Exam Code: C_S4EWM_2020

Exam Name: SAP Certified Associate - Extended Warehouse Management with SAP S/4HANA

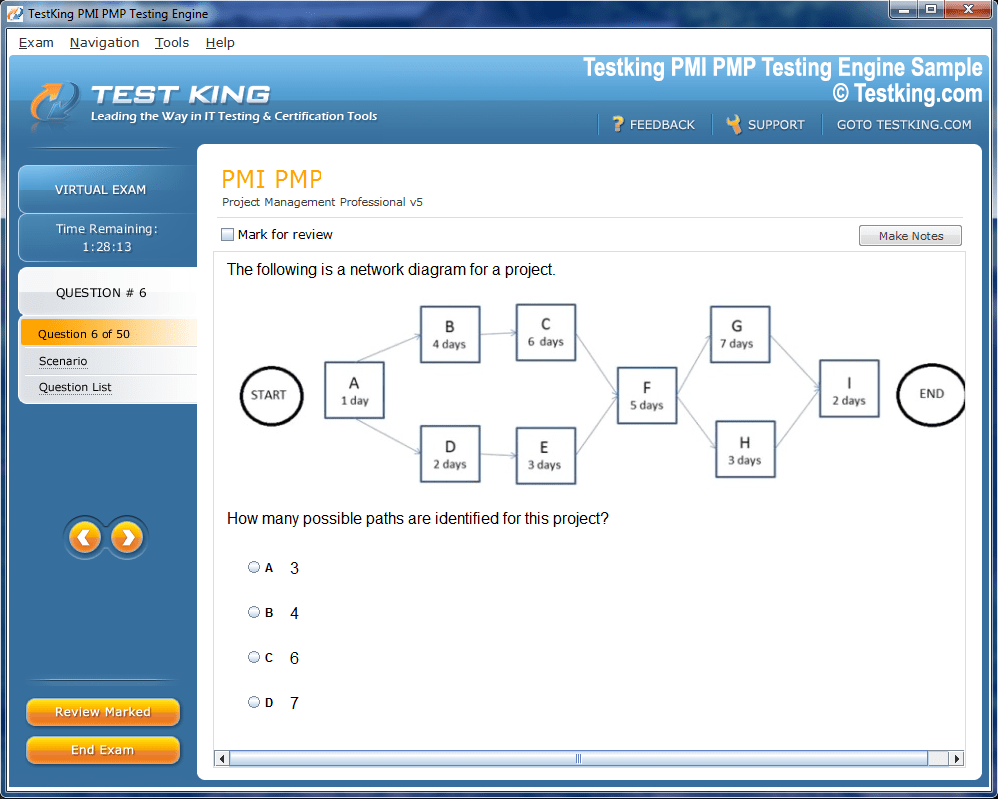

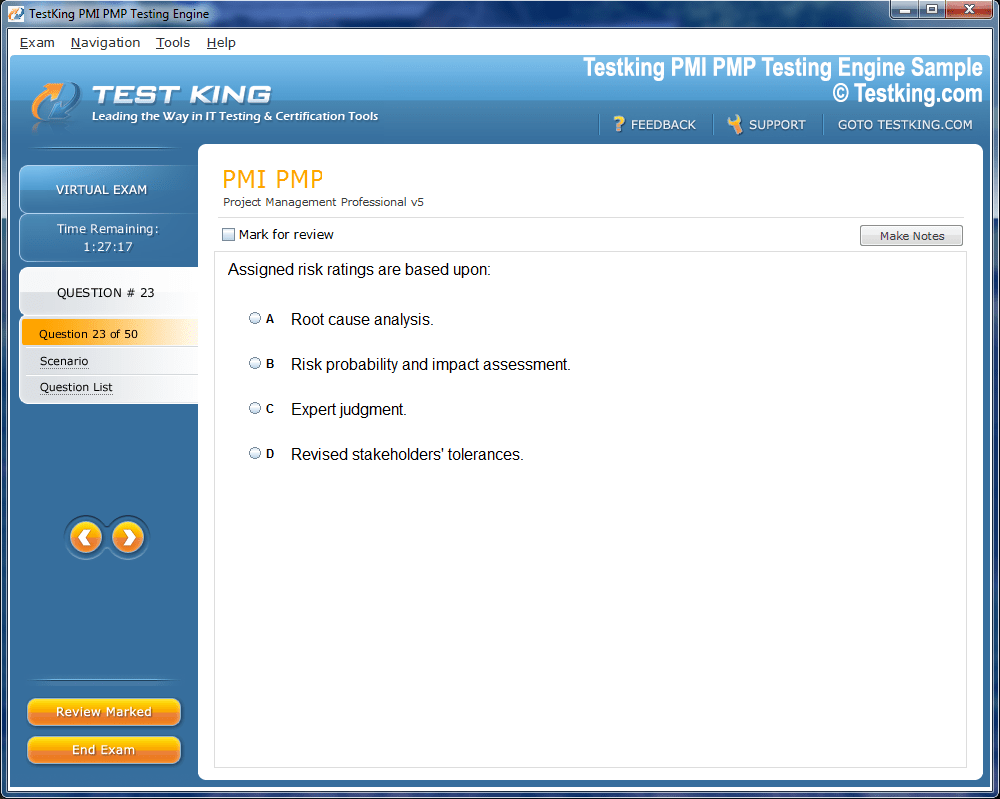

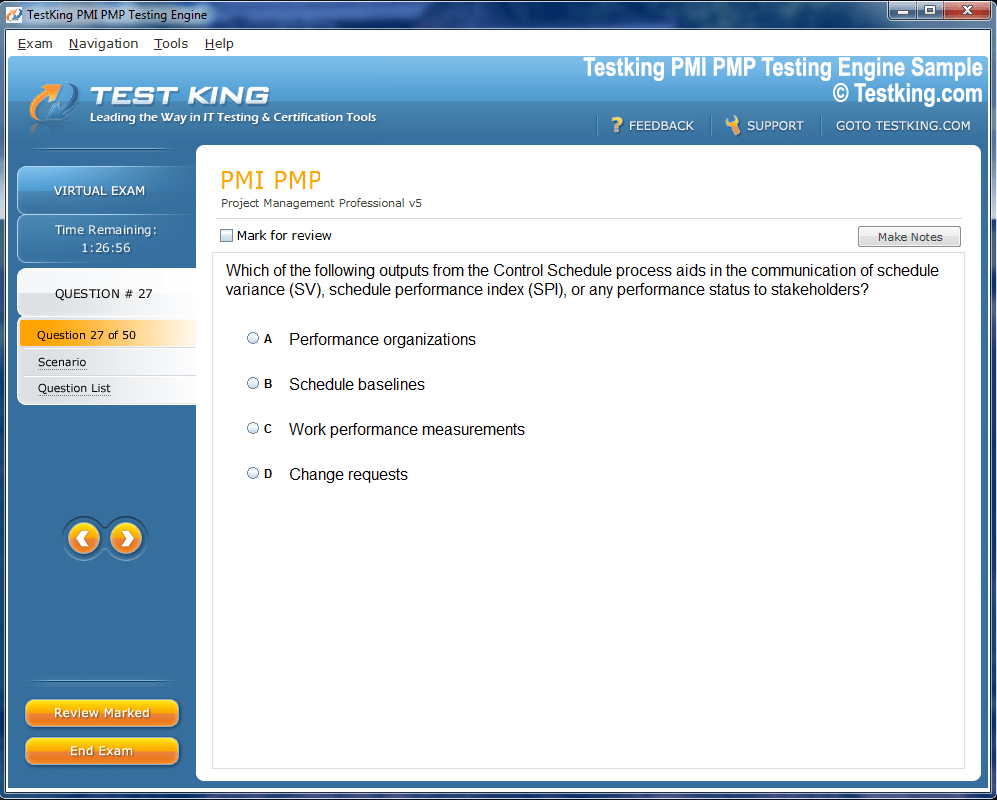

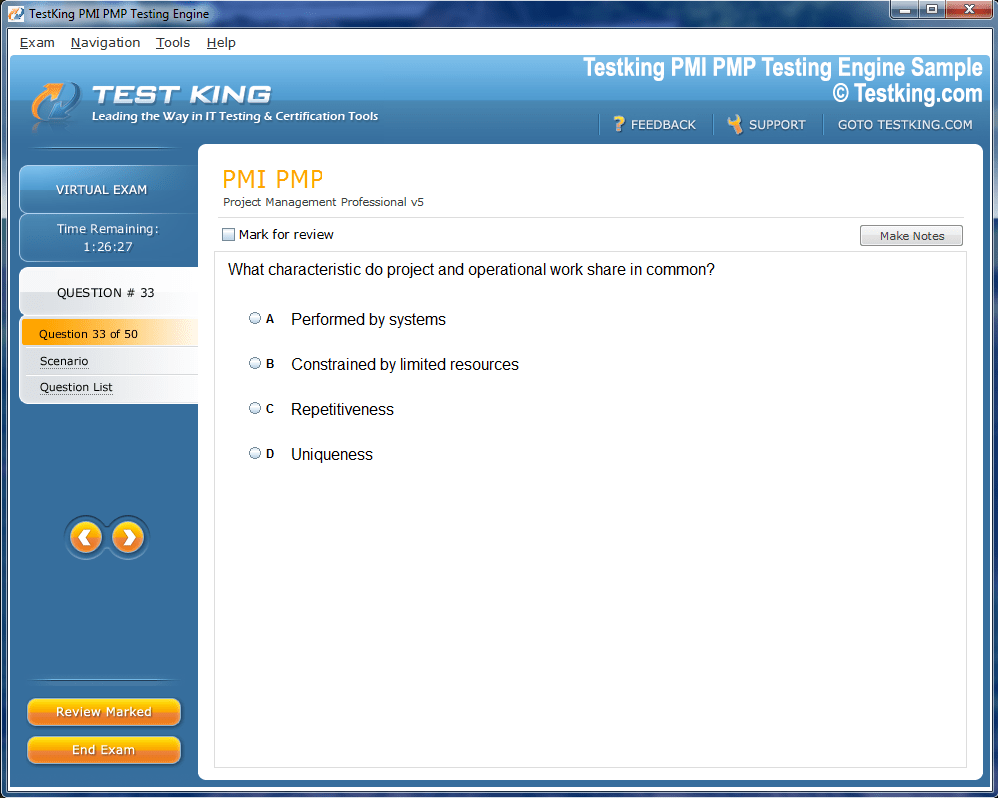

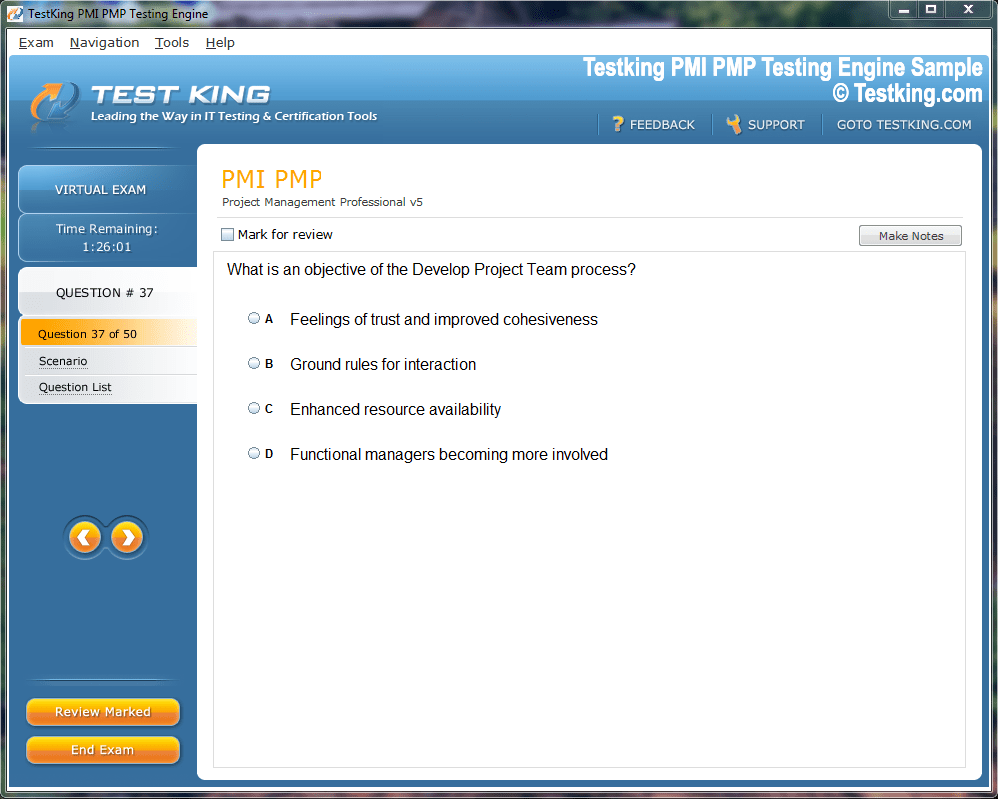

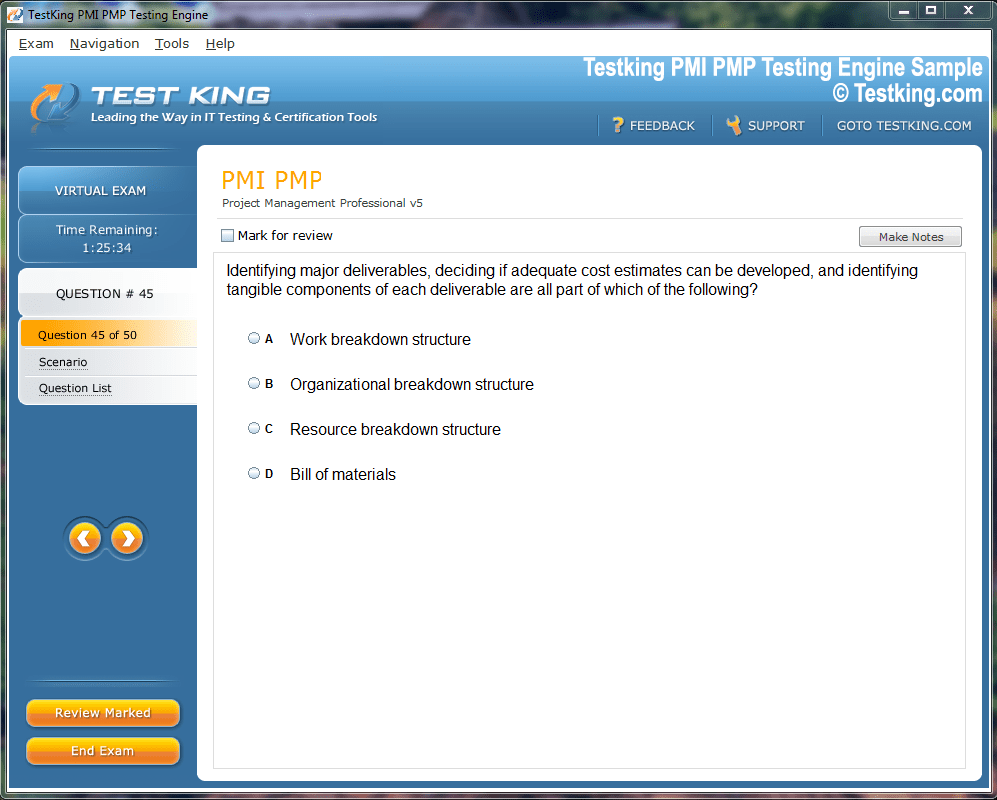

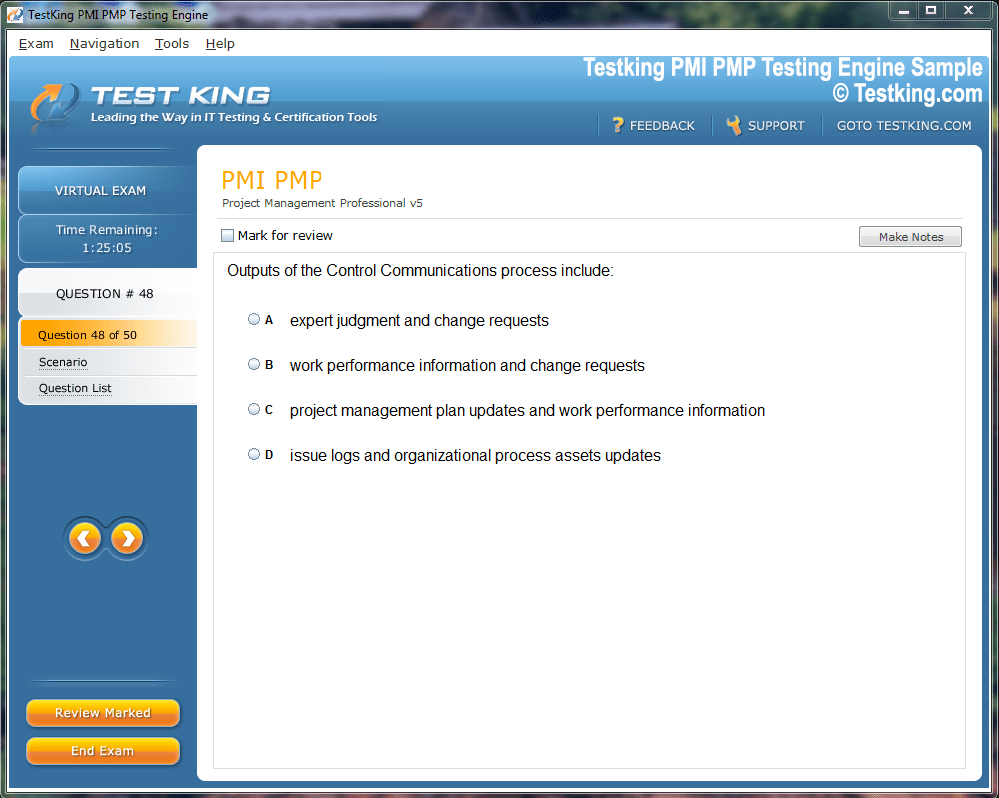

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our C_S4EWM_2020 testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top SAP Exams

- C_TS4FI_2023 - SAP Certified Associate - SAP S/4HANA Cloud Private Edition, Financial Accounting

- C_S4CFI_2504 - SAP Certified Associate - Implementation Consultant - SAP S/4HANA Cloud Public Edition, Financial Accounting

- C_ACTIVATE22 - SAP Certified Associate - SAP Activate Project Manager

- C_TADM_23 - SAP Certified Technology Consultant - SAP S/4HANA System Administration

- C_S4EWM_2023 - SAP Certified Associate - Extended Warehouse Management in SAP S/4HANA

- P_BTPA_2408 - SAP Certified Professional - Solution Architect - SAP BTP

- C_HRHPC_2505 - SAP Certified Associate - Implementation Consultant - SAP SuccessFactors Employee Central Payroll

- C_TS462_2022 - SAP Certified Application Associate - SAP S/4HANA Sales 2022

- E_S4HCON2023 - SAP Certified Specialist - SAP S/4HANA Conversion and SAP System Upgrade

- C_HCMP_2311 - SAP Certified Associate - SAP HCM Payroll for SAP S/4HANA

- C_ABAPD_2309 - SAP Certified Associate - Back-End Developer - ABAP Cloud

- C_TS452_2410 - SAP Certified Associate - SAP S/4HANA Cloud Private Edition, Sourcing and Procurement

- C_HAMOD_2404 - SAP Certified Associate - Data Engineer - SAP HANA

- C_SEC_2405 - SAP Certified Associate - Security Administrator

- C_ACT_2403 - SAP Certified Associate - Project Manager - SAP Activate

- E_ACTAI_2403 - SAP Certified Specialist - Project Manager - SAP Activate for Agile Implementation Management

Practical Skills and Insights for SAP C_S4EWM_2020 Success

The SAP C_S4EWM_2020 certification is a comprehensive credential that emphasizes proficiency in SAP S/4HANA, particularly focusing on warehouse management operations. It highlights the capability of professionals to configure and deploy warehouse solutions efficiently, integrating theoretical understanding with practical application. Warehouse management in contemporary industries requires precision, agility, and the ability to handle complex logistical processes, all of which are integral components assessed in this certification.

Warehouse operations involve a plethora of activities, from storage control to order processing, and extend to inventory management and reverse logistics. The scope of SAP S/4HANA within warehouse management allows for advanced automation, seamless integration with other enterprise modules, and enhanced decision-making capabilities through data analytics. This certification evaluates not only the candidate’s technical competence but also their ability to apply knowledge in operational contexts that mirror real-life challenges.

Professionals undertaking the SAP C_S4EWM_2020 exam are expected to demonstrate a high degree of familiarity with the SAP Warehouse Management interface, particularly the Fiori applications. Fiori provides a user-centric experience, streamlining tasks and improving efficiency in warehouse operations. Understanding Fiori’s role in simplifying complex procedures is essential, as it allows users to interact with SAP S/4HANA through intuitive dashboards, reducing the cognitive load required to execute routine and advanced warehouse functions.

The significance of this certification extends beyond the confines of software proficiency. Candidates are assessed on their understanding of how SAP S/4HANA interconnects with other modules, such as SAP Material Management and SAP Sales and Distribution. These integrations ensure that warehouse management is not an isolated process but part of a cohesive supply chain ecosystem. For instance, synchronization between inventory levels in SAP MM and outbound logistics in SAP SD is crucial for maintaining operational efficiency and avoiding bottlenecks.

Practical knowledge is a cornerstone of the SAP C_S4EWM_2020 certification. The exam often includes scenario-based tasks that mirror actual warehouse management issues. These may involve optimizing storage locations, configuring warehouse tasks, or managing stock discrepancies during physical inventory audits. By engaging with such scenarios, candidates cultivate an applied understanding of concepts that transcend theoretical knowledge, enabling them to tackle logistical challenges with analytical and systematic approaches.

A structured preparation approach is indispensable for candidates aiming to succeed in this certification. Organizing study sessions around core topics—forward and reverse logistics, storage control, warehouse order processing, and physical inventory management—ensures that learning is methodical and comprehensive. Additionally, practicing with realistic scenarios enhances problem-solving aptitude, equipping candidates to navigate both the exam and professional responsibilities effectively.

Understanding warehouse operations in SAP S/4HANA entails an appreciation for both micro and macro aspects of inventory control. On a micro level, professionals must manage storage bins, stock types, and material movements within the warehouse. At the macro level, they must ensure that these internal processes align with broader supply chain strategies, including procurement, distribution, and delivery schedules. The certification thus tests the candidate’s ability to balance granular operational tasks with strategic planning.

Warehouse management often involves handling exceptions, such as stock discrepancies, delayed shipments, or damaged goods. SAP S/4HANA equips professionals with tools to respond effectively to such anomalies, leveraging real-time data analytics and automated workflows. Candidates preparing for the C_S4EWM_2020 exam must be adept at using these tools, ensuring they can maintain operational continuity even in unpredictable situations. This requires a combination of technical skills, analytical reasoning, and operational foresight.

The integration of warehouse management with other SAP modules underscores the necessity for candidates to possess interdisciplinary knowledge. For example, coordination with SAP MM ensures that material flows are accurately recorded, while integration with SAP SD facilitates timely delivery and billing processes. This interconnected approach enhances transparency across the supply chain and supports more accurate forecasting and resource planning, demonstrating the importance of holistic competence in SAP S/4HANA.

Fiori applications play a pivotal role in modern warehouse management. Their design focuses on user experience, enabling quick access to essential functions and reducing the complexity of managing warehouse tasks. Candidates must understand how to configure and navigate Fiori apps to optimize operational efficiency. This involves learning about dashboards, alerts, and transaction flows that are central to managing daily warehouse activities, from picking and packing to shipping and inventory reconciliation.

Forward logistics processes, which include the movement of goods from suppliers to warehouses and from warehouses to customers, are central to SAP C_S4EWM_2020. Candidates must understand how to manage these processes efficiently, including the allocation of storage bins, task prioritization, and transportation scheduling. Reverse logistics, which deals with returns, repairs, or recycling of materials, requires similar attention to detail and adherence to defined workflows, ensuring that the warehouse maintains operational integrity.

Physical inventory management is another critical aspect of the certification. Accurate inventory counts are essential for financial accuracy, supply chain planning, and operational decision-making. SAP S/4HANA provides robust tools for inventory auditing, stock verification, and discrepancy resolution. Candidates must be capable of configuring inventory procedures, conducting cycle counts, and interpreting system data to identify variances and implement corrective actions, highlighting the interplay between system knowledge and practical expertise.

Warehouse order processing within SAP S/4HANA involves creating and managing warehouse tasks that direct the movement of materials. Effective order processing ensures the timely fulfillment of customer demands and reduces operational inefficiencies. Candidates are expected to understand the nuances of order creation, task sequencing, and the execution of movements within the warehouse, demonstrating proficiency in both system configuration and process execution.

The exam evaluates candidates on their ability to configure and use storage control functions. Storage control ensures that materials are stored optimally within the warehouse, taking into consideration space utilization, handling requirements, and movement efficiency. Candidates must be able to set up storage types, sections, and bins, ensuring that the warehouse layout supports efficient material flow and minimizes handling delays. Mastery of storage control reflects a deep understanding of operational optimization.

Integration with SAP MM and SAP SD highlights the systemic nature of warehouse management. SAP MM provides material flow information, ensuring that procurement and inventory records are accurate, while SAP SD facilitates delivery and distribution, linking warehouse activities with customer fulfillment. Understanding these integrations allows candidates to optimize end-to-end supply chain processes, ensuring that warehouse management is aligned with overall business objectives.

Candidates also need to develop problem-solving skills by working through practical scenarios that simulate real-world warehouse challenges. These exercises may involve handling unexpected stock shortages, reconfiguring storage layouts, or troubleshooting system errors. Engaging with such scenarios fosters a hands-on understanding of warehouse management, reinforcing theoretical knowledge and building confidence in applying SAP S/4HANA tools to operational tasks.

Exam preparation requires disciplined study and practical engagement. Allocating time to learn each module, practicing Fiori navigation, and simulating warehouse processes provides a comprehensive approach. Effective preparation also involves staying current with updates to the exam content, ensuring that candidates are familiar with the latest functionalities and system configurations. Continuous practice and revision cultivate proficiency, enhancing both performance in the exam and professional competency.

Warehouse management in SAP S/4HANA is dynamic, requiring professionals to balance technical acumen with operational insight. The C_S4EWM_2020 certification encapsulates this balance, emphasizing both the configuration of system functionalities and the practical application of knowledge in warehouse operations. Candidates must demonstrate analytical thinking, attention to detail, and the ability to integrate multiple processes within the SAP ecosystem.

Deep Dive into Forward and Reverse Logistics in SAP S/4HANA

Effective warehouse management within SAP S/4HANA requires an extensive understanding of both forward and reverse logistics processes. These processes constitute the backbone of material movement, ensuring that goods traverse the supply chain efficiently while maintaining inventory accuracy. Forward logistics encompasses the systematic movement of products from suppliers to warehouses, and subsequently from warehouses to customers, ensuring timely delivery, accurate inventory management, and alignment with demand forecasts.

Forward logistics begins with the receipt of goods from suppliers. This phase necessitates a meticulous approach to inbound processing, which includes quality checks, storage location assignments, and initial stock posting within the SAP system. The configuration of storage types, bins, and stock categories directly impacts operational efficiency. Professionals preparing for the SAP C_S4EWM_2020 exam must understand how to set up these configurations to ensure that warehouse operations function seamlessly, minimizing delays in material handling.

Storage control is integral to forward logistics. Efficient allocation of storage bins and optimization of warehouse layout reduces the handling time for incoming goods. SAP S/4HANA allows for automated storage control, leveraging predefined strategies to direct materials to appropriate locations. Candidates are expected to comprehend these strategies, including their configuration and execution within the system. This understanding enables professionals to maximize space utilization, streamline picking processes, and reduce the likelihood of inventory errors.

Warehouse order processing is closely tied to forward logistics. When an order is received, SAP generates warehouse tasks that guide material movements from storage locations to staging areas for shipping. Configuring warehouse order creation parameters, understanding task prioritization, and managing resource allocation are critical skills. Practical proficiency in these areas ensures that order fulfillment is accurate and efficient, reflecting the candidate’s ability to apply SAP S/4HANA functionalities in operational contexts.

Fiori applications enhance the management of forward logistics by providing a user-friendly interface for monitoring and executing tasks. Fiori dashboards offer real-time insights into stock levels, task progress, and warehouse performance metrics. Familiarity with these tools is essential for candidates, as the exam tests their ability to navigate and utilize Fiori applications effectively. Understanding how to configure and customize Fiori screens can further optimize task management and improve operational responsiveness.

Reverse logistics, often regarded as the inverse of forward logistics, deals with the return of goods from customers or the internal recycling of materials. This process is increasingly significant in modern warehouse management, driven by sustainability goals, regulatory requirements, and customer service considerations. Reverse logistics in SAP S/4HANA involves the management of returns, repairs, rework, or disposal, requiring careful configuration of stock postings and return workflows.

Candidates must understand the distinction between standard and exceptional reverse logistics processes. Standard processes include straightforward returns that follow predefined workflows, while exceptional processes might involve damaged goods, warranty claims, or complex replenishment scenarios. Configuring these processes within SAP S/4HANA ensures that returns are handled efficiently, minimizing disruptions to warehouse operations and preserving accurate inventory records.

Integration with other modules is critical for both forward and reverse logistics. Coordination with SAP Material Management ensures that inbound and outbound material movements are reflected accurately in procurement and inventory records. Likewise, integration with SAP Sales and Distribution guarantees that customer-facing processes, such as order cancellations or returns, are synchronized with warehouse activities. This cross-functional integration is a key area of competence for candidates pursuing the C_S4EWM_2020 certification.

Physical inventory management complements logistics processes by ensuring accurate stock records. Regular inventory audits, cycle counts, and discrepancy resolutions are essential for maintaining operational integrity. SAP S/4HANA provides automated tools to streamline these activities, allowing warehouse managers to monitor stock levels, reconcile variances, and adjust records promptly. Candidates are expected to configure inventory procedures, manage stock postings, and interpret system reports to identify potential issues and implement corrective measures.

In forward logistics, prioritization of warehouse tasks ensures that critical orders are fulfilled first, optimizing customer satisfaction and operational efficiency. SAP allows for task sorting based on various criteria, such as delivery urgency, storage location, or material type. Understanding these prioritization mechanisms and their impact on warehouse workflows is crucial for candidates. Practical exercises in task configuration and execution help reinforce this knowledge, bridging the gap between theoretical concepts and real-world application.

Reverse logistics processes often require specialized handling to ensure compliance with internal policies and external regulations. For instance, hazardous materials, expired products, or recalled items necessitate precise procedures to mitigate risks and ensure accountability. Candidates must be familiar with setting up return order types, configuring quality inspection procedures, and managing stock transfers within SAP S/4HANA. Proficiency in these areas ensures that reverse logistics operations are compliant, efficient, and seamlessly integrated with other warehouse processes.

Warehouse management strategies extend to both forward and reverse logistics. Slotting optimization, task interleaving, and wave management are examples of strategies that enhance operational efficiency. Slotting involves arranging products within the warehouse to reduce travel time and improve picking speed. Task interleaving optimizes worker movements by combining multiple tasks in a single route. Wave management schedules task execution to balance workload and resource availability. Mastery of these strategies is tested in the C_S4EWM_2020 exam, requiring candidates to demonstrate both conceptual understanding and practical application.

The examination assesses knowledge of warehouse control structures that govern logistics processes. Storage types, sections, and bins form the foundation of storage control, while warehouse process types and movement types dictate task execution. Candidates must be adept at configuring these structures, ensuring that materials flow efficiently through the warehouse. This includes understanding dependencies, sequence flows, and the impact of process variations on operational outcomes.

Fiori applications facilitate the monitoring of forward and reverse logistics by providing real-time visibility into warehouse operations. Dashboards display pending tasks, stock discrepancies, and key performance indicators. Customizing Fiori tiles, setting up alerts, and interpreting analytics are essential skills for candidates, as they enable proactive management of warehouse activities. Practical experience with these applications reinforces the candidate’s ability to manage logistics effectively and respond swiftly to operational challenges.

Integration with procurement and distribution modules ensures that warehouse logistics are aligned with broader business processes. Inbound goods receipts must be accurately recorded in SAP MM to maintain material balances, while outbound deliveries must be synchronized with SAP SD to ensure timely customer fulfillment. Understanding these linkages allows candidates to anticipate process bottlenecks, adjust workflows, and optimize inventory levels across the supply chain.

Forward and reverse logistics are inherently interdependent. Efficient forward logistics reduces the likelihood of returns by ensuring accurate order fulfillment, while effective reverse logistics enables the recovery and reallocation of returned materials. Candidates must recognize this interdependence and leverage SAP S/4HANA tools to manage both processes holistically. This includes configuring task creation, monitoring material movements, and ensuring that system postings reflect actual warehouse activities.

Practical exercises for forward and reverse logistics often involve scenario-based problem-solving. Candidates may be tasked with optimizing warehouse layout, managing a surge in inbound shipments, or handling complex return workflows. These exercises simulate real-world conditions, testing the ability to apply SAP functionalities effectively. Engaging with practical scenarios strengthens analytical skills, improves decision-making, and prepares candidates for operational challenges beyond the exam context.

Understanding material flow and task management is critical for both logistics processes. Material flow defines the movement of goods within the warehouse, while task management governs how these movements are executed. SAP S/4HANA provides tools to configure movement sequences, task types, and picking strategies. Candidates must be proficient in setting up these configurations, ensuring that material flow is smooth, tasks are executed efficiently, and warehouse resources are utilized optimally.

Quality management is intertwined with reverse logistics. Returned materials may require inspection, rework, or disposal based on predefined criteria. SAP S/4HANA enables the configuration of inspection plans, quality notifications, and stock transfers, allowing warehouse managers to maintain product integrity and compliance. Candidates must demonstrate an understanding of these processes, as well as the ability to configure and execute them within the system.

Task interleaving enhances efficiency by combining multiple movements into a single execution route. For example, a worker may simultaneously pick items for several orders or perform both inbound and outbound tasks in a single pass. This approach reduces travel time, increases productivity, and optimizes resource allocation. Mastery of task interleaving configuration and execution is a key component of the C_S4EWM_2020 exam, reflecting practical warehouse management expertise.

Wave management organizes warehouse tasks into scheduled batches, ensuring a balanced workload and timely fulfillment of orders. Candidates must understand how to define waves, assign priorities, and monitor execution. Wave management is particularly useful in high-volume operations, where task synchronization is critical to meeting delivery deadlines. Practical experience with this feature enhances the candidate’s ability to manage complex warehouse operations efficiently.

Forward logistics also involves coordination with transportation management. Proper scheduling of outbound deliveries, assignment of shipping routes, and management of delivery priorities ensure timely and cost-effective distribution. SAP S/4HANA facilitates integration with transportation management systems, providing end-to-end visibility of goods movement. Candidates must understand how warehouse operations intersect with transportation planning to optimize overall supply chain performance.

Reverse logistics emphasizes material recovery and sustainability. Effective handling of returned goods minimizes waste, reduces costs, and supports environmental objectives. Candidates must be able to configure processes for returns, rework, and disposal, ensuring compliance with company policies and regulatory requirements. Practical exercises in reverse logistics help candidates develop the analytical and operational skills necessary to manage returned materials efficiently.

Performance monitoring is essential for both logistics processes. SAP S/4HANA provides analytics tools to track key performance indicators, identify bottlenecks, and assess resource utilization. Candidates must be proficient in interpreting these analytics, configuring alerts, and implementing corrective measures. This ensures that warehouse operations remain efficient, responsive, and aligned with business objectives.

Storage Control and Warehouse Order Processing in SAP S/4HANA

Storage control and warehouse order processing form the core operational elements of SAP S/4HANA warehouse management. These components govern the internal flow of materials, determine task execution sequences, and ensure that warehouse operations remain efficient, accurate, and aligned with broader supply chain objectives. Understanding the configuration and practical application of these processes is central to success in the SAP C_S4EWM_2020 exam and to professional competence in warehouse management.

Storage control involves the systematic organization of materials within the warehouse, ensuring optimal utilization of space and resources. It encompasses the configuration of storage types, storage sections, and storage bins. Storage types define the functional areas within the warehouse, such as high-rack storage, bulk storage, or picking zones. Storage sections further subdivide storage types, enabling finer granularity in material placement. Storage bins represent the smallest unit of storage, facilitating precise tracking and movement of individual materials. Candidates must understand how to configure these elements, including the assignment of bin types, bin capacities, and replenishment indicators.

The efficiency of storage control directly impacts warehouse performance. Poorly organized storage leads to increased material handling time, higher operational costs, and potential errors in order fulfillment. SAP S/4HANA provides automated strategies to optimize storage allocation, guiding materials to appropriate locations based on predefined rules. Examples of these strategies include fixed bin assignment, nearest storage allocation, and heuristic-based placement. Candidates are expected to understand the advantages and limitations of each strategy and know when to apply them to specific warehouse scenarios.

Storage control also encompasses the management of stock types and special stock categories. Stock types include unrestricted stock, blocked stock, quality inspection stock, and consignment stock. Each stock type has distinct characteristics and movement rules, influencing how materials are handled during warehouse operations. Special stocks, such as project stock or vendor consignment stock, require additional configuration to track ownership and ensure proper allocation. Understanding these nuances is essential for candidates, as the exam evaluates the ability to manage complex inventory scenarios accurately.

Warehouse order processing translates storage control configurations into executable tasks. When an inbound or outbound movement is initiated, SAP generates warehouse orders that guide the physical handling of materials. These orders specify the sequence of movements, the personnel responsible, and the associated equipment or resources. Candidates must be proficient in configuring warehouse order creation rules, including order type assignments, priority settings, and resource allocation parameters. Proper configuration ensures that tasks are executed efficiently, minimizing delays and operational bottlenecks.

Warehouse order processing integrates closely with task management. Tasks represent individual units of work within a warehouse order, detailing the movement of materials from one location to another. SAP S/4HANA provides flexibility in defining task types, movement sequences, and execution rules. Candidates must understand how to configure task interleaving, which allows multiple tasks to be combined into a single execution route, optimizing labor utilization and reducing travel time. Task prioritization mechanisms ensure that critical orders are processed first, aligning warehouse activities with business objectives.

Wave management is another essential concept in warehouse order processing. It involves grouping warehouse orders into scheduled batches, enabling coordinated execution and workload balancing. Candidates must be familiar with defining waves, assigning orders, and monitoring progress to ensure timely order fulfillment. Wave management is particularly important in high-volume operations, where task synchronization is critical to meeting delivery deadlines and maintaining operational efficiency.

Integration with other SAP modules amplifies the impact of storage control and warehouse order processing. For example, inbound deliveries from SAP Material Management trigger warehouse tasks based on storage control configurations. Outbound deliveries in SAP Sales and Distribution generate warehouse orders for picking, packing, and shipping. Candidates must understand these interdependencies, ensuring that warehouse activities are synchronized with procurement, production, and distribution processes. This integration enhances transparency, accuracy, and responsiveness across the supply chain.

Physical inventory management intersects with storage control and warehouse order processing by providing mechanisms to verify and adjust stock levels. Inventory processes include cycle counting, periodic inventory, and continuous inventory monitoring. SAP S/4HANA enables automated inventory postings, discrepancy handling, and adjustment of stock records. Candidates must be proficient in configuring inventory procedures, defining counting methods, and interpreting system reports to identify variances and implement corrective actions. Mastery of these processes ensures operational accuracy and supports financial integrity.

Storage control also involves defining putaway and picking strategies. Putaway strategies determine how inbound materials are allocated to storage locations, while picking strategies dictate how materials are selected for outbound orders. SAP S/4HANA provides multiple strategies, such as closest bin selection, stock rotation, and wave-based picking. Candidates must understand how to configure these strategies to optimize material flow, reduce handling time, and maintain inventory accuracy. Practical exercises in putaway and picking scenarios reinforce theoretical knowledge and develop applied competence.

Special processes, such as cross-docking and value-added services, are integrated with storage control and warehouse order processing. Cross-docking involves transferring inbound materials directly to outbound shipments, bypassing storage, to expedite order fulfillment. Value-added services include activities such as labeling, kitting, or packaging modifications performed within the warehouse. Candidates must understand how to configure and execute these processes within SAP S/4HANA, ensuring that they complement standard warehouse operations and enhance operational efficiency.

Monitoring and analytics are critical for effective warehouse order processing. SAP S/4HANA provides dashboards and reports to track order status, task completion, resource utilization, and key performance indicators. Candidates must be adept at interpreting these analytics, identifying bottlenecks, and implementing corrective measures. Real-time monitoring enables proactive management of warehouse activities, ensuring that operational objectives are met and customer expectations are satisfied.

Resource management is a key aspect of warehouse order processing. Assigning appropriate personnel, equipment, and handling devices to tasks ensures that orders are executed efficiently. SAP S/4HANA allows for resource optimization, considering factors such as availability, skill levels, and equipment capacity. Candidates must understand how to configure resource assignment rules, ensuring that tasks are allocated effectively and that warehouse performance is maximized.

Complex warehouse structures require advanced configuration of storage control. Multi-aisle warehouses, automated storage and retrieval systems, and high-density storage layouts present unique challenges for task execution. SAP S/4HANA provides tools to manage these environments, including automated task generation, conveyor integration, and system-guided picking. Candidates must be proficient in configuring these advanced systems, ensuring that warehouse operations remain efficient and adaptable to changing business needs.

Exception handling is an integral part of warehouse order processing. Scenarios such as stock shortages, damaged goods, or system errors require predefined procedures to maintain operational continuity. SAP S/4HANA allows for the configuration of exception handling workflows, ensuring that anomalies are addressed promptly. Candidates must understand how to design and implement these workflows, minimizing disruptions and maintaining accurate inventory records.

Integration with logistics execution further enhances the effectiveness of storage control and warehouse order processing. Outbound deliveries trigger picking, packing, and shipping tasks that are coordinated through warehouse orders. Inbound deliveries generate putaway tasks based on storage control rules. Understanding the interplay between logistics execution and warehouse management ensures that materials flow seamlessly from suppliers to customers, reflecting the systemic nature of SAP S/4HANA operations.

Cycle counting is a critical inventory control process tied to storage control. It involves regular, systematic counting of selected stock items to verify accuracy and detect discrepancies. SAP S/4HANA provides flexible cycle counting configurations, including frequency definitions, selection criteria, and automated posting of differences. Candidates must be proficient in setting up cycle counting procedures, analyzing results, and implementing corrective actions to maintain reliable inventory records.

Warehouse order creation rules dictate how tasks are generated for inbound, outbound, and internal movements. These rules consider factors such as storage types, stock types, priority levels, and resource availability. Candidates must understand how to configure these rules to ensure efficient task generation and execution. Mastery of warehouse order creation is crucial for managing high-volume operations and ensuring the timely fulfillment of orders.

Putaway and picking strategies impact operational efficiency and resource utilization. Putaway strategies determine the most suitable storage location for incoming materials, while picking strategies optimize the selection of materials for outbound orders. SAP S/4HANA provides configurable strategies based on criteria such as proximity, stock rotation, and wave assignments. Candidates must be able to configure and apply these strategies effectively, enhancing warehouse throughput and minimizing handling costs.

Special stock handling requires careful configuration in storage control and warehouse order processing. Project stock, consignment stock, and stock subject to quality inspection have unique movement rules and reporting requirements. Candidates must understand how to manage these stocks within SAP S/4HANA, ensuring accurate inventory tracking and compliance with organizational policies. Proper management of special stocks contributes to operational integrity and financial accuracy.

Automation and digitalization are increasingly important in warehouse order processing. SAP S/4HANA supports automated task generation, system-guided picking, and integration with automated material handling equipment. Candidates must understand how to leverage these capabilities, optimizing efficiency and reducing reliance on manual processes. Practical experience with automation tools enhances proficiency, preparing candidates for modern warehouse environments.

Analytics and reporting tools within SAP S/4HANA provide insights into warehouse performance. Metrics such as order completion rates, task execution times, and stock discrepancies enable data-driven decision-making. Candidates must be proficient in configuring reports, interpreting data, and implementing improvements based on insights. Effective use of analytics ensures continuous optimization of warehouse operations and supports strategic planning.

Exception management and contingency planning are critical for resilient warehouse operations. Handling unexpected scenarios such as stock discrepancies, resource unavailability, or urgent orders requires predefined workflows and decision rules. SAP S/4HANA allows for the configuration of exception handling procedures, ensuring that warehouse processes remain uninterrupted. Candidates must demonstrate competence in designing and applying these procedures to maintain operational continuity.

Physical Inventory Management and Fiori Applications in SAP S/4HANA

Physical inventory management is a fundamental component of warehouse operations within SAP S/4HANA. It ensures the accuracy of stock records, facilitates financial reporting, and supports operational decision-making. This process involves systematic verification of stock levels, identification of discrepancies, and timely adjustment of inventory records. Mastery of physical inventory management is essential for professionals preparing for the SAP C_S4EWM_2020 certification, as it bridges the gap between theoretical knowledge and practical warehouse operations.

Physical inventory management in SAP S/4HANA encompasses multiple methodologies, including periodic, continuous, and cycle counting. Periodic inventory involves a complete stock verification at defined intervals, often annually or semiannually. Continuous inventory leverages ongoing monitoring of material movements, providing near-real-time accuracy of stock levels. Cycle counting, one of the most widely used techniques, involves regular, systematic counting of selected stock items based on predefined criteria such as material type, value, or movement frequency. Candidates must understand the configuration and execution of these methodologies, including automated posting of differences and integration with warehouse management processes.

Cycle counting in particular requires careful planning and system configuration. SAP S/4HANA allows for flexible cycle counting setups, including frequency definitions, selection of materials, and assignment of counting responsibilities to warehouse personnel. Candidates are expected to configure these parameters, ensuring that counting activities are efficient, minimally disruptive to operations, and aligned with organizational priorities. The ability to interpret cycle count results, identify discrepancies, and implement corrective measures is crucial for maintaining inventory accuracy and operational reliability.

Inventory discrepancies may arise from multiple sources, including misplacement of materials, incorrect postings, damage, or theft. SAP S/4HANA provides tools to detect and resolve these discrepancies through automated alerts, exception handling workflows, and adjustment postings. Candidates must be proficient in configuring these tools, managing stock differences, and ensuring that corrected records reflect actual physical stock. Practical exercises in discrepancy resolution help reinforce analytical skills and operational competence.

Integration with storage control and warehouse order processing is essential for effective physical inventory management. Inbound and outbound movements, internal transfers, and special stock handling directly impact inventory accuracy. SAP S/4HANA facilitates seamless coordination between these processes, allowing for real-time updates of stock levels and automated generation of inventory tasks. Candidates must understand how inventory processes interact with material movements, ensuring that warehouse operations remain synchronized and accurate.

Fiori applications have transformed the way warehouse professionals interact with SAP S/4HANA. These applications provide a user-centric interface, enabling intuitive navigation, task execution, and real-time monitoring. Fiori dashboards display critical information such as stock levels, task statuses, and key performance indicators. Candidates must be adept at navigating these applications, configuring personalized dashboards, and interpreting data to make informed operational decisions. The user-friendly design of Fiori reduces complexity, streamlines processes, and enhances overall efficiency in warehouse management.

Fiori applications support a wide range of warehouse activities, including inbound and outbound processing, picking and putaway, inventory counting, and exception handling. The integration of Fiori with underlying SAP S/4HANA functionalities allows warehouse personnel to execute tasks with minimal system knowledge while maintaining accuracy and efficiency. Candidates preparing for the C_S4EWM_2020 exam must demonstrate the ability to utilize Fiori effectively, understanding both standard functionalities and customization options to optimize warehouse workflows.

Inbound processing using Fiori applications simplifies the management of goods receipts and putaway tasks. Warehouse personnel can access task lists, confirm task execution, and update stock information in real-time. This reduces manual errors, enhances traceability, and improves operational efficiency. Candidates must understand how to configure inbound task creation, assign tasks to resources, and monitor execution through Fiori dashboards, ensuring that materials are accurately received and stored in appropriate locations.

Outbound processing is equally enhanced by Fiori applications. Tasks such as picking, packing, and shipping are guided by system-generated instructions, which can be monitored and updated through intuitive interfaces. Prioritization of tasks, resource allocation, and progress tracking are simplified, allowing warehouse managers to maintain operational control and ensure timely order fulfillment. Candidates must be proficient in configuring outbound workflows, understanding task dependencies, and leveraging Fiori tools to optimize efficiency.

Physical inventory management is closely linked with Fiori-based task execution. For example, cycle counts can be assigned as tasks within the warehouse, tracked through Fiori dashboards, and confirmed upon completion. Any discrepancies can be flagged for review, ensuring immediate corrective action. Candidates must understand how to integrate inventory tasks with warehouse order processing, enabling seamless execution and real-time reporting. This integration fosters operational transparency and supports data-driven decision-making.

Special inventory processes, such as handling blocked stock, consignment stock, or project stock, are also managed through Fiori applications. Tasks related to these stock types require additional attention, as they often involve unique movement rules, ownership considerations, and reporting requirements. Candidates must be proficient in configuring task types, managing execution flows, and ensuring compliance with organizational policies. Practical exposure to these processes reinforces system knowledge and operational competence.

Quality inspection is another critical aspect of physical inventory management. SAP S/4HANA allows for the configuration of inspection lots, quality notifications, and stock postings related to inspection results. Fiori applications provide visibility into inspection status, task assignments, and outcome reporting. Candidates must understand how to configure inspection processes, execute quality-related tasks, and integrate results into inventory records, ensuring that only compliant materials are available for operational use.

Exception handling in physical inventory management is facilitated through Fiori dashboards and system alerts. Scenarios such as missing stock, overages, or damaged materials trigger predefined workflows that guide corrective action. Candidates must demonstrate the ability to configure exception handling rules, manage task assignments, and ensure accurate posting of adjustments. Effective exception management ensures that warehouse operations remain uninterrupted and that inventory records accurately reflect physical stock.

Warehouse performance analytics are enhanced by Fiori-based reporting tools. Key metrics such as task completion rates, cycle count accuracy, and stock discrepancies are readily available for monitoring and analysis. Candidates must be proficient in interpreting these metrics, identifying trends, and implementing operational improvements. Data-driven insights support continuous optimization, enabling warehouse managers to make informed decisions and maintain high levels of operational efficiency.

Task interleaving, wave management, and resource optimization are operational strategies that leverage both physical inventory processes and Fiori applications. Task interleaving allows multiple tasks to be executed in a single route, reducing travel time and increasing productivity. Wave management schedules task execution to balance workload and ensure timely fulfillment. Resource optimization assigns personnel, equipment, and handling devices based on availability and skill levels. Candidates must understand how to configure and execute these strategies, ensuring that warehouse operations remain efficient and adaptable.

Inventory reconciliation is a key outcome of physical inventory management. Discrepancies identified during counting or task execution must be resolved promptly to maintain accurate stock records. SAP S/4HANA provides automated tools for adjustment postings, stock transfers, and reporting. Candidates must be proficient in managing reconciliation processes, interpreting system feedback, and implementing corrective measures to ensure that inventory records remain reliable and aligned with operational reality.

Fiori applications also enhance training and knowledge dissemination within warehouse operations. Interactive dashboards, guided workflows, and real-time feedback provide personnel with immediate insights into process execution and system expectations. Candidates must be aware of how to leverage these capabilities to improve team performance, facilitate onboarding, and maintain operational consistency. The use of Fiori as a training and operational support tool reinforces both individual and organizational competence.

Integration with procurement, production, and distribution modules further enhances the effectiveness of physical inventory management. Accurate stock records ensure that procurement decisions are informed, production planning is reliable, and customer deliveries are timely. Candidates must understand how warehouse processes interact with broader enterprise functions, ensuring that inventory management contributes to organizational efficiency and supply chain effectiveness.

Automation within physical inventory management is increasingly prevalent. System-guided task generation, automated posting of adjustments, and integration with robotics or automated storage and retrieval systems reduce manual intervention and enhance accuracy. Candidates must be proficient in configuring these automation features, understanding both system capabilities and operational requirements. Practical experience with automation tools strengthens problem-solving skills and prepares candidates for modern warehouse environments.

Scenario-based practice is a critical component of preparation for the SAP C_S4EWM_2020 exam. Candidates should engage with realistic inventory management scenarios, including inbound and outbound processing, cycle counting, discrepancy resolution, and exception handling. These exercises reinforce theoretical knowledge, develop practical skills, and build confidence in navigating complex warehouse operations. Scenario-based learning ensures that candidates are prepared for both exam challenges and real-world professional responsibilities.

Warehouse safety and compliance considerations are integrated into physical inventory processes. SAP S/4HANA allows for the configuration of handling requirements, hazardous material management, and regulatory compliance tracking. Fiori dashboards provide visibility into compliance-related tasks, alerts, and reporting. Candidates must understand how to manage safety and compliance processes within inventory management, ensuring that operational practices align with legal and organizational standards.

Task monitoring and reporting are enhanced by the analytical capabilities of SAP S/4HANA. Candidates must be proficient in configuring dashboards, generating reports, and interpreting performance metrics. Insights into task execution times, stock discrepancies, and resource utilization support continuous improvement initiatives. By leveraging analytical tools, warehouse managers can optimize operations, reduce errors, and ensure alignment with strategic objectives.

Integration, Practical Application, and Preparation Strategies for SAP C_S4EWM_2020

Integration within SAP S/4HANA is a pivotal aspect of warehouse management, enabling seamless coordination across multiple modules, including Material Management, Sales and Distribution, and Production Planning. For professionals pursuing the SAP C_S4EWM_2020 certification, a thorough understanding of these interconnections is essential. Integration ensures that warehouse operations are not isolated tasks but components of a broader, synchronized supply chain ecosystem. Mastery of integration processes allows candidates to manage complex logistics workflows, optimize operational efficiency, and align warehouse activities with organizational objectives.

SAP Material Management (MM) integration is critical for inbound processes and inventory accuracy. Inbound deliveries generated from procurement activities trigger warehouse tasks, including receipt confirmation, quality inspection, and putaway operations. Accurate stock updates in MM are essential for maintaining reliable material balances, supporting procurement planning, and ensuring that production schedules are not disrupted. Candidates must understand how warehouse management processes, such as storage control and inventory verification, interact with MM transactions to achieve a cohesive material flow.

Similarly, integration with Sales and Distribution (SD) governs outbound logistics and customer fulfillment. Outbound deliveries generate warehouse tasks for picking, packing, and shipping, which must be executed according to defined priorities and resource allocations. Accurate coordination ensures timely order fulfillment, reduces shipping errors, and improves customer satisfaction. SAP S/4HANA allows for real-time updates between warehouse operations and SD documents, enabling synchronized processes and transparent reporting. Candidates are expected to configure these integrations, manage task execution, and monitor performance metrics effectively.

Production Planning (PP) integration further enhances warehouse management efficiency. Materials required for production must be available at designated storage locations, aligned with production schedules, and accurately reflected in inventory records. SAP S/4HANA facilitates the flow of materials from warehouse to production, with tasks configured to support production line requirements. Candidates must comprehend how storage control, warehouse tasks, and inventory management interact with production processes, ensuring that operations remain uninterrupted and materials are accurately tracked.

Advanced warehouse management strategies are implemented to optimize these integrations. Task interleaving, wave management, and resource optimization ensure that warehouse operations are executed efficiently across inbound, outbound, and internal movements. Task interleaving combines multiple tasks into a single route to reduce travel time and increase productivity. Wave management schedules tasks in coordinated batches, balancing workload and meeting critical deadlines. Resource optimization assigns personnel and equipment based on availability, skills, and operational priorities. Candidates must demonstrate the ability to configure and manage these strategies effectively within integrated systems.

Practical application scenarios are a central component of preparation for the SAP C_S4EWM_2020 exam. Real-world scenarios simulate challenges such as handling stock discrepancies, managing urgent deliveries, or coordinating complex cross-docking operations. Candidates must analyze situations, apply system functionalities, and execute tasks that reflect operational realities. Engaging with these scenarios builds problem-solving skills, operational confidence, and a practical understanding of how SAP S/4HANA supports warehouse management.

Scenario-based learning emphasizes the interplay between configuration, task execution, and system monitoring. For example, a scenario may involve a high-volume inbound delivery that must be distributed across multiple storage types, with subsequent picking tasks scheduled for urgent outbound orders. Candidates must configure storage control settings, generate warehouse orders, assign resources, and monitor execution through Fiori dashboards. This holistic approach ensures readiness for both exam assessments and real-world operational challenges.

Physical inventory management scenarios also form a critical aspect of practical application. Candidates may be tasked with conducting cycle counts, reconciling discrepancies, and updating inventory records while maintaining operational continuity. SAP S/4HANA supports these processes through automated task creation, system-guided counting, and exception handling workflows. Mastery of inventory scenarios ensures that candidates can maintain accurate stock records, optimize warehouse efficiency, and support financial reporting requirements.

Fiori applications facilitate practical application and scenario management by providing intuitive dashboards, task lists, and real-time alerts. Candidates must understand how to configure Fiori interfaces, monitor warehouse performance, and manage exceptions effectively. The use of Fiori enhances task execution, reduces manual errors, and provides analytical insights that support informed decision-making. Familiarity with these applications is essential for candidates to navigate complex scenarios and demonstrate operational proficiency.

Exception handling and contingency planning are integral to practical warehouse operations. Scenarios such as delayed deliveries, damaged goods, stock shortages, or system errors require predefined workflows to ensure continuity and accuracy. SAP S/4HANA enables the configuration of exception handling rules, automated notifications, and corrective task creation. Candidates must demonstrate competence in managing exceptions, analyzing root causes, and implementing corrective measures to maintain operational integrity.

Strategic understanding of warehouse management is reinforced through scenario-based exercises. Candidates are expected to make decisions that balance operational efficiency, resource utilization, and customer satisfaction. For instance, prioritizing tasks in a constrained resource environment or adjusting task sequences based on real-time stock availability reflects both technical proficiency and strategic insight. SAP S/4HANA provides tools for monitoring key performance indicators, evaluating task completion rates, and assessing resource utilization, which candidates must leverage effectively.

Preparation strategies for the SAP C_S4EWM_2020 exam require a structured and disciplined approach. Candidates should begin by mastering foundational concepts, including storage types, stock types, warehouse order processing, task management, and inventory methodologies. Building a solid theoretical understanding provides the basis for applying practical skills in configuration and task execution scenarios. Structured learning ensures comprehensive coverage of all exam topics while minimizing gaps in knowledge.

Practical exercises should complement theoretical study, emphasizing scenario-based problem-solving and hands-on system interaction. Candidates can simulate warehouse operations, configure storage control, generate warehouse orders, and execute tasks through SAP S/4HANA. Engaging with these exercises enhances familiarity with system functionalities, develops operational intuition, and strengthens analytical skills required for effective warehouse management.

Time management and study planning are critical for comprehensive preparation. Candidates should allocate sufficient time to cover each module, review configuration options, practice task execution, and analyze inventory scenarios. Breaking study sessions into focused segments ensures that knowledge retention is maximized, practical skills are reinforced, and familiarity with system navigation is developed. Consistent practice and revision build confidence and readiness for the exam.

Resource utilization during preparation is equally important. Candidates should leverage SAP S/4HANA sandbox environments, practice exercises, and analytical tools to simulate operational scenarios. These resources provide hands-on experience, allowing candidates to explore system functionalities, experiment with configuration options, and monitor the outcomes of their actions. Practical engagement strengthens understanding, reduces exam anxiety, and builds problem-solving competence.

Monitoring progress and identifying areas for improvement are essential components of preparation. Candidates should regularly review performance metrics, analyze task execution accuracy, and evaluate scenario outcomes. Identifying knowledge gaps or operational weaknesses enables targeted study and practice, ensuring that preparation is both efficient and effective. Continuous assessment fosters self-awareness, operational readiness, and confidence in tackling exam challenges.

Exam simulations and practice assessments are valuable tools for reinforcing preparation. Simulated exams replicate the structure, timing, and complexity of the actual SAP C_S4EWM_2020 assessment. Candidates can test their understanding of concepts, practice task execution scenarios, and assess readiness under timed conditions. These simulations provide insights into performance, highlight areas requiring additional focus, and build familiarity with exam procedures.

Integration-focused practice is particularly critical for understanding cross-module workflows. Candidates should engage with scenarios that require coordination between warehouse management, Material Management, Sales and Distribution, and Production Planning. Configuring inbound and outbound processes, managing inventory adjustments, and synchronizing task execution across modules develops holistic competence and operational agility. This approach reinforces the systemic nature of SAP S/4HANA warehouse management.

Analytical skills are developed through the use of SAP S/4HANA reporting and Fiori dashboards. Candidates must interpret key performance indicators, identify bottlenecks, and propose corrective actions. Analytical exercises may involve evaluating task completion times, assessing cycle count discrepancies, or monitoring resource utilization. Proficiency in analytics ensures that candidates can make data-driven decisions, optimize operations, and maintain accuracy in complex warehouse environments.

Exception scenario exercises are particularly valuable for building operational resilience. Candidates may encounter situations involving urgent orders, damaged stock, or system errors. By configuring exception workflows, generating corrective tasks, and monitoring resolution through Fiori dashboards, candidates develop problem-solving capabilities and operational adaptability. Mastery of exception handling ensures that warehouse operations continue smoothly despite disruptions, reflecting professional competence and strategic foresight.

Conclusion

The SAP C_S4EWM_2020 certification represents a comprehensive benchmark of expertise in warehouse management within the SAP S/4HANA environment. Achieving proficiency in storage control, warehouse order processing, forward and reverse logistics, and physical inventory management equips professionals to handle complex operational challenges with precision and efficiency. Integration with modules such as Material Management, Sales and Distribution, and Production Planning ensures that warehouse activities are seamlessly aligned with broader supply chain processes. Practical application through scenario-based exercises, task execution, and exception handling reinforces theoretical knowledge while cultivating problem-solving skills and operational agility. Fiori applications further enhance efficiency by providing intuitive interfaces, real-time monitoring, and analytical insights. By combining systematic preparation, hands-on practice, and strategic understanding, candidates can confidently manage sophisticated warehouse operations, optimize resource utilization, and contribute to organizational success, making the certification both a valuable credential and a foundation for professional growth in modern logistics management.