Exam Code: LSSMBB

Exam Name: Lean Six Sigma Master Black Belt

Certification Provider: Six Sigma

Corresponding Certification: Lean Six Sigma Master Black Belt

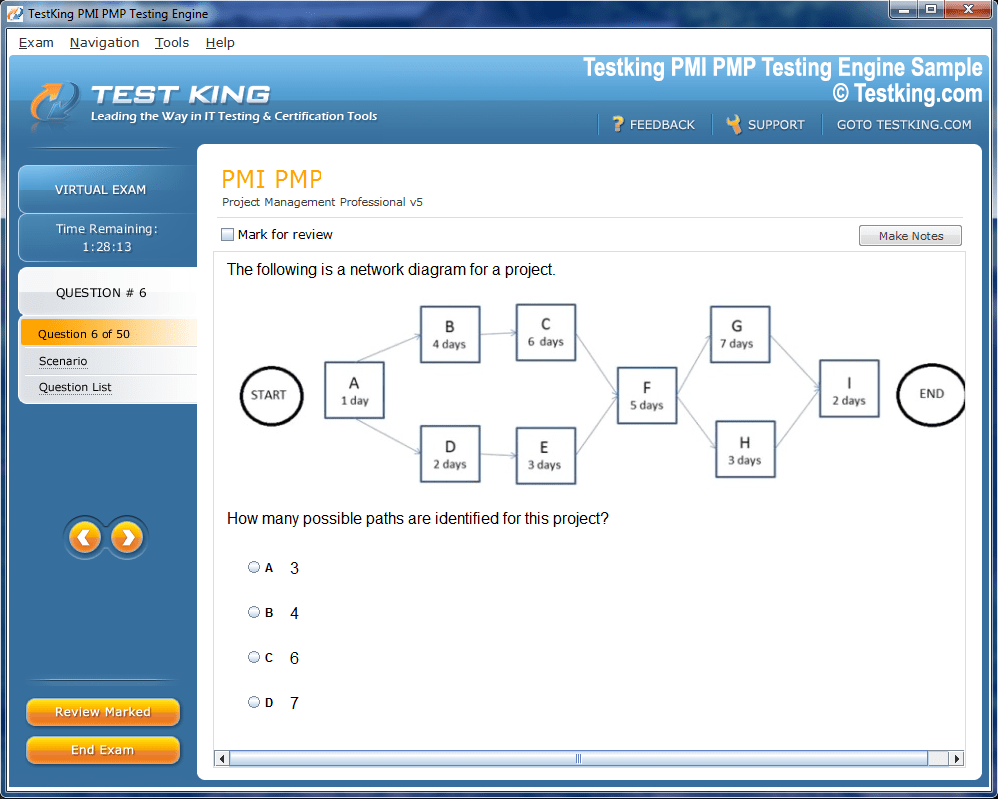

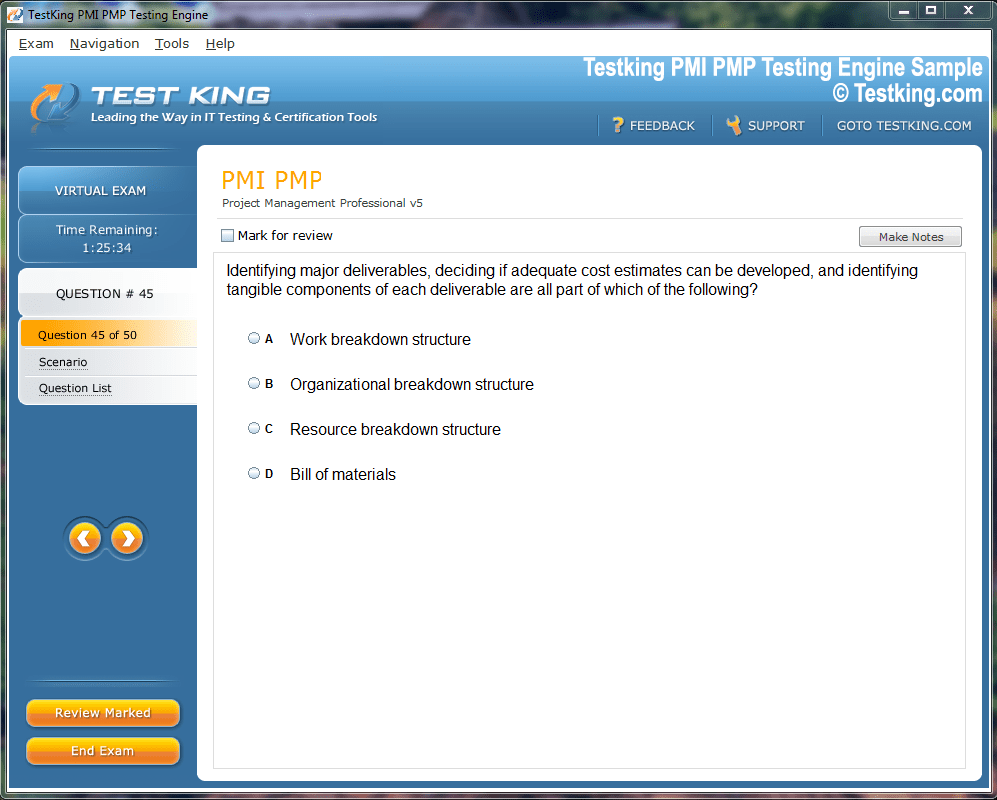

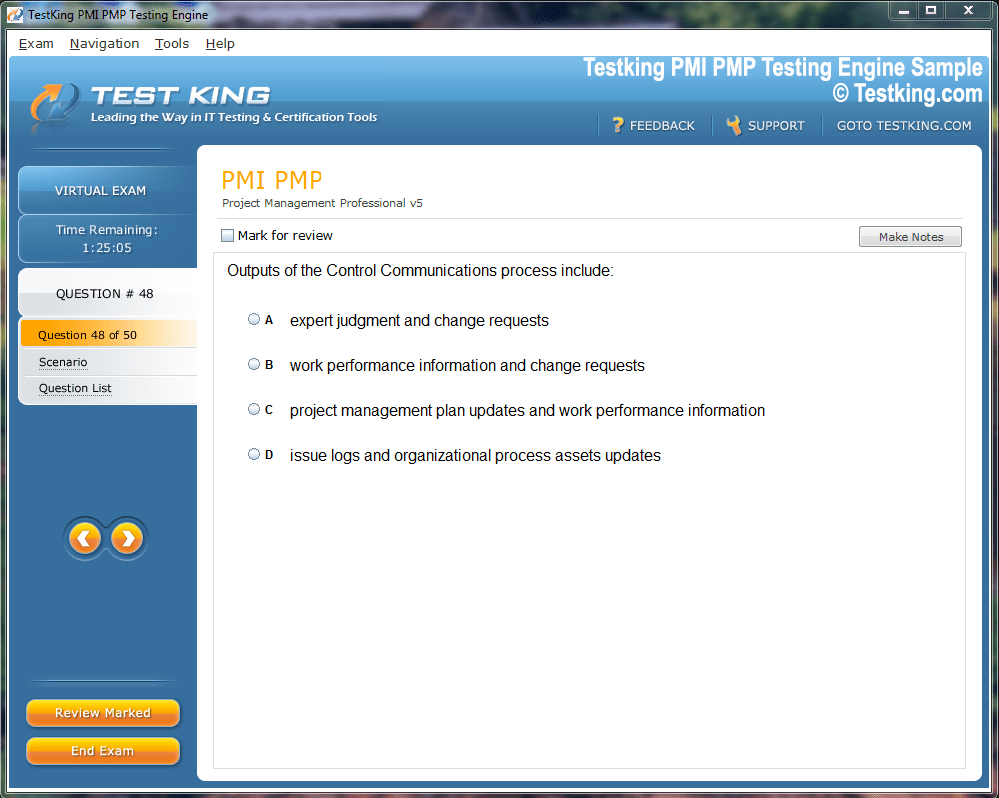

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our LSSMBB testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top Six Sigma Exams

Applying Advanced Methodologies through Six Sigma LSSMBB

The Master Black Belt stands as an indispensable figure in the architecture of any Lean Six Sigma initiative. This role embodies a rare amalgamation of technical virtuosity, strategic foresight, and the capacity to effect profound organizational change. Unlike practitioners who operate at a tactical level, the Master Black Belt orchestrates initiatives from a vantage point that integrates operational efficiency, financial impact, and customer satisfaction. The position demands not only experience and rigorous training but also an unwavering dedication to continuous improvement and a proclivity for intellectual curiosity.

In the corporate ecosystem, the Master Black Belt assumes multiple identities simultaneously: technical expert, strategic architect, mentor, and change catalyst. This polymathic function requires proficiency in complex statistical methods, a sophisticated understanding of process dynamics, and a keen perception of organizational culture. A Master Black Belt navigates the labyrinthine intricacies of business operations while translating analytical insights into actionable strategies that resonate across all levels of management. The transformative influence of this role extends beyond project completion, embedding a culture of methodological rigor and iterative enhancement that fortifies the resilience of the organization.

Transitioning into a Master Black Belt represents more than an escalation in rank or certification. It signifies an evolution in perspective from executing discrete projects to cultivating a panoramic vision of organizational performance. Individuals in this role must develop a dual lens: the meticulous scrutiny of data-driven processes alongside the broader vista of strategic objectives. By integrating both perspectives, Master Black Belts align Lean Six Sigma initiatives with corporate goals, fostering measurable improvements in operational efficiency and financial returns. Their influence shapes the trajectory of the organization, positioning them as indispensable agents of sustainable transformation.

The Journey to Master Black Belt Certification

The journey toward becoming a Master Black Belt commences with foundational Black Belt certification, which establishes both the technical bedrock and strategic sensibilities necessary for higher-level responsibilities. In structured programs, this process is typically encapsulated within a comprehensive curriculum extending over thirteen days and comprising ninety-one hours of immersive instruction. This curriculum is divided into a sequential progression of five modules, each meticulously designed to cultivate both analytical acuity and leadership competence.

The first module, Lean Management, spans two days and introduces participants to the philosophical and methodological underpinnings of operational excellence. Lean principles emphasize the eradication of waste, the harmonization of workflow, and the continuous enhancement of value streams. Participants learn to dissect processes with perspicacity, identifying inefficiencies that impede productivity. Through case studies and practical exercises, they internalize the importance of flow, pull systems, and value-stream mapping, all of which form the scaffolding upon which subsequent Six Sigma methodologies are constructed.

Following Lean Management is the Yellow Belt module, a two-day immersion that orients participants toward the foundational principles of Six Sigma. This phase emphasizes data-driven decision-making, basic statistical tools, and the identification of variation within processes. Participants acquire the cognitive scaffolding necessary to comprehend the nuances of process metrics and to contribute meaningfully to Green Belt and Black Belt projects. The Yellow Belt experience serves as a primer, instilling an analytical mindset and a disciplined approach to problem-solving that will be elaborated upon in subsequent stages.

The Green Belt module, spanning three days, introduces a deeper exploration of statistical methods, project management frameworks, and problem-solving paradigms. Participants engage with the DMAIC (Define, Measure, Analyze, Improve, Control) methodology in a hands-on manner, applying quantitative tools to real-world process issues. This stage cultivates the ability to discern patterns within data, evaluate process capabilities, and implement solutions that are both effective and sustainable. Green Belts serve as the operational linchpins in Lean Six Sigma deployments, and mastery at this level lays the groundwork for the strategic responsibilities of Black Belts and, ultimately, Master Black Belts.

The Black Belt module, also three days in duration, escalates the analytical complexity and strategic scope of training. Participants delve into advanced statistical techniques, including design of experiments, regression analysis, and hypothesis testing. Beyond methodological proficiency, this module emphasizes leadership and project orchestration, equipping participants to guide multidisciplinary teams through intricate problem-solving endeavors. Black Belts operate at the intersection of analysis and execution, translating data insights into actionable strategies while mentoring Green Belts and Yellow Belts in methodological rigor.

The culminating Master Black Belt module extends over three days and represents the apogee of Lean Six Sigma expertise. Here, participants synthesize technical mastery with strategic vision, learning to orchestrate organization-wide initiatives that maximize efficiency, reduce variation, and enhance customer value. They acquire competencies in mentoring, communication, and executive-level reporting, positioning themselves as catalysts for sustained operational excellence. This module also introduces emergent trends in the field, such as the integration of artificial intelligence and big data analytics to augment traditional Lean Six Sigma methodologies, underscoring the evolving nature of the discipline.

Core Competencies of a Master Black Belt

The role of a Master Black Belt demands a rare confluence of skills that straddle technical mastery, strategic acumen, and interpersonal dexterity. At the foundation is methodological expertise. Master Black Belts exhibit command over the full complement of DMAIC tools, statistical process controls, design of experiments, regression analysis, and hypothesis testing. This analytical rigor ensures that process improvements are not only effective but also robust, reproducible, and quantifiable. By applying these tools with precision, Master Black Belts substantiate the integrity of their interventions and provide a defensible basis for decision-making.

Equally critical is leadership capability. Master Black Belts mentor Black Belts and Green Belts, cultivating both technical competence and professional confidence within their teams. They engage in structured coaching, guiding team members through project execution, troubleshooting, and methodological refinement. By fostering autonomy and reinforcing problem-solving skills, they elevate the collective efficacy of the organization. Leadership in this context transcends hierarchical authority, relying instead on influence, persuasion, and the ability to engender trust among stakeholders.

Communication is another indispensable competency. Master Black Belts possess the ability to distill complex analytical findings into clear, actionable insights, tailored to the comprehension level of diverse audiences. They navigate interactions with senior executives, project sponsors, and operational teams with equal dexterity, ensuring that data-driven recommendations are both intelligible and persuasive. This ability to translate technical complexity into strategic clarity underpins the role’s effectiveness, securing buy-in and facilitating the implementation of transformative initiatives.

Strategic vision constitutes the final pillar of Master Black Belt competence. Individuals in this role align Lean Six Sigma initiatives with organizational objectives, ensuring that each project contributes to financial performance, customer satisfaction, and long-term sustainability. This perspective requires an understanding of market dynamics, business strategy, and corporate governance, enabling Master Black Belts to anticipate operational bottlenecks, prioritize initiatives, and deploy resources effectively. By coupling analytical rigor with strategic foresight, Master Black Belts transcend the limitations of tactical execution, driving systemic and enduring organizational improvements.

Integrating Emerging Technologies

Modern Master Black Belts increasingly leverage emergent technologies to amplify the efficacy of traditional Lean Six Sigma methodologies. Artificial intelligence, machine learning, and big data analytics are progressively integrated into process analysis, enabling predictive modeling, anomaly detection, and advanced scenario planning. These tools expand the scope and precision of process improvement initiatives, allowing organizations to anticipate operational disruptions, optimize resource allocation, and enhance decision-making.

For example, AI-driven predictive analytics can identify patterns within manufacturing data that elude conventional statistical methods, revealing opportunities for efficiency gains, quality improvements, or cost reductions. By incorporating these capabilities, Master Black Belts transform Lean Six Sigma from a reactive problem-solving framework into a proactive, foresight-driven discipline. The judicious application of technology thus becomes a hallmark of contemporary Master Black Belt practice, augmenting traditional methodologies with sophisticated, data-driven insight.

Mentoring and Knowledge Dissemination

A distinguishing feature of the Master Black Belt role is the emphasis on mentorship and knowledge dissemination. By coaching Black Belts and Green Belts, Master Black Belts ensure the continuity and scalability of Lean Six Sigma practices within the organization. Structured mentoring programs, including one-on-one sessions, workshops, and project reviews, cultivate analytical rigor and methodological consistency among team members. These programs also foster professional growth, enhancing employee engagement and retention by providing clear pathways for skill development and career advancement.

Documentation represents another critical facet of knowledge dissemination. Master Black Belts create accessible guides, procedural manuals, and repositories of best practices, ensuring that insights generated through projects are codified and preserved. This institutional memory enables the organization to replicate successful interventions, avoid repetitive errors, and sustain improvement initiatives over time. The combination of mentoring and documentation establishes a self-reinforcing cycle of learning, empowering teams to innovate and execute with confidence.

Strategic Alignment and Organizational Impact

The influence of Master Black Belts extends beyond technical problem-solving to encompass strategic alignment and organizational impact. By linking each project to overarching business objectives, Master Black Belts ensure that process improvements yield measurable returns in productivity, quality, and customer satisfaction. This alignment requires a nuanced understanding of corporate strategy, financial metrics, and operational imperatives, enabling Master Black Belts to prioritize initiatives, allocate resources effectively, and measure outcomes with precision.

Key performance indicators (KPIs) are central to this process, providing quantifiable benchmarks against which the success of initiatives can be assessed. Master Black Belts define relevant KPIs at the outset of projects and monitor progress throughout the DMAIC cycle, adjusting strategies as needed to optimize results. This rigorous measurement ensures accountability, transparency, and continuous refinement, transforming Lean Six Sigma initiatives into tangible drivers of organizational value.

Advanced Statistical Mastery in Lean Six Sigma

One of the defining characteristics of a Master Black Belt is the profound expertise in statistical methodologies. While Black Belts and Green Belts possess a functional understanding of analytical tools, Master Black Belts elevate statistical application to a level that informs organizational strategy. Their proficiency encompasses the complete spectrum of DMAIC tools, multivariate analysis, regression modeling, design of experiments, hypothesis testing, and statistical process control. This advanced acumen enables them to dissect complex operational phenomena with precision, ensuring that interventions are robust, reproducible, and grounded in empirical evidence.

Master Black Belts approach process analysis with a mindset that balances rigor with creativity. Statistical methods are not merely applied mechanistically; they are adapted to the contours of specific operational contexts. For example, design of experiments can be deployed to optimize production parameters in a manufacturing facility, while regression analysis may uncover latent relationships among process variables that influence defect rates. Such nuanced application demands not only technical competence but also an acute awareness of organizational dynamics, operational constraints, and the interplay between quantitative data and managerial decision-making.

In contemporary business environments, the integration of artificial intelligence and machine learning into statistical practice further augments the capabilities of Master Black Belts. Predictive analytics, for instance, allows practitioners to anticipate process deviations before they manifest, enabling preemptive corrective action. This proactive approach transforms Lean Six Sigma from a primarily reactive framework into a foresight-oriented discipline, wherein data is leveraged not only to solve existing problems but also to prevent potential inefficiencies and optimize resource allocation.

Leadership and Coaching in Lean Six Sigma Deployment

Beyond technical mastery, the Master Black Belt assumes a pivotal role in leadership and mentorship. The position requires the cultivation of high-performing teams, the orchestration of cross-functional initiatives, and the strategic alignment of project goals with broader corporate objectives. Unlike operational managers who may direct tasks, Master Black Belts guide, inspire, and empower team members, fostering a culture of analytical rigor and problem-solving excellence.

Mentorship is a cornerstone of this leadership. Master Black Belts provide structured guidance to Black Belts and Green Belts, assisting them in navigating complex projects, interpreting statistical findings, and implementing process improvements effectively. This mentorship extends beyond technical instruction, encompassing strategic thinking, project management, and interpersonal skills. By cultivating autonomy and reinforcing problem-solving capabilities, Master Black Belts amplify the collective competence of the organization, creating a multiplier effect in which knowledge and expertise propagate through teams and departments.

Structured coaching programs often include individualized sessions, workshops, and interactive project reviews. These mechanisms enable continuous skill development while ensuring methodological consistency across projects. The emphasis on experiential learning—engaging participants in real-world problem solving—reinforces theoretical knowledge and enhances practical application. By embedding coaching into organizational routines, Master Black Belts facilitate a culture in which Lean Six Sigma principles are internalized, operationalized, and continuously refined.

Communication and Stakeholder Influence

Effective communication is integral to the efficacy of a Master Black Belt. Conveying complex analytical insights to diverse stakeholders requires clarity, precision, and the ability to tailor messaging to different levels of understanding. Whether presenting to executives, project sponsors, or frontline operators, the Master Black Belt must translate statistical findings into actionable recommendations, bridging the gap between technical analysis and strategic decision-making.

Influence, rather than authority, characterizes this dimension of leadership. Master Black Belts secure buy-in by demonstrating the value of initiatives through tangible metrics, aligning proposed interventions with organizational objectives, and fostering trust among stakeholders. The capacity to communicate persuasively enhances the likelihood of project adoption, ensures alignment with strategic priorities, and facilitates the allocation of necessary resources. Moreover, effective communication reinforces transparency, accountability, and engagement, underpinning the long-term sustainability of process improvements.

In addition to formal presentations, Master Black Belts cultivate communication through collaborative forums, feedback mechanisms, and internal knowledge-sharing platforms. These channels enable continuous dialogue, allowing teams to discuss challenges, share lessons learned, and refine approaches collectively. By embedding communication into the operational fabric, Master Black Belts reinforce a culture of openness, adaptability, and collective learning, which is essential for sustaining Lean Six Sigma initiatives.

Strategic Vision and Organizational Alignment

A hallmark of Master Black Belt practice is the alignment of Lean Six Sigma initiatives with organizational strategy. Beyond optimizing processes, these practitioners ensure that every project contributes to overarching business objectives, whether enhancing financial performance, improving customer satisfaction, or driving operational resilience. Strategic alignment requires an understanding of corporate priorities, market conditions, resource constraints, and competitive pressures.

Master Black Belts employ analytical rigor to prioritize initiatives according to effort, expected benefit, and strategic impact. By using frameworks such as effort-benefit scoring and portfolio analysis, they allocate resources efficiently, focusing attention on projects that generate the highest value for the organization. This strategic perspective ensures that Lean Six Sigma efforts transcend tactical problem-solving and become integral to long-term organizational success.

Moreover, Master Black Belts engage in scenario planning and risk assessment, evaluating potential obstacles and devising contingency strategies. By anticipating operational and strategic challenges, they guide organizations in deploying interventions that are both feasible and sustainable. This foresight enhances the resilience of process improvement initiatives, ensuring that gains are not transient but embedded within the operational and strategic fabric of the enterprise.

Integrating Technology for Process Optimization

The technological landscape is rapidly evolving, and Master Black Belts increasingly incorporate digital tools to enhance process improvement methodologies. Big data analytics, machine learning, and artificial intelligence provide new avenues for identifying inefficiencies, predicting process deviations, and optimizing operational performance. By leveraging these technologies, Master Black Belts extend the analytical power of Lean Six Sigma beyond traditional statistical methods.

For example, predictive modeling can identify latent patterns within production data, revealing opportunities to reduce defect rates, optimize cycle times, and improve resource utilization. Machine learning algorithms can detect anomalies in real-time, enabling rapid corrective action and minimizing operational disruption. These capabilities transform Lean Six Sigma into a proactive, data-driven discipline, allowing organizations to anticipate challenges, capitalize on opportunities, and continuously enhance performance.

The integration of technology also facilitates knowledge dissemination. Digital dashboards, cloud-based repositories, and collaborative platforms enable teams to access real-time data, track project progress, and share best practices seamlessly. By harnessing technology strategically, Master Black Belts enhance both the effectiveness and scalability of process improvement initiatives, ensuring that insights are actionable and accessible throughout the organization.

Measuring Impact and Return on Investment

Master Black Belts are responsible not only for implementing process improvements but also for demonstrating their tangible impact. Quantifying operational and financial outcomes is essential for validating initiatives, securing executive support, and guiding future projects. This measurement begins with the definition of clear key performance indicators (KPIs) at the project’s inception, aligned with strategic objectives and operational priorities.

Throughout the DMAIC cycle, Master Black Belts monitor progress against these KPIs, adjusting interventions as necessary to optimize results. Performance tracking may encompass metrics such as defect reduction, cycle time improvement, cost savings, and customer satisfaction. By maintaining a rigorous focus on measurable outcomes, Master Black Belts ensure transparency, accountability, and alignment with organizational goals.

Governance structures reinforce this accountability. Regular review committees, project audits, and milestone assessments provide ongoing oversight, enabling timely identification of deviations and corrective action. For instance, in a manufacturing context, a Master Black Belt-led project could reduce defect rates by a substantial percentage within a few months, resulting in significant cost savings and operational efficiency. By documenting improvements and incorporating stakeholder feedback, Master Black Belts ensure that lessons learned are preserved and applied to future initiatives.

Cultivating a Culture of Continuous Improvement

A defining attribute of successful Master Black Belts is their ability to embed a culture of continuous improvement within the organization. This involves more than completing discrete projects; it requires shaping behaviors, reinforcing norms, and creating an environment in which process enhancement becomes habitual. By modeling methodological rigor, celebrating successes, and promoting transparency, Master Black Belts instill confidence that improvement is achievable, sustainable, and valuable.

Sustaining this culture requires ongoing initiatives such as workshops, knowledge-sharing forums, and recognition programs. These activities reinforce best practices, maintain momentum, and motivate teams to engage proactively with Lean Six Sigma principles. Over time, these practices create a self-reinforcing ecosystem in which learning, innovation, and operational excellence are integrated into daily routines. The presence of a Master Black Belt signals an organizational commitment to excellence, encouraging employees at all levels to embrace continuous improvement as a core value.

Overcoming Resistance to Change

Despite the potential for transformative impact, Lean Six Sigma initiatives can encounter resistance. Managers or employees may perceive process improvement efforts as disruptive, cumbersome, or threatening to established practices. Master Black Belts employ strategic approaches to overcome this resistance, focusing on early, visible wins that demonstrate the efficacy and value of initiatives.

By generating tangible results quickly, Master Black Belts build credibility and foster trust, creating a positive feedback loop in which stakeholders become increasingly receptive to further interventions. Effective change management also involves clear communication, inclusive planning, and the involvement of key stakeholders in decision-making processes. Through these strategies, Master Black Belts mitigate resistance, promote buy-in, and facilitate the successful implementation of process improvements across the organization.

Simplifying Complex Methodologies

The complexity of statistical tools and analytical frameworks can be intimidating for teams, particularly when advanced techniques are employed. Master Black Belts address this challenge by simplifying concepts, providing practical examples, and demonstrating real-world applications.

Hands-on exercises, case studies, and interactive workshops enable participants to engage directly with methodologies, fostering comprehension and confidence. By translating abstract concepts into tangible actions, Master Black Belts demystify statistical processes, empowering teams to apply analytical methods effectively and independently. This approach reinforces both competence and confidence, ensuring that Lean Six Sigma principles are operationalized consistently and effectively.

Advanced Process Optimization and Lean Principles

A Master Black Belt’s role extends far beyond the implementation of isolated projects; it encompasses the strategic optimization of organizational processes at a systemic level. At this stage, mastery of Lean principles is crucial, as it provides the philosophical and methodological foundation for the elimination of waste, enhancement of efficiency, and creation of value across the enterprise. Lean methodology emphasizes a relentless focus on value streams, flow, and pull systems, which collectively drive the reduction of non-value-added activities and the maximization of operational performance.

In practical terms, process optimization begins with a meticulous examination of existing workflows, identifying bottlenecks, redundancies, and inconsistencies that inhibit productivity. Master Black Belts employ techniques such as value stream mapping to visualize end-to-end processes, allowing for the identification of latent inefficiencies that may not be apparent through superficial analysis. This detailed understanding facilitates targeted interventions, ensuring that changes are both impactful and sustainable.

A nuanced comprehension of Lean tools—such as 5S, kanban, poka-yoke, and standard work—is essential. Each tool serves a distinct purpose: 5S establishes order and visual management, kanban supports just-in-time flow, poka-yoke prevents errors, and standard work ensures consistency. By deploying these tools strategically, Master Black Belts create operational systems that are both efficient and resilient, capable of adapting to changing demands without compromising quality or throughput.

Advanced DMAIC Application

The DMAIC framework—Define, Measure, Analyze, Improve, Control—is the backbone of Lean Six Sigma methodology. For Master Black Belts, mastery of DMAIC extends beyond procedural familiarity to encompass strategic application across complex, multifaceted initiatives. Each phase of the framework requires rigorous analytical thinking, stakeholder alignment, and an understanding of organizational priorities.

During the Define phase, Master Black Belts focus on articulating project goals in alignment with organizational objectives. This involves scoping projects to address high-impact areas, identifying key stakeholders, and establishing success criteria that are both measurable and meaningful. Clear definition at this stage lays the groundwork for focused, results-oriented interventions.

In the Measure phase, Master Black Belts ensure that data collection is precise, reliable, and aligned with project objectives. Advanced statistical techniques are often employed to assess process capability, quantify variation, and identify critical metrics. The quality of measurement at this stage is essential, as it directly influences the validity of subsequent analysis and improvement efforts.

The Analyze phase challenges Master Black Belts to interpret complex datasets, identify root causes of inefficiencies or defects, and generate actionable insights. Techniques such as multivariate regression, hypothesis testing, and failure modes and effects analysis (FMEA) are frequently applied to uncover relationships between variables, validate assumptions, and inform strategic interventions.

During the Improve phase, Master Black Belts design and implement targeted solutions, leveraging Lean and Six Sigma tools to optimize processes. Pilot testing, simulation, and scenario analysis are employed to evaluate potential outcomes, ensuring that improvements are both effective and sustainable. Finally, the Control phase establishes mechanisms for monitoring and sustaining gains, incorporating statistical process control, standardized procedures, and ongoing performance tracking to prevent regression and ensure long-term impact.

Mentorship and Knowledge Proliferation

A defining attribute of the Master Black Belt is the role of mentor and educator. Master Black Belts are responsible for cultivating the next generation of Lean Six Sigma practitioners, guiding Black Belts and Green Belts through complex projects, and fostering a culture of analytical rigor and continuous improvement. Mentorship encompasses technical training, strategic guidance, and leadership development, enabling team members to navigate challenges effectively and execute projects with confidence.

Structured mentorship programs typically include one-on-one coaching sessions, group workshops, and project-based learning opportunities. These mechanisms facilitate the practical application of theoretical knowledge, reinforcing methodological rigor while fostering professional growth. Master Black Belts also emphasize the importance of reflective practice, encouraging mentees to analyze outcomes, identify lessons learned, and iterate on their approach to problem solving.

Knowledge dissemination is equally critical. Master Black Belts create repositories of best practices, procedural guides, and case studies that codify insights from completed projects. By making this knowledge accessible, they ensure that improvements are replicable, institutional memory is preserved, and organizational capability is enhanced. This combination of mentorship and documentation establishes a self-reinforcing cycle of learning, empowering teams to execute Lean Six Sigma initiatives autonomously and effectively.

Integrating Artificial Intelligence and Big Data

Modern Master Black Belts increasingly leverage emerging technologies such as artificial intelligence, machine learning, and big data analytics to enhance the depth and precision of process improvement initiatives. Predictive analytics enables practitioners to anticipate deviations before they occur, identify trends within complex datasets, and optimize processes proactively. This technological integration extends the analytical power of Lean Six Sigma, transforming it into a foresight-driven discipline capable of delivering predictive and prescriptive insights.

Machine learning algorithms, for example, can detect anomalies in production processes, highlight inefficiencies, and suggest corrective actions in real time. Big data analytics facilitates the examination of vast datasets, revealing relationships and patterns that might elude conventional statistical methods. By combining these technological tools with Lean Six Sigma methodologies, Master Black Belts increase the accuracy, speed, and scalability of process improvement efforts, enabling organizations to respond dynamically to operational challenges and strategic opportunities.

Measuring Organizational Impact

A Master Black Belt’s effectiveness is measured not only by project completion but also by the tangible impact of initiatives on organizational performance. This includes operational metrics, financial outcomes, and improvements in customer satisfaction. To achieve this, Master Black Belts define key performance indicators (KPIs) at the outset of projects, aligning them with strategic goals and operational priorities. These metrics provide a quantitative basis for evaluating success, ensuring that initiatives deliver measurable and meaningful results.

Throughout the project lifecycle, Master Black Belts monitor progress rigorously, applying statistical techniques and real-time data analysis to assess performance. Adjustments are made as necessary to optimize outcomes, and results are communicated to stakeholders using clear, accessible formats such as dashboards and reports. Governance mechanisms, including project review committees and milestone assessments, provide additional oversight, reinforcing accountability and ensuring sustained impact.

Case studies illustrate the potential of Master Black Belt interventions. In manufacturing, for instance, a process optimization project might reduce defect rates by a significant percentage within six months, translating into substantial cost savings and efficiency gains. By documenting results, evaluating outcomes, and disseminating lessons learned, Master Black Belts ensure that improvements are institutionalized, replicable, and scalable across the organization.

Sustaining Continuous Improvement

Embedding continuous improvement into organizational culture is a central responsibility of Master Black Belts. This requires more than technical execution; it necessitates shaping behaviors, reinforcing best practices, and creating an environment in which iterative enhancement is habitual. By modeling analytical rigor, celebrating successes, and maintaining transparency, Master Black Belts demonstrate the value of systematic improvement and motivate teams to engage proactively.

Sustained engagement is supported through recurring initiatives such as workshops, internal knowledge-sharing forums, and recognition programs. These mechanisms reinforce methodological consistency, provide platforms for collaborative learning, and maintain momentum over time. By institutionalizing these practices, Master Black Belts cultivate a self-reinforcing culture in which operational excellence, innovation, and learning become embedded in daily routines, ensuring that gains are not ephemeral but enduring.

Overcoming Challenges in Complex Environments

Even with rigorous training and methodological expertise, Master Black Belts encounter challenges inherent to complex organizational environments. Resistance to change is a common barrier, as stakeholders may perceive Lean Six Sigma as constraining or intrusive. Master Black Belts address this by generating early, tangible successes that demonstrate value, building credibility and fostering trust. Incremental wins serve as proof points, reinforcing confidence in the methodology and motivating engagement across the organization.

Complex statistical tools can also intimidate team members, potentially limiting participation and buy-in. To mitigate this, Master Black Belts employ simplified explanations, practical examples, and hands-on exercises. By demystifying analytical methods, they empower teams to apply statistical tools effectively, reinforcing both competence and confidence.

Maintaining long-term engagement presents a further challenge. Master Black Belts address this by implementing recurring rituals, such as project reviews, newsletters, and recognition events. These practices sustain motivation, celebrate achievement, and foster a sense of shared purpose. By combining analytical expertise, strategic insight, and interpersonal dexterity, Master Black Belts overcome obstacles and drive initiatives that deliver sustainable impact.

Strategic Decision-Making and Organizational Resilience

A Master Black Belt’s influence extends beyond individual projects to the strategic resilience of the organization. By aligning process improvement initiatives with corporate objectives, Master Black Belts ensure that interventions contribute to operational stability, financial performance, and long-term adaptability. This alignment requires the integration of analytical insights, risk assessment, and strategic foresight, enabling organizations to anticipate challenges, allocate resources efficiently, and maintain competitive advantage.

Scenario planning, predictive modeling, and performance benchmarking are tools frequently employed by Master Black Belts to support strategic decision-making. These approaches enable leaders to evaluate potential outcomes, assess risk exposure, and prioritize initiatives that deliver maximal value. By embedding strategic thinking into Lean Six Sigma practice, Master Black Belts transform operational excellence from a reactive function into a proactive, resilient organizational capability.

Leadership and Strategic Oversight in Lean Six Sigma

The Master Black Belt embodies the intersection of technical mastery and organizational leadership. Beyond the execution of process improvement projects, this role encompasses strategic oversight, guiding initiatives that span multiple departments, functions, and business units. Leadership at this level demands a combination of vision, influence, and the ability to cultivate high-performing teams capable of navigating complex operational challenges.

A defining aspect of Master Black Belt leadership is the capacity to translate analytical insights into strategic action. While Black Belts and Green Belts focus on tactical problem-solving, Master Black Belts integrate process data with corporate objectives, aligning Lean Six Sigma projects with financial performance, operational resilience, and customer value. This alignment requires a nuanced understanding of organizational dynamics, resource constraints, and long-term priorities, enabling Master Black Belts to prioritize initiatives that yield the highest strategic benefit.

Influence is central to effective leadership in this role. Unlike traditional managers, Master Black Belts often lack formal authority over team members. Their capacity to guide projects and ensure alignment relies on persuasion, credibility, and the ability to foster trust. By demonstrating methodological rigor, articulating measurable outcomes, and securing early successes, Master Black Belts establish the authority needed to drive initiatives forward, ensuring that project goals are embraced by all stakeholders.

Coaching, Mentorship, and Knowledge Transmission

Mentorship is an essential dimension of Master Black Belt leadership. These practitioners serve as mentors to Black Belts and Green Belts, imparting technical expertise, guiding project execution, and fostering professional growth. Mentorship is structured, encompassing one-on-one coaching, team workshops, and immersive project-based learning. By embedding mentorship into organizational routines, Master Black Belts ensure the development of a pipeline of capable Lean Six Sigma practitioners.

Knowledge transmission is also a critical responsibility. Master Black Belts create repositories of best practices, case studies, and procedural guides that codify lessons learned from projects. This ensures that insights are preserved, disseminated, and applied across the organization, facilitating continuous improvement at scale. Documentation not only reinforces methodological consistency but also enhances organizational memory, allowing new teams to build upon prior successes without repeating mistakes.

Effective mentorship requires an understanding of both technical and interpersonal dynamics. Master Black Belts must assess the skill levels, motivations, and learning preferences of team members, adapting coaching methods to maximize engagement and comprehension. This nuanced approach enhances team autonomy, promotes confidence in decision-making, and strengthens the organization’s capacity to execute Lean Six Sigma initiatives independently.

Organizational Alignment and Strategic Integration

A key responsibility of the Master Black Belt is ensuring that process improvement initiatives are strategically aligned with organizational objectives. This entails integrating Lean Six Sigma projects into broader corporate strategy, assessing potential impact, and prioritizing initiatives according to both operational significance and expected return on investment.

Master Black Belts employ analytical frameworks to evaluate the relative importance of projects, balancing factors such as cost, effort, and potential benefits. This strategic lens ensures that resources are allocated effectively, enabling the organization to focus on initiatives that generate maximum value. In addition, Master Black Belts establish performance indicators and monitoring mechanisms to track project outcomes, ensuring that each initiative contributes measurably to corporate objectives.

Strategic integration also involves navigating organizational politics and fostering collaboration across departments. Master Black Belts engage with executives, project sponsors, and operational leaders to secure support, resolve conflicts, and align priorities. This coordination ensures that process improvement efforts are both feasible and impactful, reinforcing the organization’s capacity to achieve sustainable performance gains.

Technology Integration and Digital Transformation

Modern Master Black Belts leverage advanced technology to enhance the efficacy of Lean Six Sigma initiatives. Big data analytics, artificial intelligence, and machine learning are increasingly applied to identify process inefficiencies, predict outcomes, and optimize operational performance. By integrating these tools, Master Black Belts extend the analytical power of Lean Six Sigma beyond conventional statistical methods, enabling more accurate, scalable, and predictive process improvement efforts.

Predictive analytics, for example, allows organizations to anticipate operational disruptions and implement corrective measures before deviations occur. Machine learning algorithms can detect subtle patterns in complex datasets, revealing insights that inform decision-making and drive continuous improvement. These technologies enhance both the speed and precision of interventions, allowing organizations to respond dynamically to evolving operational challenges.

Digital dashboards and visualization tools facilitate communication and transparency. By presenting real-time metrics in accessible formats, Master Black Belts ensure that teams and stakeholders can monitor progress, identify trends, and make informed decisions quickly. This integration of technology into Lean Six Sigma practice enhances organizational agility, enabling continuous adaptation and improvement in a rapidly changing business environment.

Measuring Performance and Quantifying Impact

Master Black Belts are accountable for demonstrating the measurable impact of Lean Six Sigma initiatives. This requires defining key performance indicators (KPIs) at the project’s outset, aligning metrics with strategic goals, and rigorously monitoring outcomes throughout the DMAIC process. Performance measurement encompasses operational efficiency, defect reduction, cost savings, and customer satisfaction, among other factors.

By tracking KPIs systematically, Master Black Belts ensure transparency, accountability, and continuous improvement. Real-time monitoring and regular reporting allow for course corrections, enabling teams to optimize interventions and maximize results. Governance mechanisms, including review committees, milestone assessments, and executive reporting, reinforce oversight and accountability, ensuring that projects deliver both tangible and sustainable value to the organization.

Case studies illustrate the potential impact of Master Black Belt initiatives. In complex manufacturing environments, process optimization projects led by Master Black Belts have resulted in substantial reductions in defect rates, enhanced cycle times, and significant cost savings. These outcomes not only validate the methodology but also reinforce the strategic value of Lean Six Sigma initiatives, demonstrating their contribution to long-term organizational performance.

Advanced Problem-Solving and Root Cause Analysis

Master Black Belts employ sophisticated problem-solving techniques to identify and address underlying causes of inefficiencies and defects. Tools such as root cause analysis, failure modes and effects analysis (FMEA), and process mapping enable practitioners to dissect complex systems and uncover hidden sources of variation. This analytical depth ensures that interventions are targeted, effective, and sustainable.

Root cause analysis involves a systematic examination of processes to determine the factors contributing to undesirable outcomes. Master Black Belts leverage statistical tools, observational data, and cross-functional collaboration to identify patterns, validate hypotheses, and design corrective actions. By addressing fundamental causes rather than symptoms, Master Black Belts prevent recurrence of issues and achieve lasting improvements in operational performance.

Advanced problem-solving also involves scenario modeling and risk assessment. Master Black Belts evaluate potential interventions, assess feasibility, and prioritize solutions based on anticipated impact. This strategic approach ensures that resources are allocated efficiently and that improvements deliver measurable value to the organization.

Enhancing Organizational Resilience

The Master Black Belt’s influence extends beyond operational improvement to organizational resilience. By optimizing processes, embedding continuous improvement, and fostering strategic alignment, Master Black Belts enhance the organization’s capacity to adapt to change, mitigate risk, and sustain performance under varying conditions.

Resilient organizations anticipate challenges, respond proactively to disruptions, and maintain operational continuity. Master Black Belts contribute to this resilience by integrating predictive analytics, scenario planning, and risk management into Lean Six Sigma practice. Their strategic perspective ensures that process improvements are not only effective in the short term but also durable and adaptable, providing a foundation for long-term organizational success.

Real-World Applications of Master Black Belt Expertise

The Master Black Belt’s impact is most evident when theoretical knowledge is translated into practical, real-world applications. In diverse organizational settings—ranging from manufacturing and logistics to healthcare and service industries—Master Black Belts deploy Lean Six Sigma methodologies to address operational inefficiencies, enhance quality, and optimize resource utilization. The real-world application of their expertise requires not only technical mastery but also the ability to navigate complex organizational dynamics and adapt methodologies to contextual nuances.

In manufacturing, Master Black Belts systematically analyze production lines, identifying bottlenecks and inefficiencies that reduce throughput or compromise quality. Using value stream mapping, they uncover latent process flaws and design interventions that eliminate waste, standardize procedures, and enhance flow. Advanced statistical tools, predictive analytics, and real-time monitoring are integrated into these interventions to ensure precision and sustainability. The resulting improvements frequently include reductions in defect rates, shortened cycle times, and enhanced operational efficiency.

In service-oriented organizations, Master Black Belts focus on process consistency, customer satisfaction, and service delivery optimization. They examine end-to-end workflows to identify delays, redundancies, or variations in service quality. Tools such as process mapping, root cause analysis, and FMEA enable the identification of critical failure points. Interventions may include standardization of procedures, implementation of error-proofing techniques, and the use of digital tools to streamline operations. By applying Lean Six Sigma principles in service contexts, Master Black Belts improve reliability, enhance customer experience, and increase operational agility.

Best Practices for Sustainable Improvement

Sustainability is a core principle of Master Black Belt practice. Ensuring that process improvements endure requires meticulous planning, rigorous monitoring, and the codification of knowledge. Best practices in this domain include structured documentation, continuous mentoring, and the integration of lessons learned into standard operating procedures.

Documentation involves creating comprehensive guides, case studies, and procedural manuals that capture methodologies, project outcomes, and insights. By making this knowledge accessible, Master Black Belts ensure that improvements are replicable across teams and departments. Documentation also facilitates audits, compliance, and training for new employees, reinforcing the organization’s capacity to maintain high performance standards over time.

Mentoring remains a central pillar of sustainable improvement. Through structured coaching sessions, workshops, and project oversight, Master Black Belts cultivate the skills of Black Belts and Green Belts, enabling them to apply Lean Six Sigma methodologies independently. This mentorship not only strengthens team capability but also propagates a culture of analytical rigor and continuous improvement throughout the organization.

Leveraging Data for Continuous Enhancement

Data-driven decision-making is at the heart of Master Black Belt methodology. Real-time data collection, advanced analytics, and predictive modeling allow Master Black Belts to monitor process performance continuously, detect anomalies, and optimize interventions proactively. The integration of big data analytics and machine learning has expanded the scope of Lean Six Sigma, enabling practitioners to anticipate inefficiencies, forecast operational trends, and refine processes dynamically.

Predictive analytics can identify patterns that precede quality issues or operational delays, allowing organizations to intervene before deviations occur. Machine learning algorithms can process vast datasets, uncovering relationships and correlations that inform targeted improvement strategies. By harnessing these capabilities, Master Black Belts ensure that Lean Six Sigma initiatives evolve from reactive problem-solving approaches into proactive, predictive, and adaptive systems.

Dashboards and visualization tools are critical for communicating insights effectively. They provide stakeholders with accessible, real-time views of key metrics, facilitating transparency, alignment, and informed decision-making. By combining rigorous analysis with clear communication, Master Black Belts enhance both operational efficiency and organizational agility.

Aligning Projects with Organizational Strategy

Master Black Belts ensure that process improvement initiatives are closely aligned with broader corporate objectives. Strategic alignment requires understanding organizational priorities, assessing potential project impact, and allocating resources to initiatives that generate the greatest value. By linking process improvements to financial performance, customer satisfaction, and operational resilience, Master Black Belts ensure that Lean Six Sigma efforts contribute meaningfully to long-term organizational success.

Analytical tools such as effort-benefit scoring and portfolio analysis are employed to prioritize projects based on expected return and strategic relevance. This structured approach ensures that resources are deployed effectively and that initiatives with the highest potential impact receive appropriate attention. Additionally, Master Black Belts continuously monitor and evaluate project outcomes, adjusting interventions to maintain alignment with evolving organizational goals.

Strategic alignment also involves stakeholder engagement. Master Black Belts communicate project goals, anticipated benefits, and performance metrics to executives, sponsors, and operational teams, securing buy-in and facilitating collaboration. This ensures that projects are not only technically sound but also strategically meaningful, reinforcing the organization’s commitment to continuous improvement and operational excellence.

Overcoming Organizational Challenges

Even with expertise and strategic foresight, Master Black Belts encounter challenges inherent to organizational environments. Resistance to change, complexity of statistical tools, and long-term engagement are common obstacles. Master Black Belts employ structured strategies to address these challenges effectively.

Resistance to change is mitigated by demonstrating early, visible successes. Small-scale interventions that produce measurable improvements help build trust and credibility, encouraging broader adoption of Lean Six Sigma practices. Clear communication of benefits, inclusive planning, and active involvement of stakeholders further reduce resistance, fostering a culture that embraces methodological rigor and continuous improvement.

Complex statistical tools and methodologies can intimidate team members. Master Black Belts address this through simplified explanations, practical examples, and hands-on exercises, ensuring that analytical techniques are accessible and comprehensible. By demystifying statistical processes, they empower teams to engage confidently in data-driven problem solving, reinforcing both capability and confidence.

Long-term engagement is sustained through recurring initiatives such as workshops, knowledge-sharing sessions, and recognition programs. These practices celebrate achievements, reinforce methodological consistency, and maintain motivation over time. By combining technical expertise, strategic insight, and interpersonal skill, Master Black Belts ensure that Lean Six Sigma initiatives remain effective, impactful, and enduring.

Integrating Artificial Intelligence and Emerging Technologies

The integration of emerging technologies is a defining characteristic of modern Master Black Belt practice. Artificial intelligence, machine learning, and big data analytics enhance the precision, scalability, and predictive capacity of Lean Six Sigma initiatives. Master Black Belts employ these tools to detect inefficiencies, anticipate operational deviations, and optimize processes in real time.

Machine learning algorithms can identify subtle trends within complex datasets, revealing insights that traditional statistical methods may overlook. Predictive analytics supports proactive interventions, allowing organizations to address potential issues before they manifest. Big data analytics facilitates comprehensive evaluation of large-scale operations, enabling strategic resource allocation and continuous process refinement.

Digital tools also enhance communication and transparency. Real-time dashboards, automated reports, and interactive visualization platforms allow stakeholders to track progress, analyze trends, and make informed decisions. By combining technological sophistication with methodological rigor, Master Black Belts increase the effectiveness, adaptability, and sustainability of process improvement initiatives.

Measuring and Sustaining Impact

A critical responsibility of Master Black Belts is to quantify the impact of Lean Six Sigma initiatives and ensure the sustainability of improvements. This begins with the establishment of key performance indicators (KPIs) aligned with strategic objectives. KPIs may include defect reduction, cycle time improvement, cost savings, operational efficiency, and customer satisfaction metrics.

Master Black Belts monitor these indicators throughout the DMAIC process, using statistical tools and real-time data to assess progress and refine interventions. Governance mechanisms, such as review committees and milestone evaluations, provide oversight and ensure accountability. Documentation of results, lessons learned, and procedural changes further institutionalizes improvements, creating a framework for ongoing success.

Sustainability is reinforced through structured mentoring, knowledge dissemination, and the establishment of standard operating procedures. By embedding lessons learned into organizational routines, Master Black Belts ensure that improvements persist beyond the immediate project lifecycle. This approach transforms short-term gains into long-term organizational capability, fostering a culture of continuous improvement and operational excellence.

Preparing for Future Challenges

Master Black Belts anticipate and prepare for future organizational challenges. By integrating predictive analytics, scenario planning, and risk assessment into Lean Six Sigma initiatives, they ensure that organizations are resilient, adaptable, and capable of sustaining high performance under variable conditions.

This proactive approach allows organizations to respond effectively to market shifts, operational disruptions, and emerging risks. Master Black Belts leverage their analytical expertise, strategic insight, and leadership skills to design interventions that not only optimize current processes but also fortify the organization against future uncertainties. By aligning improvement initiatives with long-term objectives, they ensure that operational excellence is both sustainable and adaptable.

Conclusion

The Master Black Belt embodies the highest level of Lean Six Sigma expertise, merging technical mastery, strategic vision, leadership, and innovative problem-solving. This role extends beyond executing projects, encompassing organizational transformation, mentoring future practitioners, and embedding a culture of continuous improvement. Through advanced statistical analysis, Lean principles, and technology integration, Master Black Belts optimize processes, reduce inefficiencies, and enhance operational resilience. Their influence ensures that initiatives align with corporate objectives, deliver measurable value, and sustain long-term performance gains. By fostering collaboration, communicating effectively with stakeholders, and overcoming resistance to change, they create environments where improvement becomes habitual and scalable. Ultimately, the Master Black Belt is both a practitioner and a visionary, driving tangible results while shaping the organization’s capability to adapt, innovate, and thrive. Their work leaves a lasting legacy of efficiency, quality, and strategic agility that permeates every level of the enterprise.