Exam Code: TM12

Exam Name: ISTQB-BCS Certified Tester Advanced Level- Test Manager (2012)

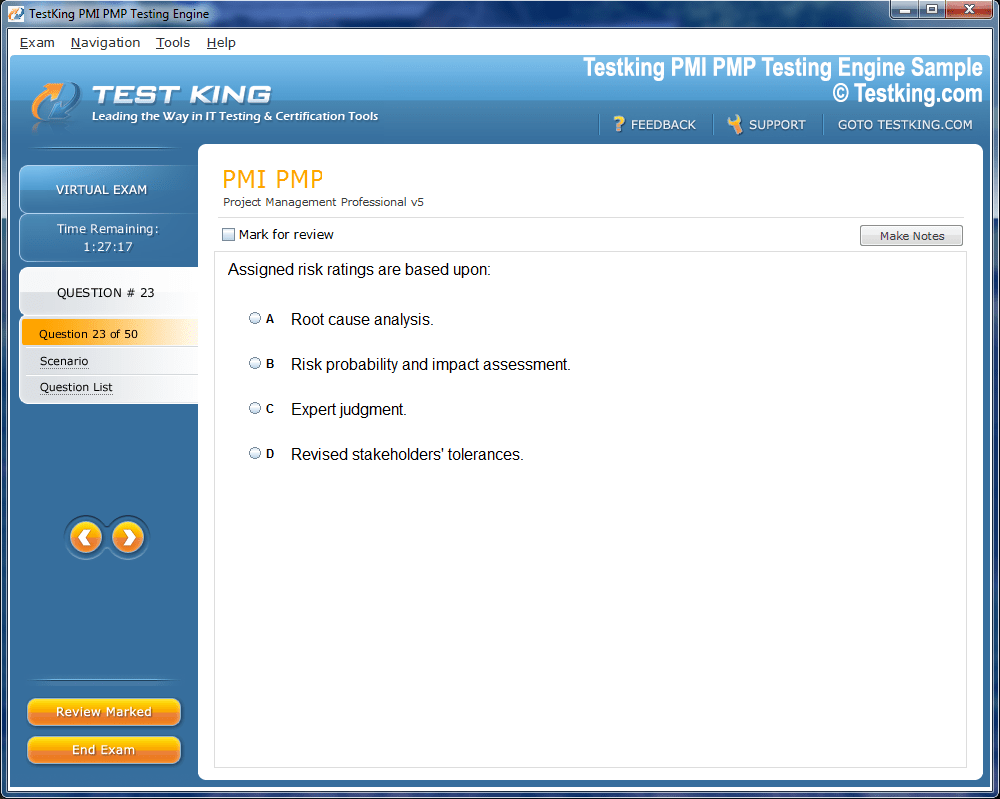

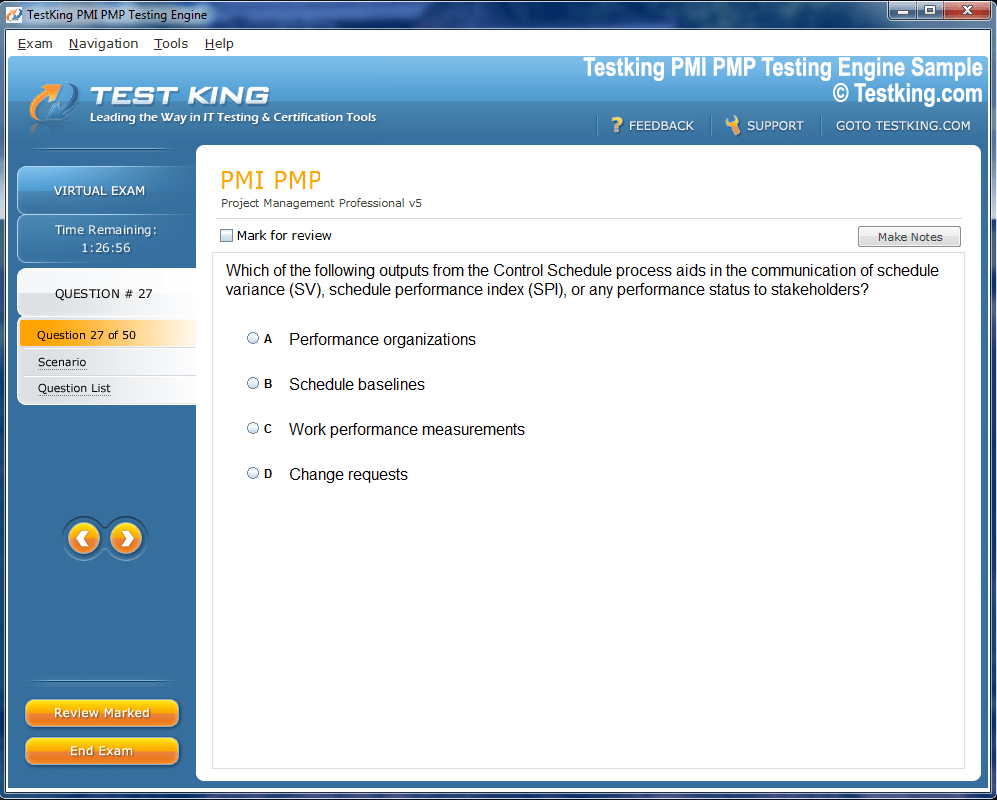

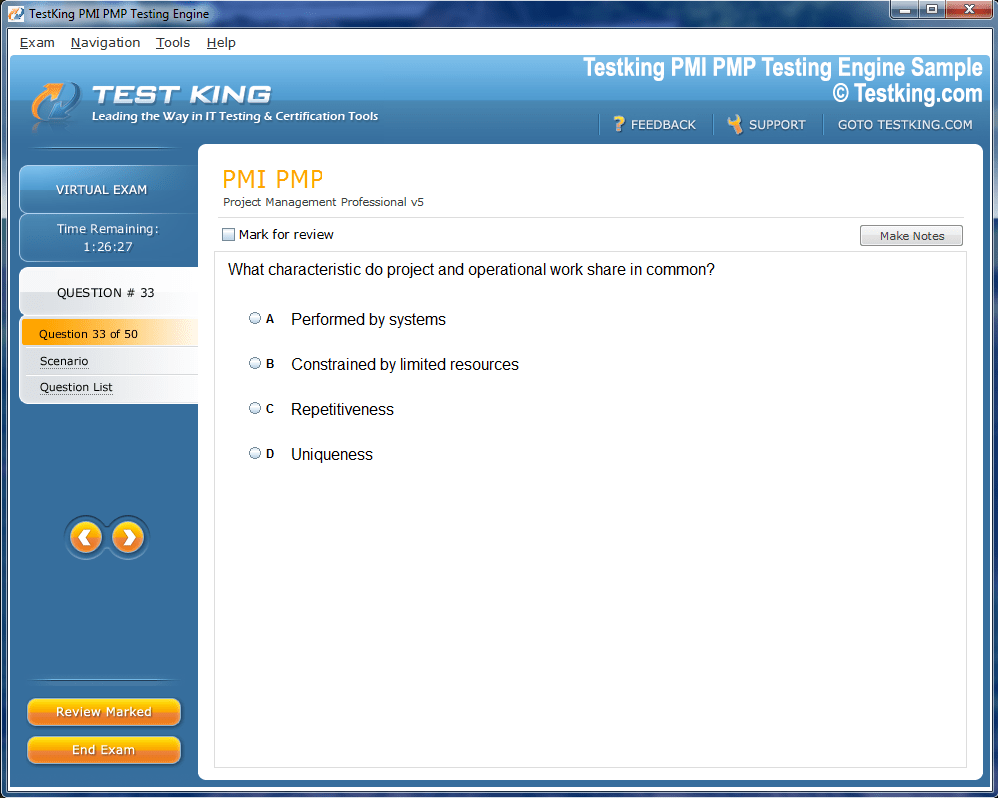

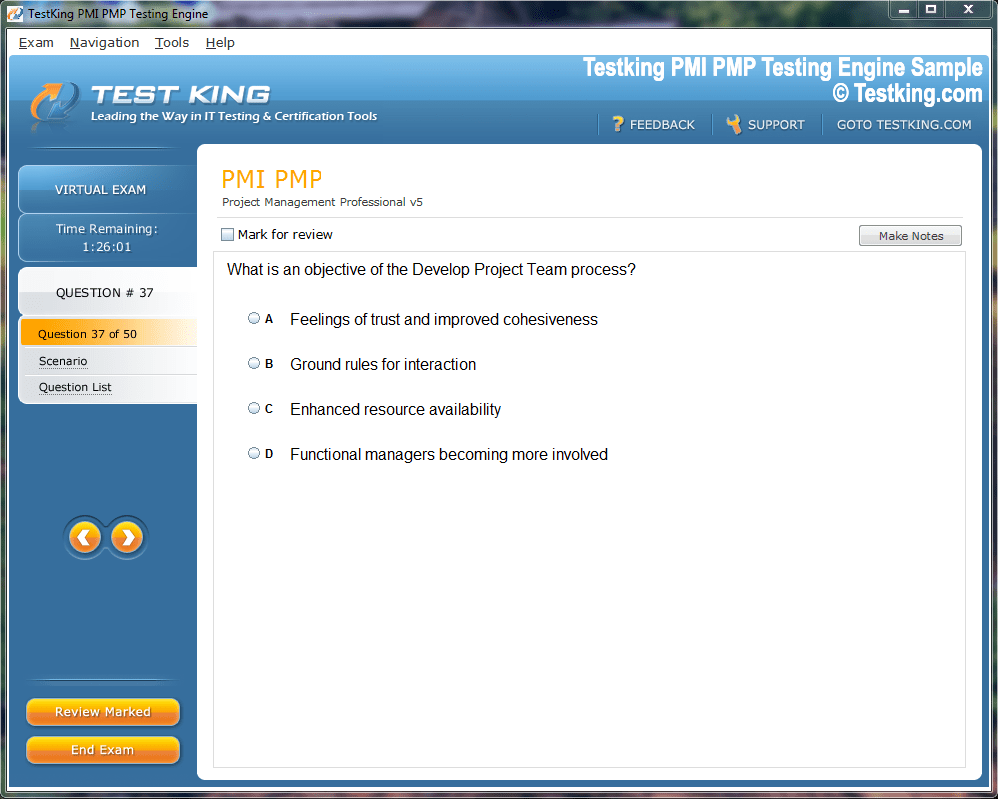

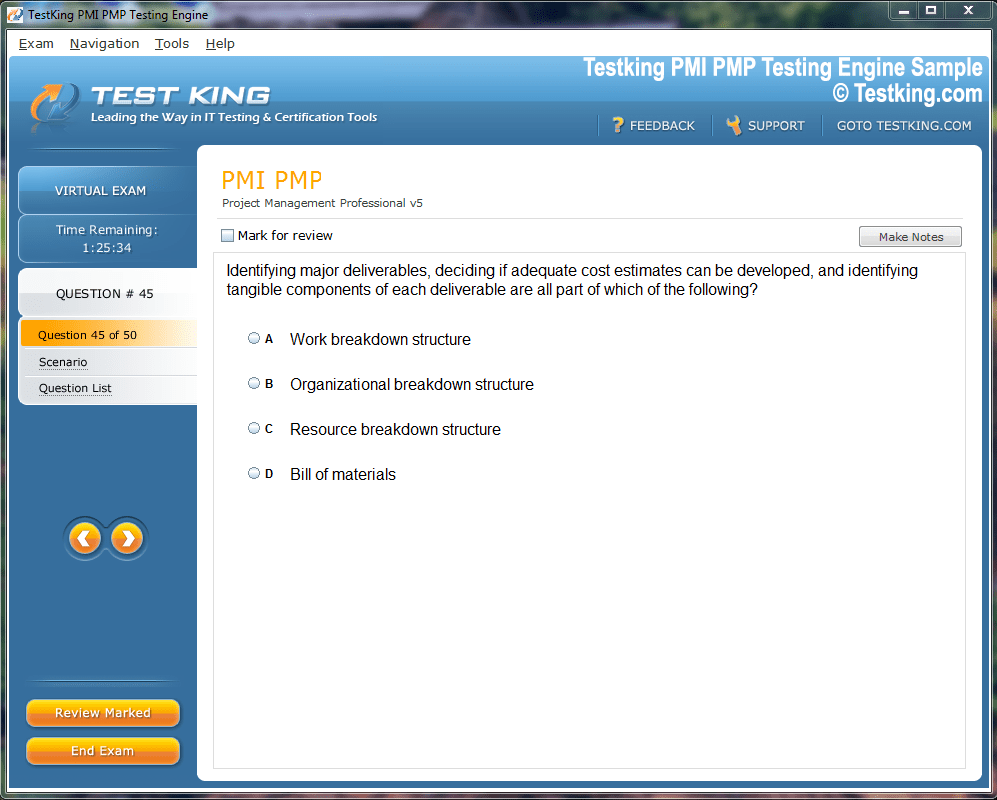

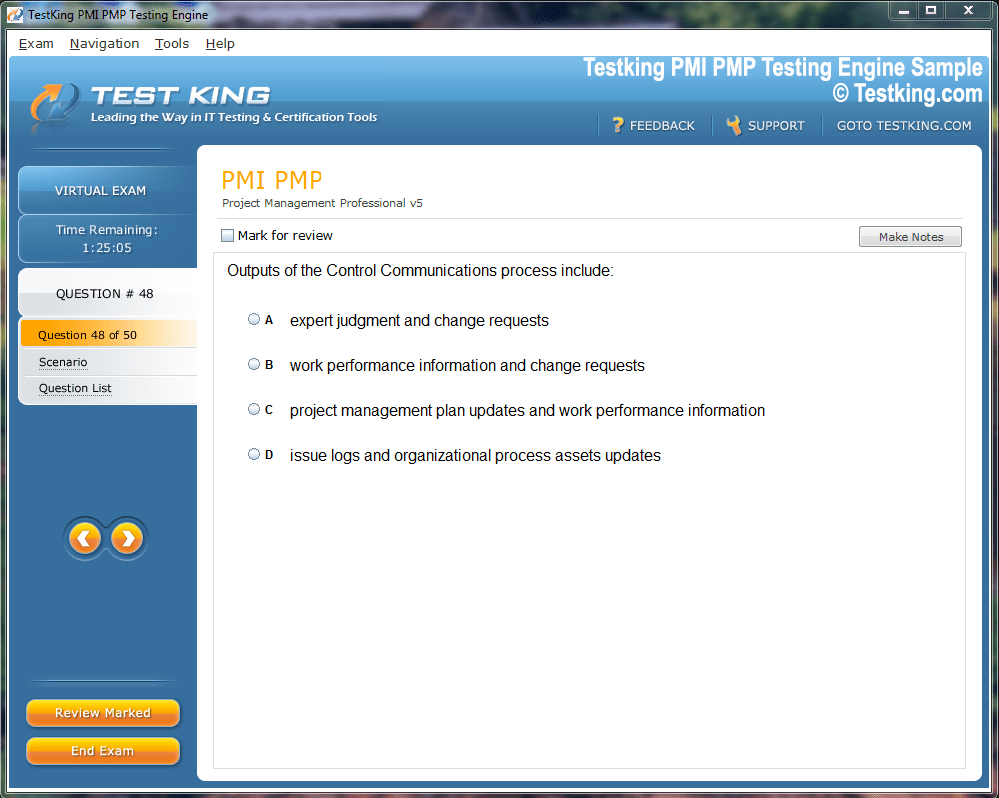

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our TM12 testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top BCS Exams

How the BCS TM12 Supports Reliable Automation for Small Enterprises

In the evolving landscape of industrial automation, collaborative robots, or cobots, have emerged as a pivotal component in optimizing workflow and enhancing productivity. Among these, the Techman TM12 holds a distinguished position for its practicality, reliability, and ease of use. The TM12 is a compact cobot designed for manufacturers who require straightforward automation solutions without the complications of advanced robotics programming or extensive customization. Its design philosophy revolves around simplicity and consistency, making it particularly suitable for light assembly, inspection, and basic pick-and-place operations.

The industrial domain increasingly values cobots for their ability to work safely alongside human operators. Safety considerations are paramount, and the TM12 addresses this with adherence to ISO 10218 and ISO/TS 15066 standards. These certifications ensure that the TM12 can collaborate with personnel in shared workspaces, mitigating the risks typically associated with traditional industrial robots. By meeting these standards, the TM12 establishes itself as a trustworthy assistant for tasks that require repetitive movements but minimal cognitive intervention. Its compliance also implies the inclusion of safety features such as torque limitation, collision detection, and emergency stop mechanisms, which collectively contribute to operational security without sacrificing efficiency.

The TM12’s architecture emphasizes compactness and versatility in moderate workspace environments. With a reach of 1300 mm, the cobot can comfortably operate across small to mid-sized workstations, allowing operators to minimize repositioning tasks while maintaining coverage over the production area. This reach, coupled with a payload capacity of 12 kilograms, renders the TM12 ideal for handling lightweight components, electronic assemblies, and parts that require precise but routine manipulation. The combination of reach and payload is particularly conducive to workflows where the continuity of operations and minimal human intervention are desired, as it can handle a range of objects without frequent recalibration or manual assistance.

The repeatability of the TM12, specified at ±0.1 mm, represents its capacity to reproduce motions with a consistent degree of accuracy. While this precision may not meet the stringent demands of ultra-high tolerance applications, it is adequate for standard pick-and-place tasks, light inspection routines, and repetitive assembly processes. Repeatability is a critical aspect in cobotics because it determines the robot’s ability to maintain quality and consistency across multiple cycles. The TM12’s reliability in this regard ensures that operators can depend on it for continuous operations without constant monitoring, reducing the cognitive load on personnel and allowing for more strategic allocation of human resources.

One of the defining characteristics of the TM12 is its integrated 2D vision system. This built-in feature allows the robot to identify and locate objects within its operational plane, facilitating straightforward automation of tasks such as sorting, alignment, and basic inspection. While the 2D vision lacks depth perception and advanced spatial awareness, it is sufficient for applications that involve flat or moderately structured objects. The vision system enhances the TM12’s utility by reducing the need for precise pre-positioning by human operators, streamlining workflows, and minimizing errors in repetitive handling operations.

Programming the TM12 is designed to be accessible to operators of varying skill levels. Utilizing a graphical user interface with block-based logic, the robot can be instructed to perform a sequence of tasks with minimal technical expertise. This interface is particularly beneficial for small and medium-sized enterprises that may not have specialized robotics engineers on staff. The intuitive nature of the programming environment allows teams to deploy the TM12 quickly, adapting it to specific tasks without extensive downtime or trial-and-error configurations. This simplicity is a cornerstone of the TM12’s design ethos, ensuring that operational efficiency is achievable without a steep learning curve.

Despite its user-friendly interface and reliability, the TM12 is characterized by a closed software ecosystem. Unlike some advanced cobots that allow for artificial intelligence or machine learning enhancements, the TM12’s functionality is largely fixed upon deployment. This design choice prioritizes stability and predictability over adaptability, making it a suitable option for environments where automation tasks remain consistent over time. The closed system reduces the complexity of maintenance and updates, ensuring that operators can manage the robot with minimal technical intervention. While this may limit scalability or integration with highly customized processes, it reinforces the TM12’s appeal as a dependable workhorse for specific automation applications.

Maintenance and operational support are essential aspects of deploying any industrial robot, and the TM12 provides resources primarily through authorized resellers. Documentation is thorough and user-friendly, enabling operators to understand installation, setup, and routine troubleshooting. However, some users have noted that while the support structure is solid for general maintenance, the longevity and uptime of the TM12 can vary depending on the frequency of use and the nature of the tasks performed. The straightforward design helps mitigate complex failures, but proactive monitoring and adherence to recommended maintenance schedules remain crucial to sustaining optimal performance.

The TM12’s installation process is straightforward, typically requiring one to two days depending on task complexity. The setup involves defining the robot’s workspace, calibrating its motion paths, and configuring the vision system for object recognition. Because the TM12 is designed for simplicity, it avoids intricate integrations or extensive software configurations, allowing teams to begin operations relatively quickly. The ease of deployment, combined with the cobot’s predictable operational behavior, makes it a viable solution for facilities seeking to introduce automation without significant disruption to existing processes.

From a use-case perspective, the TM12 excels in repetitive, low-variation tasks. Electronics assembly lines, quality inspection stations, and straightforward pick-and-place operations are ideal scenarios where the TM12 can deliver consistent performance. Its compact footprint and moderate payload capacity ensure that it can function effectively in environments where space is constrained and components are relatively lightweight. Operators can leverage the robot’s capabilities to maintain a steady throughput while reallocating human labor to more complex or cognitively demanding activities. In this context, the TM12 functions as an extension of the human workforce rather than a replacement, augmenting productivity without necessitating advanced programming or intervention.

The integration of vision-enabled technology in the TM12, though limited to two-dimensional recognition, provides a foundational level of automation intelligence. By detecting object positions and guiding manipulative actions, the robot reduces human error and increases the reliability of repeated tasks. The vision system is particularly advantageous in inspection applications where orientation and placement of components must be monitored but do not require three-dimensional spatial analysis. This capability streamlines workflow management and allows operators to focus on quality control measures without constant manual oversight.

One notable advantage of the TM12 is its accessibility to operators who may have a limited technical background. Unlike more advanced robotic systems that require extensive knowledge of programming languages or industrial protocols, the TM12’s graphical interface allows personnel to configure task sequences using drag-and-drop logic blocks. This design philosophy democratizes automation, enabling smaller teams or facilities without dedicated robotics engineers to implement reliable solutions. The simplicity of the interface ensures that training time is minimal, and operators can confidently execute tasks with predictable outcomes.

While the TM12 is reliable for consistent, low-complexity automation, it is not designed for high-mix production environments or tasks requiring fine-grained tolerances. Its repeatability and payload limitations make it unsuitable for operations involving heavy components, intricate assembly, or dynamic repositioning. However, for tasks where uniformity, repeatability, and predictable performance are valued over adaptability, the TM12 remains a robust and cost-effective solution. Manufacturers who prioritize operational stability and minimal intervention will find the TM12 an apt choice for routine applications.

The TM12 also contributes to ergonomic improvements on the shop floor. By automating repetitive pick-and-place and inspection tasks, the robot reduces the physical strain on human operators, who might otherwise be required to perform monotonous or fatiguing movements. This not only improves worker satisfaction but also minimizes the risk of repetitive strain injuries. The TM12’s predictable motion and smooth handling of components ensure that interactions with human workers remain safe and efficient, reinforcing the collaborative aspect of its design.

A further consideration in the TM12’s appeal is its compatibility with standard industrial workstations. Its moderate footprint allows it to fit seamlessly into existing production lines without necessitating extensive redesign or relocation of equipment. This compatibility is a key factor for facilities that need to introduce automation gradually, incrementally enhancing production capabilities without major capital investments in infrastructure. The robot’s placement flexibility, combined with its manageable payload and reach, enables it to integrate into diverse operational scenarios with minimal disruption.

In terms of operational workflow, the TM12 is particularly suited to environments where consistency and predictability are more critical than adaptability or advanced computational capabilities. Its closed ecosystem ensures that the robot maintains uniform performance over repeated cycles, reducing the likelihood of unforeseen errors or deviations in task execution. While this limits the robot’s capacity for innovation or on-the-fly adjustment, it enhances reliability and simplifies maintenance, which can be crucial in settings where operational continuity is paramount.

Programming and Software Capabilities of the Techman TM12

The Techman TM12 exemplifies a cobot built for accessibility and reliability rather than complex, high-adaptability operations. Its programming and software environment are deliberately designed to allow operators with limited technical expertise to configure and deploy automation tasks efficiently. The TM12’s software ecosystem emphasizes ease of use, predictability, and consistency, making it particularly suitable for small to medium-sized manufacturers or production lines where tasks are repetitive and variation is minimal. While it does not offer advanced artificial intelligence or machine learning capabilities, the TM12 compensates with a streamlined, user-friendly interface that minimizes learning curves and reduces deployment time.

At the core of the TM12’s programming environment is a graphical user interface that utilizes block-based logic. This interface allows operators to create sequences of tasks by visually arranging pre-defined action blocks, rather than requiring manual coding or script writing. For example, a pick-and-place operation can be configured by dragging blocks for “pick,” “move,” and “place,” and then specifying coordinates, speed, and motion parameters. This approach democratizes automation, allowing personnel without formal programming backgrounds to set up and modify tasks efficiently. The visual logic also aids troubleshooting, as task sequences are readily observable and modifications can be made without deciphering lines of code.

The simplicity of the TM12’s programming interface also supports incremental learning for operators. New users can begin by configuring basic sequences and gradually explore more advanced parameters, such as grip force, motion speed, and cycle timing. This gradual learning curve is crucial for facilities that do not employ robotics specialists, as it allows teams to gain confidence and proficiency over time. In addition, the interface supports simulation of tasks within the software, enabling operators to preview motion sequences and detect potential errors before execution. This reduces the risk of collisions or operational mistakes, particularly in environments with tight workspaces or delicate components.

Despite its user-friendly design, the TM12 operates within a closed software ecosystem. Unlike more advanced cobots that support third-party modules, AI enhancements, or machine learning algorithms, the TM12’s software capabilities are fixed at deployment. This approach prioritizes stability and predictability over adaptability. For tasks that remain consistent over time—such as repetitive assembly, inspection, or sorting operations—the closed system ensures reliable and repeatable performance. However, it is less suited to environments where workflows frequently change, or where dynamic reprogramming is required to accommodate a wide variety of components or variable production sequences.

The TM12 software also includes features to facilitate integrated vision-based tasks. Its built-in 2D vision system allows the robot to detect object positions and orientations within a plane, enabling automated pick-and-place operations, alignment verification, and basic inspection. Operators can define visual targets, specify detection parameters, and calibrate the robot to interact accurately with objects of varying shapes and sizes. While this 2D vision does not provide depth perception or advanced spatial reasoning, it effectively supports many standard applications, particularly where objects are flat, uniform, or presented on predictable surfaces.

Calibration and setup of the TM12’s vision system are designed to be straightforward. Operators typically define reference points and guide the robot through a short sequence of movements to teach it the relative positions of objects. Once configured, the TM12 can consistently locate objects within its field of view, reducing human intervention and ensuring repeatable handling of components. The simplicity of the vision integration is a critical feature for production lines where high throughput is desired without extensive technical support. This enables even smaller manufacturing teams to implement automation effectively, without investing in dedicated vision engineering expertise.

The TM12 also offers basic task customization options, such as motion speed, grip force, and path optimization. These parameters allow operators to tailor the robot’s behavior to specific components or operational requirements. For instance, delicate electronic assemblies can be handled with slower movements and gentler gripping, while more robust parts can be manipulated at higher speeds. The ability to adjust these parameters within the graphical interface ensures that the TM12 can adapt its performance within the boundaries of its fixed software ecosystem, providing operational flexibility while maintaining the simplicity that defines the platform.

Another aspect of the TM12’s software design is the incorporation of safety protocols within the programming interface. Operators can define speed limits, restricted zones, and emergency stop triggers, ensuring that the robot operates safely in proximity to human workers. These safety features are integrated into the software, allowing the robot to automatically reduce speed or halt movement when entering predefined zones or detecting unintended contact. This integration simplifies compliance with safety standards and mitigates risks associated with collaborative robotics, particularly in production lines where humans and robots share workspaces.

Training and documentation for the TM12’s programming environment are designed to support rapid onboarding. Techman provides comprehensive guides that detail the setup, calibration, and task configuration processes, enabling teams to deploy the cobot with minimal external assistance. Additionally, built-in help prompts and contextual guidance within the software assist operators in navigating the interface, configuring tasks, and troubleshooting common issues. This combination of accessible documentation and intuitive design fosters a positive learning experience and reduces the operational overhead typically associated with introducing robotics to production environments.

The TM12 also supports workflow simulation, which allows operators to model operations before actual execution. Simulation ensures that motion sequences, object interactions, and cycle timing are optimized and free of conflicts. By visualizing tasks in a virtual environment, operators can identify potential inefficiencies, adjust motion paths, and confirm that the robot will execute its assigned tasks reliably. This reduces the likelihood of production errors, equipment collisions, or misplacement of components, contributing to the overall reliability of the TM12 in everyday industrial operations.

While the TM12’s programming capabilities prioritize simplicity, it is essential to acknowledge the limitations inherent in its design. The robot’s closed software ecosystem prevents integration with advanced AI-driven tools or external machine learning modules, which could otherwise enable dynamic adaptation to changing workflows. In addition, its 2D vision system, while effective for flat objects, is less suitable for complex three-dimensional components or tasks requiring depth perception. Despite these constraints, the TM12 remains highly effective in scenarios where automation tasks are consistent, repetitive, and moderately complex.

The robot’s programming interface also allows for the creation of conditional logic sequences, though within a limited framework. Operators can define basic if-then scenarios, allowing the robot to respond to specific conditions detected via its sensors or vision system. For example, if an object is detected in a particular position, the robot can execute a designated pick-and-place sequence; if not, it can move to a standby position or trigger an alert. These conditional capabilities enhance the robot’s operational reliability without introducing the complexity of advanced programming languages or scripting environments.

The simplicity of the TM12’s software also contributes to reduced setup times and minimized downtime. Operators can configure and deploy new tasks quickly, which is particularly advantageous for small production runs or operations requiring occasional reconfiguration. Unlike more complex systems that demand extensive programming knowledge or the involvement of specialized integrators, the TM12 allows teams to adapt their production line with minimal disruption. This ease of deployment reinforces the robot’s appeal for facilities seeking dependable automation with predictable outcomes.

Another noteworthy aspect of the TM12’s software environment is its integration with standard industrial communication protocols. While it does not support extensive third-party extensions, the robot can interface with commonly used equipment such as conveyors, simple sensors, and peripheral devices. This allows it to function as a coherent part of a broader production ecosystem, performing tasks that complement human labor and other machinery. Such integration enhances the robot’s utility within a facility without adding the complexity of a fully open-ended software platform.

The TM12’s approach to software maintenance also aligns with its emphasis on simplicity. Updates, when available, are typically straightforward and designed to maintain operational stability rather than introduce radical changes or advanced features. This controlled approach minimizes the risk of software conflicts or unexpected downtime, ensuring that the robot continues to perform reliably over extended periods. In environments where consistency and uptime are critical, this design philosophy enhances the robot’s appeal as a low-maintenance automation solution.

From a strategic perspective, the TM12’s programming and software capabilities position it as a bridge between manual labor and fully autonomous robotics. Enabling operators to automate repetitive, light-duty tasks with minimal technical expertise allows facilities to improve efficiency while maintaining human oversight. This collaborative approach reduces the cognitive and physical burden on personnel, freeing them to focus on tasks requiring judgment, dexterity, or problem-solving skills that the robot cannot replicate. In this sense, the TM12 functions as both a practical tool and a productivity amplifier within a production environment.

The TM12’s programming framework also supports modular task design, enabling operators to construct sequences that can be reused across similar operations. For instance, a pick-and-place sequence configured for a particular component can be duplicated and slightly adjusted for another part, streamlining workflow adaptation. This modularity is particularly useful for facilities with multiple similar tasks, as it reduces the need to rebuild task sequences from scratch, thereby enhancing operational efficiency and consistency.

In addition to modularity, the TM12’s programming environment provides diagnostic and monitoring tools that help operators assess performance, identify errors, and optimize tasks. These tools offer insights into cycle times, motion paths, and object detection success rates, allowing teams to refine processes for greater accuracy and reliability. By incorporating these diagnostic capabilities into an accessible interface, the TM12 empowers operators to maintain high operational standards without requiring extensive robotics expertise or analytical training.

The robot’s vision-based programming also integrates with its motion control, ensuring that detection and manipulation are synchronized for reliable task execution. The TM12 can adjust its movement based on object positioning detected via the 2D vision system, reducing errors in pick-and-place or alignment operations. This integration highlights the robot’s practical intelligence, enabling it to execute tasks autonomously within its operational constraints. While it does not offer adaptive learning or 3D spatial reasoning, the synchronization of vision and motion ensures consistent performance in applications well-suited to its capabilities.

Real-World Applications and User Experiences with the Techman TM12

The Techman TM12 has found its place in a diverse range of industrial settings, particularly where repetitive and moderately complex tasks dominate the workflow. Its appeal lies in its combination of simplicity, reliability, and compact design, making it an accessible choice for manufacturers who wish to integrate automation without extensive technical expertise. Observing the TM12 in actual production environments reveals how its capabilities translate into operational efficiency, ergonomic improvements, and consistent task execution, while also highlighting some limitations that manufacturers must consider when planning deployments.

One of the most common applications for the TM12 is in electronics assembly. The robot’s 12 kg payload capacity and 1300 mm reach are well-suited for manipulating lightweight components such as circuit boards, connectors, and small mechanical assemblies. In these contexts, the TM12 is often tasked with repetitive pick-and-place operations, moving components from feeder trays to assembly lines with consistent accuracy. The ±0.1 mm repeatability ensures that each placement is precise enough for standard assembly requirements, reducing human error and maintaining consistent quality. Operators report that this reliability allows them to focus on more intricate tasks that the robot cannot handle, effectively optimizing human resources and workflow efficiency.

In addition to assembly, the TM12 is employed for inspection tasks where visual consistency is important but ultra-high precision is not critical. Using its built-in 2D vision system, the robot can detect the presence or absence of components, confirm alignment, and verify orientation on workstations. This reduces the need for manual inspection of every unit, enabling personnel to focus on quality assurance issues that require subjective judgment or nuanced decision-making. By automating repetitive inspection tasks, the TM12 minimizes errors caused by human fatigue or inattention, ensuring that routine checks are executed reliably throughout production cycles.

Pick-and-place operations extend beyond electronics and include packaging, labeling, and sorting. In packaging lines, the TM12 can transfer lightweight products from conveyor belts to boxes or trays with consistent timing and precision. The integrated vision system ensures that the robot accurately identifies objects’ positions and orientations, facilitating smooth handling even in slightly variable conditions. Similarly, in labeling operations, the TM12 can be configured to apply labels consistently across a range of products, reducing variability and enhancing the professional appearance of packaged goods. These applications underscore the cobot’s utility in environments where uniformity and throughput are critical but extreme precision or adaptive intelligence is unnecessary.

User experiences with the TM12 highlight its accessibility and ease of integration. Many operators without prior robotics experience have reported success in deploying the robot with minimal guidance, thanks to its graphical programming interface and intuitive task configuration. This accessibility is particularly advantageous for small and medium-sized enterprises that may lack dedicated robotics engineers. Employees can quickly learn to set up tasks, adjust parameters, and troubleshoot minor issues without extensive technical training. The TM12’s user-friendly approach democratizes automation, enabling a broader range of personnel to engage in the deployment and management of robotic systems.

Operators also appreciate the TM12’s predictable behavior and consistent performance. Unlike systems that incorporate advanced AI or adaptive learning, which can occasionally produce unexpected results or require frequent calibration, the TM12 executes tasks exactly as programmed. This predictability is valuable in environments where stability and reliability outweigh the benefits of dynamic adaptation. For instance, in assembly lines with fixed component layouts and standardized procedures, the TM12 can operate continuously with minimal human intervention, maintaining a steady workflow and reducing the likelihood of operational disruptions.

Ergonomics is another area where the TM12 demonstrates value. By automating repetitive, physically demanding tasks, the robot alleviates strain on human operators, reducing the risk of repetitive motion injuries. In tasks that involve continuous lifting, positioning, or alignment of components, the TM12 absorbs the physical workload while human personnel can focus on activities that require judgment, dexterity, or problem-solving. This collaborative approach enhances worker well-being, boosts morale, and contributes to a safer, more sustainable production environment.

Maintenance experiences with the TM12 reveal both strengths and areas for improvement. The robot’s straightforward design simplifies routine maintenance, such as lubrication, sensor calibration, and component checks. Documentation provided by Techman guides operators through these procedures, ensuring that the robot remains functional over extended periods. However, some users have reported that the vision system occasionally requires recalibration, particularly in environments with changing lighting conditions or varying object appearances. Additionally, while the TM12 is reliable for moderate workloads, prolonged use in high-intensity operations may expose wear on joints or actuators, necessitating periodic inspection and component replacement.

The robot’s deployment in mixed workflows further illustrates its versatility. Facilities that handle small assemblies, inspection, and light material handling often deploy the TM12 in multiple stations, allowing it to perform similar tasks across different points in the production line. Its moderate footprint ensures that it can operate in confined spaces, fitting seamlessly into existing workstations without requiring significant reconfiguration. This flexibility enables manufacturers to incrementally introduce automation, scaling operations at a measured pace while maintaining continuity with existing processes.

Some operators have experimented with the TM12 for kitting and small assembly tasks. In these applications, the robot assembles small sets of components into kits, which are then passed along for downstream operations. The TM12’s precision and repeatability allow for reliable placement of parts, and its integrated vision ensures correct orientation. While it cannot handle very heavy or irregularly shaped components, its performance in lightweight, standardized kits is sufficient to reduce manual labor and improve throughput. These use cases highlight the robot’s practical intelligence, combining basic vision-guided motion with consistent task execution.

Another real-world scenario involves light-duty conveyor interaction. The TM12 can synchronize with conveyor systems to pick components from moving lines, reposition items, or transfer products to designated areas. The robot’s moderate payload and reach are adequate for lightweight items, and its 2D vision system allows it to detect object placement and orientation with reasonable accuracy. In these applications, the TM12 contributes to operational continuity by reducing manual handling and ensuring that repetitive transport tasks are executed reliably, even during extended shifts.

Feedback from production managers frequently emphasizes the TM12’s reliability and predictability as key benefits. Because the robot operates within a closed software ecosystem, its behavior remains consistent across repeated cycles. Unlike adaptive robots that may alter motion paths based on environmental inputs, the TM12 maintains uniformity, which simplifies process validation, quality assurance, and workflow monitoring. This stability is especially valuable in facilities where adherence to standardized procedures is critical, such as in electronics assembly, inspection, and packaging operations.

Some users have observed that the TM12 is particularly effective in low-variation environments where tasks do not change frequently. For instance, in production lines with standardized component sizes, consistent workstation layouts, and uniform handling requirements, the TM12 excels in performing repetitive actions without the need for continual reprogramming. Its intuitive graphical interface allows operators to modify minor parameters quickly, such as grip force or motion speed, without overhauling the entire sequence. This combination of predictability and incremental configurability ensures that the TM12 remains effective in its operational niche.

Despite its advantages, certain limitations are evident in practical deployments. The TM12’s 2D vision system, while sufficient for flat or moderately structured objects, cannot accommodate complex three-dimensional components or tasks requiring depth perception. In environments where object orientation varies significantly or where irregular shapes are common, the robot may require additional fixtures, human intervention, or manual adjustment to maintain accuracy. Additionally, its closed software ecosystem precludes the integration of AI-driven adaptation or machine learning enhancements, limiting the robot’s flexibility in dynamic or high-mix production scenarios.

Users also note that while the TM12’s maintenance requirements are generally straightforward, achieving consistent uptime requires attention to environmental factors such as lighting, vibration, and component cleanliness. Variations in these conditions can impact the vision system’s effectiveness, necessitating occasional recalibration or environmental adjustment. Nevertheless, with proper setup and periodic monitoring, the TM12 demonstrates reliable performance over extended operational periods, validating its suitability for routine industrial automation tasks.

Training experiences with the TM12 consistently emphasize the accessibility of the robot’s programming interface. Operators with minimal robotics experience report that they can configure tasks and deploy the robot within hours, rather than days. The drag-and-drop logic, visual cues, and contextual guidance embedded in the software facilitate rapid learning and reduce the likelihood of configuration errors. This accessibility is particularly beneficial in small or medium-sized facilities, where staff may need to multitask or assume multiple operational responsibilities, as it reduces the dependency on specialized robotics engineers.

The TM12’s practical intelligence is further highlighted in its collaborative capabilities. Its built-in safety features, such as torque limitation and collision detection, allow it to operate safely alongside human workers. Operators can work within shared workspaces without concerns about injury from unexpected robotic motion. This aspect of collaboration extends the robot’s usability to facilities where space is constrained or where full separation between humans and machines is impractical. By enabling humans and robots to work in proximity, the TM12 contributes to operational efficiency while maintaining workplace safety.

Several industrial case studies demonstrate the TM12’s efficacy in diverse applications. In light assembly operations, the robot reduces the time required to position and secure components, allowing human operators to focus on tasks that require judgment and dexterity. In quality inspection workflows, it consistently identifies misaligned or missing parts, supporting personnel in maintaining production standards. In pick-and-place and packaging operations, it transfers lightweight items accurately and reliably, reducing manual handling and enhancing overall throughput. These practical experiences underscore the TM12’s value as a dependable, purpose-driven automation tool.

Additionally, the TM12’s compact footprint facilitates deployment in environments with space constraints. Unlike larger industrial robots, which may require significant clearance and infrastructure modifications, the TM12 integrates seamlessly into existing production lines. Its reach and payload balance allow it to operate effectively without occupying excessive workspace, preserving operational flexibility and minimizing disruption to established workflows. This spatial efficiency is particularly advantageous in small to medium-sized manufacturing facilities where floor space is at a premium.

The robot’s integration into multi-station workflows highlights its versatility within its operational limits. Facilities often deploy multiple TM12 units across different points in a line, performing similar tasks in parallel to maintain production continuity. Its consistent repeatability ensures that each unit performs identically, minimizing variability and reducing the need for intensive monitoring. This deployment strategy maximizes the benefits of the TM12’s capabilities while mitigating its limitations, such as restricted payload and fixed vision system functionality.

Maintenance, Support, and Operational Longevity of the Techman TM12

Sustaining the performance of any collaborative robot requires an attentive approach to upkeep, and the Techman TM12 is no exception. While it is designed to be approachable and easy to integrate, maintaining its operational effectiveness over extended production cycles calls for structured practices, consistent monitoring, and an understanding of how its systems respond to varied industrial conditions. Exploring its maintenance needs, support infrastructure, and long-term durability offers valuable insights into how manufacturers can preserve its reliability while avoiding disruptions.

The TM12 is, at its core, a tool meant to thrive in environments where repetitive tasks dominate. Its moderate payload, intuitive interface, and integrated vision system make it suitable for predictable workflows. Yet, even with this focus on simplicity, the robot is still a precision instrument composed of sensors, actuators, joints, and embedded vision hardware. Each of these components must remain in balance for the system to deliver consistent accuracy and smooth motion. Routine maintenance, therefore, is less about complexity and more about diligence in monitoring wear, calibrating vision systems, and ensuring that environmental variables do not undermine performance.

Mechanical Durability and Wear Management

The mechanical structure of the TM12 is engineered to withstand repetitive motion over extended timeframes. Its joints, actuators, and drive systems are rated for consistent cycling, and when operated within its design thresholds, the robot demonstrates reliable endurance. However, prolonged use in high-frequency applications inevitably introduces gradual wear. Repetitive stress on the same axes can cause slight shifts in accuracy or changes in motion smoothness, which, if left unchecked, may compromise task reliability.

Operators are encouraged to conduct periodic inspections of joint performance, listening for irregular sounds or noting deviations in repeatability. Lubrication, where applicable, must be maintained according to the recommended schedules provided in the documentation. By adhering to these preventive steps, facilities reduce the risk of unexpected downtime and extend the lifespan of the robot’s mechanical components. Simple awareness of motion quality and incremental adjustments help preserve both precision and overall efficiency.

Vision System Maintenance and Calibration

A defining feature of the TM12 is its integrated 2D vision system. While this embedded capability reduces the need for additional cameras or sensors, it also introduces specific maintenance requirements. Vision systems are highly sensitive to environmental conditions, including lighting changes, dust accumulation, or shifts in reflective surfaces. Over time, these factors can lead to inconsistencies in object recognition and positioning.

Calibration is therefore a recurring need for facilities that rely heavily on the TM12’s visual guidance. Regular recalibration sessions ensure that the system maintains alignment with actual workspace conditions. Cleaning the camera lens, controlling lighting stability, and verifying detection accuracy with test runs are essential practices. Without such diligence, small errors in recognition can accumulate into misplacements or alignment issues, undermining the robot’s reliability in tasks such as labeling, inspection, or precise pick-and-place operations.

Software Updates and System Stability

Although the TM12 operates within a closed software ecosystem, it does receive periodic updates that enhance stability, patch vulnerabilities, or refine existing functionalities. Facilities that neglect these updates risk operating with outdated control parameters, which could compromise security or lead to inefficiencies in performance. The closed nature of the ecosystem simplifies management, as updates are curated by the manufacturer and delivered in structured formats, minimizing compatibility concerns.

Applying updates requires coordination, as production downtime must be scheduled. However, the benefits of maintaining system currency outweigh the inconveniences. Software stability directly affects task execution, communication with peripheral devices, and the overall reliability of the cobot. By integrating updates into regular maintenance cycles, operators ensure that the TM12 remains aligned with the latest operational standards provided by its developers.

Safety Feature Integrity

The TM12 complies with international safety standards, including ISO 10218 and ISO/TS 15066, and its collaborative design includes built-in safeguards such as torque limitation and collision detection. Over time, the effectiveness of these safety features can be influenced by wear or environmental factors. Periodic verification of torque sensors, responsiveness to collision events, and calibration of force thresholds ensure that the cobot continues to function safely in shared workspaces.

Neglecting such checks may expose workers to unnecessary risk or reduce the confidence of personnel operating alongside the machine. Facilities that prioritize consistent validation of safety parameters not only preserve compliance but also foster a workplace culture that embraces robotics without apprehension. Safety assurance is as much about operator trust as it is about regulatory adherence, and maintaining the TM12’s safeguards ensures both.

Documentation and Guided Support

One of the strengths of the TM12 lies in the comprehensive documentation provided by its manufacturer. Manuals and guides outline recommended maintenance intervals, calibration procedures, and troubleshooting protocols. For operators with limited robotics experience, this structured documentation serves as a critical lifeline, enabling them to address routine issues without external intervention.

In addition, support is often provided through authorized resellers, who can offer both technical assistance and spare parts. This distribution of support through localized channels ensures that facilities can access guidance without lengthy delays. While reliance on resellers can sometimes lead to variability in service quality, the overall support ecosystem surrounding the TM12 is designed to be accessible and pragmatic, aligning with the robot’s focus on simplicity and predictability.

Uptime and Reliability Considerations

One recurring theme in user experiences is that the TM12 performs reliably when operating within its intended boundaries but can demonstrate reduced uptime if pushed into unsuitable scenarios. Heavy payloads, irregular shapes, or inconsistent environmental conditions strain its systems and accelerate wear. By contrast, when deployed for moderate loads, consistent tasks, and stable lighting environments, the robot maintains uptime with minimal interruptions.

Facilities that approach deployment with realistic expectations are more likely to experience sustained success. Recognizing the TM12’s limitations and configuring workflows accordingly ensures that the robot delivers value consistently. Overambitious use cases, while tempting, can undermine both longevity and dependability. The balance lies in leveraging the cobot for tasks it excels at, while reserving complex or demanding operations for more advanced systems.

Spare Parts and Replacement Cycles

As with any mechanical system, component replacement is inevitable over the lifespan of the TM12. Joints, actuators, and vision hardware are subject to gradual degradation, and facilities must anticipate replacement cycles. Planning for spare parts availability minimizes the risk of extended downtime, particularly when critical components fail unexpectedly.

Resellers typically maintain access to replacement parts, though lead times may vary. Facilities that maintain an inventory of commonly replaced components reduce the impact of such delays. Integrating spare parts management into broader maintenance planning enhances operational resilience, ensuring that the TM12 continues functioning without prolonged interruptions.

Environmental Influences on Longevity

The environments in which the TM12 operates play a pivotal role in its durability. Dust, temperature fluctuations, humidity, and vibration all contribute to gradual wear or performance variability. For example, dusty environments may obscure vision sensors, while fluctuating temperatures can affect lubrication or electronic stability.

Mitigating these influences requires thoughtful setup and environmental control. Installing the robot in clean, stable areas, controlling ambient lighting, and minimizing vibration ensures that the TM12 performs consistently over extended periods. Facilities that take a proactive approach to environmental management invariably extend the cobot’s operational lifespan while minimizing the need for frequent recalibration or servicing.

Operator Training and Knowledge Retention

Another dimension of longevity is the competence of operators responsible for deploying and maintaining the TM12. While the robot’s graphical interface reduces barriers to entry, effective use still requires an understanding of calibration, task sequencing, and basic troubleshooting. Training programs, whether provided by the manufacturer or internal supervisors, ensure that personnel can sustain effective use of the cobot without excessive reliance on external support.

Knowledge retention becomes especially critical in facilities with high staff turnover. Documenting task setups, calibration routines, and common troubleshooting steps ensures continuity of expertise, even when operators change. This approach prevents disruptions caused by knowledge gaps and sustains consistent robot performance across operational cycles.

The Economics of Longevity

From an operational standpoint, the cost-effectiveness of the TM12 is tied directly to its ability to sustain performance over time. Frequent breakdowns, extended downtime, or premature component failure erode its value. Conversely, steady performance and predictable maintenance cycles extend its usefulness, justifying the investment.

The TM12’s design emphasizes accessibility and reliability, and when paired with structured maintenance, it demonstrates commendable durability. Facilities that treat it as a reliable assistant rather than an adaptive powerhouse are better positioned to maximize its lifespan. This pragmatic approach aligns the robot’s inherent capabilities with realistic operational expectations, ensuring that it remains a valuable tool well into the future.

The Future Relevance of the Techman TM12 in Industrial Automation

The landscape of industrial automation is advancing with remarkable velocity, driven by breakthroughs in robotics, machine vision, artificial intelligence, and adaptive systems. Amid these transformative currents, the Techman TM12 occupies a distinctive space. It does not attempt to compete with systems that boast advanced adaptability or ultra-high payload capacities. Instead, it maintains its value through accessibility, predictability, and ease of use. To understand its ongoing relevance, it is necessary to situate the TM12 within the broader evolution of automation while examining how its simplicity aligns with the changing needs of manufacturers.

The TM12 exemplifies a philosophy that places emphasis on reliability rather than extravagance. Its compact structure, 12-kilogram payload capacity, and integrated vision system are not meant to dazzle with groundbreaking complexity but to provide a dependable framework for routine processes. As automation expands into smaller facilities, workshops, and mid-sized enterprises, robots like the TM12 offer a pathway into collaborative robotics without overwhelming operators or requiring extensive engineering resources. This orientation toward approachability is central to its continued role in industrial contexts.

The Expanding Automation Ecosystem

Automation is no longer confined to large-scale production facilities with high-volume, low-mix manufacturing. Small and medium-sized enterprises increasingly embrace automation to handle repetitive, labor-intensive, or ergonomically challenging tasks. This diffusion has created a demand for robots that are not only cost-effective but also intuitive.

In this environment, the TM12’s user-friendly graphical interface and straightforward deployment provide advantages. Operators with limited technical backgrounds can learn to operate it without prolonged training. It enables facilities with constrained resources to automate without hiring specialized robotics engineers. The future relevance of the TM12 rests partly on this democratization of automation—its ability to lower barriers and bring collaborative robots into workplaces that previously found them inaccessible.

The Role of Predictability in Workforce Integration

Another aspect of the TM12’s continued relevance is its role in building trust between human workers and robotic counterparts. Collaborative robots succeed not only because of their technical specifications but also because of how readily they can be integrated into existing workflows without intimidating operators.

The TM12’s predictable behavior and clear safety compliance foster confidence among personnel. Workers are more likely to embrace a cobot that behaves consistently, responds within expected thresholds, and communicates through a straightforward interface. In industries where workforce hesitation remains a barrier to adopting robotics, this predictability eases the transition. As a result, the TM12 can act as a gateway—helping facilities build a culture of robotics before advancing to more complex systems.

Addressing Workforce Challenges

Global industries continue to face challenges related to labor shortages, rising costs, and ergonomic strain. Repetitive tasks such as pick-and-place, labeling, or small assembly often struggle to attract and retain workers. Collaborative robots that can alleviate these burdens, even in limited capacity, address a pressing workforce issue.

The TM12, by automating such routine processes, reduces dependence on human labor for tasks that are physically taxing or monotonous. While it cannot replace skilled operators for complex problem-solving, it enhances workforce efficiency by reallocating human resources to higher-value activities. In the future, as labor markets tighten further, this balance of roles becomes increasingly important. Robots like the TM12 provide continuity where human availability may falter, sustaining productivity without compromising quality.

Environmental Compatibility and Compact Design

Future relevance is also linked to the environments in which automation unfolds. Not every facility is equipped with spacious layouts or sophisticated infrastructure. Many workshops operate in constrained spaces where bulky robots are impractical. The compact form of the TM12 allows it to operate effectively in tight quarters, offering automation without demanding structural redesigns of production floors.

Its 1300-millimeter reach complements this compactness, granting flexibility across workstations without requiring frequent repositioning. This spatial efficiency will remain advantageous as urban manufacturing, micro-factories, and localized production models expand. By fitting into environments where larger systems cannot, the TM12 secures its niche.

Future-Proofing Through Consistency

Although the TM12 lacks extensibility through machine learning or open APIs, its closed ecosystem ensures stability. Facilities that adopt it are not subject to the unpredictability of constant software modifications or the complications of integrating third-party modules. In this sense, its future-proofing lies not in adaptability but in consistency.

For manufacturers seeking a cobot that performs identically today and years from now, the TM12 provides assurance. This reliability appeals to industries where consistency is paramount—such as electronics handling, inspection, or routine packaging. While other robots evolve with frequent updates and shifting features, the TM12 remains a steady anchor for facilities that prize dependability over experimentation.

The Role in Education and Training

As industrial automation grows, so does the need to train the workforce in robotic operation. Educational institutions and training centers increasingly integrate collaborative robots into their curricula. The TM12, with its approachable programming interface and integrated vision, is well-suited for instructional environments.

Its simplicity allows students to grasp fundamental principles of robotics—task sequencing, calibration, safety standards, and vision-based recognition—without becoming overwhelmed. Training programs that employ the TM12 can prepare future operators to enter the workforce with practical, hands-on experience. In this capacity, the cobot contributes not only to immediate industrial productivity but also to the long-term cultivation of robotic literacy.

Sustainability and Energy Considerations

Sustainability has emerged as a central concern across industries. Robots like the TM12 contribute indirectly to sustainability by improving efficiency, reducing waste, and minimizing errors in repetitive tasks. Its modest payload and compact design also align with energy-conscious practices, as it consumes less power than larger, heavier systems.

By ensuring consistent placement, inspection, and assembly, the TM12 helps reduce defective parts, thereby lowering material waste. Facilities focused on sustainability can integrate such cobots as part of broader strategies to reduce environmental impact. This alignment with ecological considerations enhances its relevance in a future where sustainability becomes an operational imperative rather than a marketing advantage.

Conclusion

The Techman TM12 stands as a dependable cobot built for clarity, simplicity, and consistent execution in an industry often driven by rapid change. Across its design, usability, maintenance profile, and long-term outlook, it embodies a philosophy of reliability over spectacle. With a 12-kilogram payload, integrated 2D vision, and an intuitive interface, it supports small and medium-sized enterprises seeking to automate routine tasks without extensive technical overhead. While it does not rival more advanced robots in adaptability or precision, its strength lies in delivering steady performance where predictability is paramount. From training environments to compact workshops, it offers a balance of accessibility and practicality that ensures lasting relevance. As automation reshapes global manufacturing, the TM12’s enduring value will be its role as a stable, approachable assistant—one that enables organizations to embrace robotics confidently, sustainably, and without unnecessary complexity.