prepares candidates for this evolution, ensuring that they can navigate current technologies while remaining agile for future innovations.

Foundations of the Cisco IoT Operations Dashboard

At its core, the IoT Operations Dashboard serves as a centralized command center for industrial IoT infrastructures. It consolidates disparate elements — routers, gateways, switches, and edge devices — into a single pane of glass, providing clarity and coherence in otherwise fragmented systems.

This centralized visibility is vital in industries where downtime can translate into significant financial losses or safety risks. Engineers rely on the dashboard to monitor health metrics, apply configurations, and troubleshoot issues swiftly. The exam evaluates candidates’ familiarity with this foundation, ensuring they can leverage it to maintain stable, secure, and efficient networks.

Key Functions of the Dashboard

The Cisco IoT Operations Dashboard provides a broad suite of functions, each addressing a critical dimension of IoT management.

Visibility and Monitoring

The dashboard offers real-time monitoring of devices and connections. Engineers can track performance indicators such as throughput, latency, and error rates. Alerts highlight anomalies, enabling swift interventions before small issues escalate into major disruptions.

Configuration Management

Managing thousands of devices manually would be infeasible. The dashboard enables bulk configurations, templates, and remote updates. Engineers can apply consistent policies across entire fleets, reducing errors and ensuring uniformity.

Security Oversight

Security is integrated into the dashboard, with features such as access control, encryption enforcement, and anomaly detection. Engineers can monitor potential intrusions, enforce compliance, and respond to emerging threats rapidly.

Analytics and Optimization

Beyond monitoring, the dashboard provides insights derived from analytics. Patterns in device performance or traffic flows inform optimizations, enabling proactive adjustments rather than reactive fixes.

The exam expects candidates to demonstrate competence in these functions, understanding not only their technical mechanics but also their practical significance in industrial contexts.

The Role of Edge Device Manager (EDM)

The IoT Operations Dashboard is closely linked with Edge Device Manager (EDM), a tool that provides granular control over routers and gateways. EDM allows engineers to set up, configure, and maintain these critical devices directly from the dashboard interface.

For example, an engineer overseeing a fleet of industrial routers can use EDM to push firmware updates simultaneously, ensuring consistency and reducing the risk of vulnerabilities. Similarly, EDM facilitates the onboarding of new devices, streamlining integration into existing architectures.

The exam includes EDM as a central topic, requiring candidates to understand how it enhances operational efficiency and security. Mastery of EDM reflects an engineer’s ability to scale management practices effectively across distributed infrastructures.

Secure Equipment Access and Its Framework

Secure access to equipment is a cornerstone of modern IoT management. In industrial settings, where devices are often deployed in remote or hazardous environments, engineers must be able to access them remotely without compromising security.

The Cisco IoT Operations Dashboard incorporates a Secure Equipment Access framework that balances convenience with robust protection. This framework leverages encryption, authentication, and access controls to ensure that only authorized personnel can interact with devices.

Engineers can initiate remote sessions through the dashboard, diagnose issues, and apply fixes without physical presence. This capability not only saves time and cost but also enhances safety by reducing the need for field interventions in dangerous environments.

The exam assesses knowledge of this framework, emphasizing its role in safeguarding operations while enabling efficient remote management.

Real-World Applications of the IoT Operations Dashboard

Understanding the practical applications of the dashboard helps illuminate its importance.

In an energy utility, the dashboard provides visibility into substations spread across vast territories. Engineers can monitor load balances, identify anomalies, and deploy updates remotely, ensuring uninterrupted service delivery.

In logistics, the dashboard enables oversight of routers and gateways installed on transport vehicles. Fleet-wide updates can be applied simultaneously, while real-time monitoring ensures that connectivity remains consistent across moving assets.

In manufacturing, the dashboard facilitates predictive maintenance. By analyzing device performance data, it identifies early signs of wear or failure, allowing interventions before breakdowns occur.

The exam challenges candidates with scenarios such as these, requiring them to determine how the dashboard and its features can be deployed to solve specific industrial challenges.

Challenges Addressed by the Dashboard

The IoT Operations Dashboard resolves several persistent challenges that engineers face in industrial IoT environments.

Scale

Managing thousands of devices without centralized oversight is unsustainable. The dashboard enables scalability by providing tools for bulk operations, automated workflows, and simplified onboarding.

Complexity

Industrial networks often combine diverse devices, protocols, and topologies. The dashboard abstracts this complexity, presenting a unified interface that simplifies oversight without sacrificing depth.

Security

The openness of IoT ecosystems introduces security risks. By embedding monitoring, access control, and compliance enforcement, the dashboard strengthens defenses against intrusions and data breaches.

Efficiency

Manual interventions are resource-intensive and error-prone. The dashboard automates repetitive tasks, reduces travel requirements, and enables proactive problem resolution.

The exam tests whether candidates understand how the dashboard addresses these challenges, requiring them to connect features with outcomes in practical contexts.

Security Integration in IoT Management

Security is not an afterthought but a defining element of the IoT Operations Dashboard. Engineers must not only monitor threats but also actively enforce policies across devices.

Through the dashboard, engineers can:

Configure encrypted communication channels

Restrict device access to authorized personnel

Segment networks to isolate critical traffic

Detect and respond to anomalies in real time

The exam ensures candidates understand how to leverage these capabilities to create secure, compliant IoT environments. This includes recognizing the interplay between centralized oversight and distributed enforcement, where policies flow seamlessly from dashboard to device.

Analytical Capabilities of the Dashboard

Data is the lifeblood of IoT, and the dashboard transforms raw data into actionable intelligence.

By analyzing traffic flows, device performance, and historical trends, engineers can identify inefficiencies or predict failures. For instance, if a router consistently shows rising error rates, the dashboard may flag it for maintenance before it disrupts operations.

Analytics also inform capacity planning. Engineers can anticipate growth in device connections or bandwidth demands and adjust infrastructure accordingly.

The exam evaluates candidates’ ability to interpret these analytics, ensuring they can translate insights into practical improvements for performance, reliability, and resilience.

Study Strategies for the IoT Operations Dashboard

To prepare for this section of the exam, candidates should adopt structured study approaches:

Familiarize themselves with the dashboard’s architecture and its integration into Cisco’s IoT ecosystem.

Explore each function, from monitoring to configuration and security oversight, understanding how they interrelate.

Practice using EDM to manage routers and gateways, focusing on bulk operations and remote updates.

Study the Secure Equipment Access framework, emphasizing its role in balancing accessibility with protection.

Review case studies to see how the dashboard is applied in industries such as energy, logistics, and manufacturing.

By combining conceptual learning with scenario-based practice, candidates can build confidence and competence in this crucial domain.

Future Directions of IoT Operations Management

The IoT Operations Dashboard is not static but continually evolving to meet emerging challenges.

Integration with artificial intelligence promises predictive analytics that go beyond detecting current anomalies to forecasting future risks. Machine learning algorithms could dynamically adjust configurations to optimize performance or security without human intervention.

Cloud-native architectures are also shaping the future, enabling dashboards to operate seamlessly across hybrid environments that combine on-premises and cloud infrastructure. This hybrid flexibility allows enterprises to scale rapidly while retaining control over sensitive operations.

In the long term, dashboards may incorporate digital twin technologies, where virtual models of networks mirror real-world counterparts. Engineers could simulate configurations or updates in these twins before deploying them, minimizing risks.

The exam positions candidates to engage with these future directions, ensuring they remain adaptable as technologies advance.

The Broader Significance of the Dashboard in IoT Ecosystems

Beyond its technical functions, the IoT Operations Dashboard represents a shift in how organizations approach IoT management. It embodies the principle that complexity must be tamed through visibility, automation, and intelligence.

For engineers, it reduces operational burdens and enhances control. For organizations, it delivers resilience, security, and efficiency. And for industries at large, it accelerates the adoption of IoT technologies by reducing the risks and costs associated with large-scale deployments.

The Cisco 700-821 exam underscores this significance by ensuring candidates understand not just how to operate the dashboard, but why it matters in shaping the future of connected industries.

Conclusion

The Cisco 700-821 IoT Essentials exam stands as a pivotal certification for professionals aiming to validate their expertise in the design, deployment, and management of industrial IoT solutions. Across its comprehensive syllabus, the exam examines essential domains including industrial Ethernet switching, wireless connectivity, routing and gateway functions, and the IoT Operations Dashboard. Each of these areas reflects the realities of modern connected infrastructures, where resilience, security, and scalability are paramount.

Industrial Ethernet switching provides the foundation for dependable communication, ensuring that critical devices exchange data without interruption. Wireless connectivity extends this foundation, offering mobility and flexibility in environments where cabling is impractical. Industrial routing and gateways expand the ecosystem further, bridging diverse devices and enabling communication across wide geographies with features like SD-WAN for dynamic control and resilience.

Success in the 700-821 exam requires more than rote memorization. Candidates must demonstrate the ability to integrate knowledge across domains, applying it to real-world scenarios where industrial challenges such as interference, legacy device integration, and harsh environmental conditions are prevalent. This practical orientation ensures that certified professionals are prepared to deliver tangible value in industries ranging from manufacturing to energy and logistics.

As IoT technologies continue to evolve, professionals equipped with the insights tested in the Cisco 700-821 exam will be positioned at the forefront of innovation. The certification verifies not only technical competence but also readiness to contribute to the design of secure, efficient, and scalable IoT ecosystems that can withstand both current and future demands.