Exam Code: CLSSBB

Exam Name: Certified Lean Six Sigma Black Belt

Corresponding Certification: CLSSBB

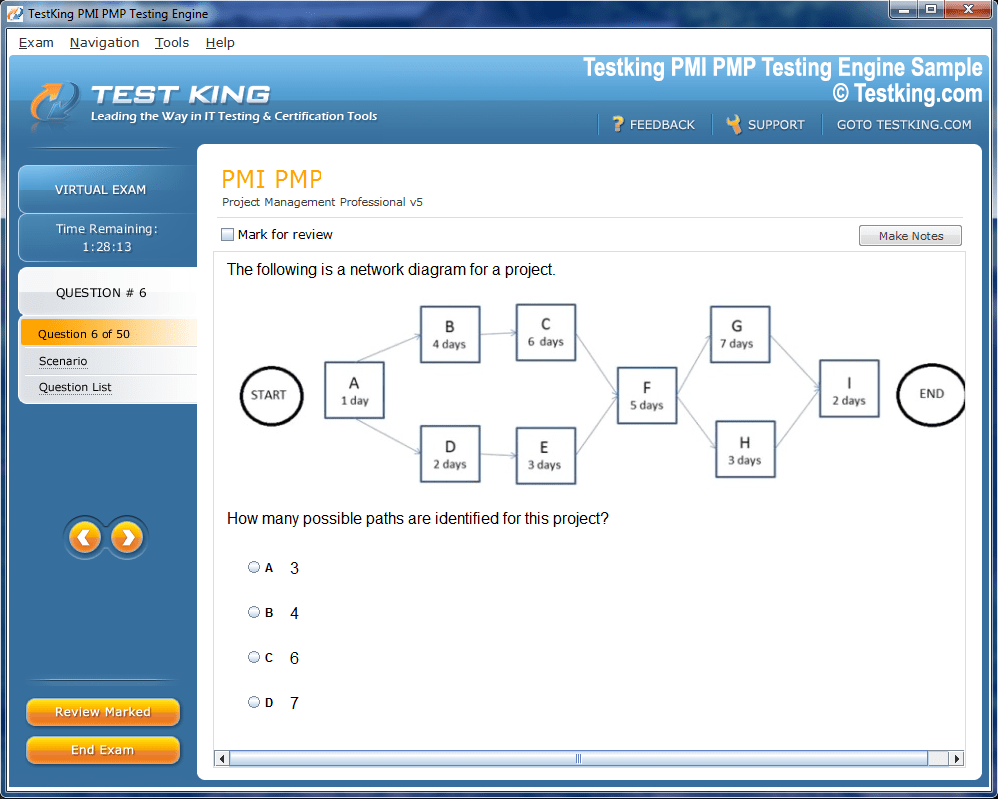

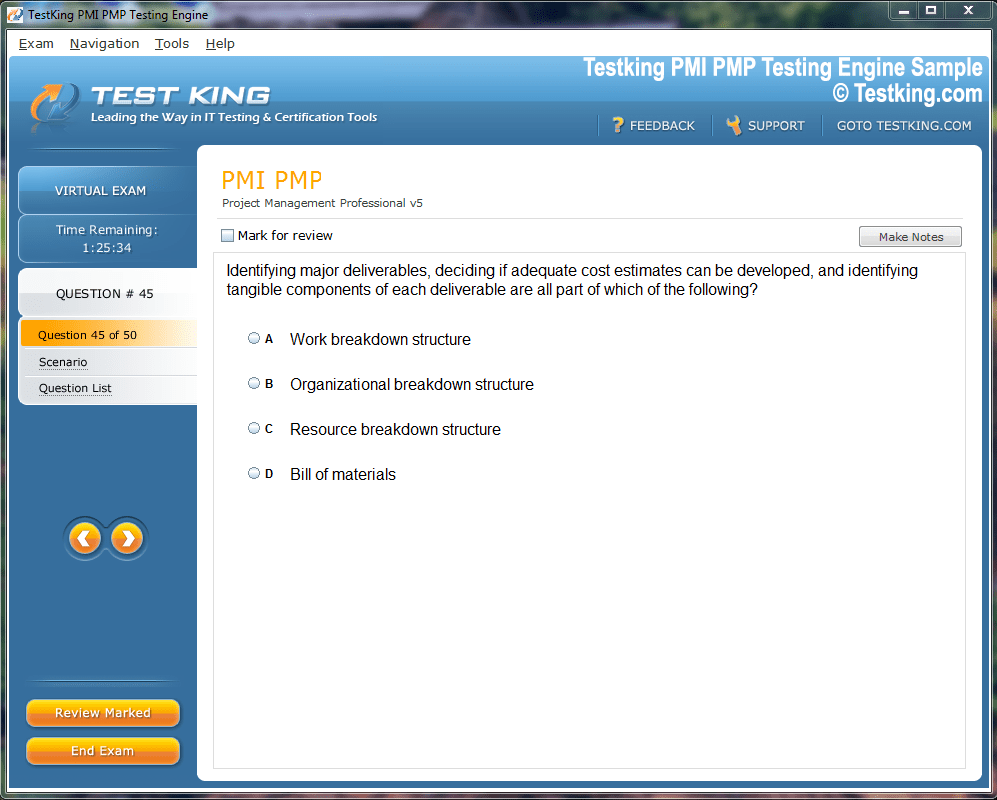

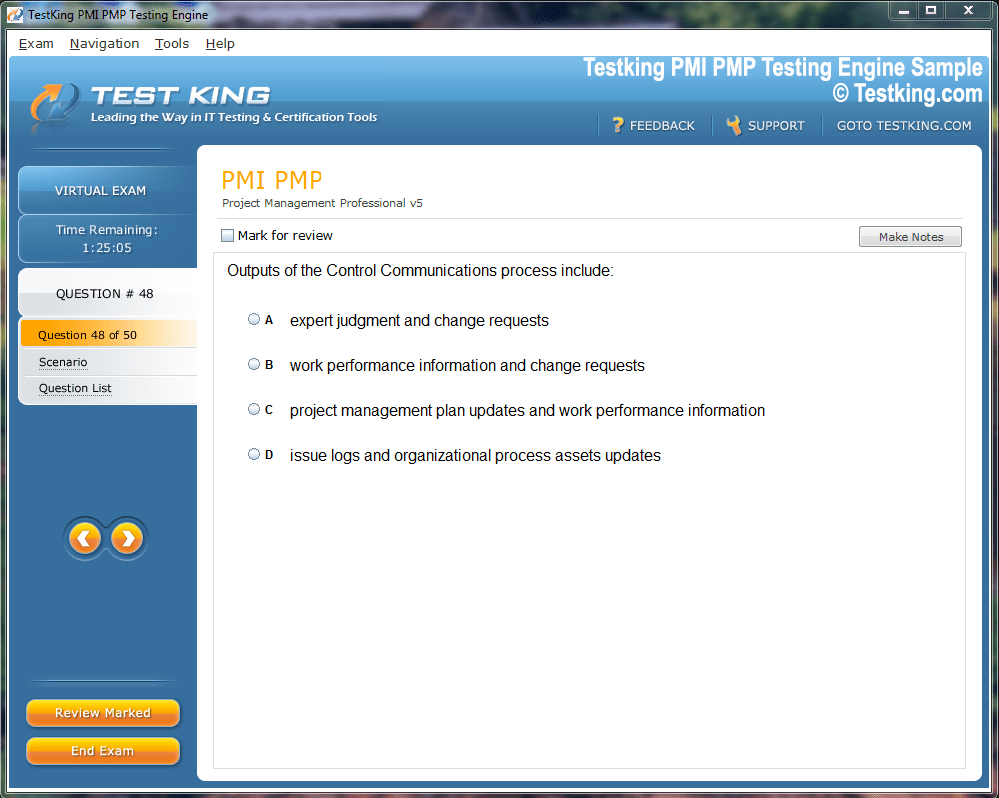

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our CLSSBB testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top GAQM Exams

Driving Organizational Success with GAQM CLSSBB Certification

In the modern era of relentless global competition, organizations across industries confront a formidable challenge: they must continuously refine operations, reduce inefficiencies, and exceed rising customer expectations. The marketplace has little tolerance for stagnation, and enterprises that fail to evolve often find themselves eclipsed by more nimble rivals. Against this backdrop, the Lean Six Sigma Black Belt certification—often abbreviated as CLSSBB—has emerged as a vital credential for professionals committed to mastering the art and science of process optimization.

This certification represents a synthesis of two influential paradigms: Lean and Six Sigma. Together, these approaches create a robust framework for improving quality, cutting costs, and enhancing overall organizational agility. While countless methodologies claim to drive performance gains, few possess the documented history and methodical rigor that characterize Lean Six Sigma. Understanding its core principles and how the Black Belt credential fits into the broader landscape of operational excellence is essential for anyone intent on spearheading transformative change.

The Imperative of Continuous Improvement

The corporate world is defined by rapid technological advancements, shifting customer preferences, and volatile economic conditions. Under such circumstances, incremental adjustments are rarely sufficient. Companies require a disciplined approach to continuous improvement—one that not only identifies problems but systematically eliminates their root causes. Lean Six Sigma offers such a path.

The Black Belt designation within this methodology is more than a mere title. It signals that an individual possesses deep analytical capabilities, leadership acumen, and the capacity to manage complex projects from inception to completion. Those who attain this level of expertise are frequently entrusted with high-stakes initiatives aimed at driving efficiency, elevating quality, and strengthening competitiveness.

Origins of Lean and Six Sigma

To appreciate the significance of the Black Belt certification, it is useful to understand the lineage of its two foundational components.

Lean principles trace their heritage to early 20th-century manufacturing, most famously refined within the Toyota Production System. Lean focuses on the relentless eradication of waste—any activity or resource that fails to add value from the customer’s perspective. By streamlining workflows, eliminating unnecessary steps, and enhancing process flow, Lean methods cultivate a culture of efficiency and responsiveness.

Six Sigma, meanwhile, emerged in the late 1980s at Motorola as a data-driven approach to minimizing defects and variability in production and service delivery. Its statistical rigor enables organizations to identify process deviations and measure performance with extraordinary precision, striving for no more than 3.4 defects per million opportunities. While Lean emphasizes speed and waste reduction, Six Sigma zeroes in on quality and consistency.

The marriage of these two methodologies into Lean Six Sigma creates a powerful, synergistic framework. It combines Lean’s focus on speed and efficiency with Six Sigma’s commitment to precision and defect reduction, offering organizations a comprehensive strategy for continuous improvement.

Black Belt: The Apex of Professional Mastery

Within the Lean Six Sigma hierarchy, the Black Belt represents an advanced level of mastery. Professionals who earn this credential demonstrate not only technical proficiency but also the capacity to guide teams through multifaceted improvement projects. They are adept at using sophisticated statistical tools, leading cross-functional groups, and translating analytical insights into actionable strategies.

The pathway to becoming a Black Belt typically builds upon earlier experience, often beginning with Green Belt training or equivalent exposure to process-improvement projects. Black Belts are expected to exhibit both a deep understanding of Lean Six Sigma principles and a track record of applying them to achieve measurable results.

Why the Black Belt Matters in Today’s Economy

In an age defined by global supply chains, complex service networks, and rapid technological disruption, organizations cannot afford inefficiency. The Lean Six Sigma Black Belt certification equips professionals to address these challenges with methodical precision. Whether in manufacturing, healthcare, finance, or technology, the skills honed through Black Belt training are universally applicable.

Consider the pressures facing a modern healthcare provider. Patient expectations for quality and speed of service have never been higher, while regulatory requirements grow more intricate. A Black Belt professional in this environment might lead initiatives to streamline patient intake processes, reduce wait times, and eliminate redundant paperwork—achieving improvements that benefit both patients and staff. Similarly, in a manufacturing setting, Black Belts may spearhead projects that curtail production defects, reduce inventory waste, and optimize supply chain logistics.

These examples underscore how the Black Belt credential serves as both a career catalyst and a means of driving organizational transformation. The ability to systematically identify inefficiencies and implement sustainable improvements is invaluable in virtually every industry.

Key Attributes of a Lean Six Sigma Black Belt

Attaining the Black Belt designation requires more than technical knowledge. Successful practitioners embody a blend of analytical insight, leadership capability, and interpersonal finesse. Some of the essential attributes include:

Analytical Acumen: Black Belts must be proficient in statistical methods, data interpretation, and the application of complex tools such as regression analysis, design of experiments, and hypothesis testing.

Leadership and Mentorship: These professionals often guide project teams that span multiple departments. Strong communication skills, the ability to inspire others, and a talent for conflict resolution are indispensable.

Strategic Thinking: Beyond executing tactical improvements, Black Belts align their projects with broader organizational goals, ensuring that each initiative contributes to long-term strategic objectives.

Change Management Skills: Implementing process changes frequently encounters resistance. Effective Black Belts anticipate challenges, manage stakeholder expectations, and cultivate buy-in across all levels of an organization.

These characteristics distinguish Black Belts as transformative figures who bridge the gap between technical analysis and practical execution.

From Theory to Application

One of the defining features of Lean Six Sigma is its emphasis on measurable outcomes. Black Belt professionals do not simply theorize about potential improvements; they deliver tangible results. Projects are typically guided by the DMAIC framework—Define, Measure, Analyze, Improve, and Control—which ensures a structured approach to problem-solving.

For instance, a logistics company struggling with late deliveries might begin by defining the specific issue, measuring current performance metrics, analyzing the root causes of delays, implementing targeted improvements, and establishing controls to sustain the gains. The disciplined application of DMAIC provides a replicable template for success, regardless of industry.

A Credential with Global Recognition

The Lean Six Sigma Black Belt certification enjoys widespread recognition across continents and sectors. Multinational corporations, mid-sized firms, and even public-sector agencies view it as a reliable indicator of advanced process-improvement capability. This global acceptance enhances the credential’s value, allowing certified professionals to pursue opportunities in diverse geographic regions and professional arenas.

Moreover, the credential’s focus on measurable outcomes resonates with organizations that prioritize evidence-based decision-making. By emphasizing data-driven analysis and verifiable results, the Black Belt certification aligns perfectly with contemporary business imperatives.

Personal and Organizational Benefits

While the Black Belt designation offers obvious advantages to employers—such as cost savings and quality enhancements—it also delivers significant benefits to the individuals who earn it. Certified professionals often report increased career mobility, higher earning potential, and a heightened sense of professional credibility. The rigorous training fosters a mindset of continuous learning and critical thinking that extends beyond the workplace, enhancing problem-solving abilities in many facets of life.

For organizations, employing Black Belt practitioners can translate into substantial financial gains. Projects led by these experts frequently yield dramatic reductions in operational costs, improvements in customer satisfaction, and more agile responses to market changes. In many cases, the return on investment from employing or developing Black Belt professionals far exceeds the initial training costs.

Adapting to a Dynamic Future

The relevance of Lean Six Sigma Black Belt expertise is unlikely to wane. If anything, the rise of digital technologies, automation, and artificial intelligence amplifies the need for structured process improvement. As industries incorporate advanced analytics and machine learning into daily operations, professionals with a grounding in Lean Six Sigma principles are uniquely positioned to integrate these innovations into a coherent strategy.

Future Black Belts may find themselves applying their skills not only to traditional manufacturing or service processes but also to data-driven environments, where predictive analytics and real-time monitoring redefine efficiency. Their ability to interpret complex data sets and translate insights into practical improvements will remain a cornerstone of organizational success.

Lean Six Sigma Black Belt Methodology and Foundational Principles

Lean Six Sigma Black Belt certification is more than a title; it represents mastery of a disciplined methodology designed to drive measurable improvement. The core principles behind this approach blend two historically proven strategies—Lean, which emphasizes waste reduction, and Six Sigma, which focuses on minimizing variation. This synthesis creates a holistic framework capable of transforming complex business processes across industries, from manufacturing to healthcare, finance, and technology. Understanding the methodology’s foundational elements is crucial for anyone seeking to develop expertise in process optimization and operational excellence.

The Dual Pillars: Lean and Six Sigma

Lean and Six Sigma, while complementary, address different aspects of process performance. Lean methodology originated from the Toyota Production System and prioritizes efficiency by eliminating activities that do not add value. It seeks to create a seamless workflow, reducing delays, redundancies, and unnecessary steps. Concepts such as value stream mapping, 5S workplace organization, and just-in-time production exemplify Lean’s focus on streamlining operations.

Six Sigma, in contrast, arose as a statistical approach to process improvement, primarily in manufacturing but later expanded into services. Its objective is to reduce defects and process variation through data-driven analysis. The Six Sigma methodology uses precise measurement and quantitative techniques to uncover root causes of inefficiencies. Statistical tools, including control charts, process capability analysis, and hypothesis testing, are employed to ensure process consistency and performance predictability.

By integrating these two philosophies, Lean Six Sigma achieves both efficiency and quality. Lean accelerates workflow and reduces waste, while Six Sigma ensures accuracy, consistency, and minimal variation. Black Belt professionals are trained to leverage both paradigms simultaneously, creating an approach that is rigorous, scalable, and repeatable.

DMAIC Framework: The Backbone of Process Improvement

At the heart of Lean Six Sigma methodology lies the DMAIC framework, which stands for Define, Measure, Analyze, Improve, and Control. This structured problem-solving approach provides a roadmap for process improvement initiatives and is fundamental to the work of a Black Belt.

Define: This initial phase involves identifying the problem or opportunity for improvement, outlining project goals, and defining the scope. A clear definition ensures alignment between organizational objectives and project outcomes. Black Belts must also identify stakeholders, establish a project charter, and set measurable objectives.

Measure: Accurate measurement is critical for understanding current performance. Data collection strategies are designed to capture relevant process metrics. Measurement not only establishes a baseline but also ensures that improvements can be quantified objectively. Black Belts employ tools like process mapping, data collection plans, and measurement system analysis to ensure data integrity.

Analyze: During the analysis phase, Black Belts investigate the underlying causes of process inefficiencies. Statistical analysis and root cause identification techniques, such as cause-and-effect diagrams, Pareto charts, and regression analysis, are employed to determine what drives defects or delays. The goal is to separate symptoms from root causes, providing actionable insights for improvement.

Improve: The improvement phase involves designing and implementing solutions to address the identified root causes. Lean tools such as kaizen events, standardized work, and error-proofing (poka-yoke) often complement Six Sigma statistical strategies. Black Belts lead pilot projects, test solutions, and refine interventions to maximize impact while minimizing unintended consequences.

Control: Sustaining improvements is as important as achieving them. The control phase focuses on monitoring the implemented changes, creating standardized procedures, and establishing metrics for ongoing performance management. Control charts, audits, and training programs are used to ensure that gains are maintained and that processes do not revert to prior inefficiencies.

Key Lean Tools and Concepts

Black Belt professionals must possess a thorough understanding of Lean tools, which provide practical means for enhancing workflow efficiency. Some of the most widely used include:

5S (Sort, Set in Order, Shine, Standardize, Sustain): A systematic approach to workplace organization and efficiency.

Value Stream Mapping: Visualizes the flow of materials and information, identifying waste and bottlenecks.

Kaizen: A philosophy of continuous incremental improvement that encourages employees to propose enhancements.

Just-in-Time (JIT): A methodology aimed at reducing inventory costs and delivering products only as needed.

Poka-Yoke: Error-proofing techniques designed to prevent defects from occurring.

These tools are applied across industries to enhance productivity, reduce lead times, and eliminate activities that do not contribute value from the customer’s perspective.

Core Six Sigma Techniques

Six Sigma provides the analytical rigor necessary to understand variability and ensure predictable outcomes. Black Belts employ a range of statistical tools to achieve these objectives:

Control Charts: Monitor process stability and detect variation.

Process Capability Analysis: Evaluates whether a process can consistently meet specifications.

Design of Experiments (DOE): Identifies relationships between variables and optimizes process parameters.

Hypothesis Testing: Assesses assumptions about processes, ensuring improvements are statistically valid.

Root Cause Analysis: Identifies the underlying factors contributing to defects or inefficiencies.

Mastery of these techniques allows Black Belts to quantify performance, validate improvement strategies, and make evidence-based decisions that drive sustainable results.

Leadership and Change Management

A distinctive feature of Black Belt professionals is their dual role as both technical experts and change leaders. While proficiency in analytical tools is essential, the ability to lead teams, manage stakeholders, and navigate organizational dynamics is equally critical. Black Belts are often responsible for cross-functional projects that require collaboration between departments, each with its own priorities and constraints.

Effective leadership involves several key competencies:

Communication Skills: Clearly articulating complex data, explaining improvement strategies, and engaging diverse stakeholders.

Coaching and Mentorship: Guiding team members through Lean Six Sigma processes, ensuring skill transfer and capability building.

Conflict Resolution: Addressing resistance and reconciling differing perspectives to maintain project momentum.

Strategic Alignment: Ensuring that improvement initiatives align with broader organizational goals and deliver measurable value.

Change management is integral to sustaining improvements. Black Belts must anticipate resistance, address concerns, and foster a culture that embraces continuous enhancement. Through structured interventions and active stakeholder engagement, they increase the likelihood that improvements are adopted and maintained over the long term.

Project Management in Lean Six Sigma

Successful Black Belt projects require more than analytical insight—they necessitate disciplined project management. Black Belts must define clear objectives, allocate resources effectively, and monitor progress against milestones. This combination of project management and technical expertise ensures that initiatives deliver tangible results on time and within budget.

Critical project management activities include:

Developing a detailed project charter with objectives, scope, and timelines.

Identifying and mitigating risks that could compromise project outcomes.

Tracking performance metrics and making adjustments to maintain alignment with goals.

Reporting progress to stakeholders and ensuring accountability at all levels.

Practical Application Across Industries

Lean Six Sigma Black Belt methodology is remarkably versatile, allowing application in virtually any organizational context. In manufacturing, Black Belts streamline production lines, reduce defect rates, and optimize inventory management. In healthcare, they improve patient flow, reduce errors, and enhance service quality. In finance and insurance, process analysis minimizes transactional errors, accelerates response times, and ensures regulatory compliance.

Even in emerging technology sectors, Lean Six Sigma principles can enhance operational efficiency, from optimizing software development workflows to improving data processing pipelines. The methodology’s adaptability ensures that Black Belts remain valuable assets, capable of applying structured problem-solving in diverse environments.

Integration of Technology and Analytics

The modern Black Belt operates in a data-rich environment. Advanced analytics, business intelligence tools, and automation are increasingly integrated with Lean Six Sigma practices. Predictive modeling and machine learning can complement traditional statistical methods, enabling professionals to anticipate process deviations before they occur. Digital dashboards and real-time monitoring systems enhance visibility, allowing for more proactive management and faster corrective actions.

Black Belts must therefore cultivate not only statistical expertise but also a comfort with digital tools that expand the scope and impact of process improvement initiatives. This integration ensures that Lean Six Sigma remains relevant in the era of digital transformation.

Developing a Problem-Solving Mindset

At its core, Lean Six Sigma Black Belt methodology fosters a disciplined approach to problem-solving. Practitioners learn to frame problems clearly, gather relevant data, and analyze information with rigor. Solutions are designed to be evidence-based, tested in real-world contexts, and sustained through structured control mechanisms.

This mindset extends beyond technical projects. Black Belts often apply these skills to strategic planning, operational decision-making, and organizational development, demonstrating that the methodology is as much about thinking systematically as it is about implementing tools.

Benefits of Lean Six Sigma Black Belt Certification for Professionals and Organizations

Lean Six Sigma Black Belt certification represents a synthesis of advanced analytical capability, leadership skill, and process improvement expertise. Beyond the prestige of the credential, it delivers measurable benefits to both professionals and the organizations they serve. The certification distinguishes individuals as leaders in operational excellence, equipping them to implement strategies that improve quality, enhance efficiency, and deliver sustained business impact. Understanding these benefits is essential to appreciating the significance of pursuing the Black Belt credential.

Career Advancement and Professional Recognition

Achieving Black Belt certification positions professionals as subject matter experts capable of leading high-stakes initiatives. This expertise often translates into elevated roles within organizations, including managerial and executive positions. Certified Black Belts frequently oversee cross-functional teams and direct complex projects, which cultivates leadership experience and organizational influence.

Recognition as a Black Belt professional also conveys credibility. Colleagues and supervisors acknowledge the individual’s ability to apply rigorous analytical techniques, manage intricate processes, and drive results. The credential signals a commitment to operational excellence and continuous learning, which can distinguish professionals in competitive labor markets. This enhanced visibility often opens doors to new responsibilities, challenging assignments, and opportunities for career progression that might otherwise remain inaccessible.

Increased Earning Potential

The specialized skills developed through Black Belt training carry tangible economic value. Organizations are willing to compensate individuals who can deliver measurable improvements in efficiency, quality, and cost reduction. Studies and industry reports indicate that Black Belt professionals often command salaries above industry averages due to their ability to influence performance outcomes.

Earning potential is also influenced by the scope of impact associated with Black Belt projects. Professionals who successfully implement process improvements that generate significant cost savings or revenue growth enhance their value proposition. Over time, the financial benefits of holding a Black Belt certification may include higher base salaries, performance-based incentives, and accelerated career advancement opportunities.

Enhanced Analytical and Problem-Solving Skills

Lean Six Sigma Black Belt training is grounded in rigorous data analysis and structured problem-solving. Professionals learn to collect, interpret, and leverage quantitative and qualitative data to identify inefficiencies and develop practical solutions. This analytical foundation enables individuals to dissect complex problems, determine root causes, and design interventions that are both effective and sustainable.

Beyond technical proficiency, Black Belts cultivate a mindset of systematic inquiry. They approach challenges with a structured methodology, ensuring that decisions are evidence-based rather than intuitive. This skill set extends beyond organizational projects, enhancing personal decision-making, strategic thinking, and the ability to navigate complex environments.

Leadership and Team Management Abilities

Black Belt professionals are not only analytical experts but also leaders capable of guiding teams through challenging initiatives. Training emphasizes the importance of interpersonal skills, including communication, negotiation, and coaching. Effective leadership ensures that team members understand their roles, are motivated to contribute, and collaborate to achieve project objectives.

Managing cross-functional projects often involves navigating differing perspectives and priorities. Black Belts develop the ability to align stakeholders, mitigate conflicts, and maintain focus on project goals. These leadership competencies extend beyond specific projects, enhancing the individual’s ability to influence organizational culture, foster collaboration, and drive strategic initiatives.

Contribution to Organizational Success

The impact of Black Belt professionals on organizational performance can be profound. By applying Lean Six Sigma principles, they identify inefficiencies, reduce process variation, and optimize operations. The resulting improvements often lead to tangible outcomes such as cost reduction, increased productivity, improved product quality, and enhanced customer satisfaction.

Organizations benefit not only from project-specific results but also from the broader cultural influence of Black Belt practitioners. These professionals champion a data-driven, results-oriented approach to problem-solving, promoting continuous improvement across departments. Over time, their efforts can create a ripple effect, fostering a culture that prioritizes efficiency, quality, and measurable outcomes.

Efficiency and Process Optimization

One of the primary benefits of Black Belt expertise is the ability to streamline operations. Professionals trained in Lean principles systematically eliminate waste—non-value-added activities that consume resources without contributing to outcomes. This includes reducing excess inventory, minimizing redundant steps, and optimizing workflow patterns. Combined with Six Sigma’s focus on process variation, Black Belts enhance both the speed and reliability of operations.

Efficiency gains can extend to multiple dimensions of an organization, including production cycles, service delivery, supply chain management, and administrative processes. Black Belts approach these areas holistically, identifying interconnected inefficiencies and implementing solutions that improve performance across the enterprise.

Quality Improvement and Defect Reduction

Lean Six Sigma Black Belt professionals are uniquely equipped to reduce defects and improve quality. By employing statistical analysis and rigorous measurement techniques, they identify variability in processes and develop interventions to achieve consistent results. The reduction of errors, defects, or deviations enhances customer satisfaction, strengthens brand reputation, and reduces costs associated with rework or warranty claims.

Quality improvements are not limited to tangible products. Service-oriented organizations also benefit from enhanced accuracy, timeliness, and consistency in service delivery. Black Belts play a critical role in establishing standard operating procedures, monitoring performance metrics, and ensuring that improvements are sustained over time.

Strategic Alignment and Decision Support

Black Belt professionals serve as strategic partners within organizations. Their work ensures that process improvement initiatives align with broader business objectives, creating a direct link between operational performance and strategic outcomes. By analyzing data and quantifying improvements, they provide leadership with actionable insights that inform decision-making and resource allocation.

The ability to translate complex analytical findings into strategic recommendations distinguishes Black Belts as valuable contributors to organizational planning. Executives rely on their insights to prioritize initiatives, allocate capital effectively, and anticipate potential risks. This strategic contribution reinforces the Black Belt’s role as both a technical expert and a trusted advisor.

Versatility Across Industries

The methodologies mastered by Black Belt professionals are highly adaptable, making the credential relevant across diverse sectors. In manufacturing, Black Belts optimize production lines, reduce scrap, and enhance throughput. In healthcare, they streamline patient care processes, improve compliance, and elevate service quality. In financial services, they enhance transaction accuracy, reduce processing times, and ensure regulatory adherence. Technology firms benefit from Black Belts’ ability to optimize development cycles, improve data workflows, and implement operational standards.

This cross-industry applicability ensures that Black Belt certification provides enduring value, allowing professionals to transition between sectors while maintaining the relevance of their skills.

Risk Reduction and Problem Prevention

A key aspect of Black Belt expertise is the capacity to anticipate and mitigate risks. Through rigorous analysis and process monitoring, professionals identify potential failure points before they escalate. This proactive approach prevents costly errors, minimizes operational disruptions, and enhances organizational resilience.

By embedding preventive measures into processes, Black Belts ensure that improvements are not transient but become integral to the organization’s operational fabric. This capability is particularly valuable in high-stakes environments such as healthcare, aerospace, or finance, where errors can have significant consequences.

Enhanced Organizational Culture

Black Belt professionals influence organizational culture by modeling disciplined, data-driven approaches to problem-solving. Their emphasis on measurement, accountability, and continuous improvement encourages colleagues to adopt similar practices. Over time, the presence of Black Belts can transform an organization into a learning-oriented, improvement-focused environment.

This cultural shift extends beyond process optimization. Employees learn to approach challenges analytically, collaborate effectively, and value measurable outcomes. Organizations with a culture of continuous improvement tend to experience higher employee engagement, stronger operational performance, and greater adaptability in the face of market changes.

Long-Term Career Impact

For individuals, the benefits of Black Belt certification extend well beyond immediate project outcomes. Professionals gain a distinctive skill set that enhances employability, career mobility, and professional credibility. The certification signals expertise in both technical and leadership domains, making individuals attractive candidates for senior management roles, consulting positions, or specialized operational functions.

Additionally, Black Belt training fosters a mindset of lifelong learning and adaptability. Professionals develop the ability to navigate complex challenges, apply structured problem-solving in novel contexts, and continuously refine their skill set. This intellectual agility positions them for sustained success in dynamic industries.

Networking and Professional Community

Black Belt certification also offers access to a broader professional community of process improvement experts. This network provides opportunities for collaboration, knowledge exchange, and mentorship. Engaging with peers who share a commitment to operational excellence can accelerate professional growth, expose individuals to best practices, and facilitate the adoption of innovative approaches.

Participation in professional communities allows Black Belts to benchmark practices, share insights, and learn from diverse experiences. This collaborative dimension enhances the value of the certification, ensuring that professionals remain at the forefront of industry trends and methodological advancements.

Return on Investment for Organizations

From an organizational perspective, investing in Black Belt professionals often yields a substantial return. Projects led by Black Belts deliver measurable improvements in efficiency, quality, and customer satisfaction. Cost savings, revenue enhancement, and process optimization contribute directly to the bottom line, often exceeding the investment in training and development.

Moreover, the influence of Black Belts on organizational culture amplifies their impact. By promoting structured problem-solving, data-driven decision-making, and continuous improvement, these professionals help organizations sustain operational excellence over time. The long-term benefits include greater competitiveness, resilience, and strategic adaptability.

Lean Six Sigma Black Belt Training Pathways, Eligibility, and Practical Application

Achieving Lean Six Sigma Black Belt certification requires a structured blend of theoretical knowledge, hands-on experience, and practical application. The journey involves not only mastering analytical tools and process improvement methodologies but also developing leadership and project management skills that enable professionals to drive significant organizational change. Understanding the training pathways, eligibility requirements, and practical applications is critical for individuals seeking to advance in process excellence.

Eligibility Criteria for Black Belt Programs

Enrollment in a Lean Six Sigma Black Belt program typically requires prior experience and foundational knowledge in process improvement. Most programs mandate a combination of professional experience and earlier certification levels, ensuring candidates possess the maturity and background necessary to tackle complex projects. Common eligibility prerequisites include:

Completion of Foundational Training: Candidates often need to have completed Lean Six Sigma Green Belt certification or equivalent training. This foundational knowledge provides familiarity with core concepts, tools, and basic project experience, forming a stepping stone toward Black Belt mastery.

Professional Experience: Programs may require a defined number of years working in roles that involve process improvement, quality management, operations, or related fields. This practical experience equips candidates with context for applying advanced methodologies.

Project Participation: Demonstrated involvement in Lean Six Sigma projects, even at a Green Belt level, is often required. Candidates should have experience with data collection, root cause analysis, and basic improvement initiatives.

Educational Background: While formal education requirements vary, many programs favor candidates with undergraduate degrees in business, engineering, healthcare, or related disciplines, as this provides a foundation for analytical and managerial concepts.

Eligibility standards differ across certifying bodies, but the underlying principle is consistent: candidates must have both a conceptual understanding and practical exposure to process improvement before advancing to the Black Belt level.

Selecting a Training Pathway

Once eligibility is established, professionals must determine the appropriate training pathway. Training formats vary to accommodate different learning preferences, schedules, and organizational contexts. The three primary pathways include:

Instructor-Led Training: Traditional classroom instruction provides structured guidance from experienced instructors. This format allows for real-time interaction, collaborative exercises, and immediate clarification of complex concepts.

Online Self-Paced Learning: Flexible online courses enable candidates to progress at their own pace, accommodating professional responsibilities. High-quality programs provide video lectures, interactive modules, and digital resources to replicate the depth of classroom instruction.

Blended Learning: Combining in-person instruction with online modules, blended learning offers a hybrid approach that balances flexibility with engagement. This pathway often integrates real-world case studies and hands-on exercises to enhance practical understanding.

Selecting the appropriate pathway depends on individual learning style, professional commitments, and the availability of organizational support. Candidates should consider programs that provide comprehensive coverage of Lean and Six Sigma principles, statistical tools, project management techniques, and leadership development.

Core Components of Black Belt Training

A robust Lean Six Sigma Black Belt program encompasses multiple components designed to develop technical expertise, analytical skill, and leadership capability. Key elements include:

Lean and Six Sigma Methodologies: Training covers the full spectrum of Lean tools and Six Sigma techniques, ensuring candidates understand both waste elimination and defect reduction. Topics may include value stream mapping, 5S workplace organization, process capability analysis, and control charts.

DMAIC Framework: Mastery of the Define, Measure, Analyze, Improve, and Control methodology is essential. Candidates learn to apply this structured approach to real-world problems, guiding projects from inception to sustained improvement.

Statistical Analysis and Data-Driven Decision Making: Black Belts develop proficiency in data collection, statistical evaluation, and hypothesis testing. Analytical software tools such as Minitab or similar platforms are often incorporated into training to simulate real-world analysis scenarios.

Project Management: Training emphasizes project planning, resource allocation, risk management, and milestone tracking. Black Belts learn to ensure that improvement initiatives are executed efficiently and deliver measurable results.

Leadership and Change Management: Professionals are equipped to manage cross-functional teams, address resistance, and foster buy-in from stakeholders. Skills in communication, coaching, and strategic alignment are integral to successful project execution.

Hands-On Exercises and Case Studies: Applying concepts to real-world scenarios reinforces understanding. Candidates work on simulated projects, analyze data, implement solutions, and evaluate outcomes, bridging theory and practice.

These components collectively ensure that candidates are prepared not only to pass the certification exam but also to lead impactful improvement projects in their organizations.

Practical Application of Black Belt Skills

Black Belt certification emphasizes practical, results-oriented application. Professionals must demonstrate the ability to implement Lean Six Sigma principles in operational contexts. Typical applications include:

Process Optimization: Streamlining workflows, reducing redundancies, and improving cycle times in manufacturing, service, or administrative processes.

Defect Reduction and Quality Enhancement: Applying statistical analysis to identify sources of variation and implementing corrective measures to improve product or service quality.

Cost Reduction: Identifying inefficiencies, waste, and non-value-added activities to reduce operational expenses.

Customer Satisfaction Improvement: Enhancing the customer experience through process improvement, faster delivery, and consistent quality.

Operational Risk Management: Anticipating potential failure points, implementing preventive measures, and reducing the likelihood of errors or disruptions.

Hands-on projects are a crucial aspect of Black Belt training. Candidates typically complete one or more improvement initiatives under supervision, providing concrete evidence of their ability to translate knowledge into action. These projects often form the basis for assessment during certification evaluations.

Developing Competencies Beyond Technical Skills

While technical mastery is essential, Black Belt training also emphasizes broader competencies that enable professionals to drive organizational change:

Strategic Thinking: Aligning projects with organizational objectives ensures that improvements contribute to long-term business goals. Black Belts learn to evaluate how individual initiatives fit within broader operational and strategic frameworks.

Interpersonal and Communication Skills: Effective communication allows Black Belts to convey complex analytical findings, facilitate team collaboration, and secure stakeholder buy-in.

Change Leadership: Implementing new processes often encounters resistance. Black Belts develop strategies to engage teams, address concerns, and sustain improvements over time.

Decision-Making under Uncertainty: Complex projects often involve incomplete data or ambiguous scenarios. Black Belts are trained to make evidence-based decisions while managing risk and uncertainty.

These competencies ensure that Black Belt professionals are not only skilled analysts but also capable leaders and change agents within their organizations.

Assessment and Certification Examination

Certification typically culminates in an examination that evaluates both theoretical knowledge and practical application. The exam may include:

Multiple-Choice Questions: Assess understanding of Lean and Six Sigma concepts, DMAIC methodology, and statistical principles.

Scenario-Based Questions: Test the ability to apply analytical and problem-solving techniques to realistic operational challenges.

Project Submission: Candidates may be required to submit a detailed report of a completed process improvement project, demonstrating their ability to apply concepts in practice.

Passing the exam confirms that candidates have acquired the knowledge, skills, and experience required to perform at an advanced level in process improvement and project leadership.

Real-World Integration

The ultimate value of Black Belt certification lies in its integration into real-world operations. Certified professionals are expected to:

Lead projects that achieve measurable results, such as reducing cycle times, lowering defect rates, or cutting costs.

Implement standardized processes to sustain improvements over time.

Serve as mentors or coaches for Green Belt or team members, extending knowledge throughout the organization.

Continuously monitor performance metrics to identify new opportunities for improvement.

This practical orientation ensures that Black Belt certification translates into organizational impact rather than theoretical knowledge alone.

Mentorship and Knowledge Transfer

A hallmark of Black Belt training is the emphasis on mentorship. Experienced Black Belts often guide project teams, provide feedback on methodology application, and help less experienced practitioners develop competence. This transfer of knowledge is crucial for maintaining organizational capability and creating a culture of continuous improvement.

Mentorship also reinforces accountability. Black Belts are responsible not only for project outcomes but also for developing the next generation of process improvement leaders. This dual role enhances both professional satisfaction and organizational effectiveness.

Continuous Learning and Skill Enhancement

Lean Six Sigma methodology evolves, incorporating new tools, techniques, and digital technologies. Black Belt professionals are encouraged to engage in ongoing learning, staying current with emerging best practices and advancements in analytics, automation, and process optimization. Continuous skill enhancement ensures that professionals remain relevant and capable of addressing increasingly complex operational challenges.

Engaging in professional communities, attending workshops, and pursuing advanced training are common strategies for sustaining knowledge and fostering innovation. This commitment to lifelong learning differentiates high-performing Black Belts and contributes to long-term career growth.

Cross-Functional Impact

Black Belt projects often span multiple departments, requiring collaboration across functional areas. This cross-functional exposure broadens the professional’s understanding of organizational dynamics and enhances the ability to identify systemic improvements. Working across departments also reinforces leadership skills, as Black Belts must navigate differing priorities, resource constraints, and organizational cultures.

Such exposure is invaluable for professionals aspiring to senior management or executive roles, as it provides insight into enterprise-wide operations and strategic decision-making.

Long-Term Relevance, Future Trends, and Strategic Importance of Lean Six Sigma Black Belt Professionals

Lean Six Sigma Black Belt professionals occupy a unique position in modern organizations. They combine technical expertise, analytical rigor, and leadership capability to influence processes, drive performance, and cultivate cultures of continuous improvement. As organizations face increasingly complex operational landscapes, the role of Black Belts is evolving, becoming more strategic, data-driven, and technologically integrated. Understanding the long-term relevance, emerging trends, and strategic importance of these professionals is essential for appreciating the full value of Black Belt certification.

Enduring Relevance in Dynamic Industries

Industries worldwide are subject to rapid change due to technological innovation, shifting consumer demands, globalization, and regulatory pressures. In this environment, operational excellence is not optional; it is a critical determinant of competitive success. Lean Six Sigma Black Belt professionals provide organizations with the ability to adapt, innovate, and maintain high performance.

The combination of Lean and Six Sigma principles ensures that Black Belts address both efficiency and quality. They eliminate waste, reduce variability, and create streamlined processes, enabling organizations to respond quickly to market changes. Their expertise transcends individual departments, allowing cross-functional improvements that enhance enterprise-wide performance.

In sectors ranging from healthcare and manufacturing to finance and technology, the impact of Black Belts is tangible. In healthcare, for example, they streamline patient workflows, reduce errors, and optimize resource allocation, improving outcomes and patient satisfaction. In manufacturing, they enhance production efficiency, minimize defects, and reduce operational costs. Across industries, their contributions reinforce operational resilience and competitive advantage.

The Growing Role of Data and Analytics

The modern Black Belt professional operates in a data-intensive environment. Organizations increasingly rely on advanced analytics, real-time monitoring, and predictive models to manage operations and anticipate challenges. Black Belts integrate traditional Lean Six Sigma tools with contemporary data analytics to make more informed decisions and achieve superior results.

Statistical analysis remains a core competency, but emerging technologies such as business intelligence platforms, machine learning, and predictive modeling are becoming integral to process improvement. Black Belts can leverage these tools to identify patterns, anticipate process deviations, and implement proactive interventions. The ability to interpret complex datasets, generate actionable insights, and translate analysis into operational improvements enhances both organizational performance and professional relevance.

Integration of Automation and Digital Technologies

Automation, artificial intelligence (AI), and machine learning are increasingly embedded in operational processes. Black Belt professionals are positioned to lead digital transformation initiatives by integrating Lean Six Sigma methodologies with technological innovations.

For example, robotic process automation (RPA) can streamline repetitive administrative tasks, while AI algorithms can detect anomalies in production or service processes. Black Belts apply their analytical and process expertise to configure, monitor, and optimize these technologies, ensuring that automation delivers maximum efficiency and quality gains. Their strategic application of digital tools allows organizations to reduce costs, improve consistency, and maintain high service levels in a competitive environment.

Strategic Leadership and Organizational Impact

Black Belt professionals are more than technical specialists; they are strategic leaders. Their work influences organizational priorities, resource allocation, and long-term planning. By aligning process improvement initiatives with corporate strategy, Black Belts ensure that operational gains translate into meaningful business outcomes.

They serve as catalysts for change, fostering a culture of continuous improvement across all levels of the organization. Their leadership extends to mentoring Green Belts and other team members, embedding process excellence principles throughout the workforce. By demonstrating the value of data-driven decision-making and evidence-based problem-solving, Black Belts contribute to more resilient, adaptable, and agile organizations.

Global Relevance and Professional Mobility

Lean Six Sigma Black Belt certification is recognized internationally, providing professionals with global mobility and versatility. Multinational corporations, consulting firms, and international organizations value Black Belts for their ability to implement standardized methodologies across diverse operational contexts.

This global applicability allows certified professionals to pursue opportunities in different regions, industries, or functional domains. Their expertise in process optimization, project leadership, and analytical problem-solving remains valuable regardless of organizational or geographic context. For individuals seeking dynamic careers with cross-border potential, Black Belt certification offers a unique advantage.

Long-Term Career Growth

The benefits of Black Belt certification extend well beyond immediate project outcomes. Professionals gain enduring competencies in problem-solving, project management, data analysis, and leadership, equipping them for long-term career growth.

Certification often serves as a gateway to senior management or executive roles, where strategic oversight and cross-functional expertise are essential. Black Belts may advance to positions such as operations manager, process excellence leader, quality director, or chief operating officer. Their ability to drive measurable outcomes and lead complex projects positions them as invaluable contributors to organizational strategy.

Fostering a Culture of Continuous Improvement

Black Belt professionals play a pivotal role in cultivating a culture of continuous improvement. Their approach to problem-solving emphasizes measurement, accountability, and evidence-based decision-making. By modeling these behaviors and mentoring colleagues, they encourage a mindset of systematic enhancement throughout the organization.

Organizations that embrace this culture experience lasting operational gains. Employees at all levels adopt structured methodologies, focus on data-driven solutions, and continuously seek ways to optimize processes. The presence of Black Belts accelerates this cultural shift, transforming organizations into learning-oriented, agile entities capable of sustaining high performance over time.

Addressing Emerging Challenges

Modern organizations face complex challenges that extend beyond traditional operational concerns. Market volatility, regulatory pressures, technological disruption, and customer expectations require adaptive, forward-thinking solutions. Black Belt professionals are uniquely equipped to address these challenges by combining analytical rigor, strategic insight, and operational expertise.

They identify inefficiencies, assess risk, and implement interventions that anticipate future needs. For example, in supply chain management, Black Belts may optimize logistics networks to reduce vulnerability to disruptions. In healthcare, they may implement predictive models to enhance patient outcomes and resource allocation. Across contexts, their skills enable organizations to navigate uncertainty while maintaining operational excellence.

Cross-Functional Collaboration

Black Belt initiatives often require collaboration across multiple departments, functions, and organizational levels. This cross-functional engagement broadens the professional’s perspective, enhances problem-solving capabilities, and strengthens the organization’s ability to implement enterprise-wide improvements.

Working across silos, Black Belts develop insight into interdependencies, resource constraints, and operational bottlenecks. This experience is invaluable for strategic decision-making and positions professionals to assume roles with broader organizational impact. Collaborative engagement also fosters stronger relationships, improves communication, and aligns stakeholders around shared objectives.

Adaptation to Industry Evolution

Industries are evolving rapidly, influenced by technology, globalization, and customer expectations. Lean Six Sigma Black Belt professionals must adapt to these changes to remain effective. Their foundational knowledge in process improvement, combined with flexibility and analytical acumen, allows them to respond to evolving operational challenges.

For instance, as organizations integrate digital supply chains, e-commerce platforms, or advanced manufacturing technologies, Black Belts apply Lean Six Sigma principles to optimize processes, reduce variation, and ensure quality standards are met. This adaptability ensures that their expertise remains relevant and impactful, regardless of industry transformation.

Leveraging Predictive and Prescriptive Analytics

The integration of predictive and prescriptive analytics into Lean Six Sigma expands the capabilities of Black Belt professionals. Predictive analytics enables forecasting of process deviations or failures before they occur, while prescriptive analytics recommends optimal courses of action.

Black Belts skilled in these techniques enhance organizational agility, reduce operational risk, and improve decision-making precision. By combining traditional statistical methods with advanced analytics, they provide a comprehensive framework for continuous improvement and strategic foresight.

Mentorship and Knowledge Transfer

Black Belts not only lead projects but also mentor Green Belts and team members, ensuring knowledge transfer and capability building. This mentorship reinforces organizational competency, promotes sustainable improvement practices, and multiplies the impact of individual expertise.

By guiding others, Black Belts cultivate future leaders, strengthen organizational capacity, and embed Lean Six Sigma principles across the enterprise. Knowledge transfer also accelerates innovation, as teams are empowered to identify and implement improvements independently while maintaining alignment with strategic objectives.

Sustaining Competitive Advantage

The long-term presence of Black Belt professionals contributes directly to sustained competitive advantage. Their work reduces waste, enhances quality, and improves operational efficiency, enabling organizations to deliver superior products or services.

Additionally, their strategic role ensures that process improvement initiatives are aligned with organizational priorities, creating measurable value and supporting growth objectives. Organizations that leverage Black Belt expertise consistently outperform competitors by maintaining agility, responsiveness, and operational excellence.

Preparing for Future Industry Trends

The future of Lean Six Sigma Black Belt professionals involves adapting to emerging trends in technology, business strategy, and organizational behavior. Areas of growing significance include:

Artificial Intelligence and Machine Learning: Enhancing predictive capabilities and optimizing decision-making.

Automation and Robotics: Streamlining repetitive tasks and integrating with process improvement methodologies.

Sustainability and Environmental Efficiency: Applying Lean principles to reduce resource consumption and improve environmental performance.

Digital Transformation: Supporting organizational adoption of advanced platforms, analytics, and workflow automation.

Global Supply Chain Optimization: Applying Lean Six Sigma to enhance resiliency, reduce risk, and improve operational continuity.

By staying attuned to these trends, Black Belts ensure that their skills remain relevant and their contributions strategically impactful.

Long-Term Professional Value

The value of Lean Six Sigma Black Belt certification extends well beyond immediate project outcomes. Professionals acquire a versatile toolkit for addressing complex challenges, optimizing operations, and leading transformative initiatives. The combination of technical mastery, analytical capability, and leadership acumen enables long-term career growth and sustained organizational impact.

Moreover, Black Belts cultivate a mindset of continuous learning, adaptability, and strategic thinking. These attributes equip them to thrive in dynamic industries, navigate uncertainty, and contribute meaningfully to organizational success over the long term.

Conclusion

Lean Six Sigma Black Belt certification represents more than a professional credential; it is a gateway to mastering operational excellence, strategic leadership, and analytical expertise. Through rigorous training, practical application, and project leadership, certified professionals develop the skills to drive measurable improvements, reduce inefficiencies, and enhance quality across diverse industries. Beyond technical proficiency, Black Belts cultivate leadership, mentorship, and problem-solving capabilities, enabling them to influence organizational culture and foster continuous improvement. As businesses increasingly rely on data-driven decision-making, automation, and advanced analytics, the role of Black Belt professionals becomes ever more strategic and future-ready. Their contributions translate into cost savings, higher productivity, and sustained competitive advantage, while also supporting long-term career growth. Ultimately, Lean Six Sigma Black Belt certification equips individuals to lead transformative initiatives, create lasting organizational impact, and thrive in a dynamic, evolving business landscape.