Exam Code: MB-335

Exam Name: Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert

Certification Provider: Microsoft

Corresponding Certification: Microsoft Certified: Dynamics 365 Supply Chain Management Functional Consultant Expert

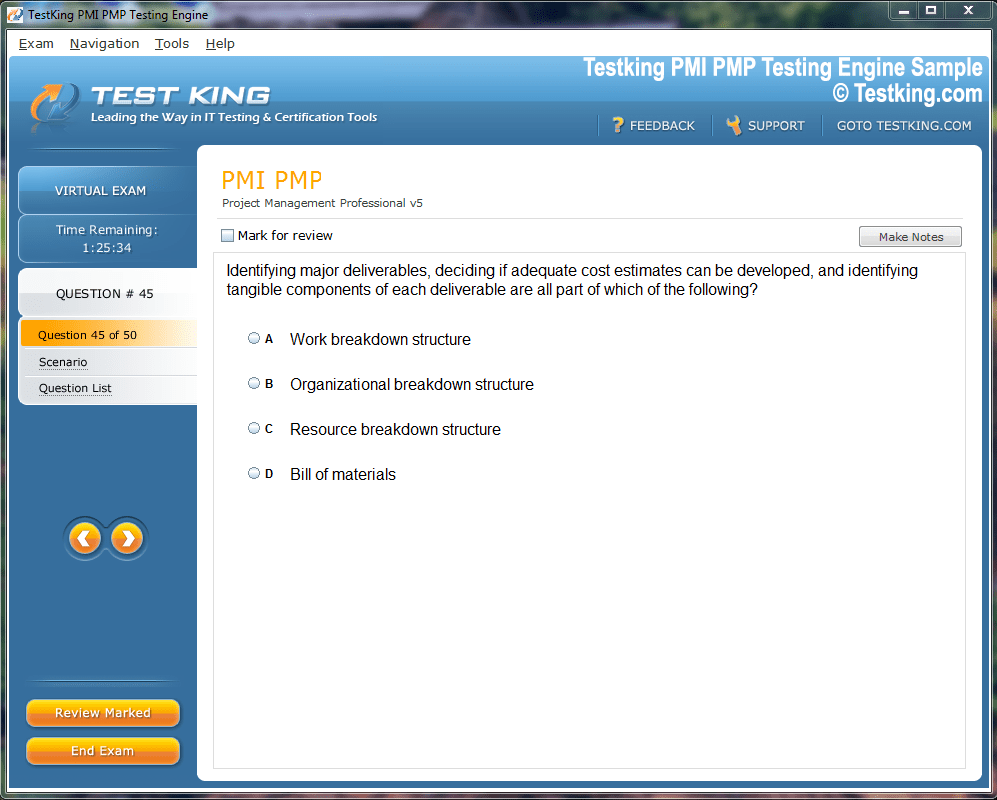

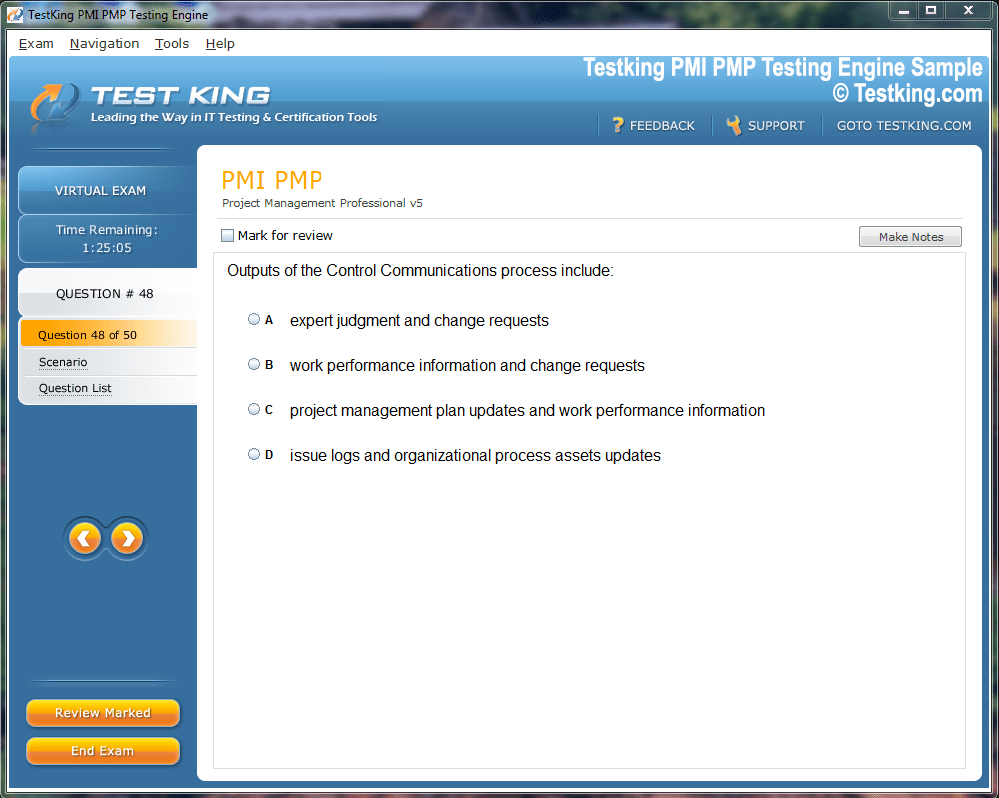

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our MB-335 testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top Microsoft Exams

- AZ-104 - Microsoft Azure Administrator

- AI-900 - Microsoft Azure AI Fundamentals

- DP-700 - Implementing Data Engineering Solutions Using Microsoft Fabric

- AI-102 - Designing and Implementing a Microsoft Azure AI Solution

- AZ-305 - Designing Microsoft Azure Infrastructure Solutions

- PL-300 - Microsoft Power BI Data Analyst

- AZ-900 - Microsoft Azure Fundamentals

- MD-102 - Endpoint Administrator

- AZ-500 - Microsoft Azure Security Technologies

- SC-300 - Microsoft Identity and Access Administrator

- SC-200 - Microsoft Security Operations Analyst

- MS-102 - Microsoft 365 Administrator

- SC-401 - Administering Information Security in Microsoft 365

- AZ-204 - Developing Solutions for Microsoft Azure

- DP-600 - Implementing Analytics Solutions Using Microsoft Fabric

- AZ-700 - Designing and Implementing Microsoft Azure Networking Solutions

- SC-100 - Microsoft Cybersecurity Architect

- PL-200 - Microsoft Power Platform Functional Consultant

- AZ-400 - Designing and Implementing Microsoft DevOps Solutions

- AZ-800 - Administering Windows Server Hybrid Core Infrastructure

- SC-900 - Microsoft Security, Compliance, and Identity Fundamentals

- AZ-140 - Configuring and Operating Microsoft Azure Virtual Desktop

- PL-400 - Microsoft Power Platform Developer

- PL-600 - Microsoft Power Platform Solution Architect

- MS-900 - Microsoft 365 Fundamentals

- AZ-801 - Configuring Windows Server Hybrid Advanced Services

- DP-300 - Administering Microsoft Azure SQL Solutions

- MS-700 - Managing Microsoft Teams

- GH-300 - GitHub Copilot

- MB-280 - Microsoft Dynamics 365 Customer Experience Analyst

- PL-900 - Microsoft Power Platform Fundamentals

- MB-330 - Microsoft Dynamics 365 Supply Chain Management

- MB-800 - Microsoft Dynamics 365 Business Central Functional Consultant

- MB-310 - Microsoft Dynamics 365 Finance Functional Consultant

- DP-100 - Designing and Implementing a Data Science Solution on Azure

- DP-900 - Microsoft Azure Data Fundamentals

- MB-820 - Microsoft Dynamics 365 Business Central Developer

- MB-230 - Microsoft Dynamics 365 Customer Service Functional Consultant

- MB-700 - Microsoft Dynamics 365: Finance and Operations Apps Solution Architect

- MS-721 - Collaboration Communications Systems Engineer

- GH-200 - GitHub Actions

- PL-500 - Microsoft Power Automate RPA Developer

- GH-900 - GitHub Foundations

- MB-500 - Microsoft Dynamics 365: Finance and Operations Apps Developer

- MB-920 - Microsoft Dynamics 365 Fundamentals Finance and Operations Apps (ERP)

- DP-420 - Designing and Implementing Cloud-Native Applications Using Microsoft Azure Cosmos DB

- MB-910 - Microsoft Dynamics 365 Fundamentals Customer Engagement Apps (CRM)

- MB-335 - Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert

- GH-500 - GitHub Advanced Security

- MB-240 - Microsoft Dynamics 365 for Field Service

- GH-100 - GitHub Administration

- AZ-120 - Planning and Administering Microsoft Azure for SAP Workloads

- SC-400 - Microsoft Information Protection Administrator

- DP-203 - Data Engineering on Microsoft Azure

- AZ-303 - Microsoft Azure Architect Technologies

- 62-193 - Technology Literacy for Educators

- MB-210 - Microsoft Dynamics 365 for Sales

- MB-900 - Microsoft Dynamics 365 Fundamentals

- 98-383 - Introduction to Programming Using HTML and CSS

- MO-100 - Microsoft Word (Word and Word 2019)

Microsoft MB-335 Supply Chain Management Functional Consultant Expert Career Path Strategies

The contemporary business landscape is characterized by intricate supply chains, sophisticated manufacturing processes, and a heightened demand for operational efficiency. In this milieu, expertise in enterprise resource planning (ERP) solutions becomes not merely an advantage but a strategic necessity. Microsoft Dynamics 365 Supply Chain Management (D365 SCM) stands at the forefront of this technological evolution, offering a comprehensive platform for managing production, logistics, asset management, and advanced supply chain operations. Recognizing the need for formal validation of expertise in this domain, Microsoft has introduced the Microsoft Certified: Dynamics 365 Supply Chain Management Functional Consultant Expert certification, accompanied by the MB-335 exam.

This certification serves as a rigorous testament to a professional's capacity to implement, configure, and optimize the advanced features of Dynamics 365 Supply Chain Management. Unlike introductory certifications, it is targeted at individuals with substantial experience in supply chain operations, including senior or principal functional consultants, IT professionals, developers, and information workers who are intimately familiar with enterprise-level supply chain challenges. By achieving this certification, professionals demonstrate their proficiency in navigating complex supply chain environments and their aptitude for applying best practices in production, logistics, master planning, and asset management.

The inception of this certification reflects Microsoft’s strategic alignment of professional credentials with real-world roles and responsibilities. By encompassing practical use cases, advanced configuration scenarios, and integrated technological applications such as mixed reality, the certification ensures that candidates are equipped not only with theoretical knowledge but also with the practical skills required for contemporary supply chain environments. The certification path establishes a structured roadmap, guiding aspirants from foundational knowledge to expert-level competence.

Candidate Profile and Prerequisites

The MB-335 exam is explicitly designed for expert or senior supply chain functional consultants who possess advanced knowledge of the operational intricacies of supply chain management. Candidates are expected to implement and configure sophisticated features of Dynamics 365 Supply Chain Management to meet complex business requirements. Core areas of expertise include production scheduling, resource management, inventory optimization, logistics, and asset maintenance. Additionally, candidates should demonstrate familiarity with emerging technologies such as mixed reality, enabling the integration of digital overlays and immersive workflows in manufacturing and warehouse processes.

To pursue this certification, candidates must first achieve proficiency through the foundational MB-330 exam, Microsoft Dynamics 365 Supply Chain Management Functional Consultant. This prerequisite ensures that candidates possess a robust understanding of basic configuration, implementation, and operational principles before advancing to more complex scenarios. Notably, the MB-300 Core exam is not required, which alleviates the necessity of mastering some of the more technical or system administration-focused content. This makes the certification path more focused on functional expertise, aligning it with the needs of professional consultants who prioritize business application over underlying technical infrastructure.

The candidate profile for this certification emphasizes not only technical acumen but also analytical and strategic thinking. Professionals are expected to identify and address business problems using a structured approach, optimize production workflows, and configure resources in a manner that maximizes efficiency and minimizes operational bottlenecks. The exam validates the ability to bridge the gap between operational requirements and digital implementation, ensuring that certified consultants are equipped to deliver measurable improvements in supply chain performance.

Implementing Product Information for Production

A fundamental aspect of Dynamics 365 Supply Chain Management is the ability to configure and manage product information effectively. This encompasses a wide array of activities, from defining planning items and co-products to configuring catch weight handling policies and managing inventory batches. Proper configuration of product attributes and batch inheritance is crucial for maintaining regulatory compliance, optimizing production processes, and ensuring accurate reporting.

Dimension-based products require special attention, as they involve the management of various attributes such as size, color, and configuration variants. Consultants must define configuration groups, establish routing processes, and manage products with constraint-based or pre-defined variants. This allows for flexible production planning while maintaining consistency and traceability throughout the manufacturing cycle. The implementation of bills of materials (BOMs), formulas, and production routes enables efficient material allocation, scrap management, and workflow optimization.

Dynamics 365 also offers the Product Configurator, a sophisticated tool that supports the creation and management of product configuration models. Candidates must demonstrate proficiency in defining model components, subcomponents, and calculation rules. Differentiating between table constraints and expression constraints is essential for accurate configuration and operational alignment. Additionally, BOM lines and route operations must be integrated seamlessly into configuration models to ensure that production workflows reflect real-world scenarios. Pricing management and model validation further enhance the operational relevance of the configuration, ensuring that products are accurately represented and efficiently manufactured.

Engineering Change Management

Engineering Change Management (ECM) represents a pivotal domain in modern supply chain operations, particularly for organizations that manage complex product lifecycles. Dynamics 365 Supply Chain Management equips consultants with tools to design and control engineering products, configure engineering categories, and define product readiness and release policies. Creating engineering products with specific attributes allows for precise tracking and process integration, ensuring that each item adheres to organizational standards and regulatory requirements.

The release management process involves reviewing, accepting, and integrating released products into production, sales, and purchase orders. ECM also encompasses the scheduling and execution of change requests, ensuring that modifications to products or processes are implemented systematically. This reduces the risk of disruption, maintains product integrity, and facilitates compliance with industry standards. By mastering ECM, consultants can optimize production planning, improve resource allocation, and enhance overall supply chain resilience.

Configuring Production Prerequisites

Effective production management begins with the configuration of foundational elements such as resources, routes, and calendars. Dynamics 365 enables consultants to implement work calendars, define working times, and configure resource capabilities. Proper resource management includes establishing resource groups, assigning operations, and managing production routes to align with organizational objectives.

Production units, groups, pools, and journal names form the backbone of production tracking and control. Integration between production control modules and general ledger functions ensures accurate financial reporting, while reservation management optimizes the allocation of raw materials and finished goods. Warehouse processes, including picking and put-away operations, are closely linked to production workflows, reinforcing the interconnected nature of modern supply chains. Understanding unified manufacturing approaches, which combine discrete and process manufacturing modes, allows consultants to configure production parameters and monitor order process statuses effectively.

Costing is an integral component of production management, encompassing the configuration of costing sheets, indirect costs, and cost groups. Consultants must manage cost allocations for co-products and burden allocations for by-products while performing BOM and formula calculations. Activating item prices and analyzing production variances ensures that financial performance is accurately tracked and optimized. Cost management in Dynamics 365 supports informed decision-making and fosters operational efficiency across production processes.

Production Methods

Dynamics 365 Supply Chain Management supports multiple production methods, each tailored to specific operational requirements. Discrete manufacturing involves the creation and processing of production orders, picking lists, job cards, and route journals. Consultants must configure production-related reservations and ensure that workflows reflect operational realities. Process manufacturing, by contrast, focuses on batch orders, consolidated batch processes, batch balancing, and formula management. Proper execution of reports as finished journals, including co-products and by-products, ensures accurate tracking and regulatory compliance.

Lean manufacturing emphasizes value streams, production flows, and kanban systems. Consultants implement production flow costing, configure kanban rules, and manage fixed, scheduled, and event kanbans to optimize operational efficiency. Each production method requires careful planning, configuration, and monitoring, highlighting the necessity of advanced expertise for certified consultants. The MB-335 certification rigorously evaluates proficiency across these production methodologies, ensuring that candidates are capable of managing diverse manufacturing environments.

Advanced Production Control in Dynamics 365 Supply Chain Management

Production control within Microsoft Dynamics 365 Supply Chain Management represents a pivotal area for optimizing operational efficiency, reducing waste, and maintaining consistent output quality. Effective production control demands a comprehensive understanding of discrete, process, and lean manufacturing principles, as well as the integration of advanced scheduling and resource management techniques. Consultants seeking the Microsoft Certified: Dynamics 365 Supply Chain Management Functional Consultant Expert certification must demonstrate proficiency in implementing and managing production control processes that align with organizational goals.

Within Dynamics 365, production control configuration begins with resource management. Resources include machinery, labor, and tooling, each of which must be precisely defined, grouped, and scheduled. Resource groups allow for collective management of similar assets, while production pools and units facilitate operational monitoring and allocation. Work calendars and working times ensure that resources are available when needed, while also accommodating downtime for maintenance and unexpected delays. Configuring resources effectively is essential for achieving optimal production throughput and minimizing bottlenecks in the manufacturing process.

Subcontracting Processes and Integration

Subcontracting is an essential production strategy for organizations that rely on external partners for specialized processes. Dynamics 365 enables the implementation of activity-based subcontracting, allowing consultants to define the scope, resources, and routing of outsourced operations. BOM and formula lines for subcontracted items can be configured to integrate seamlessly with internal production workflows, ensuring traceability and accountability throughout the supply chain. Service items for subcontracting must be accurately created and tracked to ensure proper invoicing and compliance.

Processing subcontracting purchase orders is another critical aspect. Consultants must configure the system to manage procurement, delivery, and production integration, ensuring that subcontracted work aligns with internal timelines and capacity constraints. The MB-335 exam evaluates candidates on their ability to configure these workflows, emphasizing efficiency, cost control, and quality management. Proper subcontracting implementation allows organizations to leverage specialized expertise while maintaining visibility and control over production outcomes.

Manufacturing Execution and Floor Operations

Manufacturing execution within Dynamics 365 provides real-time oversight of production activities on the shop floor. Consultants configure time and attendance prerequisites, activate workers for time registration, and establish interfaces for job card terminals. These processes enable accurate tracking of labor hours, machine utilization, and task completion, providing a foundation for operational analysis and performance optimization.

Processing production and batch orders using manufacturing execution workflows ensures that materials and resources are allocated correctly, production steps are completed in sequence, and outputs meet quality standards. The configuration of production floor execution interfaces allows workers to interact with the system directly, entering job completion data and reporting anomalies in real time. By integrating manufacturing execution with resource planning, inventory management, and scheduling, consultants can maintain a cohesive operational environment that maximizes productivity while reducing errors and delays.

Advanced Master Planning Scenarios

Master planning is a cornerstone of effective supply chain management, enabling organizations to anticipate demand, allocate resources, and optimize production schedules. Dynamics 365 supports advanced master planning scenarios that include intercompany planning, forecast model configuration, demand forecasting, and planned order processing. Consultants must configure forecast models to reflect organizational patterns and adjust planning parameters based on real-time operational data.

Planned orders serve as the foundation for scheduling production activities, providing a detailed roadmap for resource allocation and material procurement. Intercompany planning ensures coordination across multiple facilities, warehouses, and manufacturing units, allowing organizations to respond dynamically to fluctuations in demand or supply constraints. Running demand forecasting processes and validating explosion results ensures that production plans are realistic, achievable, and aligned with business objectives. Advanced master planning requires analytical acuity, attention to detail, and an understanding of complex dependencies across production, procurement, and inventory processes.

Production Scheduling and Capacity Planning

Production scheduling and capacity planning are critical functions that ensure manufacturing operations proceed efficiently without overburdening resources. Dynamics 365 enables the definition of scheduling parameters, monitoring of production schedules, and configuration of capacity for machines, labor, and tooling. Consultants must differentiate between infinite and finite scheduling models, applying the appropriate approach to each production scenario to maintain balance between demand and available capacity.

Operations and job scheduling differ in their scope and application. Operations scheduling focuses on individual tasks and their sequence, while job scheduling addresses the broader context of production orders and resource allocation. Effective scheduling requires the consideration of lead times, setup requirements, machine availability, and workforce allocation. By implementing scheduling strategies within Dynamics 365, consultants ensure that production timelines are optimized, deadlines are met, and resource utilization is maximized. Advanced capacity planning also involves identifying bottlenecks, adjusting schedules in real time, and integrating data from multiple production units for holistic decision-making.

Integration of Cloud and Edge Scale Units

Modern supply chains increasingly leverage cloud and edge computing to extend operational capabilities and enable real-time decision-making. Dynamics 365 supports scale units that allow for the distribution of workloads between cloud environments and local edge units, particularly for warehouse and manufacturing processes. Consultants must understand the value proposition of scale units, including reduced latency, localized processing, and enhanced reliability during high-volume operations.

Implementing scale units involves configuring processes that can operate independently or in conjunction with centralized cloud systems. Warehouse management processes, for example, can be executed on scale units to manage high-speed picking, put-away, and inventory control operations without reliance on centralized servers. Similarly, certain manufacturing processes, including real-time production monitoring and quality assurance, benefit from edge computing capabilities. Consultants must evaluate organizational requirements, operational constraints, and technological considerations to configure scale units effectively.

Mixed Reality Integration in Supply Chain Operations

Mixed reality technologies, such as Dynamics 365 Guides, provide immersive solutions for training, process visualization, and operational guidance. Consultants implementing mixed reality integration must define use cases where augmented workflows enhance productivity, reduce errors, and improve compliance. In manufacturing, mixed reality can guide workers through complex assembly processes, provide real-time performance feedback, and ensure adherence to engineering specifications. In asset management, mixed reality enables visualization of equipment status, predictive maintenance guidance, and interactive troubleshooting.

Integrating mixed reality with Dynamics 365 involves configuring system interfaces, defining user roles, and establishing workflows that align with operational objectives. Consultants must ensure that the technology complements existing processes rather than introducing disruption. Proper implementation enhances operational efficiency, reduces training time, and fosters a culture of continuous improvement within the supply chain environment. Mastery of mixed reality integration is an advanced skill evaluated in the MB-335 certification, reflecting the evolving intersection of digital technology and supply chain management.

Asset Management Implementation

Effective asset management ensures that equipment, machinery, and facilities operate at peak performance, minimizing downtime and maintenance costs. Dynamics 365 provides tools for configuring maintenance plans, managing functional locations, and overseeing work orders. Consultants must define maintenance schedules, allocate resources, and monitor the execution of maintenance tasks to maintain operational continuity.

Maintenance requests and work order management are central components of asset management. Consultants configure systems to track consumption of resources, assign tasks, and schedule activities according to priority and operational impact. Real-time monitoring of work orders ensures that corrective actions are implemented promptly, reducing the risk of production delays. Integration with production, scheduling, and inventory modules ensures that asset management activities are coordinated with broader supply chain operations. The MB-335 certification validates the ability to implement comprehensive asset management strategies that enhance productivity and reduce operational risk.

Cost and Resource Optimization

Cost control and resource optimization are intertwined with production control, scheduling, and asset management. Dynamics 365 enables consultants to configure cost allocations, manage indirect costs, and analyze production variances. Costing sheets, item prices, and BOM calculations provide a foundation for accurate financial reporting and operational planning.

Resource optimization involves balancing machine utilization, labor deployment, and tooling availability to achieve maximum efficiency. Consultants apply advanced techniques such as workload leveling, capacity forecasting, and resource pooling to ensure that operations proceed without disruption. Integrating cost and resource management ensures that production decisions consider both financial and operational impacts, fostering sustainable practices that support long-term organizational success.

Product Configuration in Dynamics 365 Supply Chain Management

Product configuration in Microsoft Dynamics 365 Supply Chain Management is a critical function for organizations that produce complex or highly customizable goods. This aspect of the platform enables consultants to design and manage configurable products, implement rules for variants, and ensure that manufacturing processes accommodate customer-specific requirements. The MB-335 certification evaluates a candidate’s ability to implement and maintain these advanced configurations, ensuring that products meet both operational standards and client expectations.

The Product Configurator within Dynamics 365 allows the creation of configuration models composed of components and subcomponents. Each element can be assigned specific attributes and rules that govern its behavior in the production environment. Consultants must differentiate between table constraints, which define permissible values based on predefined tables, and expression constraints, which use conditional logic to enforce complex relationships between product features. This distinction is essential for creating models that are both flexible and reliable, enabling organizations to deliver tailored products efficiently.

Bills of Materials and Formulas

Bills of materials (BOMs) form the backbone of production planning and control in Dynamics 365. A BOM is a hierarchical representation of a product’s components, assemblies, and subassemblies, detailing the quantities and relationships necessary for production. Consultants are responsible for creating and managing BOMs to ensure accurate material allocation, process sequencing, and cost tracking. Effective BOM configuration reduces waste, optimizes inventory, and ensures that production orders align with operational capacity.

Formulas, used primarily in process manufacturing, define the combination of raw materials and processing steps required to produce a batch of goods. Consultants must configure formulas to account for co-products, by-products, and rework processes, maintaining consistency and compliance throughout production. The integration of BOMs and formulas allows organizations to manage both discrete and process manufacturing workflows within a unified system, supporting flexible production strategies and precise inventory control.

Managing Product Variants

Managing product variants is an essential skill for functional consultants. Variants allow organizations to produce multiple versions of a product with different attributes, such as size, color, or material composition, without creating separate BOMs for each variation. Dynamics 365 supports dimension-based, constraint-based, and predefined variants, each serving a specific operational purpose. Dimension-based variants manage products with measurable attributes, such as length or width, while constraint-based variants enforce logical relationships between components, and predefined variants cater to standard product configurations.

Consultants must configure routes, configuration groups, and production sequences to ensure that variants are manufactured accurately and efficiently. The system must validate that selected options are feasible and comply with business rules, reducing errors and production delays. Proper variant management enhances operational flexibility, allows for customized offerings, and supports responsiveness to market demands.

Advanced Product Compliance

Regulatory compliance is a critical consideration in modern supply chain operations. Dynamics 365 enables consultants to manage regulated and restricted items, ensuring adherence to industry standards and government regulations. Product compliance configuration involves defining compliance rules, monitoring adherence throughout production, and maintaining documentation for audits and inspections. Consultants must also manage product attributes, batch tracking, and inventory lot inheritance to ensure traceability from raw materials to finished goods.

Advanced compliance management integrates with other system modules, including production, inventory, and asset management, to maintain operational integrity. For organizations operating in highly regulated industries, such as pharmaceuticals, food, and beverage, or chemicals, robust compliance capabilities are essential. The MB-335 certification assesses the consultant’s ability to implement these features effectively, demonstrating competence in managing risk and ensuring quality throughout the supply chain.

Engineering Change Management in Depth

Engineering Change Management (ECM) within Dynamics 365 Supply Chain Management allows organizations to control modifications to products, processes, and production documentation systematically. ECM encompasses designing engineering product lifecycles, configuring engineering categories, and implementing product readiness and release policies. Consultants are responsible for creating engineering products with specific attributes, reviewing and accepting released items, and integrating these products into production, sales, and purchase orders.

The ECM process also involves scheduling and executing engineering change requests and change orders. Proper configuration ensures that changes are documented, approved, and implemented without disrupting ongoing operations. Consultants must coordinate across multiple departments, balancing the need for agility with the requirement for stability and traceability. Mastery of ECM enables organizations to innovate while maintaining operational continuity, and it is a key competency evaluated in the MB-335 exam.

Configuring Production Settings and Processes

Production settings and processes in Dynamics 365 form the operational foundation for manufacturing activities. Consultants configure production units, groups, pools, and journal names to align with organizational structures and workflows. Integration between production control and general ledger modules ensures that financial and operational data are synchronized, supporting accurate reporting and cost tracking.

Warehouse processes, including raw materials picking and finished goods put-away, are closely linked to production operations. Consultants must configure these processes to maintain inventory accuracy, optimize storage space, and ensure timely delivery of materials to production lines. Understanding unified manufacturing, which combines discrete and process methods, allows consultants to configure production parameters that accommodate a variety of manufacturing environments, enhancing operational flexibility and efficiency.

Production Costing and Financial Integration

Costing is an integral component of production management, influencing pricing strategies, profitability analysis, and operational decision-making. Dynamics 365 enables consultants to configure costing sheets, indirect costs, cost groups, and cost categories, as well as perform allocations for co-products and burden allocations for by-products. BOM and formula calculations provide accurate cost data for materials, labor, and overhead, supporting informed management decisions.

Activating item prices, analyzing production variances, and reviewing cost allocations are essential activities for maintaining financial control. Consultants must ensure that production costs are accurately reflected in the general ledger, supporting budgeting, forecasting, and performance analysis. Integration of production costing with other operational modules ensures that financial and operational metrics are aligned, facilitating a holistic approach to supply chain management.

Implementing Discrete and Process Manufacturing

Discrete manufacturing involves the production of distinct items, each with a unique BOM and production order. Consultants configure production orders, picking lists, job cards, and route journals, ensuring that operations follow the defined sequence and that materials are allocated correctly. Process manufacturing, on the other hand, focuses on batch production, formula management, and handling of co-products and by-products. Consultants must configure batch reservations, sequencing, and balancing to optimize process efficiency.

Lean manufacturing principles are also integrated into Dynamics 365, allowing consultants to create value streams, production flows, and kanban systems. Configuring kanban rules, processing orders via kanban boards, and managing fixed, scheduled, and event-driven kanbans ensures that production is synchronized with demand and resource availability. Mastery of discrete, process, and lean manufacturing is essential for the MB-335 exam, demonstrating the consultant’s ability to manage complex and varied production environments.

Production Control and Scheduling Integration

Production control and scheduling are interdependent components of effective manufacturing operations. Consultants define scheduling parameters, monitor production schedules, and configure capacity for machines, labor, and tooling. Infinite and finite scheduling methods provide flexibility in managing resources, allowing organizations to balance demand with operational constraints. Operations and job scheduling require detailed configuration to ensure that production sequences are efficient and that resources are utilized optimally.

Advanced scheduling techniques include workload leveling, critical path analysis, and real-time adjustment based on operational changes. By integrating scheduling with production control, consultants can optimize throughput, reduce delays, and improve overall efficiency. Proper configuration ensures that production orders are completed on time, resources are allocated effectively, and operational performance meets organizational targets.

Integration with Asset Management

Asset management is closely tied to production, ensuring that equipment, machinery, and facilities operate efficiently. Dynamics 365 provides tools for configuring maintenance plans, functional locations, and work order management. Consultants define maintenance schedules, allocate resources, and monitor the execution of tasks to minimize downtime and optimize performance.

Integration of asset management with production and scheduling modules ensures that maintenance activities do not disrupt manufacturing workflows. Consultants must coordinate preventive maintenance, corrective actions, and resource allocation to maintain continuous operations. Effective asset management supports productivity, reduces operational risk, and enhances the lifespan of critical equipment, all of which are key considerations in the MB-335 certification.

Advanced Warehouse Management in Dynamics 365 Supply Chain Management

Warehouse management within Microsoft Dynamics 365 Supply Chain Management is a cornerstone of efficient supply chain operations, providing organizations with the ability to optimize inventory storage, streamline material handling, and ensure timely delivery of goods. The MB-335 certification emphasizes advanced warehouse management skills, focusing on configuring processes, managing resources, and integrating warehouse activities with production, distribution, and asset management functions.

Effective warehouse management begins with the configuration of storage locations, zones, and warehouse hierarchies. Consultants define physical layouts, assign items to specific locations, and configure rules for replenishment, picking, and put-away operations. By structuring the warehouse environment efficiently, organizations can reduce travel time, improve inventory accuracy, and enhance throughput. Dynamics 365 also allows for advanced features such as work templates, wave processing, and mobile device integration, enabling automated and streamlined operations.

Inventory Management and Batch Tracking

Inventory management in Dynamics 365 encompasses real-time tracking of materials, finished goods, and work-in-progress items. Consultants configure item attributes, batch numbers, and lot tracking to ensure precise visibility across the supply chain. Batch attributes and lot inheritance allow organizations to maintain traceability, manage expiration dates, and comply with regulatory requirements. Proper inventory configuration is critical for ensuring product quality, minimizing waste, and facilitating accurate reporting.

Managing catch weight items, co-products, and by-products adds complexity to inventory operations. Consultants must establish rules for allocation, calculation, and consumption, integrating these processes with production workflows. Inventory transactions, including receipts, issues, transfers, and adjustments, must be meticulously configured to maintain accurate stock levels. Advanced inventory management supports predictive replenishment, reduces stockouts, and enhances overall supply chain responsiveness.

Supply Chain Optimization and Advanced Planning

Dynamics 365 provides tools for advanced supply chain planning, enabling organizations to anticipate demand, allocate resources, and optimize production schedules. Consultants configure forecast models, intercompany planning parameters, and demand planning processes to create robust supply chain strategies. Advanced planning considers factors such as lead times, production capacity, supplier constraints, and seasonal demand fluctuations, ensuring that operations remain agile and efficient.

Planned orders, demand forecasting, and explosion validation are integral components of advanced planning. Consultants must ensure that production schedules are feasible, resource allocation is optimized, and inventory levels meet anticipated demand. The integration of planning with warehouse management, production control, and asset management ensures that the supply chain operates cohesively, minimizing delays and maximizing efficiency. Advanced planning techniques also support scenario analysis, allowing organizations to evaluate the impact of changes in demand, supply, or operational constraints.

Capacity Planning and Resource Allocation

Capacity planning in Dynamics 365 involves the strategic allocation of machines, labor, and tooling to meet production requirements. Consultants configure capacity for individual resources, resource groups, and production units, applying finite or infinite scheduling models as appropriate. Effective capacity planning ensures that production processes are balanced, resources are utilized optimally, and bottlenecks are identified and mitigated.

Resource allocation extends beyond production to include warehouse operations, maintenance activities, and subcontracting processes. Consultants must consider interdependencies, operational priorities, and timing constraints when assigning resources. Advanced capacity planning tools within Dynamics 365 allow for real-time monitoring, predictive adjustments, and scenario modeling, enabling organizations to respond dynamically to changing operational conditions. This capability is essential for maintaining high levels of efficiency and meeting customer expectations consistently.

Intercompany and Multisite Operations

Large organizations often operate across multiple facilities, regions, or countries, requiring coordination between sites to optimize supply chain performance. Dynamics 365 supports intercompany master planning, allowing consultants to synchronize production, inventory, and logistics activities across multiple entities. This ensures that materials and finished goods are available where needed, reducing delays, minimizing excess inventory, and improving customer satisfaction.

Multisite operations also involve the management of transportation, distribution, and intercompany transfers. Consultants configure workflows to handle shipping, receiving, and cross-site replenishment efficiently. Integration with warehouse management and production modules ensures that intercompany transactions are accurately recorded and coordinated. Mastery of multisite operations is critical for organizations with complex supply chains, and the MB-335 certification evaluates candidates’ ability to configure and manage these processes effectively.

Advanced Production Scheduling Techniques

Production scheduling in Dynamics 365 extends beyond basic timelines, encompassing advanced techniques that optimize the flow of materials, labor, and equipment. Consultants define scheduling parameters, monitor progress, and adjust schedules in real-time to accommodate operational changes. Techniques such as finite scheduling, capacity leveling, and critical path analysis ensure that production remains aligned with demand and resource availability.

Scheduling also considers interdependencies between operations, job priorities, and resource constraints. Consultants configure production calendars, working times, and shift patterns to maximize throughput and minimize downtime. Advanced scheduling capabilities enable organizations to respond proactively to disruptions, manage peak workloads, and ensure the timely completion of production orders. These skills are essential for achieving the operational efficiency required for the MB-335 certification.

Subcontracting and Outsourced Operations

Subcontracting is an essential strategy for organizations that leverage external expertise or capacity. Dynamics 365 allows consultants to implement activity-based subcontracting, configure BOM and formula lines for subcontracted items, and manage associated resources and routes. Service items for subcontracting must be created, tracked, and integrated with production workflows to maintain transparency and control.

Processing subcontracting purchase orders involves coordinating with external partners, ensuring the timely delivery of materials, and integrating completed work into internal production schedules. Consultants must configure the system to handle procurement, cost allocation, and quality verification for subcontracted operations. Proper subcontracting management ensures that outsourced activities align with organizational standards, reduce operational risk, and maintain production continuity.

Integration of Mixed Reality in Warehouse and Production Operations

Mixed reality technologies provide immersive and interactive solutions for warehouse and production environments. Dynamics 365 Guides enables consultants to implement guided workflows, interactive training modules, and visual instructions that enhance operational efficiency and reduce errors. In warehouse operations, mixed reality can guide workers through complex picking, packing, and put-away processes, improving accuracy and reducing processing time.

In production environments, mixed reality supports assembly, maintenance, and inspection tasks, providing real-time feedback and ensuring adherence to engineering specifications. Consultants configure user roles, workflows, and system interfaces to integrate mixed reality effectively, complementing traditional processes without disruption. Mastery of mixed reality integration is increasingly relevant in modern supply chains, reflecting the intersection of technology and operational excellence.

Asset and Maintenance Optimization

Asset management within Dynamics 365 supports maintenance planning, work order scheduling, and resource allocation. Consultants configure functional locations, define maintenance plans, and monitor work order execution to ensure the reliability and efficiency of machinery and equipment. Effective asset management reduces downtime, extends equipment lifespan, and enhances overall production capacity.

Maintenance processes are integrated with production and warehouse operations to minimize disruptions. Preventive maintenance, corrective actions, and predictive analytics enable organizations to proactively address potential failures and optimize resource utilization. Consultants must also manage inventory for maintenance activities, ensuring that spare parts and tools are available when needed. The MB-335 certification evaluates the ability to implement and manage comprehensive asset management strategies that support operational resilience.

Compliance and Regulatory Considerations

Compliance management is a critical aspect of supply chain operations, particularly for organizations operating in regulated industries. Dynamics 365 enables consultants to configure regulatory controls, monitor adherence, and maintain traceability for items, batches, and processes. Advanced compliance features include tracking of regulated substances, restricted materials, and hazardous products, ensuring that organizations meet legal and industry standards.

Compliance extends to production, inventory, and maintenance activities, requiring integration across multiple modules. Consultants configure alerts, approval workflows, and reporting mechanisms to detect deviations, document processes, and maintain audit readiness. Ensuring compliance reduces operational risk, safeguards organizational reputation, and enhances customer trust. The MB-335 certification tests candidates on their ability to implement these controls effectively within the Dynamics 365 ecosystem.

Supply Chain Analytics and Reporting

Analytics and reporting are essential for monitoring supply chain performance, identifying inefficiencies, and supporting strategic decision-making. Dynamics 365 provides tools for generating operational reports, analyzing inventory levels, evaluating production efficiency, and monitoring compliance. Consultants configure dashboards, key performance indicators, and data visualizations to provide actionable insights for stakeholders.

Advanced analytics enable predictive and prescriptive decision-making, allowing organizations to anticipate demand, adjust production schedules, and optimize resource allocation. Integration of operational data across production, warehouse, and asset management modules ensures that analytics provide a comprehensive view of supply chain performance. Consultants must ensure that reporting tools are accurate, timely, and aligned with organizational objectives, reinforcing the value of certified expertise.

Specialized Production Methods in Dynamics 365 Supply Chain Management

Specialized production methods form a pivotal part of Microsoft Dynamics 365 Supply Chain Management, enabling organizations to optimize workflows, reduce waste, and respond flexibly to varying product demands. The MB-335 certification evaluates consultants’ expertise in implementing discrete manufacturing, process manufacturing, lean manufacturing, and mixed-mode production processes. Mastery of these production methods ensures that operations are not only efficient but also adaptable to changes in demand, resource availability, or regulatory requirements.

Discrete manufacturing focuses on the production of distinct, countable products. Consultants configure production orders, route operations, and resource allocations to ensure seamless material flow and accurate production tracking. Work journals, including job cards and route cards, are integrated into production processes to maintain visibility and traceability of operations. Managing picking lists, inventory reservations, and production outputs is essential for minimizing disruptions and achieving consistent output quality.

Process manufacturing, by contrast, emphasizes the creation of products in batches, involving formulations, co-products, by-products, and rework processes. Consultants configure batch order processes, batch balancing, sequencing, and formula management to maintain accuracy, consistency, and compliance. Reports-as-finished journals capture production completion and validate adherence to operational and regulatory requirements. Effective management of process manufacturing requires an understanding of material flows, recipe calculations, and batch tracking to optimize efficiency and minimize waste.

Lean manufacturing principles are integrated within Dynamics 365 to enhance operational flexibility and reduce inefficiencies. Consultants implement value streams, configure production flows, and establish kanban rules for inventory and production control. Kanban orders, whether fixed, scheduled, or event-driven, are processed through kanban boards to maintain a continuous production rhythm. Lean methodologies complement discrete and process manufacturing approaches, creating a hybrid system capable of responding dynamically to changing production requirements.

Mixed-mode manufacturing combines elements of discrete and process methods, providing organizations with the flexibility to manage diverse product portfolios. Consultants must configure unified manufacturing processes, integrating batch processing, discrete operations, and lean principles into a coherent workflow. This approach allows organizations to optimize resource utilization, reduce downtime, and maintain consistency across varied production types. Mastery of mixed-mode manufacturing is a key competency for the MB-335 certification, reflecting the ability to design adaptable, efficient, and resilient production environments.

Advanced Costing and Financial Integration

Costing in Dynamics 365 Supply Chain Management is critical for financial control, profitability analysis, and strategic decision-making. Consultants configure costing sheets, cost groups, indirect costs, and cost categories to ensure accurate cost tracking across production processes. Cost allocations for co-products and burden allocations for by-products must be meticulously configured to reflect the true financial impact of production activities.

BOM and formula calculations are central to accurate costing, integrating material, labor, and overhead costs. Item pricing, production posting profiles, and variance analysis provide insights into operational efficiency and financial performance. Consultants must ensure seamless integration between production costing and general ledger modules, enabling real-time visibility into production expenditures and facilitating budgeting, forecasting, and performance evaluation.

Advanced costing also involves evaluating production methods, resource utilization, and operational efficiency to identify areas for improvement. Consultants apply techniques such as standard costing, activity-based costing, and variance reporting to enhance financial control. By integrating costing with production planning, inventory management, and asset management, organizations gain a holistic view of operational and financial performance, supporting informed decision-making and strategic planning.

Master Planning and Scheduling Scenarios

Master planning within Dynamics 365 Supply Chain Management encompasses demand forecasting, planned order processing, intercompany coordination, and capacity planning. Consultants configure forecast models, parameters, and planning calendars to anticipate production needs, optimize inventory levels, and ensure resource availability. Effective master planning supports organizational agility, enabling timely responses to market fluctuations and operational disruptions.

Planned orders are generated to coordinate production, procurement, and distribution activities. Consultants must validate explosions, adjust schedules, and integrate planned orders across multiple facilities to ensure feasibility and alignment with operational capacity. Intercompany planning extends these principles to multisite operations, synchronizing production, inventory, and logistics across various locations to optimize resource utilization and reduce supply chain inefficiencies.

Advanced scheduling techniques, including finite and infinite scheduling, capacity leveling, and critical path analysis, ensure that resources are allocated efficiently and production sequences are optimized. Consultants configure scheduling parameters, monitor execution, and adjust plans in real time to accommodate unexpected changes. Integration with warehouse management, production control, and asset management ensures that scheduling decisions reflect the realities of operational constraints and organizational priorities.

Integration of Warehouse, Production, and Asset Management

Effective supply chain management relies on the seamless integration of warehouse, production, and asset management functions. Dynamics 365 enables consultants to synchronize operations across these domains, ensuring accurate inventory levels, optimized production flows, and efficient maintenance scheduling. Integration supports real-time visibility, allowing stakeholders to monitor performance, identify bottlenecks, and make informed decisions.

Warehouse management processes, including picking, put-away, replenishment, and batch tracking, are linked to production scheduling and resource allocation. Consultants configure workflows that facilitate the timely delivery of materials, minimize stockouts, and maintain compliance with regulatory standards. Asset management is integrated with production and maintenance schedules, ensuring that equipment availability and reliability support uninterrupted operations. This cohesive approach enhances efficiency, reduces costs, and strengthens organizational resilience.

Mixed Reality and Technological Integration

The integration of mixed reality technologies within Dynamics 365 Supply Chain Management enhances operational efficiency and training effectiveness. Dynamics 365 Guides allows consultants to implement interactive workflows, visual instructions, and immersive training modules for warehouse and production personnel. Mixed reality applications improve accuracy, reduce errors, and facilitate knowledge transfer across complex operational processes.

In production environments, mixed reality supports assembly guidance, maintenance instructions, and quality checks, providing real-time feedback and ensuring adherence to engineering specifications. In warehouse operations, it guides picking, packing, and put-away tasks, improving speed and precision. Consultants configure roles, workflows, and system interfaces to ensure smooth integration of mixed reality technologies, complementing traditional processes without disruption.

Subcontracting and Outsourced Production Management

Subcontracting remains a vital strategy for organizations leveraging external expertise or capacity constraints. Dynamics 365 allows consultants to implement activity-based subcontracting, configure BOM and formula lines, and manage associated resources and routing for outsourced operations. Service items for subcontracted tasks must be accurately tracked and integrated into internal workflows, ensuring transparency and accountability.

Processing subcontracting purchase orders involves coordination with external vendors, timely delivery, and seamless integration into internal production schedules. Consultants configure procurement, cost allocations, and quality assurance processes to ensure that subcontracted operations meet organizational standards. Proper management of subcontracting enhances operational flexibility, reduces risk, and maintains continuity across complex supply chains.

Compliance, Regulatory, and Quality Management

Compliance and regulatory adherence are integral to supply chain management, particularly in industries subject to strict standards. Dynamics 365 provides tools to manage regulated and restricted items, track batch, and lot information, and maintain documentation for audits and inspections. Consultants configure alerts, approval workflows, and reporting mechanisms to ensure adherence to internal and external standards.

Quality management integrates with production, inventory, and asset management to monitor operational performance, detect deviations, and implement corrective actions. Consultants configure inspection plans, track non-conformances, and ensure that processes comply with regulatory requirements. Advanced compliance and quality management enhance operational integrity, mitigate risk, and reinforce organizational reputation.

Analytics, Reporting, and Continuous Improvement

Analytics and reporting are essential for evaluating supply chain performance, identifying inefficiencies, and supporting continuous improvement initiatives. Dynamics 365 provides tools for operational reporting, cost analysis, production efficiency evaluation, and compliance monitoring. Consultants configure dashboards, key performance indicators, and data visualizations to deliver actionable insights.

Advanced analytics enable predictive and prescriptive decision-making, allowing organizations to anticipate demand, optimize production schedules, and allocate resources effectively. Integration of data across warehouse, production, and asset management modules ensures comprehensive visibility and supports data-driven strategies. Continuous improvement initiatives leverage analytics to refine processes, enhance efficiency, and maintain competitiveness in dynamic markets.

Strategic Integration and Operational Excellence

The MB-335 certification emphasizes not only technical proficiency but also the ability to integrate multiple supply chain functions into a coherent, strategic framework. Consultants must ensure that production methods, warehouse operations, asset management, costing, scheduling, and compliance processes work harmoniously to achieve organizational objectives. This requires analytical thinking, problem-solving skills, and an understanding of both operational realities and strategic imperatives.

Strategic integration extends to advanced technologies, such as mixed reality, cloud and edge computing, and automated workflows. Consultants leverage these tools to enhance operational visibility, improve efficiency, and reduce risk. The ability to orchestrate complex supply chain operations with precision and foresight distinguishes expert-level functional consultants from those with foundational knowledge, underscoring the value of the MB-335 certification.

Conclusion

The Microsoft Certified: Dynamics 365 Supply Chain Management Functional Consultant Expert certification validates advanced expertise in managing complex supply chain environments. Across product configuration, bills of materials, formulas, production variants, and engineering change management, consultants demonstrate the ability to optimize manufacturing workflows and ensure compliance with regulatory standards. Advanced production control, scheduling, capacity planning, and integration of warehouse and asset management processes enable organizations to maximize efficiency and maintain operational continuity. Mastery of specialized production methods, costing, subcontracting, mixed-mode manufacturing, and lean principles ensures adaptability to evolving business needs. Integration of modern technologies, such as mixed reality and cloud-scale units, further enhances operational precision and workforce effectiveness. Through analytics, reporting, and strategic orchestration of interrelated supply chain functions, certified consultants deliver measurable improvements in productivity, cost management, and operational resilience. Achieving this certification signifies both technical proficiency and the strategic insight necessary to lead complex supply chain initiatives effectively.