Certification: CLSSBB

Certification Full Name: Certified Lean Six Sigma Black Belt

Certification Provider: GAQM

Exam Code: CLSSBB

Exam Name: Certified Lean Six Sigma Black Belt

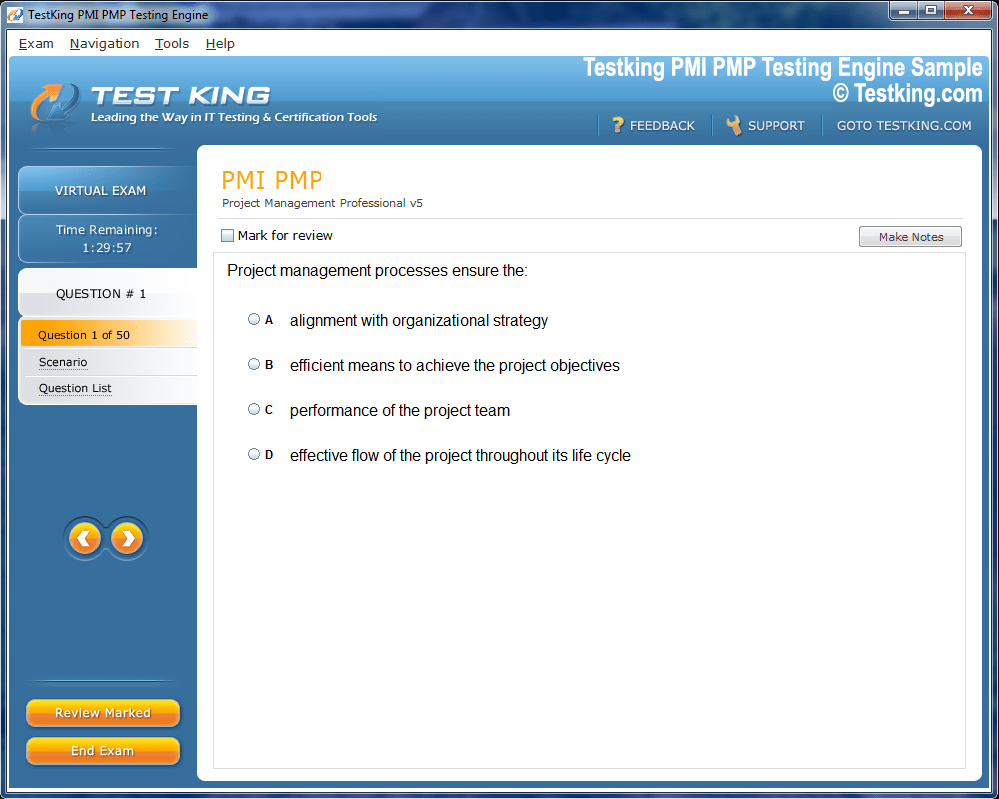

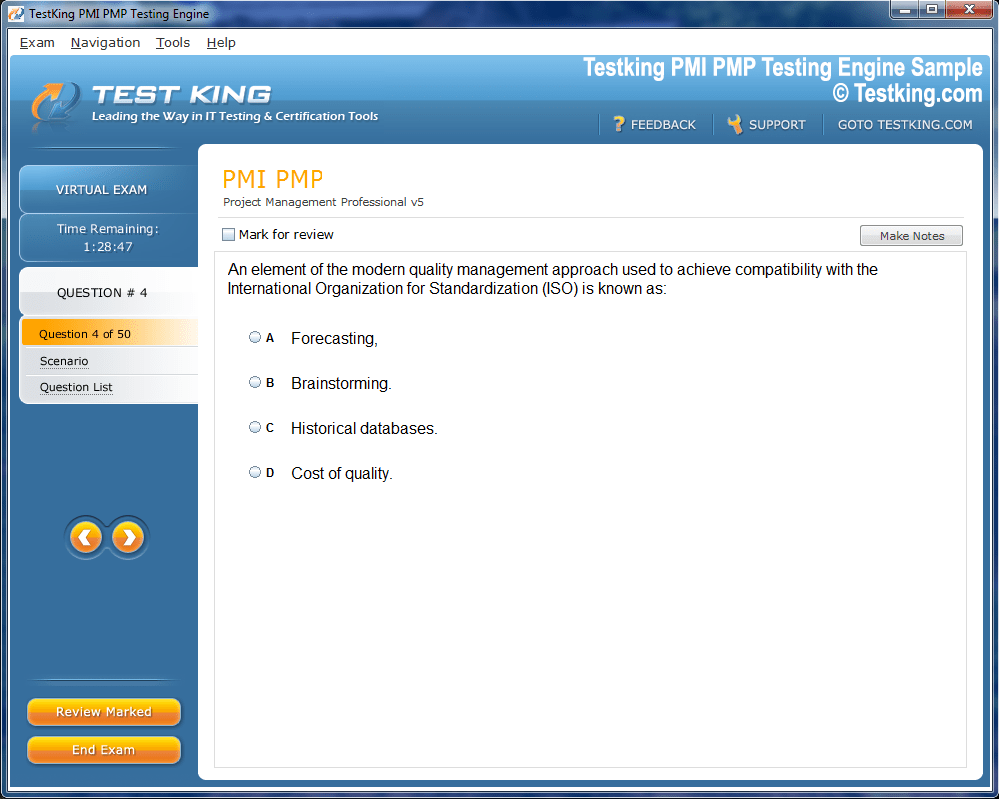

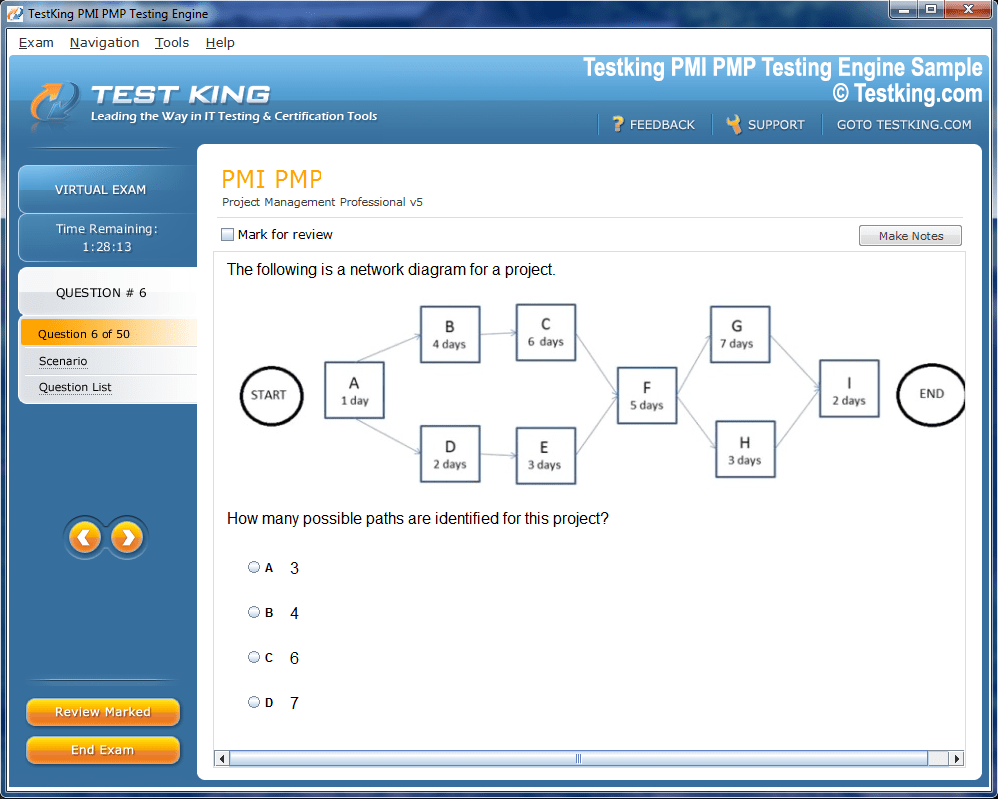

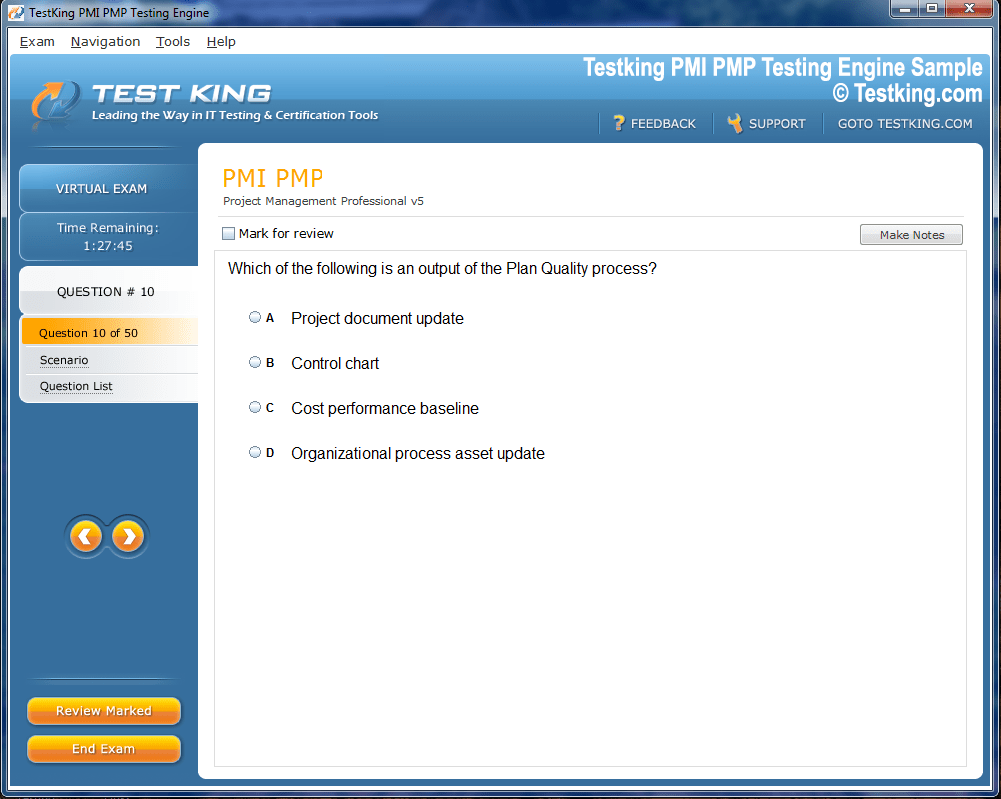

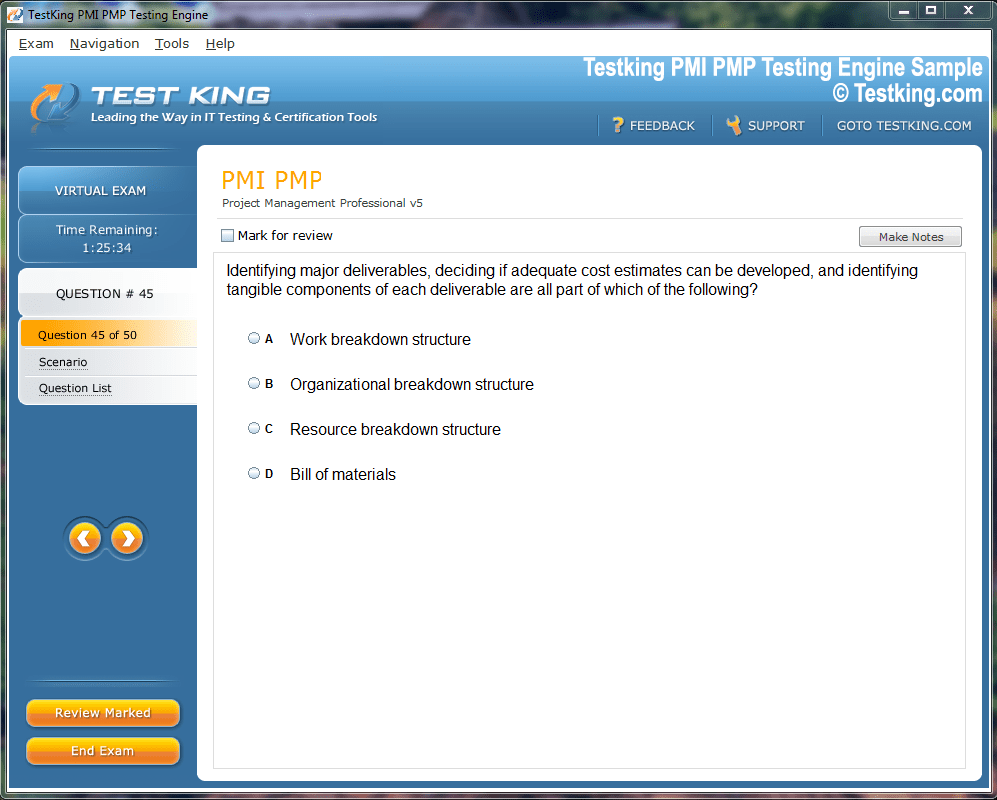

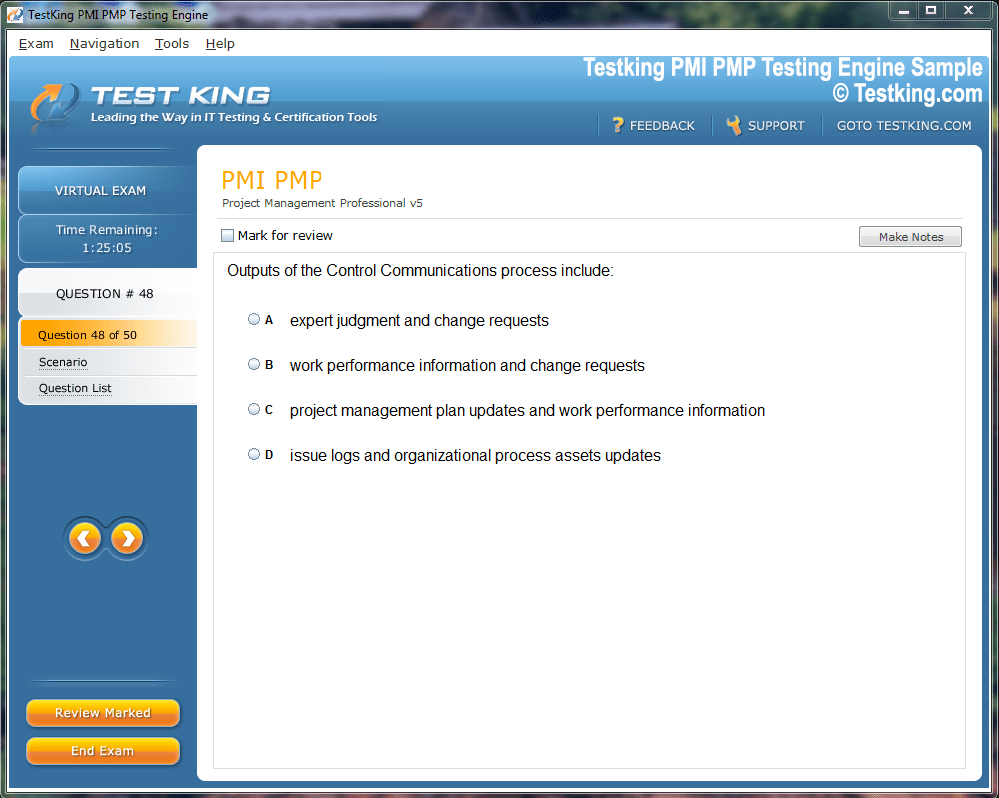

Product Screenshots

nop-1e =1

Leading Process Improvement Initiatives with CLSSBB Certification

In contemporary organizational landscapes, enterprises constantly strive to augment efficiency, minimize operational wastage, and elevate the quality of their offerings. The pursuit of operational excellence is not a transient trend; it has become a fundamental requisite for businesses aspiring to maintain competitiveness in an ever-evolving global market. Within this milieu, the role of Lean Six Sigma Black Belt professionals has gained unprecedented significance. Earning the Lean Six Sigma Black Belt, CLSSBB certification, denotes mastery in process optimization and qualifies an individual to spearhead complex projects that enhance productivity and foster sustainable growth.

Lean Six Sigma is more than a methodology; it is a strategic philosophy that intertwines analytical precision with practical applications. Organizations that embrace Lean Six Sigma principles aim to achieve a delicate equilibrium between efficiency and quality, thereby delivering enhanced value to stakeholders. The certification process for Lean Six Sigma Black Belt signifies not only technical acumen but also leadership capability, as Black Belts often orchestrate cross-functional teams to realize transformative results.

The journey toward Lean Six Sigma Black Belt certification is rigorous and intellectually demanding. It encompasses theoretical understanding, statistical analysis, and applied project management, culminating in a credential that is globally recognized. For professionals seeking to distinguish themselves in domains such as manufacturing, healthcare, finance, and technology, attaining the CLSSBB certification represents both a personal milestone and a tangible career asset.

Fundamentals of Lean Six Sigma

To comprehend the significance of the Lean Six Sigma Black Belt certification, it is essential first to understand the foundational tenets of Lean Six Sigma. The methodology synthesizes Lean principles, which focus on waste elimination and process streamlining, with Six Sigma principles, aimed at reducing variability and enhancing quality. By amalgamating these approaches, Lean Six Sigma provides a comprehensive framework for process improvement that is both systematic and adaptable.

Lean principles revolve around the identification and eradication of non-value-added activities within processes. Every operational step is scrutinized to determine its contribution to the overall value chain. Practices such as value stream mapping, 5S methodology, and continuous flow optimization exemplify Lean thinking. These techniques not only reduce inefficiencies but also cultivate a culture of vigilance and proactive problem-solving within the organization.

Six Sigma, on the other hand, emphasizes statistical analysis to diminish defects and deviations in processes. By employing tools such as hypothesis testing, control charts, and process capability analysis, Six Sigma professionals quantify performance gaps and implement data-driven solutions. The convergence of Lean and Six Sigma ensures that process improvements are not only swift and efficient but also statistically robust and sustainable over time.

The Lean Six Sigma Black Belt designation reflects an advanced level of expertise in these methodologies. Black Belts are expected to possess a profound understanding of both Lean and Six Sigma tools and demonstrate the ability to apply them strategically across complex organizational landscapes. The certification is both a testament to technical proficiency and a declaration of readiness to lead transformational initiatives.

The Role and Responsibilities of a Black Belt Professional

A Lean Six Sigma Black Belt functions as a linchpin in process improvement initiatives, bridging the gap between analytical insights and operational execution. Unlike Green Belts, who typically support projects under supervision, Black Belts assume full accountability for the design, implementation, and evaluation of improvement projects. Their responsibilities are multifaceted, encompassing strategic, analytical, and leadership dimensions.

At the strategic level, Black Belts align projects with organizational objectives, ensuring that improvement efforts contribute tangibly to operational efficiency and customer satisfaction. They evaluate business processes holistically, identifying areas where interventions will yield the most significant impact. This requires an amalgamation of analytical prowess, industry insight, and judicious decision-making.

Analytically, Black Belts utilize a plethora of tools to dissect complex problems. Techniques such as root cause analysis, regression modeling, and design of experiments facilitate a deep understanding of process behavior. The application of these methodologies enables professionals to isolate critical variables, optimize workflows, and implement interventions that minimize variability and enhance quality metrics.

Leadership forms another crucial facet of the Black Belt role. Professionals in this position guide multidisciplinary teams, fostering collaboration and knowledge transfer. Effective communication is imperative, as Black Belts must translate intricate data findings into actionable recommendations that stakeholders across various functions can comprehend and implement. Their influence extends beyond project execution to mentoring Green Belts and cultivating a culture of continuous improvement.

Moreover, Black Belts are custodians of process governance. They establish metrics, monitor progress, and ensure that improvements are sustained over time. This stewardship entails not only technical acumen but also an unwavering commitment to organizational excellence. By executing projects that reduce operational costs, enhance quality, and improve customer satisfaction, Black Belts substantively contribute to organizational resilience and competitiveness.

Benefits of Lean Six Sigma Black Belt Certification

The attainment of Lean Six Sigma Black Belt certification confers a multitude of advantages, both tangible and intangible, for professionals and the organizations they serve. The certification functions as an external validation of expertise, signifying mastery of advanced process improvement techniques and leadership capabilities.

Career Advancement and Professional Recognition

One of the foremost benefits of Black Belt certification is career advancement. Certified professionals are often entrusted with high-stakes projects, which positions them as influential figures within their organizations. The credential signals a proficiency that extends beyond technical knowledge to encompass strategic vision and leadership acumen, thereby enhancing professional visibility and credibility. This recognition can catalyze promotions, leadership opportunities, and increased responsibility within organizational hierarchies.

Enhanced Analytical and Problem-Solving Abilities

Black Belt training rigorously develops analytical capabilities. Professionals learn to dissect intricate processes, identify inefficiencies, and implement statistically validated solutions. These problem-solving skills transcend professional boundaries, equipping individuals with a versatile toolkit applicable in diverse scenarios. The ability to approach challenges methodically, using data-driven insights, is highly prized in contemporary business environments.

Contribution to Organizational Efficiency

Certified Black Belts directly influence operational performance. Their interventions can lead to significant reductions in process variability, cost savings, and enhanced product or service quality. By applying Lean Six Sigma principles, organizations realize measurable improvements in efficiency and customer satisfaction. The strategic deployment of Black Belt expertise ensures that improvement initiatives are not isolated events but integral components of an organization’s long-term performance strategy.

Financial Incentives

The demand for skilled Lean Six Sigma Black Belt professionals often translates into superior remuneration. Organizations recognize the value that certified individuals bring, particularly in sectors where process optimization directly impacts profitability. Consequently, certified professionals frequently command higher salaries and incentives, reflecting their specialized knowledge and the quantifiable impact of their work.

Personal and Professional Fulfillment

Beyond tangible career benefits, Lean Six Sigma Black Belt certification fosters intellectual growth and personal satisfaction. Professionals gain confidence in their ability to tackle complex problems, lead diverse teams, and effect meaningful change. The journey toward certification is intellectually rigorous, and the resulting sense of accomplishment can bolster self-efficacy and professional identity.

Lean Six Sigma Black Belt Training Process

Achieving Lean Six Sigma Black Belt certification requires a structured training regimen that combines theoretical instruction with practical application. The training process is designed to ensure mastery of Lean Six Sigma methodologies and the development of competencies necessary to lead high-impact projects.

Eligibility and Prerequisites

Candidates typically need to fulfill certain prerequisites before enrolling in Black Belt training programs. These often include the completion of Lean Six Sigma Green Belt certification, relevant work experience, and documented participation in improvement projects. Such prerequisites ensure that participants possess foundational knowledge and practical exposure, enabling them to grasp advanced concepts effectively.

Curriculum Overview

A comprehensive Black Belt training curriculum encompasses a wide array of topics. Core elements include Lean and Six Sigma principles, statistical analysis, project management, and leadership skills. The DMAIC framework—Define, Measure, Analyze, Improve, Control—serves as a central pillar of instruction, guiding professionals through structured process improvement methodologies.

Statistical tools are integral to the curriculum. Techniques such as hypothesis testing, regression analysis, control charts, and design of experiments equip professionals with quantitative methods to evaluate and optimize processes. Additionally, practical exercises and case studies reinforce theoretical knowledge, providing candidates with real-world experience in implementing process improvements.

Training Modalities

Training is available in diverse formats to accommodate varied learning preferences. Traditional classroom instruction allows for direct interaction with instructors and peer collaboration. Online courses, whether self-paced or instructor-led, provide flexibility and accessibility. Blended learning approaches combine the benefits of in-person engagement with the convenience of virtual study, catering to professionals balancing training with work commitments.

Duration and Intensity

The duration of training programs varies based on format and depth of content. Intensive boot camps may span a few days, focusing on concentrated knowledge acquisition, whereas comprehensive programs may extend over several weeks or months, providing in-depth exploration of Lean Six Sigma principles and extensive project work.

Project Experience and Practical Application

A distinguishing feature of Lean Six Sigma Black Belt certification is the requirement for hands-on project experience. Candidates must demonstrate their ability to apply principles in real organizational contexts. These projects involve analyzing processes, identifying inefficiencies, implementing improvement strategies, and quantifying outcomes. Mentorship and guidance during project execution ensure that candidates develop practical competencies alongside theoretical knowledge.

Practical application reinforces learning, bridging the gap between abstract concepts and operational realities. By leading process improvement projects, candidates gain insights into organizational dynamics, stakeholder management, and change implementation. This experiential learning cultivates both technical acumen and leadership finesse, essential attributes of a proficient Black Belt.

Certification Exam and Credentialing

Upon completion of training and project requirements, candidates become eligible for the Lean Six Sigma Black Belt certification examination. The exam evaluates proficiency in Lean Six Sigma concepts, statistical methods, and practical application. Passing the examination confirms that the professional possesses the requisite knowledge and skills to lead high-impact improvement initiatives.

Certification is a globally recognized testament to expertise. It validates an individual’s capability to analyze complex processes, implement data-driven solutions, and guide teams toward operational excellence. Beyond the credential itself, the process instills confidence and reinforces a commitment to continuous improvement.

Skill Development Beyond Technical Proficiency

While technical mastery is central to Black Belt certification, the process also cultivates ancillary competencies. Leadership, communication, and strategic thinking are honed through project execution and team management. Certified professionals learn to navigate organizational complexities, influence decision-making, and foster a culture of continuous improvement. These skills amplify the value of certification, positioning individuals as versatile contributors capable of driving organizational transformation.

Advanced Lean Six Sigma Methodologies

Lean Six Sigma Black Belt professionals operate at the intersection of analytical rigor and strategic implementation. Beyond foundational principles, mastery of advanced methodologies distinguishes Black Belts as transformative agents within organizations. These methodologies are structured to address complex operational challenges while maximizing efficiency and minimizing defects.

At the core of advanced Lean Six Sigma is the DMAIC framework, which serves as a structured approach to problem-solving. Each phase—Define, Measure, Analyze, Improve, and Control—requires a combination of critical thinking, statistical analysis, and pragmatic intervention. Black Belts must navigate each phase with precision, balancing technical accuracy with organizational dynamics.

The Define phase involves the articulation of project objectives, identification of critical stakeholders, and scoping of processes. Professionals employ tools such as project charters, process maps, and stakeholder analysis to ensure clarity and alignment. This phase establishes the foundation for subsequent analytical work and ensures that efforts are strategically aligned with organizational priorities.

Measurement is the subsequent phase, emphasizing the collection and validation of data. Black Belts employ statistical techniques to quantify process performance, identify variability, and establish baselines. Accurate measurement is pivotal; it provides the evidentiary basis for analysis and ensures that subsequent improvements are grounded in reliable data.

During the Analyze phase, professionals scrutinize data to identify root causes of inefficiencies or defects. Tools such as fishbone diagrams, Pareto analysis, regression modeling, and hypothesis testing are leveraged to uncover underlying process dynamics. The analytical rigor exercised in this phase allows Black Belts to pinpoint interventions that will have the most significant impact on outcomes.

The Improve phase involves the development and implementation of solutions to optimize processes. Black Belts design experiments, pilot interventions, and refine solutions iteratively. Collaboration with cross-functional teams is essential during this stage, as practical insights from operational staff inform and validate improvement strategies.

Finally, the Control phase ensures that improvements are sustainable over time. Control charts, process monitoring plans, and documentation protocols are employed to maintain process stability. This phase embodies the philosophy that true operational excellence is not a transient achievement but a sustained capability embedded within organizational practices.

Statistical and Analytical Competencies

A distinguishing attribute of Lean Six Sigma Black Belt professionals is their command over statistical and analytical tools. While Green Belts may employ basic statistical techniques, Black Belts are expected to wield advanced methodologies to drive process optimization. Statistical competencies enable the identification of patterns, validation of hypotheses, and measurement of improvement efficacy.

Design of experiments (DOE) is a cornerstone of Black Belt analytics. Through DOE, professionals can systematically manipulate process variables to ascertain causal relationships and optimize performance. Regression analysis, ANOVA, and multivariate techniques further empower Black Belts to understand complex interactions between process elements and predict outcomes under varying conditions.

Control charts, histograms, and scatter plots are employed to visualize data, monitor process behavior, and detect deviations from expected performance. The ability to interpret these analytical representations allows Black Belts to make informed, evidence-based decisions and anticipate potential challenges proactively.

Furthermore, Lean Six Sigma Black Belts integrate data analytics with qualitative insights. While statistical analysis provides objectivity, contextual understanding of organizational culture, workflow, and stakeholder dynamics ensures that improvements are pragmatic and sustainable. This duality of quantitative and qualitative acumen distinguishes exceptional Black Belts from their peers.

Leadership and Organizational Influence

While technical mastery forms the backbone of Black Belt proficiency, leadership skills are equally critical. Black Belts lead cross-functional teams, influence stakeholders, and facilitate organizational change. The ability to inspire, guide, and coordinate teams amplifies the impact of process improvement initiatives.

Effective communication is a key attribute. Black Belts translate complex statistical findings into actionable insights that diverse stakeholders can comprehend and implement. They craft narratives that connect data to business outcomes, ensuring that project recommendations resonate across organizational hierarchies.

Mentorship is another dimension of leadership. Black Belts guide Green Belts and team members, fostering a culture of continuous learning and process improvement. By cultivating talent and disseminating knowledge, they ensure that Lean Six Sigma principles permeate the organizational fabric beyond individual projects.

Strategic thinking is intertwined with operational execution. Black Belts evaluate the long-term implications of interventions, aligning projects with organizational objectives and ensuring that improvements contribute to sustainable competitiveness. Their influence extends beyond immediate project outcomes to shape the organization’s capability for ongoing process excellence.

Practical Project Management

Lean Six Sigma Black Belt certification emphasizes the integration of project management and process improvement. Black Belts manage complex projects that often span multiple departments and require coordination across diverse operational functions. Proficiency in project management ensures that initiatives are completed on time, within scope, and aligned with defined objectives.

Project scoping is a critical initial step. Black Belts identify project boundaries, establish measurable objectives, and allocate resources effectively. This structured approach prevents scope creep and ensures that projects address the most impactful opportunities.

Execution involves the systematic application of Lean Six Sigma methodologies. Black Belts oversee data collection, analysis, and solution implementation, ensuring rigor at every stage. They coordinate with operational teams, communicate progress to stakeholders, and troubleshoot challenges in real time.

Monitoring and control are ongoing responsibilities. Black Belts implement performance metrics, track improvement outcomes, and adjust strategies as necessary to ensure sustained success. This continuous oversight reinforces the principle that process optimization is iterative and adaptive, rather than static.

Integrating Lean Six Sigma Across Industries

The versatility of Lean Six Sigma methodologies enables Black Belt professionals to apply their skills across a wide range of industries. Manufacturing, healthcare, finance, logistics, and information technology all benefit from process improvement initiatives driven by Black Belt expertise.

In manufacturing, Lean Six Sigma Black Belts focus on production efficiency, defect reduction, and workflow optimization. Projects often involve reengineering processes to minimize downtime, reduce waste, and improve product quality. The analytical tools and statistical methods employed enable precise measurement of outcomes and identification of improvement opportunities.

Within healthcare, Black Belts streamline clinical and administrative processes, enhancing patient care while controlling costs. Initiatives may include optimizing patient flow, reducing medical errors, or improving supply chain management. The integration of Lean Six Sigma principles in healthcare has demonstrated significant impacts on patient outcomes and operational efficiency.

In financial services, Black Belts apply methodologies to enhance transaction accuracy, minimize process delays, and optimize compliance procedures. Analytical rigor and process governance are essential in ensuring that interventions align with regulatory requirements while improving operational performance.

Across industries, the ability to translate Lean Six Sigma principles into actionable projects underscores the universal applicability of Black Belt expertise. Professionals equipped with the CLSSBB credential possess the analytical sophistication, leadership capability, and strategic insight required to effect meaningful change in diverse organizational contexts.

Sustaining Continuous Improvement

Lean Six Sigma Black Belts are not solely focused on one-off projects; they are custodians of continuous improvement within organizations. The philosophy of continuous improvement, or Kaizen, emphasizes incremental changes that cumulatively enhance efficiency, quality, and value. Black Belts institutionalize this mindset, embedding improvement practices into organizational culture.

Sustaining gains involves monitoring key performance indicators, conducting periodic audits, and adjusting processes based on evolving data. Black Belts utilize control plans, standard operating procedures, and process documentation to maintain improvements over time. This long-term perspective ensures that operational gains are preserved and amplified, reinforcing the organization’s competitive advantage.

Moreover, Black Belts foster a learning culture. They encourage feedback, facilitate cross-functional collaboration, and mentor colleagues to perpetuate process improvement knowledge. By embedding continuous improvement into organizational routines, Black Belts transform temporary interventions into enduring capabilities.

Soft Skills and Interpersonal Competencies

Technical and analytical expertise must be complemented by interpersonal competencies. Black Belts navigate organizational complexity by cultivating skills in negotiation, conflict resolution, and stakeholder engagement. The capacity to build consensus and influence decision-making is critical when implementing process changes that affect multiple departments.

Emotional intelligence plays a pivotal role in leadership effectiveness. Black Belts manage team dynamics, motivate personnel, and mediate challenges with empathy and insight. Effective leaders recognize the human element in operational transformation, balancing analytical rigor with interpersonal sensitivity.

Time management and adaptability are equally vital. Black Belts often juggle multiple projects simultaneously, requiring prioritization and flexible problem-solving. The ability to adapt methodologies to specific organizational contexts ensures that interventions are both practical and impactful.

Exam Preparation and Knowledge Validation

Earning the Lean Six Sigma Black Belt certification involves rigorous assessment. The examination evaluates comprehension of Lean and Six Sigma principles, proficiency in statistical analysis, and capacity for project leadership. Exam preparation reinforces understanding and ensures that candidates can apply knowledge effectively in real-world scenarios.

Study plans typically incorporate theoretical instruction, practical exercises, and project case studies. Candidates review the DMAIC framework, statistical tools, process mapping techniques, and leadership strategies. Mock exams and practice questions enhance readiness, while mentorship and collaborative study provide additional insights into complex topics.

Passing the certification exam signifies that a professional has achieved a high level of mastery. The credential confirms both analytical capabilities and practical competence, marking the individual as qualified to lead sophisticated process improvement initiatives.

The Strategic Value of Black Belt Professionals

Organizations that integrate Lean Six Sigma Black Belts into their operational framework derive significant strategic advantages. Black Belts serve as catalysts for transformation, aligning process improvement efforts with corporate objectives and market demands. Their expertise drives cost reduction, quality enhancement, and operational agility.

By identifying and eliminating inefficiencies, Black Belts enhance resource utilization, reduce cycle times, and optimize workflows. These improvements contribute to profitability and competitive positioning, demonstrating the tangible value of Lean Six Sigma expertise. Furthermore, the analytical rigor and disciplined methodology that Black Belts bring to projects foster organizational confidence in the outcomes of improvement initiatives.

The strategic influence of Black Belts extends to innovation. By applying data-driven insights and systematic problem-solving approaches, they identify opportunities for process reengineering, technology integration, and workflow enhancement. This capacity for forward-looking intervention ensures that organizations remain adaptive, resilient, and primed for sustainable growth.

Career Implications and Professional Growth

Attaining the Lean Six Sigma Black Belt credential has profound implications for career trajectories. Certified professionals are positioned to assume leadership roles, manage high-stakes projects, and contribute to organizational strategy. The combination of analytical acumen, project management capability, and leadership competence distinguishes Black Belts as highly valuable assets in diverse professional contexts.

Professional growth extends beyond immediate project outcomes. The skills cultivated through Black Belt training—critical thinking, data analysis, communication, and strategic planning—equip individuals for successive advancement in managerial or executive capacities. Certification provides both recognition and a platform for influence, enabling professionals to shape organizational processes and contribute to long-term success.

Furthermore, networking opportunities emerge through engagement with fellow Black Belts and practitioners. Collaborative forums, professional associations, and peer interactions facilitate the exchange of insights, methodologies, and best practices. These networks enrich professional development and provide ongoing support for continuous learning.

Project Execution and Implementation Strategies

Effective execution of Lean Six Sigma Black Belt projects requires meticulous planning, structured methodology, and disciplined oversight. Black Belts orchestrate initiatives that often involve multiple departments, complex processes, and diverse stakeholders. The success of such projects hinges on the ability to integrate analytical tools, leadership acumen, and practical execution strategies.

Project initiation begins with clear goal articulation. Defining the project scope, objectives, and success criteria ensures that all stakeholders share a coherent understanding of desired outcomes. Black Belts employ tools such as project charters, SIPOC diagrams (Suppliers, Inputs, Process, Outputs, Customers), and process flow maps to visualize workflows and delineate responsibilities. These instruments serve as navigational aids, aligning the project with organizational objectives and facilitating communication across functional boundaries.

During the planning phase, Black Belts allocate resources, identify potential risks, and develop mitigation strategies. Contingency planning is critical, as process improvement projects often encounter unforeseen challenges. Risk assessments, failure mode and effects analysis (FMEA), and scenario planning are employed to anticipate obstacles and ensure that interventions remain resilient under varying conditions.

Execution of the project involves applying Lean Six Sigma methodologies in a systematic manner. The DMAIC framework guides Black Belts in analyzing processes, implementing improvements, and monitoring results. Collaboration with cross-functional teams is essential; team members contribute operational insights that refine and validate proposed solutions. This collective approach ensures that interventions are practical, contextually relevant, and capable of yielding measurable results.

Monitoring and control are ongoing processes during project implementation. Black Belts establish key performance indicators, track progress against benchmarks, and adjust strategies as needed. Control charts, process audits, and periodic reviews ensure that improvements are sustained and that deviations are promptly addressed. By embedding a culture of vigilance and accountability, Black Belts transform process improvement from episodic interventions into enduring operational excellence.

Advanced Statistical Analysis in Black Belt Projects

Statistical analysis lies at the heart of Lean Six Sigma Black Belt effectiveness. Beyond basic descriptive statistics, Black Belts leverage advanced analytical techniques to understand complex process behavior and optimize outcomes. These competencies enable evidence-based decision-making and enhance the precision of improvement interventions.

Regression analysis is a foundational tool for identifying relationships between process variables. By modeling the influence of independent variables on outcomes, Black Belts can predict the impact of changes and prioritize interventions. Multiple regression, logistic regression, and multivariate analysis extend this capability to scenarios involving interdependent factors and categorical outcomes.

Design of experiments (DOE) is another critical technique. DOE allows professionals to systematically manipulate process inputs to determine their effects on performance outputs. Factorial designs, response surface methodologies, and robust parameter optimization enable Black Belts to fine-tune processes efficiently while minimizing experimentation costs and resource expenditure.

Hypothesis testing, analysis of variance (ANOVA), and statistical process control (SPC) are additional tools that provide empirical evidence for decision-making. Black Belts interpret these analyses to identify deviations, assess significance, and implement interventions that are statistically validated. The rigorous application of statistical techniques ensures that improvements are not arbitrary but grounded in quantifiable insights.

Furthermore, data visualization plays a vital role in translating statistical results into actionable knowledge. Scatter plots, histograms, Pareto charts, and control charts facilitate communication with stakeholders and enhance comprehension of complex findings. By coupling analytical rigor with intuitive presentation, Black Belts drive informed decisions and foster stakeholder confidence.

Leadership in Complex Improvement Initiatives

Leadership is a distinguishing feature of Lean Six Sigma Black Belt professionals. Beyond technical expertise, Black Belts navigate organizational complexities, influence stakeholders, and drive transformational change. Leadership involves a synthesis of strategic insight, interpersonal skills, and operational oversight.

Influence and negotiation are pivotal. Black Belts must garner support for projects, reconcile divergent priorities, and advocate for resource allocation. Effective communication and persuasive argumentation ensure that initiatives gain traction across hierarchical and functional boundaries.

Team facilitation is another crucial aspect. Black Belts lead cross-functional groups, fostering collaboration, knowledge sharing, and joint problem-solving. Conflict resolution and motivational strategies are employed to maintain engagement and sustain momentum. By cultivating a cohesive and purpose-driven team environment, Black Belts amplify project impact and ensure successful implementation.

Strategic foresight underpins effective leadership. Black Belts anticipate operational bottlenecks, market shifts, and organizational changes that could influence project outcomes. By integrating long-term considerations into immediate project planning, they ensure that interventions are both impactful and sustainable. Leadership, therefore, extends beyond project execution to shaping organizational capability and culture.

Cross-Functional Collaboration

Lean Six Sigma Black Belt projects frequently span multiple departments, necessitating robust cross-functional collaboration. The ability to work effectively with diverse teams is central to successful process improvement. Collaboration ensures that interventions are grounded in practical realities, operational knowledge, and organizational priorities.

Effective collaboration begins with stakeholder identification. Black Belts map the network of individuals and groups affected by process changes, assessing their influence, interest, and potential contributions. Engaging stakeholders early and consistently fosters buy-in, minimizes resistance, and aligns expectations.

Communication strategies are tailored to diverse audiences. While technical teams may require detailed analytical reports, executive stakeholders benefit from concise summaries highlighting strategic implications. Black Belts adapt their messaging to ensure clarity, relevance, and actionable insights for each audience segment.

Workshops, kaizen events, and collaborative problem-solving sessions facilitate team engagement. These interactive forums provide opportunities for brainstorming, consensus building, and iterative refinement of solutions. By harnessing collective intelligence, Black Belts generate innovative approaches and ensure that solutions are practically implementable.

Documentation and knowledge transfer are also integral to collaboration. Black Belts codify processes, lessons learned, and project outcomes to ensure continuity and scalability. This institutional knowledge supports future initiatives and reinforces a culture of continuous improvement.

Practical Tools and Techniques for Black Belts

Lean Six Sigma Black Belts employ a sophisticated repertoire of tools and techniques to analyze, optimize, and control processes. These instruments extend beyond basic problem-solving, enabling professionals to tackle complex operational challenges with precision and efficiency.

Value stream mapping provides a visual representation of process flows, highlighting areas of waste, redundancy, and inefficiency. By mapping the end-to-end process, Black Belts identify bottlenecks and prioritize interventions that yield the greatest impact.

Root cause analysis (RCA) techniques, including fishbone diagrams, 5 Whys analysis, and fault tree analysis, allow professionals to uncover underlying causes of defects or inefficiencies. Identifying root causes ensures that solutions address fundamental issues rather than superficial symptoms.

Process capability analysis measures a system’s ability to produce outputs within specification limits. Black Belts use capability indices, sigma levels, and performance metrics to assess process robustness and guide improvement efforts.

Failure mode and effects analysis (FMEA) anticipates potential failures and quantifies associated risks. By prioritizing high-impact risks, Black Belts implement preventive measures that mitigate operational vulnerabilities and enhance reliability.

Control plans, standard operating procedures, and process audits are employed to sustain gains. These tools institutionalize best practices, monitor ongoing performance, and ensure that improvements persist beyond the duration of the initial project.

Industry Applications and Case Insights

The versatility of Lean Six Sigma methodologies enables Black Belts to drive impactful change across diverse sectors. While tools and principles are consistent, contextual adaptation is essential to align interventions with industry-specific requirements.

In manufacturing, Black Belts optimize production lines, reduce defects, and streamline supply chains. Projects may involve redesigning workflows, implementing just-in-time production, or improving equipment utilization. The combination of statistical analysis and Lean principles enables precise identification of inefficiencies and effective process realignment.

Healthcare applications focus on patient care optimization, cost control, and operational efficiency. Black Belts analyze patient flow, reduce medical errors, and improve administrative processes. The implementation of Lean Six Sigma enhances clinical outcomes and increases organizational capacity to serve patients effectively.

Financial services benefit from process standardization, error reduction, and compliance optimization. Black Belts examine transactional processes, enhance reporting accuracy, and streamline client service workflows. By integrating quantitative analysis with operational knowledge, professionals ensure robust performance improvements.

Logistics and supply chain domains leverage Black Belts to optimize inventory management, distribution processes, and transportation efficiency. Projects often involve route optimization, warehouse layout redesign, and demand forecasting, resulting in cost reduction and enhanced delivery performance.

Across industries, Lean Six Sigma Black Belts serve as catalysts for innovation, operational resilience, and sustained performance enhancement. Their skill set transcends sector-specific boundaries, demonstrating the universal applicability and strategic value of the CLSSBB credential.

Sustaining Project Gains and Continuous Monitoring

The conclusion of a project marks the beginning of a sustainability phase. Black Belts ensure that improvements are not transient but embedded into operational routines. This involves continuous monitoring, control mechanisms, and iterative refinement.

Key performance indicators (KPIs) are established to measure ongoing process performance. Metrics such as defect rates, cycle times, throughput, and customer satisfaction provide quantifiable evidence of improvement and highlight areas requiring attention.

Periodic audits and review sessions reinforce accountability and adherence to established standards. Black Belts assess performance data, identify deviations, and implement corrective measures to prevent regression. This cyclical monitoring embodies the principle of continuous improvement, ensuring that processes remain agile, efficient, and aligned with organizational goals.

Sustainability also relies on cultural integration. Black Belts mentor teams, disseminate best practices, and foster a mindset that values incremental improvement. By institutionalizing Lean Six Sigma principles, organizations cultivate a self-sustaining ecosystem of process excellence that endures beyond individual projects.

Soft Skills for Black Belt Excellence

Beyond analytical expertise, Lean Six Sigma Black Belts cultivate a suite of soft skills essential for professional effectiveness. Communication, negotiation, emotional intelligence, and adaptability are crucial in navigating complex organizational environments.

Black Belts articulate project findings in a manner that resonates with diverse stakeholders, translating technical insights into strategic narratives. Negotiation skills facilitate resource allocation, conflict resolution, and stakeholder alignment. Emotional intelligence underpins effective team management, fostering collaboration, motivation, and resilience.

Adaptability enables Black Belts to tailor methodologies to specific organizational contexts, adjusting strategies in response to emerging challenges. Time management, prioritization, and resilience further enhance the capacity to handle multifaceted projects with precision and poise.

Exam Preparation and Certification Readiness

Certification validation is a critical milestone in the Black Belt journey. The examination assesses mastery of Lean Six Sigma principles, statistical methodologies, project execution strategies, and leadership competencies.

Preparation involves comprehensive review of theoretical concepts, hands-on exercises, and real-world case studies. Candidates refine their understanding of DMAIC phases, advanced statistical techniques, process mapping, and risk assessment tools. Simulated exam scenarios enhance familiarity with question formats and time management, ensuring readiness for formal assessment.

The credential not only validates knowledge but also signifies readiness to implement Lean Six Sigma methodologies at an organizational scale. Achieving certification demonstrates proficiency, commitment, and capability, providing recognition within professional and industry contexts.

Emerging Trends in Lean Six Sigma Black Belt Practices

The landscape of Lean Six Sigma continues to evolve, influenced by technological advancements, data analytics, and shifting business paradigms. Black Belt professionals who integrate these emerging trends into their practice are positioned to drive enhanced operational value and strategic innovation.

One significant trend is the integration of digital transformation within process improvement initiatives. Black Belts increasingly leverage data analytics platforms, business intelligence tools, and process automation technologies to optimize workflows. Real-time monitoring, predictive analytics, and automated reporting enable professionals to identify inefficiencies, track performance, and implement interventions with unprecedented precision.

Artificial intelligence (AI) and machine learning (ML) are also reshaping the scope of Lean Six Sigma. Predictive modeling and algorithmic analysis allow Black Belts to anticipate process deviations and proactively implement corrective measures. These technologies augment decision-making capabilities, enabling more accurate root cause identification and solution design.

The proliferation of cloud-based collaboration tools facilitates cross-functional coordination. Black Belts can engage teams across geographies, share insights in real time, and maintain continuity in project execution. This trend enhances knowledge transfer, accelerates problem-solving, and strengthens organizational alignment with Lean Six Sigma objectives.

Sustainability and social responsibility have emerged as complementary considerations in process improvement. Black Belts increasingly incorporate environmental impact, resource optimization, and ethical standards into their projects. Lean Six Sigma initiatives that balance operational efficiency with sustainability principles enhance organizational reputation and long-term viability.

Digital Integration and Process Optimization

Digital integration is becoming a cornerstone of contemporary Lean Six Sigma practice. Black Belts harness digital tools to automate data collection, streamline process monitoring, and facilitate real-time decision-making. Process mining, for example, enables professionals to analyze operational workflows using digital event logs, identifying bottlenecks and deviations with remarkable granularity.

Robotic process automation (RPA) is another pivotal tool. By automating repetitive tasks, Black Belts reduce variability, enhance accuracy, and free human resources for more strategic activities. Integration of RPA within Lean Six Sigma projects amplifies efficiency gains while ensuring consistency in operational outcomes.

Advanced analytics dashboards provide dynamic visualization of process metrics, enabling continuous monitoring and rapid intervention. Black Belts utilize these tools to track key performance indicators, assess project progress, and communicate insights effectively to stakeholders. This integration of digital technology enhances agility, reduces latency in decision-making, and supports evidence-based management.

Complex Problem-Solving Methodologies

Black Belt professionals are adept at tackling multifaceted operational challenges that defy simplistic solutions. Complex problem-solving requires the synthesis of analytical rigor, creative thinking, and practical experience. Lean Six Sigma methodologies provide a structured yet flexible framework for navigating such challenges.

Root cause analysis is extended through multivariate analysis and predictive modeling. Black Belts employ advanced statistical techniques to identify interdependencies among process variables, enabling nuanced understanding of process behavior. This capability is essential in high-stakes environments where minor deviations can propagate significant operational consequences.

Scenario planning and simulation models augment problem-solving capacity. By modeling potential outcomes under varying conditions, Black Belts anticipate risks, evaluate alternatives, and select interventions that maximize performance gains. Simulation tools, such as Monte Carlo analysis and discrete event modeling, provide insights that enhance decision-making precision.

Creative problem-solving complements analytical rigor. Black Belts facilitate brainstorming sessions, design thinking workshops, and ideation forums to generate innovative solutions. By blending structured analysis with imaginative approaches, professionals address challenges comprehensively and devise interventions that are both effective and sustainable.

Innovation Through Lean Six Sigma

Lean Six Sigma is traditionally associated with efficiency and defect reduction; however, Black Belts increasingly leverage the methodology as a driver of innovation. By systematically analyzing processes, uncovering inefficiencies, and envisioning optimized workflows, professionals identify opportunities for novel product development, service enhancements, and business model innovation.

Innovation emerges from the disciplined application of DMAIC principles. In the Define phase, problem statements may reveal latent opportunities for creativity. During Measure and Analyze, data-driven insights highlight gaps in service delivery, product functionality, or operational performance. Improvement strategies often incorporate novel approaches, technologies, or workflows, translating analytical findings into inventive solutions.

Collaboration amplifies innovation. Black Belts engage cross-functional teams to harness diverse perspectives, combining operational expertise with strategic vision. Iterative testing, piloting, and feedback loops ensure that innovative interventions are validated, practical, and capable of scaling across the organization.

Furthermore, Lean Six Sigma innovation fosters a culture of continuous exploration. By embedding analytical rigor, creative thinking, and iterative improvement into organizational routines, Black Belts contribute to long-term adaptability, resilience, and competitive differentiation.

Professional Growth and Leadership Development

Lean Six Sigma Black Belt certification is both a technical credential and a catalyst for professional growth. Beyond acquiring analytical and process optimization skills, professionals cultivate leadership competencies essential for influencing organizational outcomes.

Strategic leadership is a hallmark of Black Belt proficiency. Professionals develop the ability to align projects with organizational objectives, anticipate future operational challenges, and prioritize interventions that yield maximal impact. Leadership development encompasses vision articulation, stakeholder engagement, and strategic decision-making.

Mentorship is integral to professional growth. Black Belts guide Green Belts, operational teams, and junior colleagues, fostering a culture of learning, accountability, and continuous improvement. By disseminating knowledge and modeling best practices, Black Belts extend their influence and enhance organizational capability.

Career trajectories for certified Black Belts often include senior management roles, process excellence leadership, and operational strategy positions. The combination of analytical expertise, project management skills, and leadership capacity distinguishes Black Belts as high-value professionals capable of shaping organizational direction.

Networking and Knowledge Exchange

Professional networking plays a pivotal role in the Black Belt journey. Engagement with peers, mentors, and industry experts facilitates knowledge exchange, collaborative problem-solving, and access to emerging best practices. Networking enhances professional visibility, provides avenues for learning, and fosters community among practitioners committed to operational excellence.

Workshops, conferences, and peer forums provide platforms for discussing challenges, sharing insights, and exploring innovative applications of Lean Six Sigma. These interactions cultivate intellectual agility, expose professionals to diverse perspectives, and stimulate creative thinking. Knowledge exchange ensures that Black Belts remain at the forefront of methodological advancements and industry trends.

Sustaining a Culture of Continuous Improvement

Lean Six Sigma Black Belts are not merely project executors; they are architects of enduring operational excellence. Embedding continuous improvement within organizational culture is essential for long-term sustainability and competitiveness.

Cultural integration involves education, engagement, and empowerment. Black Belts mentor teams, communicate the value of process improvement, and encourage proactive problem identification. By fostering accountability and ownership, professionals cultivate an environment where continuous improvement becomes intrinsic to operational routines.

Measurement and monitoring reinforce cultural sustainability. Performance dashboards, control plans, and audit protocols ensure that process gains are maintained and that deviations are addressed promptly. Black Belts institutionalize these practices, transforming episodic improvements into systematic organizational capabilities.

Leveraging Technology for Enhanced Impact

Technology amplifies the influence of Lean Six Sigma Black Belts. Data analytics platforms, workflow automation, and digital collaboration tools enable professionals to optimize processes more effectively and implement improvements with greater precision.

Predictive analytics allows Black Belts to anticipate process anomalies, forecast outcomes, and proactively adjust strategies. Workflow automation reduces variability and accelerates operational tasks, freeing resources for higher-value activities. Digital dashboards and reporting tools enhance transparency, facilitate stakeholder engagement, and enable data-driven decision-making at all organizational levels.

Technology integration also supports scalability. Black Belts can replicate successful interventions across multiple sites, geographies, or functional units, ensuring consistency and maximizing organizational benefits. This technological leverage transforms individual projects into enterprise-wide performance enhancements.

Strategic Decision-Making and Impact Assessment

Black Belt professionals contribute to strategic decision-making by providing data-driven insights and evidence-based recommendations. Process improvement initiatives inform operational planning, resource allocation, and policy formulation, enabling organizations to achieve strategic objectives more efficiently.

Impact assessment is central to this role. Black Belts quantify the benefits of interventions, measuring cost savings, efficiency gains, quality improvements, and customer satisfaction enhancements. Comprehensive evaluation ensures that improvements are validated, replicable, and aligned with broader organizational priorities.

Through strategic analysis, Black Belts identify opportunities for continuous enhancement, anticipate emerging operational challenges, and guide management decisions. Their ability to link process optimization with strategic outcomes reinforces the organizational value of Lean Six Sigma initiatives.

Integrating Lean Six Sigma with Organizational Strategy

Lean Six Sigma Black Belt initiatives are most impactful when integrated with overarching organizational strategy. Black Belts align projects with corporate goals, market imperatives, and operational priorities, ensuring that process improvements contribute to long-term performance enhancement.

Strategic alignment involves prioritization, resource allocation, and stakeholder engagement. Black Belts assess the potential impact of projects, select initiatives with the highest strategic value, and coordinate execution to maximize organizational benefit. This alignment ensures that Lean Six Sigma efforts are not isolated exercises but integral components of strategic planning.

Continuous feedback loops reinforce integration. Black Belts monitor outcomes, assess alignment with evolving objectives, and adjust interventions as necessary. By embedding Lean Six Sigma within organizational strategy, professionals enhance agility, resilience, and competitive advantage.

Advanced Tools for Process Excellence

Lean Six Sigma Black Belt professionals employ a sophisticated array of tools to drive operational improvement. Beyond basic analytical instruments, these tools enable nuanced understanding of complex processes and facilitate sustainable change.

Process mapping remains foundational, providing a visual representation of workflows and identifying potential inefficiencies. Black Belts expand traditional mapping techniques by incorporating value stream mapping, spaghetti diagrams, and process simulation models. These approaches uncover bottlenecks, redundancy, and waste, providing actionable insights for improvement.

Root cause analysis is applied through advanced methods such as Failure Mode and Effects Analysis (FMEA), fault tree analysis, and the 5 Whys methodology. These tools enable professionals to systematically diagnose process defects, prioritize corrective actions, and prevent recurrence. The depth and precision of these analyses differentiate Black Belts from practitioners at lower certification levels.

Statistical process control (SPC) is employed to monitor process stability over time. Control charts, capability indices, and performance trend analysis allow professionals to detect deviations early and implement timely interventions. Black Belts leverage these metrics not only to ensure immediate process fidelity but also to establish long-term operational consistency.

Design of experiments (DOE) and regression analysis provide advanced problem-solving capabilities. By systematically manipulating process variables, Black Belts identify causal relationships, optimize outcomes, and validate improvement initiatives. These tools enhance both precision and predictability in process enhancement efforts.

Complex Project Leadership

Lean Six Sigma Black Belts frequently manage multifaceted projects involving multiple departments and high-stakes operational goals. Effective project leadership requires the integration of strategic vision, operational oversight, and interpersonal influence.

Project initiation involves defining objectives, establishing success criteria, and identifying key stakeholders. Black Belts utilize project charters, SIPOC diagrams, and process flowcharts to ensure clarity and alignment from the outset. This structured approach provides a roadmap for execution and facilitates stakeholder engagement throughout the project lifecycle.

During execution, Black Belts coordinate cross-functional teams, balancing analytical rigor with practical implementation. Leadership skills are essential for motivating team members, resolving conflicts, and maintaining focus on project milestones. Regular progress reviews, performance tracking, and adaptive planning enable professionals to navigate unforeseen challenges effectively.

Risk management is integral to project leadership. Black Belts identify potential obstacles using FMEA, risk matrices, and scenario planning. Mitigation strategies are developed proactively, ensuring that projects remain resilient and capable of delivering targeted outcomes despite operational complexities.

Cross-Functional Collaboration and Organizational Integration

Collaboration across departments is critical for successful Lean Six Sigma initiatives. Black Belts bridge functional silos, ensuring that process improvements are informed by diverse perspectives and operational realities.

Stakeholder analysis allows professionals to identify individuals and groups with influence over, or impact from, the project. Engagement strategies are tailored to the needs, concerns, and communication preferences of each stakeholder. Early and consistent involvement fosters buy-in and reduces resistance to change.

Interactive workshops, kaizen events, and cross-departmental problem-solving sessions facilitate collaborative innovation. Black Belts guide teams through structured ideation processes, combining data-driven insights with practical experience to generate effective solutions.

Knowledge transfer is a crucial aspect of collaboration. Black Belts document processes, lessons learned, and project outcomes, ensuring that improvements are replicable and scalable. Institutionalizing knowledge supports continuous improvement across the organization and strengthens overall operational capability.

Measuring Impact and Sustaining Gains

Lean Six Sigma Black Belts are responsible not only for implementing improvements but also for ensuring their sustainability. Establishing performance metrics, monitoring progress, and embedding continuous improvement practices are essential for long-term success.

Key performance indicators (KPIs) provide quantifiable measures of project impact. Metrics such as cycle time reduction, defect rates, cost savings, and customer satisfaction scores enable professionals to assess improvement efficacy and identify areas requiring further attention.

Control plans, standard operating procedures, and periodic audits reinforce sustainability. Black Belts institutionalize process improvements by establishing standardized practices, monitoring ongoing performance, and intervening when deviations occur. This ensures that gains are maintained and that process excellence becomes embedded in organizational culture.

Feedback mechanisms further support continuous improvement. Black Belts solicit input from operational teams, review performance data, and adapt interventions based on evolving conditions. This iterative approach strengthens the resilience and effectiveness of process enhancements over time.

Enhancing Problem-Solving Prowess

The advanced problem-solving capabilities of Black Belt professionals extend beyond analytical skills to encompass creativity, adaptability, and strategic thinking. Lean Six Sigma provides a structured framework, but exceptional outcomes often require innovative approaches.

Critical thinking is essential for interpreting complex data, evaluating alternative solutions, and identifying the most impactful interventions. Black Belts apply analytical tools while considering operational realities, organizational dynamics, and long-term implications of process changes.

Scenario planning and simulation techniques augment problem-solving capabilities. By modeling potential outcomes under varying conditions, professionals can anticipate risks, test interventions virtually, and select strategies that optimize process performance.

Creative thinking complements structured methodologies. Brainstorming, design thinking workshops, and iterative prototyping encourage the generation of novel solutions that may not emerge from purely analytical approaches. This dual emphasis on structured analysis and imaginative exploration defines the expertise of high-performing Black Belts.

Strategic Influence and Organizational Impact

Lean Six Sigma Black Belts are catalysts for organizational transformation. Their interventions extend beyond operational efficiency to influence strategic decision-making, resource allocation, and organizational culture.

By aligning projects with corporate objectives, Black Belts ensure that process improvements contribute to long-term strategic goals. Their data-driven insights inform management decisions, optimize resource deployment, and enhance competitive positioning.

Cost reduction, quality enhancement, and efficiency gains represent tangible benefits of Black Belt initiatives. Beyond these measurable outcomes, the cultural impact is profound. Black Belts foster a mindset of continuous improvement, accountability, and evidence-based decision-making that permeates all levels of the organization.

The integration of Lean Six Sigma with organizational strategy amplifies impact. Professionals prioritize initiatives with the greatest strategic value, monitor alignment with evolving objectives, and adjust interventions proactively. This alignment ensures that improvements are both operationally effective and strategically meaningful.

Career Trajectories and Professional Recognition

Obtaining Lean Six Sigma Black Belt certification significantly enhances career prospects. Certified professionals are recognized for their analytical acumen, leadership capabilities, and capacity to drive tangible organizational results.

Career advancement often includes leadership roles in process excellence, operational strategy, and organizational transformation. Black Belts may lead enterprise-wide initiatives, oversee cross-functional teams, or serve as strategic advisors to senior management.

Professional recognition extends beyond formal titles. Black Belts become trusted advisors within their organizations, valued for their ability to translate data into actionable insights and lead initiatives that yield measurable impact. This recognition enhances influence, credibility, and opportunities for further career growth.

Networking with peers, mentors, and industry experts further supports professional development. Engagement in forums, conferences, and collaborative communities facilitates knowledge exchange, exposes professionals to emerging best practices, and strengthens career resilience.

Leveraging Technology for Operational Excellence

Technological integration amplifies the effectiveness of Lean Six Sigma Black Belts. Data analytics platforms, digital dashboards, and process automation tools enhance monitoring, decision-making, and intervention precision.

Predictive analytics enables professionals to anticipate deviations, forecast performance trends, and implement proactive solutions. Robotic process automation (RPA) reduces manual effort, increases consistency, and allows Black Belts to focus on higher-value tasks.

Digital collaboration platforms enhance cross-functional coordination, supporting knowledge sharing, project tracking, and remote engagement. These tools increase project agility, enable rapid problem resolution, and strengthen organizational alignment with Lean Six Sigma objectives.

Technology also facilitates scalability. Improvements validated in one area can be replicated across departments, regions, or operational units, ensuring consistency and maximizing organizational benefit. Black Belts leverage technology not only to optimize processes but also to institutionalize best practices and sustain long-term performance gains.

Sustaining Continuous Improvement

Lean Six Sigma Black Belts ensure that process improvements are maintained over time. Continuous improvement is not a transient goal but a core operational philosophy embedded into organizational routines.

Performance monitoring is central to sustainability. Black Belts track KPIs, conduct periodic audits, and implement corrective actions when deviations occur. This ongoing oversight preserves process gains and reinforces accountability.

Cultural integration is equally important. Black Belts mentor teams, promote best practices, and cultivate an environment that encourages proactive problem identification. By embedding continuous improvement principles into daily operations, professionals create a self-sustaining ecosystem of operational excellence.

Feedback loops support iterative refinement. Black Belts encourage team input, analyze performance trends, and adapt interventions to changing conditions. This dynamic approach ensures that processes remain agile, effective, and aligned with organizational objectives.

Preparing for Certification and Exam Success

Achieving Lean Six Sigma Black Belt certification requires rigorous preparation. Professionals must demonstrate mastery of DMAIC methodology, statistical tools, project leadership, and strategic implementation.

Preparation involves comprehensive review of theoretical concepts, practical exercises, and real-world case studies. Mock exams, practice projects, and interactive workshops enhance readiness, allowing candidates to apply knowledge under simulated conditions.

Certification validates proficiency, signaling readiness to lead complex process improvement initiatives. It affirms analytical capability, leadership acumen, and strategic insight, providing recognition and credibility within professional contexts.

Real-World Success Stories of Lean Six Sigma Black Belts

The transformative power of Lean Six Sigma Black Belt certification is best illustrated through real-world applications. Professionals who have embraced the methodology have consistently delivered measurable improvements in operational efficiency, quality, and customer satisfaction.

In manufacturing, a Black Belt professional led a project to optimize a production line that was plagued with frequent downtime and defects. Through meticulous process mapping, root cause analysis, and application of DMAIC principles, the team identified critical bottlenecks and implemented targeted interventions. The result was a 25% reduction in production cycle time and a 40% decrease in defective units, translating into substantial cost savings and enhanced customer satisfaction.

In the healthcare sector, a Black Belt analyzed patient flow and administrative processes within a large hospital. By applying statistical process control and redesigning workflows, the project reduced patient wait times by 30% and improved staff allocation efficiency. This initiative not only enhanced patient experience but also optimized operational expenditure, demonstrating the versatility of Lean Six Sigma in non-manufacturing environments.

A finance industry example highlights the impact of Lean Six Sigma on transactional processes. A Black Belt led a project to streamline loan processing operations. Through data-driven analysis, identification of redundant steps, and automation of repetitive tasks, the team cut processing times by 35% while maintaining compliance standards. This improvement increased customer satisfaction, minimized operational risk, and elevated organizational performance.

In logistics and supply chain management, a Black Belt professional optimized warehouse layout, implemented inventory tracking systems, and applied predictive analytics for demand forecasting. The initiatives led to a 20% reduction in order fulfillment time and a 15% decrease in inventory holding costs. By integrating Lean Six Sigma principles with technological tools, the professional delivered substantial efficiency gains and operational resilience.

These success stories exemplify the tangible benefits of Lean Six Sigma Black Belt certification. Professionals equipped with advanced analytical skills, process improvement methodologies, and leadership capabilities are capable of generating substantial operational and strategic impact across industries.

Embracing Emerging Technologies in Lean Six Sigma

The future of Lean Six Sigma is increasingly intertwined with emerging technologies. Black Belt professionals who embrace these innovations can extend the reach, efficiency, and impact of process improvement initiatives.

Artificial intelligence and machine learning provide predictive capabilities that enhance problem-solving and decision-making. Black Belts can utilize AI algorithms to anticipate process deviations, model potential interventions, and optimize resource allocation. These technologies enable proactive management of operational processes, reducing defects and inefficiencies before they manifest.

Robotic process automation is another transformative tool. By automating repetitive, rule-based tasks, Black Belts can streamline workflows, reduce variability, and free human resources for more strategic responsibilities. This integration amplifies the benefits of Lean Six Sigma while maintaining process fidelity.

Digital dashboards and data visualization tools support real-time monitoring of key performance indicators. Black Belts can track progress, identify emerging issues, and communicate insights effectively across organizational hierarchies. This technological leverage enhances agility, responsiveness, and decision-making precision.

Cloud-based collaboration platforms facilitate seamless cross-functional engagement. Black Belts can coordinate projects across geographies, ensuring continuity, knowledge sharing, and alignment with strategic objectives. These technologies expand the scope and scalability of Lean Six Sigma initiatives, reinforcing the global relevance of certified professionals.

Continuous Professional Development

Lean Six Sigma Black Belt certification is not an endpoint but a milestone in a lifelong learning journey. Continuous professional development is essential to maintain expertise, adapt to emerging trends, and sustain organizational impact.

Black Belts engage in ongoing learning through industry seminars, professional workshops, and advanced courses. This continuous engagement with evolving methodologies, statistical tools, and best practices ensures that professionals remain at the forefront of process improvement.

Mentorship and peer collaboration are integral to professional growth. Experienced Black Belts mentor Green Belts, facilitate knowledge transfer, and cultivate a culture of continuous improvement within their organizations. Peer engagement provides exposure to diverse challenges, innovative solutions, and emerging industry practices.

Professional development also involves exploring interdisciplinary applications. Black Belts increasingly integrate principles from project management, quality engineering, data analytics, and digital transformation to enhance their effectiveness. This broadens their skill set, reinforces versatility, and strengthens their capacity to drive organizational excellence.

Driving Organizational Transformation

The impact of Lean Six Sigma Black Belt professionals extends beyond project execution to organizational transformation. By embedding continuous improvement principles, data-driven decision-making, and structured problem-solving into operational routines, Black Belts foster enduring operational resilience.

Black Belts contribute to strategic planning by aligning improvement initiatives with corporate objectives, assessing operational risks, and recommending interventions that maximize value. Their analytical insights inform leadership decisions, optimize resource allocation, and enhance competitiveness in dynamic markets.

Cultural transformation is a critical dimension. Black Belts champion a mindset of accountability, innovation, and proactive problem-solving. Through mentorship, training, and example-setting, they cultivate teams that embrace process excellence as a core organizational value.

Sustained operational performance is achieved by combining rigorous monitoring, continuous feedback loops, and strategic alignment. Black Belts institutionalize best practices, ensuring that process improvements endure and evolve alongside organizational needs.

The Global Significance of Lean Six Sigma Black Belts

Lean Six Sigma Black Belt certification holds universal relevance across industries and regions. The principles of waste elimination, defect reduction, and process optimization are applicable in manufacturing, healthcare, finance, logistics, technology, and service sectors worldwide.

Global organizations recognize the value of certified Black Belts in driving operational efficiency, strategic alignment, and competitive differentiation. Professionals with this certification are equipped to lead complex initiatives, adapt to diverse operational contexts, and deliver measurable results across organizational boundaries.

Moreover, the universality of Lean Six Sigma principles allows certified professionals to transition across industries with relative ease. The analytical rigor, project leadership skills, and strategic insight developed through Black Belt training are transferable assets, enhancing professional versatility and career mobility.

Preparing for Certification Success

Achieving Lean Six Sigma Black Belt certification requires disciplined preparation, practical experience, and mastery of both methodology and analytical tools. Candidates engage in intensive training programs that encompass DMAIC methodology, advanced statistical techniques, leadership strategies, and real-world case studies.

Practice projects provide hands-on experience, allowing candidates to apply theoretical knowledge to complex operational challenges. Simulated exam exercises, interactive workshops, and scenario-based assessments further enhance readiness, ensuring that candidates can demonstrate proficiency in practical, real-world contexts.

Successful certification validates expertise and readiness to lead transformative projects. It signals to employers, peers, and stakeholders that the professional possesses the analytical acumen, problem-solving capability, and leadership skills necessary to deliver sustained operational improvement.

Future Trends in Lean Six Sigma

The evolution of Lean Six Sigma is closely linked with technological innovation, organizational complexity, and data-driven decision-making. Future Black Belt professionals will increasingly engage with AI, machine learning, predictive analytics, and digital automation to extend the effectiveness of process improvement initiatives.

Sustainability, social responsibility, and ethical considerations are emerging as integral components of Lean Six Sigma projects. Black Belts will integrate these dimensions into process redesign, ensuring that operational excellence aligns with broader societal and environmental imperatives.

The emphasis on continuous learning will intensify, as professionals adapt to evolving methodologies, sector-specific challenges, and technological advancements. Black Belts who embrace lifelong learning, cross-disciplinary integration, and innovation will remain at the forefront of organizational transformation.

Maximizing Career and Organizational Impact

Certified Lean Six Sigma Black Belts are positioned to achieve significant professional growth while driving meaningful organizational change. Their combination of analytical expertise, project leadership, and strategic insight makes them invaluable contributors to operational and strategic initiatives.

Career advancement often includes leadership roles in operations, process excellence, quality management, and strategic planning. Black Belts are recognized for their ability to translate complex data into actionable solutions, optimize processes, and enhance organizational performance.

The organizational impact extends beyond efficiency gains to encompass cultural transformation, knowledge institutionalization, and strategic alignment. Black Belts foster environments where continuous improvement becomes ingrained, processes are resilient, and teams are empowered to innovate.

Final Reflections on Lean Six Sigma Black Belt Excellence

The journey to Lean Six Sigma Black Belt certification is transformative, equipping professionals with the skills, knowledge, and mindset to drive profound operational and strategic improvements. Through rigorous training, hands-on projects, and practical application, Black Belts acquire competencies that distinguish them as leaders in process optimization and organizational excellence.

The value of certification extends beyond personal career advancement. Black Belts contribute to cost reduction, efficiency enhancement, quality improvement, and customer satisfaction. Their interventions leave lasting impact, shaping organizational culture and enabling sustainable performance gains.