Exam Code: ICYB

Exam Name: IASSC Certified Lean Six Sigma Yellow Belt

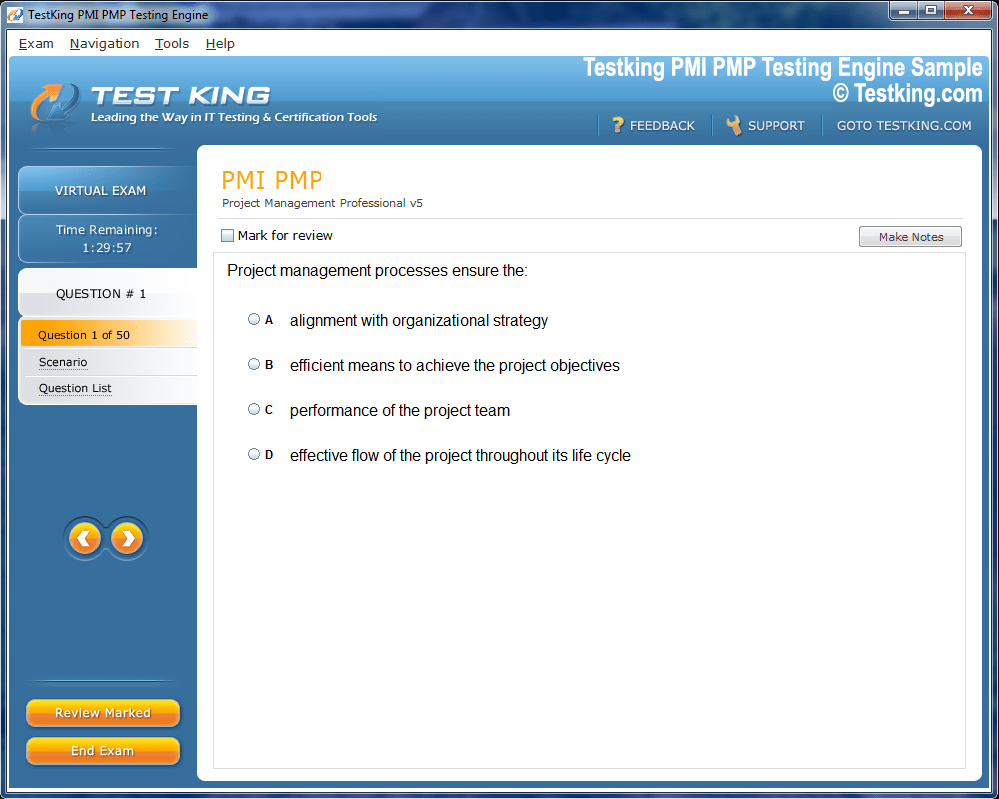

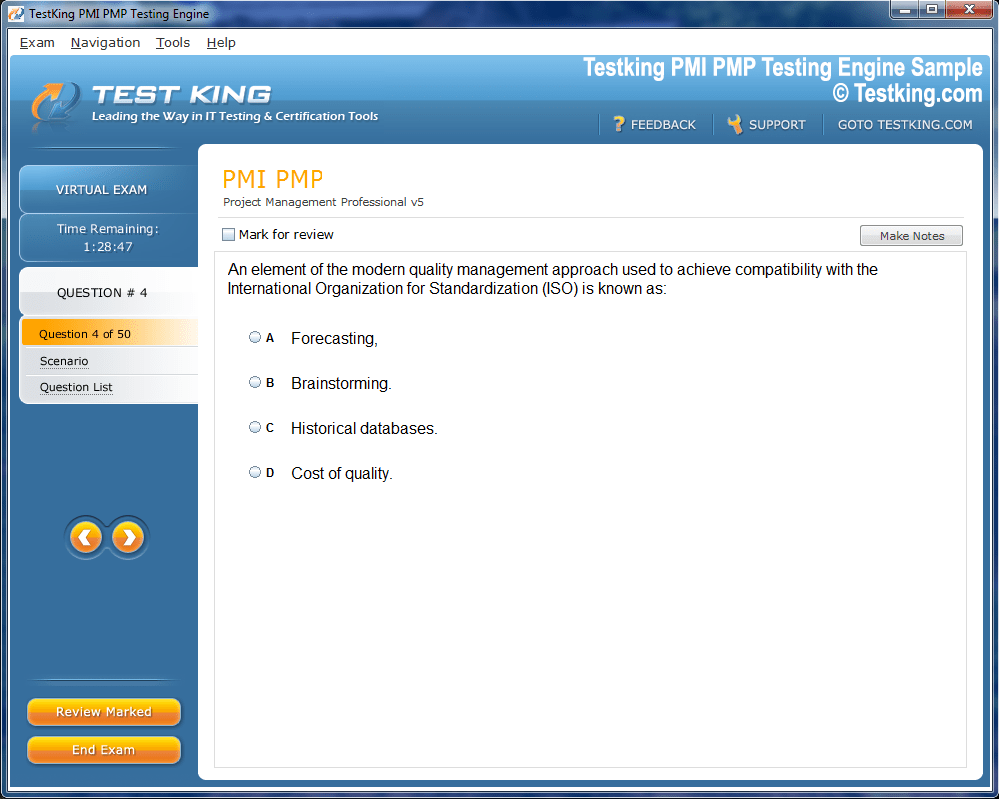

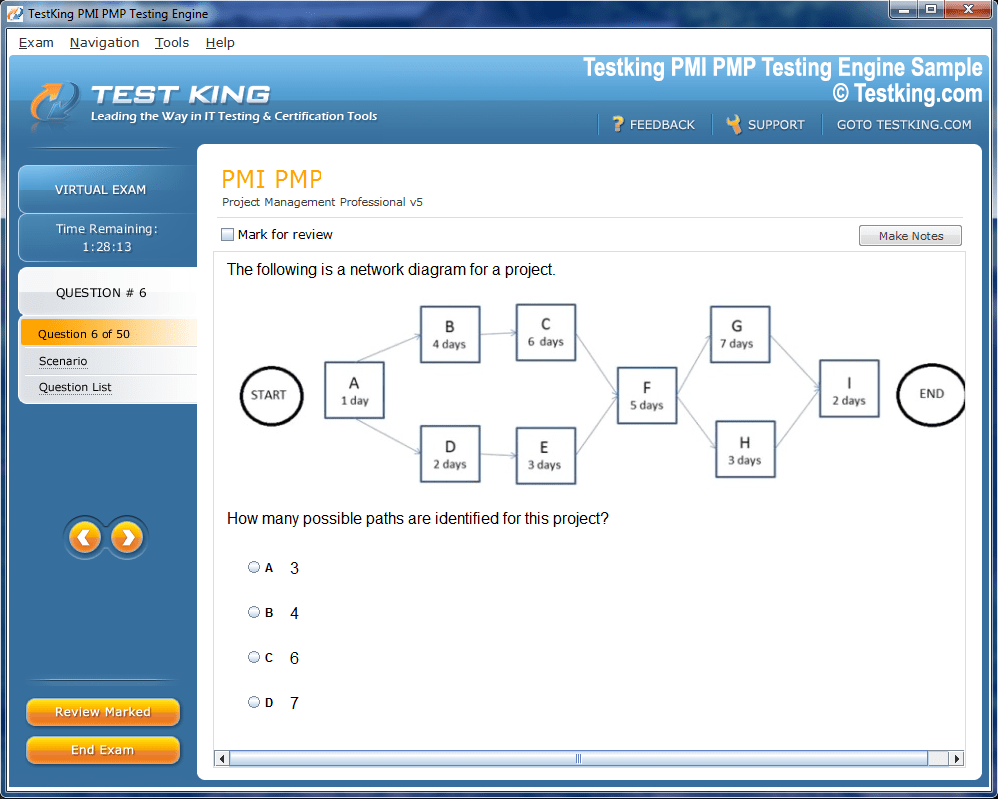

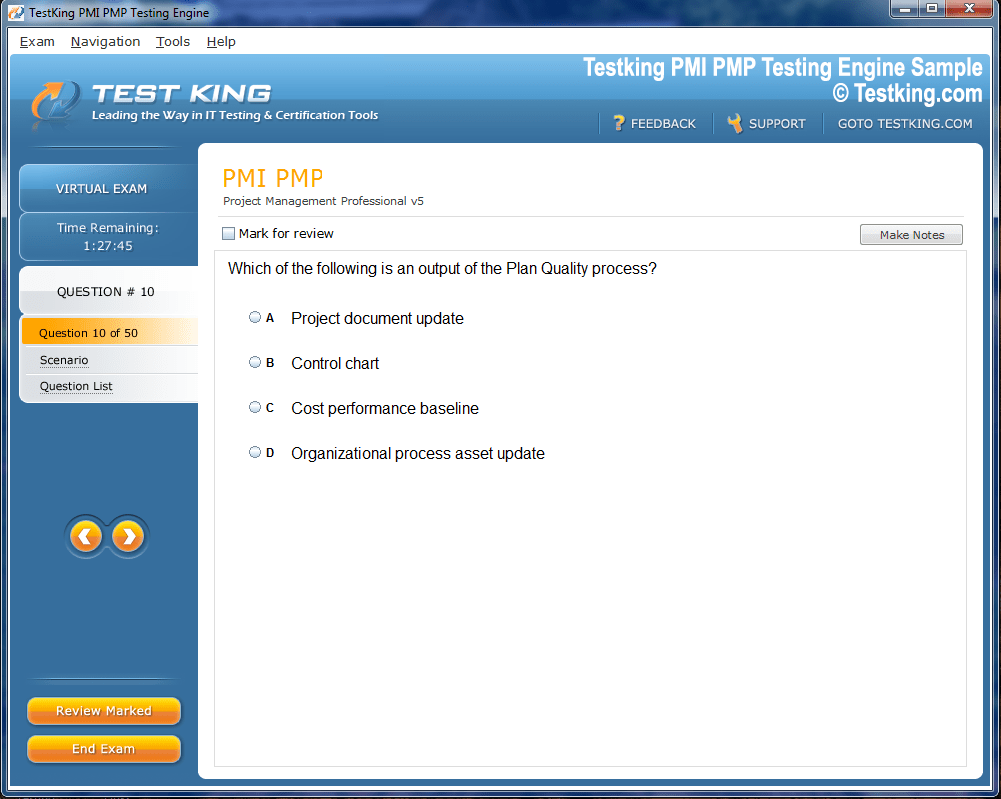

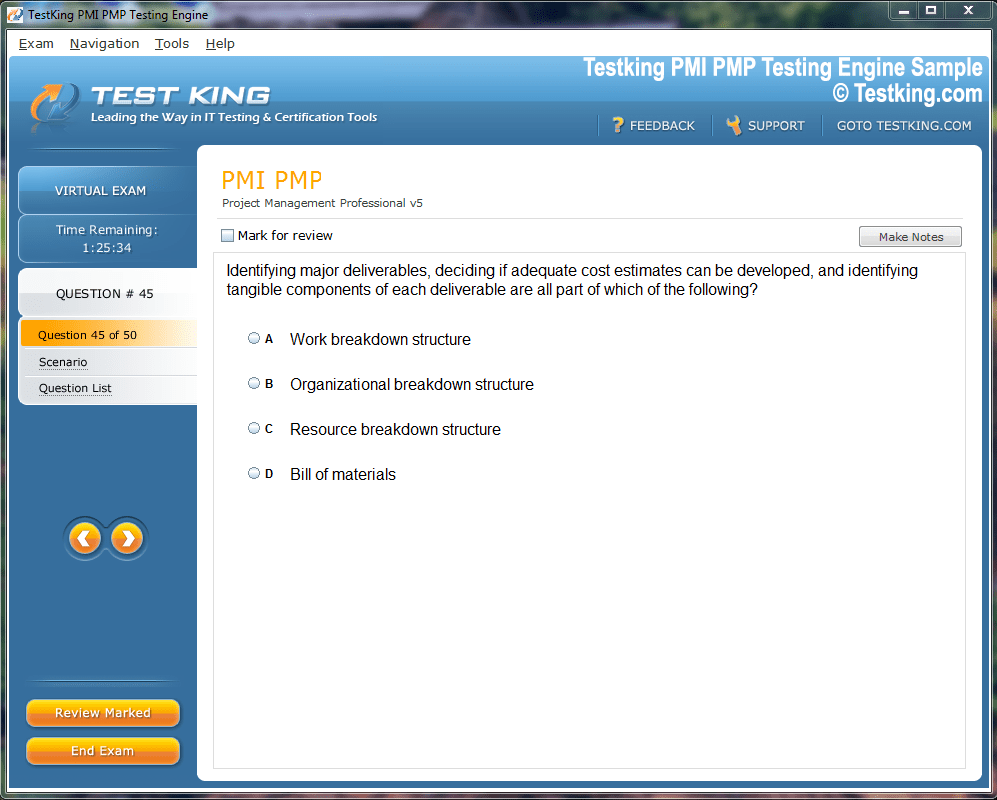

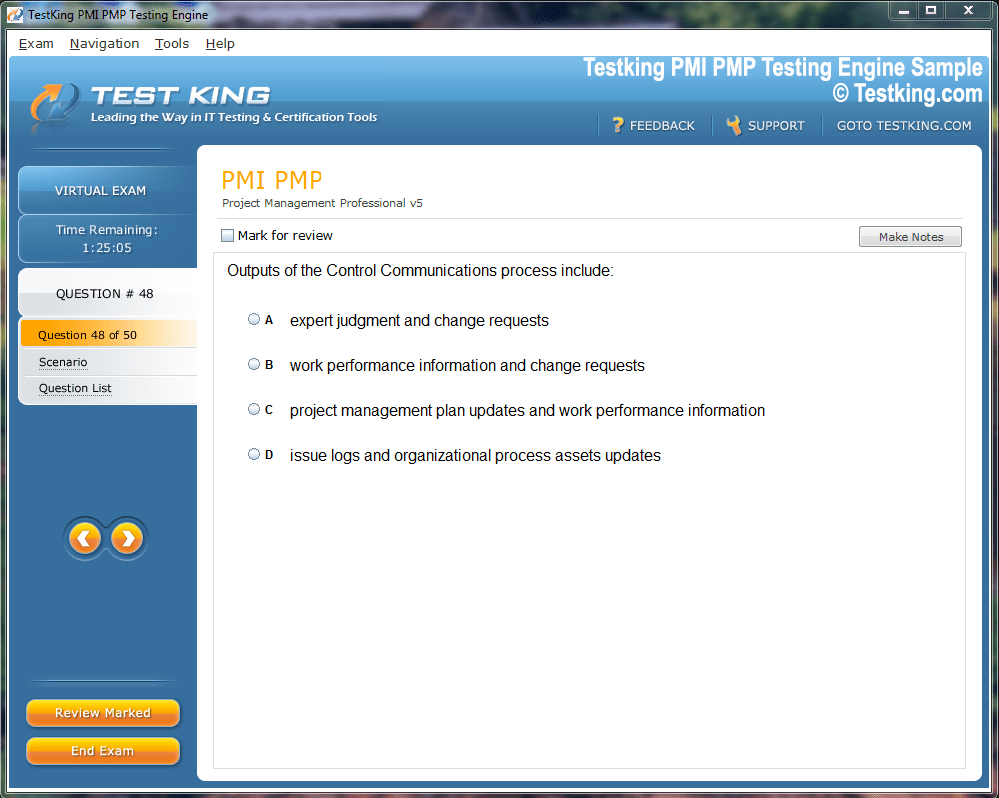

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our ICYB testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top Six Sigma Exams

Unlocking Career Opportunities Through Six Sigma ICYB

The Certified Lean Six Sigma Yellow Belt represents a professional who has delved into the fundamental tenets of Lean Six Sigma methodology. This designation is not simply an introductory title but signifies a practitioner capable of contributing meaningfully to process improvement initiatives, often under the guidance of more advanced Green or Black Belt professionals. Yellow Belts are instrumental in assisting with project execution and leading smaller-scale initiatives where the scope and complexity are manageable. Their responsibilities often include data collection, process documentation, and supporting problem-solving efforts that enhance organizational efficiency.

Lean Six Sigma itself is a methodology that merges the principles of Lean manufacturing with Six Sigma’s statistical rigor. Lean principles focus on reducing waste, optimizing flow, and enhancing value from the customer’s perspective, while Six Sigma emphasizes precision, variation reduction, and defect minimization. When combined, these methodologies offer a powerful framework that organizations use to streamline operations, reduce inefficiencies, and improve overall performance. A Yellow Belt professional is expected to understand this hybrid methodology sufficiently to implement improvement projects and support larger initiatives effectively.

The Role of a Yellow Belt in Process Improvement

Yellow Belt professionals occupy a critical support role within process improvement projects. Unlike Green or Black Belts, who often spearhead projects, Yellow Belts typically participate as team members. They are responsible for executing specific tasks, such as gathering data, conducting process observations, and performing basic analysis. Their contributions help provide a reliable foundation for project decision-making and ensure that improvement initiatives are grounded in accurate, comprehensive information.

One of the primary frameworks Yellow Belts utilize is the DMAIC process, an acronym representing Define, Measure, Analyze, Improve, and Control. This structured approach provides a systematic path for problem-solving and process optimization. In the Define phase, Yellow Belts assist in clarifying project goals and mapping out process boundaries. During Measure, they gather data, track performance metrics, and identify critical process variables. In Analyze, they may conduct rudimentary statistical assessments to pinpoint root causes of inefficiencies or defects. During the Improve and Control phases, Yellow Belts support the implementation of solutions and help establish monitoring mechanisms to sustain improvements over time.

Beyond DMAIC, Yellow Belts are often involved in smaller projects that utilize the PDCA (Plan, Do, Check, Act) cycle. PDCA is particularly suited for incremental improvements, where iterative testing and validation can gradually enhance processes. In these projects, Yellow Belts may lead initiatives that address localized issues or department-level inefficiencies, applying Lean Six Sigma tools in a contained environment. Their work ensures that small improvements accumulate over time, creating a culture of continuous enhancement across the organization.

Six Sigma Yellow Belt as an Entry Point

The Six Sigma Yellow Belt is often regarded as the first formal step into the realm of process improvement. While it does not require prior experience, it provides a robust foundation for understanding the key concepts and methodologies that underpin Lean Six Sigma. This certification introduces practitioners to the basic statistical tools, process mapping techniques, and analytical methods essential for identifying inefficiencies and implementing sustainable improvements.

The certification itself demonstrates a commitment to operational excellence and equips professionals with the skills necessary to contribute effectively to project teams. For many individuals, obtaining a Yellow Belt serves as a gateway to more advanced certifications, such as Green Belt or Black Belt, allowing for deeper specialization in process improvement strategies. However, the knowledge acquired at the Yellow Belt level is sufficient to make a measurable impact within an organization, especially in roles that involve supporting project execution, quality control, or operational enhancements.

Lean Six Sigma Methodology Overview

Lean Six Sigma methodology is an amalgamation of two complementary approaches. Lean emphasizes the elimination of waste, whether in the form of time, materials, or effort, with a focus on maximizing customer value. Lean tools such as 5S, value stream mapping, and visual management help create efficient, organized, and easily navigable processes. The 5S methodology, for instance, involves sorting, straightening, shining, standardizing, and sustaining, which fosters an environment conducive to operational excellence. Value stream mapping allows teams to visualize the entire workflow, identifying bottlenecks, delays, and redundant steps, which can then be addressed through targeted improvement actions.

Six Sigma, on the other hand, centers on reducing variation and defects using statistical analysis. By applying quantitative tools such as control charts, cause-and-effect diagrams, and hypothesis testing, practitioners can identify the underlying causes of problems and develop solutions that improve consistency and quality. The integration of Lean and Six Sigma provides a holistic framework that not only enhances efficiency but also ensures that improvements are data-driven and sustainable.

The Lean Six Sigma Yellow Belt Body of Knowledge

The body of knowledge for Lean Six Sigma Yellow Belts encompasses the fundamental skills and concepts required to participate effectively in improvement initiatives. Key areas of expertise include understanding the DMAIC process, basic statistical analysis, process documentation, and the use of Lean tools. This knowledge allows Yellow Belts to support projects in a meaningful way, contributing to data collection, performance monitoring, and problem identification.

Proficiency in these areas also involves understanding the distinct roles within a Six Sigma project. Yellow Belts are typically not expected to perform advanced statistical analysis, a responsibility more suited to Green Belts. Instead, their focus is on supporting project execution, ensuring accurate data capture, and helping implement process improvements within the defined scope. This clarity in role definition prevents overlap and ensures that each team member contributes optimally to the project’s success.

Exam Structure and Requirements

The Lean Six Sigma Yellow Belt examination is designed to assess a candidate’s understanding of the methodology and their ability to apply it in practical scenarios. The exam typically consists of 100 questions, combining multiple-choice and true/false formats. Candidates are allotted two hours to complete the assessment, which is often delivered online to accommodate flexibility in scheduling.

No formal prerequisites are required to sit for the exam, making it accessible to professionals at various stages of their careers. While prior experience in quality management or statistical analysis may be advantageous, it is not mandatory. Candidates are encouraged to undergo formal training to familiarize themselves with the concepts and tools covered in the Body of Knowledge. Such preparation can include self-study, corporate training programs, or academic courses. Many programs also offer practice exams or evaluation tests to gauge readiness before attempting the official certification exam.

Benefits of Yellow Belt Certification

Obtaining a Lean Six Sigma Yellow Belt provides numerous advantages for professionals. First, it clarifies the practitioner’s role within project teams, ensuring that responsibilities are aligned with skills and competencies. Yellow Belts gain an understanding of project workflows, process improvement techniques, and Lean Six Sigma terminology, enabling them to contribute effectively.

Second, the certification enhances employability by signaling a commitment to operational excellence and process optimization. Employers recognize the value of personnel who can identify inefficiencies, support structured improvement initiatives, and contribute to cost savings. While certification does not guarantee higher compensation, it often positions candidates as more versatile and valuable team members within their organizations.

Additionally, the certification offers intellectual enrichment. Yellow Belts acquire knowledge of foundational Lean Six Sigma tools, such as control charts, process mapping, and the 5S methodology. They learn to quantify process performance, identify critical variables, and implement incremental improvements that can produce substantial cumulative benefits. This knowledge not only supports professional development but also fosters a mindset oriented toward continuous improvement and operational efficiency.

Training Content Overview

Training for Lean Six Sigma Yellow Belt candidates covers an array of topics designed to build a comprehensive understanding of process improvement. The curriculum includes the history and evolution of Lean Six Sigma, key concepts of Lean thinking, statistical analysis tools, and structured problem-solving frameworks such as DMAIC.

Yellow Belt candidates are introduced to foundational formulas like y = f(x), which relate process inputs to outputs, enabling practitioners to identify causal relationships within operational workflows. Training also covers the creation and interpretation of control charts, which help monitor process performance over time, and value stream mapping, which provides a visual representation of workflow from start to finish.

In addition, training emphasizes the importance of workplace organization through the 5S methodology. By applying sorting, straightening, shining, standardizing, and sustaining principles, Yellow Belts contribute to creating environments that facilitate efficiency, visibility, and adherence to Lean principles. These tools collectively prepare candidates to participate in projects, support data-driven decision-making, and contribute to incremental and sustainable improvements.

Lean Six Sigma Yellow Belt Roles and Responsibilities

The Certified Lean Six Sigma Yellow Belt occupies a pivotal role within the framework of organizational improvement initiatives. Unlike Green and Black Belts, who often orchestrate projects and design solutions, Yellow Belts primarily serve in supportive and contributory capacities, facilitating the practical execution of tasks. Their responsibilities include gathering and validating data, documenting processes, participating in analysis sessions, and assisting with the implementation of improvement measures. Despite not leading complex projects, Yellow Belts are vital in maintaining project accuracy, efficiency, and alignment with established objectives.

A Yellow Belt’s involvement extends to smaller projects where they can lead initiatives independently, provided the scope is manageable. In these cases, they apply Lean Six Sigma methodologies such as the PDCA cycle to achieve incremental improvements. Through structured iterations of planning, execution, verification, and adjustment, Yellow Belts can bring about meaningful operational changes while honing their analytical and managerial skills. These experiences also prepare them for larger, more complex projects under the guidance of higher-level Belt professionals.

Integration of DMAIC in Yellow Belt Functions

A cornerstone of Lean Six Sigma training is the DMAIC methodology, which provides a systematic approach to process improvement. Yellow Belts engage extensively with the initial stages of DMAIC, namely Define, Measure, and Control, acquiring the competencies necessary to support higher-level analytical work.

During the Define phase, Yellow Belts help clarify project objectives, identify stakeholders, and map out the boundaries of the process under scrutiny. They may create preliminary process flow diagrams, helping the team visualize how operations unfold and where bottlenecks or inefficiencies occur. In the Measure phase, Yellow Belts are responsible for collecting reliable data, ensuring accuracy in measurement systems, and recording key performance indicators. This phase is crucial, as precise measurement underpins effective analysis and decision-making.

In the Control phase, Yellow Belts assist in sustaining improvements by monitoring processes and ensuring that newly implemented changes adhere to planned standards. While they are not typically responsible for advanced statistical analysis, they can utilize basic tools like control charts to observe trends, detect anomalies, and confirm that processes remain stable over time. Their involvement ensures that improvements are not merely temporary but become ingrained in organizational operations.

Lean Principles for Yellow Belts

Lean principles focus on creating value by minimizing waste and enhancing operational efficiency. For Yellow Belts, understanding these principles is essential for contributing effectively to process improvement projects. Lean tools such as 5S, value stream mapping, and visual management provide practical mechanisms to organize workspaces, streamline workflows, and facilitate clarity in operations.

The 5S methodology—Sort, Straighten, Shine, Standardize, Sustain—is particularly relevant for Yellow Belts. By implementing these steps, practitioners establish a structured and organized environment that enhances visibility and reduces inefficiencies. For example, sorting ensures that only essential items are retained in a workspace, while standardizing promotes uniform practices across teams. These interventions, though seemingly simple, create cumulative benefits by fostering a culture of consistency and operational discipline.

Value stream mapping enables Yellow Belts to visualize the flow of materials, information, and activities across a process. By identifying bottlenecks, redundancies, or delays, they can propose targeted improvements that enhance efficiency and reduce cycle time. Visual management tools, such as process dashboards and workflow charts, provide real-time insights into performance, enabling teams to respond quickly to emerging issues and maintain alignment with project objectives.

Statistical Tools for Yellow Belts

Although advanced statistical analysis is primarily the domain of Green and Black Belts, Yellow Belts are introduced to fundamental statistical concepts that aid in understanding process behavior. Tools such as basic control charts, cause-and-effect diagrams, and simple descriptive statistics allow Yellow Belts to observe trends, measure variation, and identify potential areas for improvement.

Control charts, for instance, track process performance over time, visually highlighting deviations from expected norms. By understanding these variations, Yellow Belts contribute to the early detection of potential problems, enabling corrective actions before issues escalate. Cause-and-effect diagrams, often referred to as fishbone diagrams, help Yellow Belts identify potential root causes of inefficiencies or defects in a structured and logical manner. These tools complement Lean methodologies, ensuring that process enhancements are data-driven and grounded in evidence.

Training and Preparation for Certification

Preparation for the Lean Six Sigma Yellow Belt certification emphasizes a combination of conceptual knowledge and practical application. Candidates are encouraged to undergo formal training, which may be offered through academic institutions, corporate programs, or recognized Lean Six Sigma instructors. Such training covers the DMAIC methodology, Lean principles, basic statistical tools, process documentation techniques, and the roles and responsibilities of project team members.

Practice exams and non-proctored evaluation tests are commonly incorporated into training programs to help candidates gauge their readiness for the official certification exam. These practice assessments replicate the structure and content of the certification test, allowing participants to familiarize themselves with question types, time management strategies, and the application of Lean Six Sigma principles in hypothetical scenarios.

Examination Details and Structure

The Lean Six Sigma Yellow Belt exam is designed to evaluate a candidate’s comprehension of the methodology and their ability to apply it in practical situations. Typically delivered online, the exam consists of multiple-choice and true/false questions, requiring candidates to complete it within a specified time frame, usually two hours. No prior experience is required, making it accessible to professionals at all levels seeking foundational expertise in process improvement.

Certification validates the practitioner’s understanding of essential Lean Six Sigma concepts, their familiarity with DMAIC, and their ability to support project teams effectively. Candidates who achieve a passing score are awarded a recognized credential, which confirms their competencies and provides formal acknowledgment of their knowledge in process improvement practices.

Career Advantages and Opportunities

Obtaining a Lean Six Sigma Yellow Belt offers significant career advantages. By demonstrating foundational expertise in process improvement, professionals position themselves as valuable contributors to organizational initiatives aimed at enhancing efficiency and reducing waste. Employers recognize the benefits of having personnel who can support structured improvement efforts, ensuring reliable execution and accurate data collection.

The certification enhances professional credibility, indicating that the individual possesses verified skills and knowledge in Lean Six Sigma methodologies. This recognition can lead to increased responsibilities, opportunities for project participation, and pathways for advancement to higher Belt levels. Furthermore, the certification fosters a mindset oriented toward continuous improvement, empowering professionals to identify inefficiencies, implement solutions, and sustain operational gains over time.

Practical Application of Yellow Belt Knowledge

In real-world scenarios, Yellow Belts apply their knowledge to a variety of process improvement tasks. These may include mapping workflows, collecting performance data, conducting basic analyses, and supporting the implementation of corrective actions. Through hands-on involvement, Yellow Belts develop a practical understanding of how Lean Six Sigma principles operate in complex organizational environments.

For example, in manufacturing settings, Yellow Belts may track production line performance, identify delays or defects, and propose solutions to enhance throughput. In service environments, they might examine customer service processes, reduce response times, or streamline administrative procedures. Regardless of the sector, Yellow Belts use their training to create measurable improvements that contribute to overall organizational efficiency.

Integration with Green and Black Belt Projects

Yellow Belts often collaborate with Green and Black Belts on larger-scale projects. While Green Belts typically lead projects within specific departments and Black Belts manage cross-functional or enterprise-level initiatives, Yellow Belts provide critical support. Their role includes data collection, preliminary analysis, documentation, and monitoring of process changes.

This collaboration ensures that projects are executed with accuracy, that process changes are sustainable, and that data-driven insights inform decision-making. By supporting higher-level Belts, Yellow Belts gain exposure to advanced methodologies, statistical tools, and project management techniques, preparing them for eventual progression to Green or Black Belt certification.

Certification, Recognition, and Validity

Upon successful completion of the Lean Six Sigma Yellow Belt exam, candidates receive a credential that verifies their foundational expertise. This certification is recognized globally, providing professional legitimacy and signaling to employers and colleagues that the individual has mastered core Lean Six Sigma concepts.

The certification is valid indefinitely, reflecting the enduring relevance of fundamental process improvement principles. Additionally, certified Yellow Belts gain access to ongoing learning opportunities and may choose to pursue higher-level certifications, such as Green Belt or Black Belt, to deepen their analytical capabilities and project leadership skills.

Lean Six Sigma Yellow Belt Training and Knowledge Acquisition

The Lean Six Sigma Yellow Belt is designed to equip professionals with foundational skills in process improvement and operational optimization. Training focuses on both conceptual understanding and practical application, enabling practitioners to participate effectively in projects and contribute to measurable organizational gains. Yellow Belts gain knowledge in Lean principles, Six Sigma methodologies, basic statistical tools, and structured problem-solving frameworks, providing them with a toolkit to identify inefficiencies and implement solutions.

Training often begins with an overview of Lean Six Sigma history and its evolution as a methodology for operational excellence. Understanding the origins of these concepts allows Yellow Belts to appreciate the rationale behind key principles, tools, and techniques. Lean Six Sigma merges the efficiency-oriented Lean approach with the precision and variation-reduction focus of Six Sigma. By learning this integrated framework, Yellow Belts develop a holistic perspective that emphasizes both waste elimination and quality improvement.

Conceptual Foundations: Lean Principles

Lean principles form a crucial component of Yellow Belt training. Lean emphasizes maximizing value for the customer while minimizing waste in all forms, including unnecessary time, materials, and effort. Yellow Belts are introduced to tools such as 5S, value stream mapping, and visual management, which are applied to create efficient and organized processes.

The 5S methodology—Sort, Straighten, Shine, Standardize, Sustain—provides a systematic approach to workplace organization. Yellow Belts learn to implement these steps to establish a clean, orderly, and visually manageable environment that supports operational efficiency. Value stream mapping, another core Lean tool, enables practitioners to visualize the flow of materials, information, and activities, identify bottlenecks, and propose targeted improvements. Visual management techniques, including process dashboards and workflow charts, allow teams to track performance and respond promptly to deviations or inefficiencies.

Introduction to Six Sigma Methodology

In addition to Lean, Yellow Belt training emphasizes the Six Sigma approach to process improvement, which focuses on reducing variation and enhancing quality through statistical analysis. Yellow Belts learn to apply basic statistical tools, such as control charts, histograms, and cause-and-effect diagrams, to monitor processes and identify areas for improvement.

Control charts, for example, allow practitioners to observe trends over time, identify deviations from expected performance, and implement corrective actions when necessary. Cause-and-effect diagrams, often referred to as fishbone diagrams, help Yellow Belts systematically determine potential sources of process variation or defects. By combining these tools with Lean techniques, Yellow Belts gain a comprehensive understanding of how to optimize processes while ensuring consistent quality.

The DMAIC Framework for Yellow Belts

The DMAIC methodology—Define, Measure, Analyze, Improve, Control—serves as the primary framework for Lean Six Sigma projects and is central to Yellow Belt responsibilities. During the Define phase, Yellow Belts assist in clarifying project objectives, establishing boundaries, and identifying stakeholders. Process mapping and preliminary documentation often occur at this stage, enabling teams to visualize workflows and understand operational dynamics.

In the Measure phase, Yellow Belts are tasked with collecting accurate data, tracking key performance indicators, and verifying measurement systems. This data forms the foundation for subsequent analysis and ensures that process decisions are informed by reliable evidence. During the Analyze phase, Yellow Belts contribute to identifying potential root causes of inefficiencies, though advanced statistical evaluations are typically handled by Green or Black Belts.

The Improve and Control phases focus on implementing solutions and sustaining gains. Yellow Belts assist with the execution of improvement initiatives, monitor performance metrics, and employ tools such as control charts to ensure changes remain effective. By engaging with the full DMAIC cycle, even in a supporting capacity, Yellow Belts develop practical experience in structured problem-solving and continuous improvement.

Statistical Tools and Analytical Competencies

While Yellow Belts do not perform complex statistical analyses, their training introduces essential analytical tools to support process improvement. Basic statistics, process capability assessment, and trend monitoring equip Yellow Belts to observe operational performance and contribute meaningful insights to project teams.

Control charts are particularly valuable, providing a visual representation of process stability over time. By identifying variations outside established limits, Yellow Belts can flag potential issues and collaborate with higher-level Belts to implement corrective measures. Descriptive statistics, such as averages, ranges, and standard deviations, allow Yellow Belts to summarize process data and support decision-making. Cause-and-effect analysis further aids in understanding relationships between inputs and outputs, ensuring that improvements address underlying problems rather than surface-level symptoms.

Certification Preparation and Examination

Preparing for Lean Six Sigma Yellow Belt certification involves both theoretical study and practical exercises. Training programs typically offer comprehensive coverage of the Body of Knowledge, which includes DMAIC methodology, Lean principles, basic statistical tools, and process improvement techniques. Candidates are encouraged to participate in practice exams or evaluation tests to assess readiness for the official certification exam.

The Yellow Belt exam is generally conducted online and consists of multiple-choice and true/false questions. Candidates are allotted a defined period, typically two hours, to complete the test. The exam evaluates knowledge of Lean Six Sigma concepts, the ability to apply tools in practical scenarios, and an understanding of project roles and responsibilities. A passing score validates that the candidate possesses foundational competencies and can contribute effectively to process improvement initiatives.

Career Applications and Workplace Integration

Lean Six Sigma Yellow Belt certification provides tangible advantages in professional environments. Certified Yellow Belts are recognized for their foundational expertise and ability to support project teams effectively. In practice, they may collect and analyze operational data, assist in workflow mapping, and help implement improvements across various departments.

In manufacturing settings, Yellow Belts often track production line performance, identify inefficiencies, and propose small-scale interventions to enhance throughput. In service industries, they may streamline administrative processes, reduce cycle times, and improve customer satisfaction. Regardless of sector, Yellow Belts apply their knowledge to produce measurable improvements, demonstrating the value of structured problem-solving and operational efficiency.

Collaboration with Higher-Level Belts

Yellow Belts frequently collaborate with Green and Black Belts on complex projects. While Green Belts lead departmental initiatives and Black Belts manage enterprise-level improvements, Yellow Belts provide essential support. Their contributions include data collection, documentation, preliminary analysis, and monitoring of implemented changes.

This collaborative structure ensures that projects are executed accurately, that improvements are data-driven, and that process enhancements are sustainable. Working alongside higher-level Belts exposes Yellow Belts to advanced methodologies, analytical tools, and strategic decision-making, preparing them for potential advancement to Green or Black Belt certification.

Benefits of Certification for Professionals

Achieving Lean Six Sigma Yellow Belt certification conveys multiple professional benefits. It clarifies the practitioner’s role in project teams, equips them with foundational knowledge and tools, and enhances credibility within the organization. Certified Yellow Belts demonstrate their understanding of DMAIC methodology, Lean principles, and basic statistical analysis, signaling to employers their capability to support structured improvement initiatives.

Certification also encourages a mindset focused on continuous improvement, fostering awareness of inefficiencies, and promoting proactive problem-solving. Professionals gain the confidence to participate meaningfully in projects, contribute to operational gains, and collaborate effectively with colleagues across departments.

Practical Implementation of Yellow Belt Skills

In operational settings, Yellow Belts apply their skills to a variety of tasks, ranging from process mapping to performance tracking and improvement implementation. They may observe workflows, collect relevant data, and assist in analyzing performance metrics to identify improvement opportunities.

By engaging in practical applications, Yellow Belts develop a nuanced understanding of operational processes and the effects of incremental improvements. Their interventions, though often small in scope, contribute to cumulative organizational benefits, including reduced waste, enhanced efficiency, and improved quality outcomes.

Organizational Impact of Yellow Belt Involvement

The involvement of Lean Six Sigma Yellow Belts positively influences organizational performance. Through structured methodologies, Lean tools, and basic statistical analysis, Yellow Belts facilitate process improvements that enhance efficiency, reduce costs, and support customer satisfaction.

Their participation also encourages a culture of continuous improvement, where operational processes are routinely assessed, inefficiencies are addressed, and gains are maintained over time. Organizations benefit from a structured approach to problem-solving, ensuring that improvements are evidence-based, systematic, and sustainable.

Certification, Recognition, and Professional Growth

Upon successful completion of the Lean Six Sigma Yellow Belt exam, practitioners receive a credential that validates their foundational expertise. This certification is recognized internationally, providing professional legitimacy and signaling proficiency in process improvement principles.

The certification is valid indefinitely and serves as a stepping stone for further advancement within Lean Six Sigma. Yellow Belts can pursue higher-level certifications, such as Green or Black Belt, to gain deeper analytical skills and assume leadership roles in complex improvement projects. Certification not only enhances professional credibility but also cultivates a mindset oriented toward operational excellence and continuous learning.

Lean Six Sigma Yellow Belt Practical Applications

The Lean Six Sigma Yellow Belt serves as a foundation for professionals seeking to contribute to process improvement initiatives in diverse organizational environments. By mastering foundational concepts, Yellow Belts are equipped to participate effectively in projects, identify inefficiencies, and help implement solutions that generate measurable operational benefits. Their role is particularly valuable in supporting both small-scale initiatives and more complex projects managed by Green or Black Belts.

In practical terms, Yellow Belts are often responsible for data collection, workflow observation, and process documentation. These tasks ensure that project teams have accurate and comprehensive information to inform decision-making. By observing operational patterns, identifying bottlenecks, and recording performance metrics, Yellow Belts provide critical insights that allow teams to analyze processes effectively and target interventions where they are most impactful.

Lean Tools and Methodologies for Yellow Belts

Lean tools and methodologies form the backbone of Yellow Belt training and practical application. Among the most important are 5S, value stream mapping, and visual management, each of which helps organize workspaces, streamline processes, and improve operational clarity.

The 5S methodology—Sort, Straighten, Shine, Standardize, Sustain—provides a structured approach to organizing workspaces for efficiency and safety. Sorting removes unnecessary items, straightening ensures a logical arrangement of resources, and shining maintains cleanliness. Standardizing creates consistency across tasks, while sustaining ensures ongoing adherence to these practices. By implementing 5S, Yellow Belts help cultivate an organized environment that reduces waste and enhances process flow.

Value stream mapping allows Yellow Belts to visualize the entire process flow from start to finish, highlighting delays, redundancies, and non-value-added steps. This tool is particularly useful in identifying areas for improvement and in providing a roadmap for targeted interventions. Visual management tools, such as dashboards and workflow charts, enable teams to monitor performance in real time, quickly identifying deviations and making data-informed decisions to maintain process efficiency.

Statistical Foundations for Yellow Belts

While advanced statistical analysis is typically the domain of Green and Black Belts, Yellow Belts are introduced to essential statistical concepts that support process monitoring and improvement. Basic tools such as control charts, histograms, and cause-and-effect diagrams allow practitioners to observe process trends, identify variations, and support problem-solving efforts.

Control charts provide a visual representation of process stability over time, helping Yellow Belts detect deviations from expected performance levels. Histograms summarize data distributions, enabling teams to understand the frequency and magnitude of variations. Cause-and-effect diagrams, also known as fishbone diagrams, systematically identify potential sources of process inefficiency, guiding the development of corrective actions. By applying these statistical tools, Yellow Belts contribute to data-driven decision-making and support sustainable improvements.

The Role of DMAIC in Practical Application

The DMAIC methodology—Define, Measure, Analyze, Improve, Control—is central to Lean Six Sigma projects and provides a structured approach for Yellow Belt practitioners. In the Define phase, Yellow Belts assist in clarifying project objectives, mapping process boundaries, and identifying stakeholders. These activities ensure that the project team operates with clear goals and a well-defined scope.

During the Measure phase, Yellow Belts gather data, validate measurement systems, and document key performance indicators. Accurate data collection is essential for reliable analysis and subsequent decision-making. In the Analyze phase, Yellow Belts contribute to identifying potential root causes of inefficiencies and defects. Although advanced statistical analyses are often handled by Green and Black Belts, Yellow Belts provide supporting data and observations that facilitate deeper examination.

The Improve and Control phases involve implementing solutions and sustaining gains. Yellow Belts help execute improvements, monitor process performance, and apply basic tools such as control charts to ensure that changes are effective and lasting. This hands-on engagement with DMAIC fosters practical experience and reinforces the importance of structured problem-solving.

Certification Preparation and Examination Insights

Preparing for Lean Six Sigma Yellow Belt certification involves understanding both theoretical principles and practical applications. Training programs often cover the Body of Knowledge, including DMAIC methodology, Lean tools, basic statistics, and process documentation techniques. Candidates may also participate in practice exams or informal evaluations to assess their readiness for the official certification test.

The Yellow Belt exam typically consists of multiple-choice and true/false questions and is conducted online within a set time frame, usually two hours. Successful completion demonstrates a candidate’s understanding of Lean Six Sigma concepts, practical application of tools, and ability to support project teams effectively. Certification validates foundational competencies and provides formal acknowledgment of the practitioner’s knowledge and skills.

Career Impact of Yellow Belt Certification

Lean Six Sigma Yellow Belt certification offers numerous professional advantages. Certified Yellow Belts are recognized for their ability to contribute meaningfully to improvement initiatives, providing accurate data, documenting processes, and supporting workflow enhancements. These competencies enhance employability, as organizations value personnel capable of applying structured methodologies to optimize operations.

In practical terms, Yellow Belts can influence operational efficiency by identifying bottlenecks, reducing waste, and implementing incremental improvements. Their participation in projects also exposes them to advanced methodologies, analytical tools, and strategic problem-solving, preparing them for potential progression to Green and Black Belt roles. This career pathway fosters both professional growth and the acquisition of increasingly sophisticated skills.

Collaboration with Green and Black Belts

Yellow Belts frequently collaborate with Green and Black Belts, who lead departmental and enterprise-level projects, respectively. By providing support in data collection, documentation, and monitoring, Yellow Belts ensure that project initiatives are executed accurately and efficiently. This collaborative structure allows for effective division of responsibilities and ensures that project teams operate cohesively.

Exposure to higher-level project management and analytical techniques through collaboration enables Yellow Belts to develop insights into more advanced applications of Lean Six Sigma. They gain experience in problem-solving strategies, process mapping, and statistical analysis, preparing them for expanded responsibilities and potential certification at higher Belt levels.

Practical Implementation in Various Industries

Yellow Belts apply Lean Six Sigma principles across multiple industries, from manufacturing to healthcare, finance, and service sectors. In manufacturing, Yellow Belts may monitor production lines, track output quality, and propose minor adjustments to improve throughput. In healthcare, they might streamline patient workflows, reduce wait times, or optimize administrative procedures. In service sectors, Yellow Belts can enhance customer service processes, reduce errors, and improve efficiency in routine operations.

By applying standardized methodologies and tools, Yellow Belts help organizations achieve measurable improvements regardless of industry. Their practical contributions often serve as catalysts for broader initiatives, fostering a culture of continuous improvement and operational excellence.

Enhancing Organizational Efficiency

The involvement of Lean Six Sigma Yellow Belts enhances organizational efficiency by applying structured approaches to problem-solving and workflow optimization. Through data collection, process observation, and basic analysis, Yellow Belts identify inefficiencies and contribute to targeted improvements that reduce waste and enhance productivity.

Organizations benefit from the systematic approach Yellow Belts bring, including increased transparency in workflows, more accurate performance monitoring, and a proactive approach to problem resolution. These contributions create tangible results, such as reduced operational costs, improved quality outcomes, and enhanced customer satisfaction.

Fostering a Culture of Continuous Improvement

One of the key impacts of Yellow Belt practitioners is the promotion of a culture of continuous improvement. By actively participating in process evaluation, suggesting incremental changes, and supporting project implementation, Yellow Belts encourage colleagues to adopt similar practices. This cultural shift fosters ongoing operational enhancement, ensures sustained gains, and creates a work environment that prioritizes efficiency, quality, and adaptability.

Through consistent application of Lean Six Sigma principles, organizations can maintain high performance levels while fostering employee engagement and accountability. Yellow Belts play a critical role in initiating this cultural change, acting as both practitioners and advocates of structured problem-solving.

Professional Recognition and Credential Value

Successful completion of the Lean Six Sigma Yellow Belt exam provides practitioners with a globally recognized certification, validating their foundational knowledge and practical competencies. This credential enhances professional credibility, signaling to employers and colleagues that the individual possesses verified skills in process improvement methodologies.

The certification is valid indefinitely, reflecting the enduring applicability of foundational Lean Six Sigma principles. It serves as a stepping stone for further professional development, allowing Yellow Belts to pursue Green or Black Belt certification and assume greater responsibility in complex projects. Recognition of this credential strengthens career prospects and positions individuals as valuable contributors to organizational excellence.

Continuous Learning and Advancement Opportunities

Yellow Belts are encouraged to continue developing their expertise through practical experience, advanced training, and higher-level certifications. By participating in increasingly complex projects and collaborating with Green and Black Belts, they gain exposure to sophisticated analytical techniques, project management practices, and strategic problem-solving.

This continuous learning process enhances their ability to lead initiatives, manage cross-functional projects, and implement sustainable improvements. Career advancement opportunities are abundant for Yellow Belts who demonstrate proficiency, initiative, and a commitment to operational excellence, providing a clear pathway toward Green and Black Belt roles.

Advancing Through Lean Six Sigma Yellow Belt Certification

The Lean Six Sigma Yellow Belt certification serves as an essential foundation for professionals seeking to enhance their process improvement capabilities. While the Yellow Belt primarily focuses on supporting project execution, mastering these principles provides a platform for advancing to higher-level certifications, such as Green Belt or Black Belt. This certification equips practitioners with both theoretical understanding and practical experience, allowing them to contribute effectively to organizational initiatives and to gain recognition for their skills.

Yellow Belts acquire knowledge in foundational Lean Six Sigma concepts, the DMAIC methodology, and basic statistical tools. This knowledge allows them to observe processes critically, collect accurate data, and participate in analysis, all while adhering to project objectives defined by higher-level Belts. The certification validates the practitioner’s competence, signaling to employers and colleagues that they possess verified skills in structured problem-solving and operational optimization.

Core Competencies and Practical Expertise

Certified Lean Six Sigma Yellow Belts develop competencies that enable them to contribute meaningfully to improvement initiatives. Key areas of expertise include understanding the DMAIC framework, applying Lean tools such as 5S and value stream mapping, and utilizing basic statistical tools to monitor and interpret process data. These skills empower Yellow Belts to assist with both small-scale projects and larger initiatives led by Green or Black Belts.

In practice, Yellow Belts are responsible for tasks such as workflow observation, data collection, process documentation, and monitoring the implementation of improvements. Their contributions ensure that projects maintain accuracy, efficiency, and alignment with predefined goals. Additionally, the practical experience gained through project involvement reinforces theoretical knowledge, providing a solid foundation for career advancement and further Lean Six Sigma certifications.

Applying Lean Principles in Operational Contexts

Lean principles emphasize maximizing value by minimizing waste, improving efficiency, and enhancing customer satisfaction. Yellow Belts are trained to implement these principles through practical tools and methodologies, fostering a culture of operational discipline.

The 5S methodology—Sort, Straighten, Shine, Standardize, Sustain—remains a key component of Yellow Belt training. By applying these steps, practitioners create organized, efficient, and visually manageable workspaces. Value stream mapping enables Yellow Belts to visualize the flow of materials, information, and processes, helping identify inefficiencies, delays, and redundancies. Visual management tools, such as process dashboards and workflow charts, allow teams to monitor performance and respond proactively to emerging issues.

Introduction to Statistical Analysis

While advanced statistical analysis is generally reserved for Green and Black Belts, Yellow Belts are introduced to fundamental concepts that support data-driven decision-making. Basic tools such as control charts, histograms, and cause-and-effect diagrams help practitioners monitor process stability, detect variations, and support improvement efforts.

Control charts allow Yellow Belts to visualize process performance over time, identifying trends and deviations from expected outcomes. Histograms summarize data distributions, providing insight into the frequency and magnitude of variations. Cause-and-effect diagrams, also known as fishbone diagrams, facilitate the identification of potential sources of inefficiency or defects, guiding corrective actions. By understanding and applying these statistical tools, Yellow Belts contribute to evidence-based improvements and help ensure that changes are both effective and sustainable.

DMAIC Framework and Yellow Belt Application

The DMAIC methodology—Define, Measure, Analyze, Improve, Control—is central to Lean Six Sigma projects and serves as the guiding structure for Yellow Belt participation. During the Define phase, Yellow Belts assist in clarifying project goals, mapping process boundaries, and identifying key stakeholders. These activities establish a clear scope and framework for the project, enabling teams to work cohesively toward targeted objectives.

In the Measure phase, Yellow Belts are responsible for accurate data collection, validation of measurement systems, and documentation of key performance indicators. This data is essential for reliable analysis and decision-making in subsequent phases. During the Analyze phase, Yellow Belts contribute to identifying root causes of inefficiencies, providing supporting observations and preliminary analysis to guide more advanced evaluations by Green or Black Belts.

The Improve and Control phases involve implementing corrective actions and ensuring sustainability. Yellow Belts support these efforts by monitoring process performance, documenting changes, and using basic tools to confirm that improvements are effective. Through engagement in the full DMAIC cycle, Yellow Belts gain hands-on experience in structured problem-solving, laying the groundwork for more advanced roles in Lean Six Sigma methodology.

Certification Preparation and Readiness

Preparing for Lean Six Sigma Yellow Belt certification requires a combination of theoretical study and practical application. Training programs cover the Body of Knowledge, including Lean principles, DMAIC methodology, basic statistical analysis, and process documentation techniques. Candidates may also participate in practice exams or evaluation assessments to determine readiness for the official certification test.

The Yellow Belt exam is typically online, consisting of multiple-choice and true/false questions, with a defined time frame for completion, usually around two hours. Successful completion demonstrates a candidate’s proficiency in Lean Six Sigma concepts, practical application of tools, and ability to support project teams effectively. Certification validates foundational skills, offering formal recognition of the practitioner’s competencies in process improvement.

Career Advancement and Professional Development

Lean Six Sigma Yellow Belt certification provides tangible advantages for career growth. Professionals with this credential are recognized for their foundational expertise and ability to contribute to improvement initiatives, enhancing employability and professional credibility.

In practice, Yellow Belts influence operational efficiency by identifying bottlenecks, reducing waste, and implementing incremental improvements. Their participation in projects exposes them to advanced methodologies, analytical tools, and strategic problem-solving approaches, preparing them for progression to Green and Black Belt roles. This pathway encourages continuous professional development, expanding both practical expertise and theoretical knowledge.

Collaboration with Green and Black Belts

Yellow Belts often work alongside Green and Black Belts on departmental and enterprise-level projects. While Green Belts lead initiatives within specific departments and Black Belts manage complex organizational projects, Yellow Belts provide crucial support through data collection, documentation, and preliminary analysis.

This collaboration ensures projects are executed accurately, process improvements are data-driven, and changes are sustainable. Working closely with higher-level Belts exposes Yellow Belts to advanced analytical techniques and project management strategies, preparing them for higher-level responsibilities and certification advancement.

Practical Implementation Across Industries

Lean Six Sigma Yellow Belts apply their knowledge in a wide range of industries, including manufacturing, healthcare, finance, and service sectors. In manufacturing, Yellow Belts may monitor production lines, analyze workflow inefficiencies, and suggest incremental improvements to increase throughput. In healthcare, they might optimize patient flow, reduce wait times, or streamline administrative processes. In service industries, Yellow Belts may enhance customer service operations, improve efficiency in routine procedures, or implement quality control measures.

Regardless of industry, Yellow Belts apply structured methodologies to generate measurable improvements. Their interventions, although often localized, contribute to broader organizational gains and support the development of a continuous improvement culture.

Enhancing Organizational Performance

The involvement of Lean Six Sigma Yellow Belts enhances organizational performance by applying structured methodologies to process evaluation and improvement. Yellow Belts contribute to identifying inefficiencies, implementing solutions, and sustaining gains, resulting in increased productivity, reduced operational costs, and improved customer satisfaction.

Their systematic approach promotes transparency, accountability, and evidence-based decision-making. Organizations benefit from the presence of certified Yellow Belts, who ensure that process improvements are not only implemented effectively but are maintained over time. This contributes to long-term operational excellence and a more resilient organizational structure.

Fostering a Continuous Improvement Mindset

Certified Yellow Belts play a pivotal role in cultivating a culture of continuous improvement within organizations. By consistently applying Lean Six Sigma principles, observing processes, and suggesting incremental enhancements, Yellow Belts encourage colleagues to adopt similar practices.

This mindset ensures that operational gains are sustained, workflows are regularly evaluated, and inefficiencies are addressed proactively. The presence of Yellow Belts reinforces the importance of structured problem-solving, operational discipline, and ongoing enhancement, creating a work environment committed to excellence and efficiency.

Certification, Recognition, and Value

Upon successful completion of the Lean Six Sigma Yellow Belt exam, practitioners receive a globally recognized certification validating their foundational expertise. This credential enhances professional credibility, signaling that the individual possesses verified knowledge and practical skills in Lean Six Sigma methodologies.

The certification is valid indefinitely, reflecting the enduring relevance of foundational process improvement principles. It also serves as a stepping stone for further certification, allowing Yellow Belts to pursue Green or Black Belt qualifications, gain advanced analytical capabilities, and assume leadership roles in complex projects. Professional recognition of this credential strengthens career prospects and positions individuals as valuable contributors to organizational improvement initiatives.

Continuous Learning and Professional Growth

Yellow Belts are encouraged to pursue continuous learning to deepen their expertise and expand their professional opportunities. Engaging in practical projects, collaborating with higher-level Belts, and participating in additional training enhances their skills in analytical techniques, project management, and strategic problem-solving.

Continuous learning prepares Yellow Belts for progression to Green and Black Belt roles, enabling them to manage larger projects, analyze complex data, and implement organization-wide improvements. This ongoing development reinforces a commitment to operational excellence and fosters a mindset of lifelong learning in process improvement disciplines.

Conclusion

The Lean Six Sigma Yellow Belt certification provides professionals with essential knowledge and practical skills for process improvement and operational excellence. By mastering foundational concepts such as Lean principles, the DMAIC methodology, and basic statistical analysis, Yellow Belts are equipped to contribute meaningfully to projects, support Green and Black Belts, and drive measurable improvements in efficiency, quality, and workflow. Their role in data collection, process observation, and documentation ensures that initiatives are executed accurately and sustainably, fostering a culture of continuous improvement across organizations. Certification validates competencies, enhances professional credibility, and opens pathways for career advancement, including progression to Green and Black Belt levels. By integrating structured problem-solving techniques and Lean Six Sigma tools, Yellow Belts establish themselves as valuable assets in any operational environment, creating long-term benefits for both organizations and their own professional growth, while laying a strong foundation for future expertise in quality management.