Exam Code: ICS-SCADA

Exam Name: ICS-SCADA Cyber Security

Certification Provider: ECCouncil

Corresponding Certification: ICS-SCADA Cybersecurity

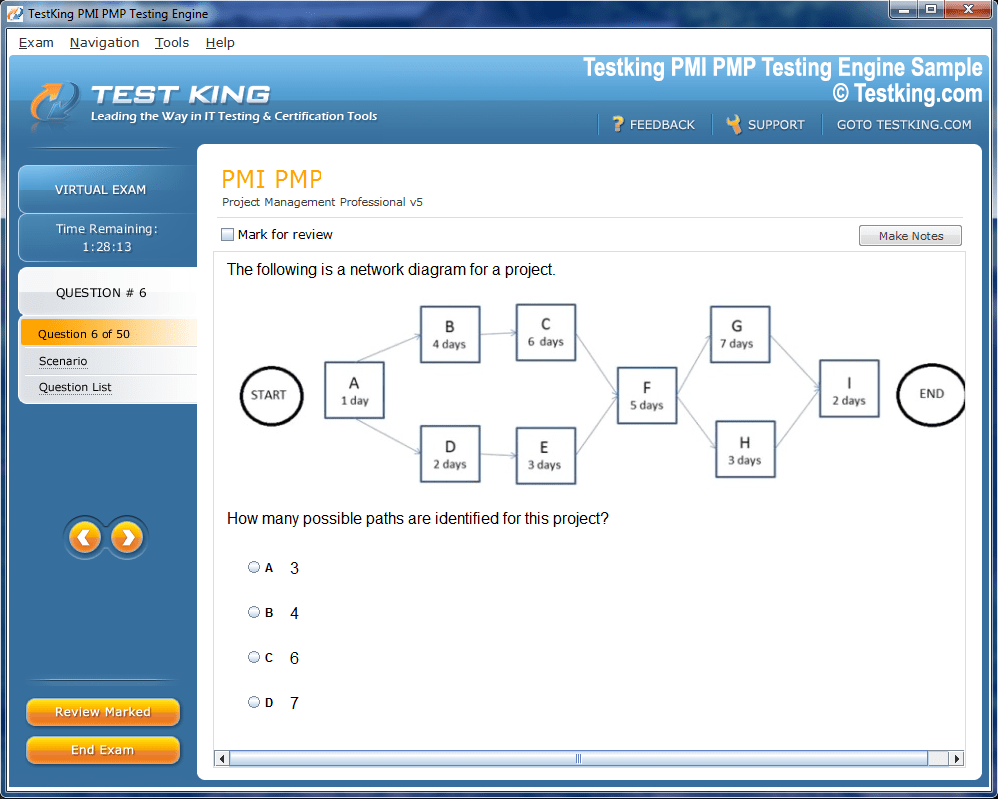

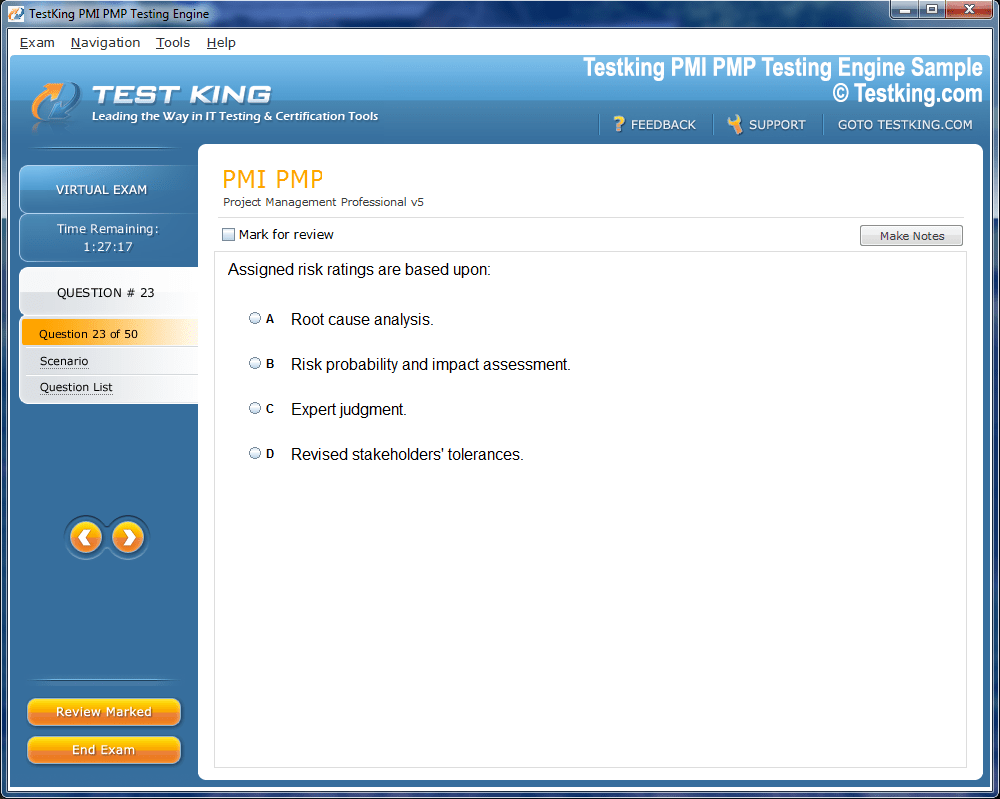

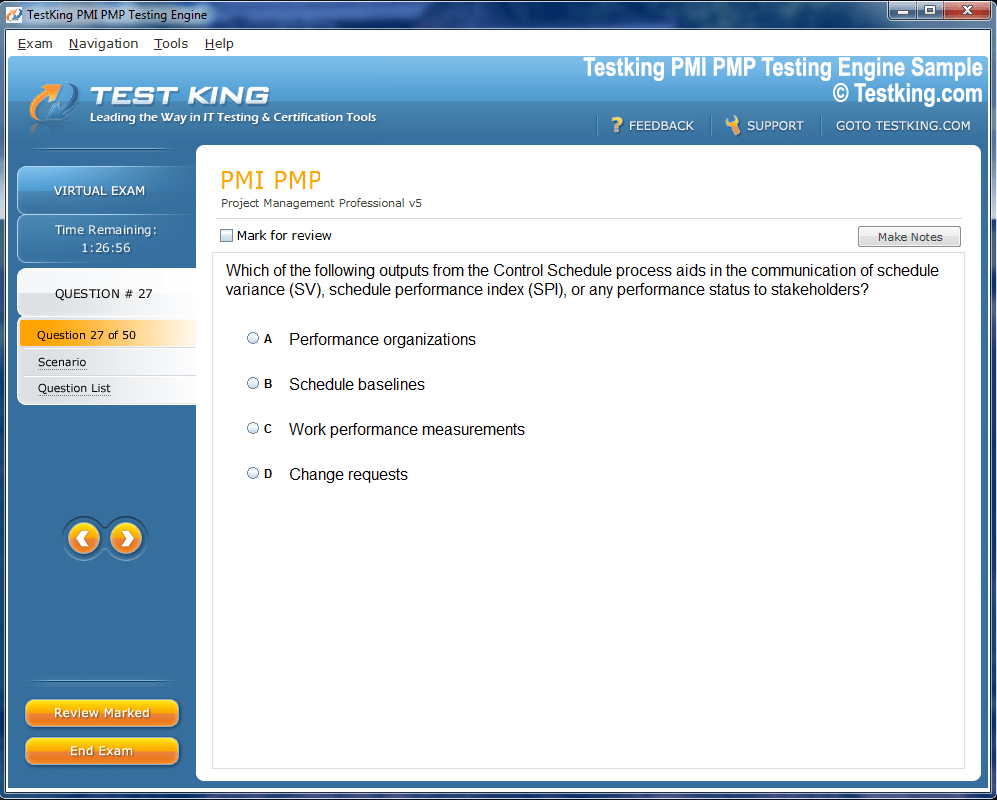

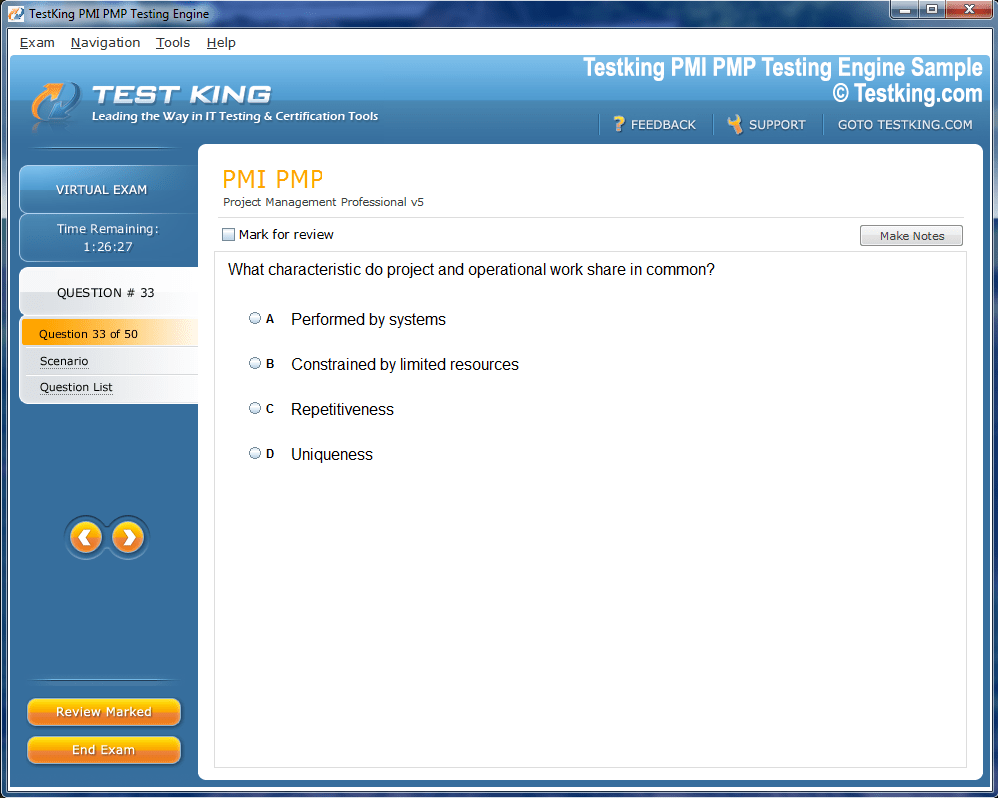

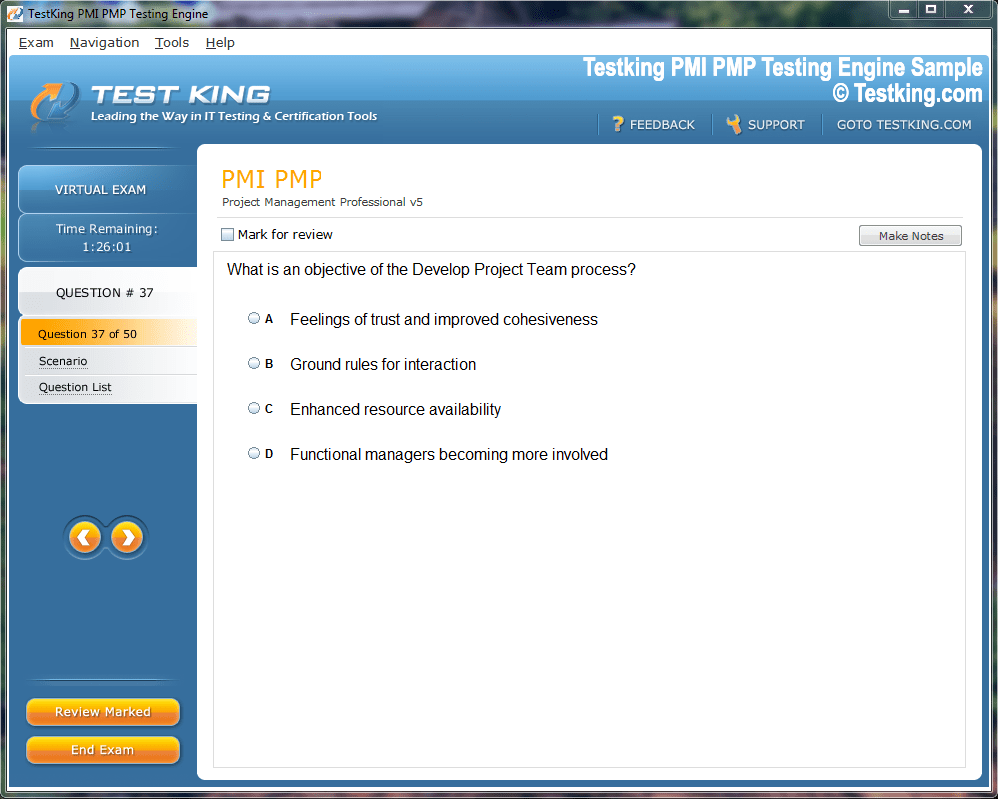

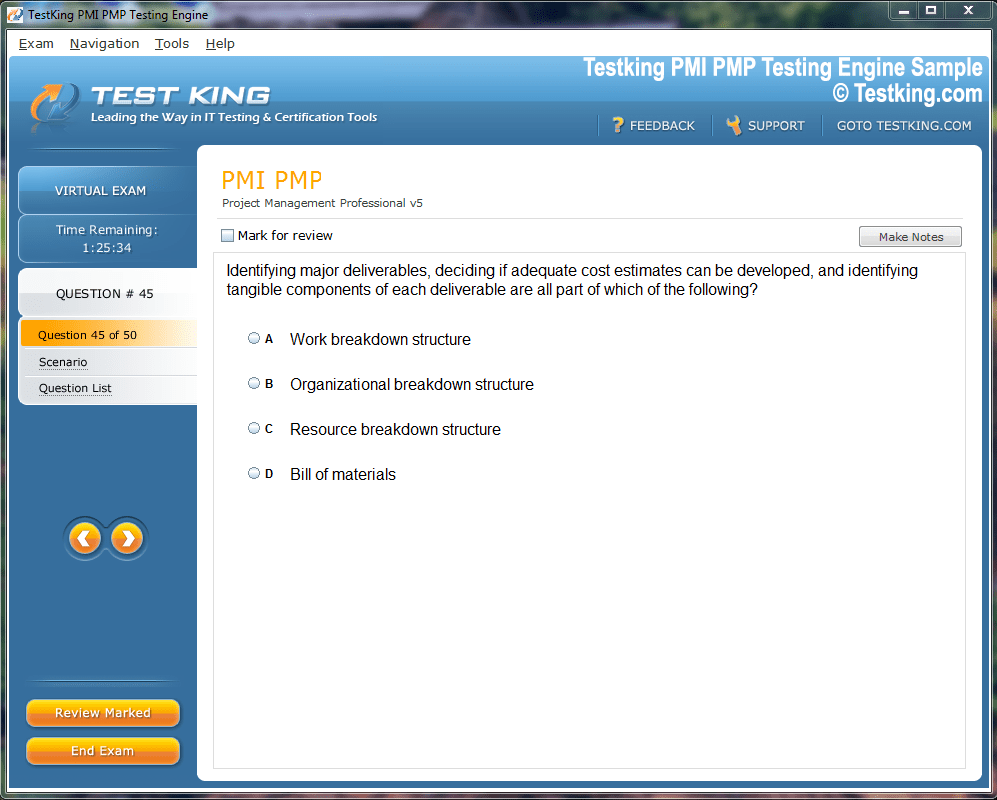

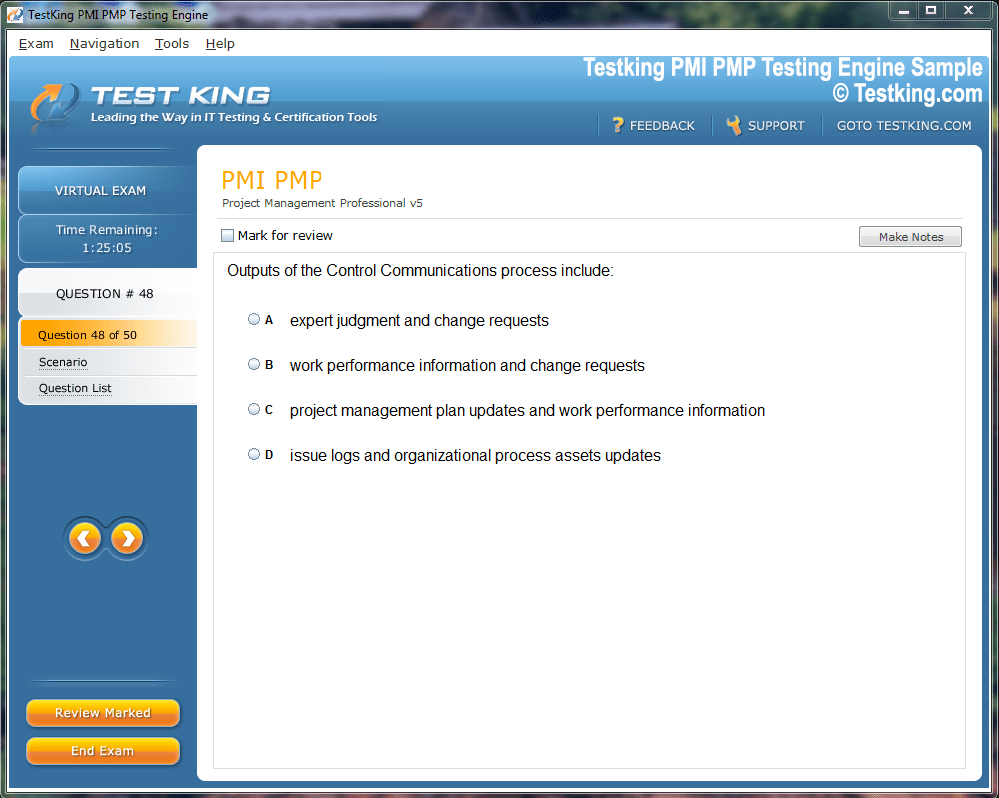

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our ICS-SCADA testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top ECCouncil Exams

- 312-50v13 - Certified Ethical Hacker v13

- 312-39v2 - Certified SOC Analyst (CSA) v2

- 312-38 - Certified Network Defender

- 712-50 - EC-Council Certified CISO

- 212-89 - EC-Council Certified Incident Handler

- 312-85 - Certified Threat Intelligence Analyst

- 212-82 - Certified Cybersecurity Technician

- 312-50 - CEH Certified Ethical Hacker (312-50v9)

- 312-39 - Certified SOC Analyst

- 312-97 - Certified DevSecOps Engineer (ECDE)

- 312-49v11 - Computer Hacking Forensic Investigator

- 312-49v10 - Computer Hacking Forensic Investigator

- 312-50v12 - Certified Ethical Hacker v12 Exam

- 312-40 - Certified Cloud Security Engineer

- 312-49 - Computer Hacking Forensic Investigator

- 212-81v3 - EC-Council Certified Encryption Specialist

- ECSS - EC-Council Certified Security Specialist

- 312-76 - EC-Council Disaster Recovery Professional

Securing Industrial Control Systems with EC-Council ICS-SCADA Certification

In an era characterized by relentless digital transformation, the security of industrial environments has become an indispensable concern. As industrial operations evolve through automation and connectivity, the integration of advanced digital technologies has rendered critical infrastructures more efficient yet paradoxically more susceptible to cyber threats. Industrial Control Systems (ICS) and Supervisory Control and Data Acquisition (SCADA) systems serve as the backbone of essential sectors, including energy, manufacturing, water treatment, and transportation. Their pervasive influence on everyday operations underscores the gravity of potential cyber intrusions. Unlike conventional IT networks that manage primarily informational assets, ICS and SCADA systems are responsible for governing physical processes. A breach in such systems can precipitate catastrophic consequences, encompassing operational paralysis, significant financial losses, and even jeopardy to human life.

The transition from isolated operational technologies to interconnected digital networks has exponentially expanded the threat landscape. Industrial sectors that were once insulated due to their proprietary architectures now confront unprecedented exposure. The integration of Internet of Things (IoT) devices, cloud computing, and remote monitoring platforms has elevated operational efficiency but simultaneously introduced vulnerabilities that cyber adversaries are eager to exploit. Malicious actors increasingly leverage sophisticated techniques such as advanced persistent threats, zero-day exploits, and ransomware attacks specifically tailored to industrial environments. These attacks target both the software and hardware layers of ICS and SCADA systems, aiming not only at data exfiltration but also at disrupting physical processes, which can have real-world consequences.

Distinguishing Industrial Systems from Traditional IT Networks

A critical aspect of understanding ICS and SCADA security lies in recognizing the fundamental differences between traditional IT networks and industrial control environments. IT networks primarily manage informational flows and digital assets, where breaches usually result in data loss, reputational harm, or financial implications. In contrast, ICS and SCADA systems govern tangible processes, such as controlling turbines in power plants, regulating chemical flows in treatment facilities, or orchestrating transportation logistics. The operational repercussions of a cyber breach in these systems extend beyond data compromise and may include catastrophic physical outcomes, environmental hazards, and even human casualties.

Industrial systems often incorporate legacy components with minimal security considerations, designed decades ago under the assumption of physical isolation. These systems typically operate with deterministic protocols, prioritize uptime over patching, and may lack robust encryption or authentication mechanisms. When such systems are connected to modern networks or exposed to external interfaces, they become prime targets for cyber attackers. Furthermore, the coexistence of IT and operational technology (OT) domains introduces complexities that necessitate specialized knowledge to be secured effectively. Understanding these nuances is essential for any professional seeking to navigate the intricacies of industrial cybersecurity.

The Expanding Threat Landscape in Industrial Environments

Cybersecurity threats to industrial systems are escalating in both frequency and sophistication. Nation-state actors, criminal organizations, and hacktivists are increasingly targeting ICS and SCADA infrastructures due to the strategic impact such attacks can yield. Examples of these threats include malware that can manipulate programmable logic controllers, ransomware that can halt critical production lines, and network intrusions that compromise safety systems. High-profile attacks have illustrated the devastating potential of these intrusions, demonstrating that the industrial sector is no longer immune to cyber disruption.

Unlike traditional IT attacks, which often focus on data exfiltration or financial fraud, ICS and SCADA attacks may have kinetic consequences. For instance, compromising a power grid can result in widespread outages, while tampering with water treatment processes can contaminate public supplies. The gravity of such risks has elevated industrial cybersecurity to a strategic priority for both private enterprises and government agencies. Organizations are increasingly investing in risk assessments, threat intelligence, and cybersecurity frameworks specifically tailored to industrial environments, underscoring the necessity of specialized expertise in this domain.

Core Objectives of Industrial Cybersecurity

The primary objective of industrial cybersecurity is to ensure the continuity, reliability, and safety of critical operations. This requires a multifaceted approach that encompasses proactive risk mitigation, real-time threat detection, rapid incident response, and post-incident forensic analysis. Risk mitigation involves evaluating the vulnerabilities inherent in ICS and SCADA architectures and implementing measures to reduce exposure, including network segmentation, access controls, and redundancy planning. Real-time threat detection is facilitated through monitoring tools, intrusion detection systems, and anomaly detection mechanisms designed to identify deviations from normal operational patterns.

Incident response in industrial environments is particularly complex due to the convergence of cyber and physical processes. Effective response protocols require a nuanced understanding of both the operational technology being controlled and the cybersecurity principles protecting it. Post-incident forensic analysis aims to reconstruct attack vectors, understand the methodologies employed by adversaries, and develop strategies to prevent recurrence. Together, these components form a holistic framework that enhances the resilience of industrial infrastructures against cyber threats.

Bridging the Skills Gap in Industrial Cybersecurity

A critical challenge facing the industrial sector is the shortage of cybersecurity professionals equipped to handle ICS and SCADA environments. While the broader cybersecurity workforce has expanded in response to IT threats, industrial systems demand a unique combination of technical acumen and operational insight. Professionals must understand network protocols, control logic, and process automation, while also being capable of identifying potential attack vectors, assessing risk, and deploying effective countermeasures. This dual expertise distinguishes industrial cybersecurity from conventional IT security and underscores the importance of targeted training programs.

Specialized certification programs in industrial cybersecurity address this skills gap by equipping professionals with the knowledge and hands-on experience necessary to defend ICS and SCADA systems. These programs cover critical topics such as risk analysis, intrusion detection, malware analysis, digital forensics, and incident response. Additionally, they encourage an offensive mindset, enabling candidates to anticipate attacker strategies and fortify defenses accordingly. Such training ensures that certified professionals are prepared to mitigate risks in environments where cyber attacks can have real-world, potentially catastrophic impacts.

Risk Assessment and Vulnerability Management in Industrial Systems

Risk assessment in industrial environments requires a systematic evaluation of potential threats and vulnerabilities across both hardware and software layers. Industrial systems are often composed of heterogeneous components, including legacy devices, modern sensors, programmable logic controllers, and networked communication interfaces. Each element introduces distinct vulnerabilities that must be identified, quantified, and addressed. Effective risk assessment involves mapping system interdependencies, simulating potential attack scenarios, and evaluating the operational consequences of breaches.

Vulnerability management is an ongoing process that entails continuous monitoring, patch management, and configuration oversight. Unlike conventional IT environments, where frequent patching is standard practice, industrial systems often prioritize uptime and stability, making patch deployment more challenging. Security professionals must balance the need for operational continuity with the imperative of mitigating vulnerabilities, employing strategies such as staged updates, redundancy implementation, and intrusion containment. This delicate equilibrium is central to maintaining resilient industrial operations.

Intrusion Detection and Real-Time Monitoring

Intrusion detection in ICS and SCADA environments involves monitoring network traffic, system logs, and process signals for anomalies that may indicate unauthorized activity. Advanced detection mechanisms leverage machine learning algorithms, behavioral analytics, and signature-based monitoring to identify potential threats. Real-time alerting allows security teams to respond immediately, mitigating damage before it escalates into a full-scale operational disruption.

Industrial intrusion detection must account for the unique characteristics of OT networks, including deterministic traffic patterns, proprietary protocols, and the criticality of uninterrupted operations. False positives can have severe consequences, as unnecessary interventions may disrupt essential processes. Therefore, professionals must develop a nuanced understanding of normal operational baselines and the contextual indicators of compromise, enabling precise detection and timely response.

Malware Analysis and Threat Neutralization

Malware targeting industrial systems is often specifically engineered to exploit operational technologies and control mechanisms. Threats such as logic bombs, trojans, and ransomware can manipulate control logic, halt production lines, or compromise safety protocols. Malware analysis in this context involves identifying malicious code, dissecting its functionality, and determining its potential impact on industrial processes.

Threat neutralization requires coordinated efforts that combine technical remediation, system recovery, and preventive measures. Security teams must remove malicious artifacts, restore affected systems to a safe state, and implement safeguards to prevent recurrence. Understanding the tactics, techniques, and procedures employed by attackers enables professionals to anticipate future threats and reinforce industrial defenses proactively.

Digital Forensics in Industrial Cybersecurity

Digital forensics plays a pivotal role in understanding the intricacies of cyber attacks on ICS and SCADA systems. Forensic investigations aim to reconstruct attack sequences, identify exploited vulnerabilities, and ascertain the scope of compromise. Industrial forensics often involves analyzing network traffic, control logic, sensor data, and system logs to build a comprehensive picture of the incident.

The insights gained from forensic analysis inform both immediate remediation efforts and long-term security strategies. By understanding attacker methodologies, organizations can refine detection mechanisms, improve incident response protocols, and strengthen overall resilience. In industrial environments, where operational continuity is paramount, timely and accurate forensic analysis is critical for minimizing downtime and safeguarding critical processes.

Advancing Industrial Cybersecurity Through Specialized Certification

As industrial systems grow increasingly interconnected, the demand for professionals with expertise in protecting these infrastructures has escalated. Industrial Control Systems and Supervisory Control and Data Acquisition systems are no longer isolated from external networks; they are integral components of global digital operations. Consequently, the skill set required to safeguard these systems has become highly specialized, blending cybersecurity principles with operational technology knowledge. Certification programs designed for ICS and SCADA security have emerged as critical avenues for professionals to acquire the expertise necessary to mitigate risks, respond to threats, and ensure operational resilience.

Certification in industrial cybersecurity goes beyond theoretical understanding. It cultivates proficiency in practical, hands-on scenarios that reflect the unique challenges of protecting ICS and SCADA environments. Professionals develop the ability to evaluate risk, monitor for anomalies, analyze malware, conduct forensic investigations, and orchestrate incident response protocols. By mastering these competencies, certified individuals are prepared to secure infrastructures where cyber attacks can lead to tangible, potentially catastrophic consequences.

The Role of Industrial Cybersecurity Professionals

The responsibilities of industrial cybersecurity professionals are multifaceted and vital. They are entrusted with the protection of critical infrastructures that underpin national security, economic stability, and public safety. These professionals must comprehend the operational intricacies of systems controlling power generation, water treatment, transportation logistics, and manufacturing processes. Their work involves constant vigilance, threat anticipation, and rapid response to incidents that could disrupt physical operations.

A defining characteristic of industrial cybersecurity is the necessity for an offensive mindset. Professionals must anticipate potential attack vectors, simulate adversarial behaviors, and proactively fortify systems against sophisticated threats. Unlike traditional IT security, where reactive measures often suffice, industrial environments demand a proactive approach. By understanding how attackers operate, cybersecurity specialists can implement strategies that prevent breaches, maintain operational continuity, and protect both human life and critical assets.

Risk Analysis and Strategic Defense

Risk analysis is a foundational element of industrial cybersecurity. It involves the systematic identification, assessment, and mitigation of potential vulnerabilities across both software and hardware components. Industrial systems often encompass diverse elements, from legacy control devices to modern sensors and networked interfaces. Each component introduces distinct risks that must be addressed to maintain overall system integrity.

Effective risk management requires a comprehensive understanding of system interdependencies and potential points of compromise. Security professionals conduct simulations and scenario analyses to anticipate the consequences of cyber intrusions. These evaluations inform the implementation of robust defense mechanisms, including network segmentation, access controls, encryption, and redundancy planning. By integrating these measures, organizations can significantly reduce their exposure to cyber threats while maintaining uninterrupted operations.

Intrusion Detection in Industrial Networks

Monitoring and detecting unauthorized activity within industrial networks is a critical aspect of safeguarding ICS and SCADA systems. Intrusion detection systems are designed to analyze network traffic, system logs, and process signals for signs of anomalies or malicious behavior. These systems often employ a combination of signature-based detection, behavioral analytics, and machine learning to identify potential threats in real time.

Industrial intrusion detection presents unique challenges due to the deterministic nature of operational networks and the criticality of continuous process operations. False positives can lead to unnecessary disruptions, while undetected intrusions can result in severe physical and operational consequences. Security professionals must develop a nuanced understanding of normal operational patterns and the contextual indicators of compromise to ensure accurate detection and timely intervention.

Malware Analysis and Threat Mitigation

Industrial systems are increasingly targeted by malware specifically engineered to exploit operational technologies. Threats may include ransomware that halts production lines, logic bombs that manipulate control sequences, and trojans that compromise safety systems. Analyzing such malware involves identifying its functionality, understanding its propagation methods, and evaluating its potential impact on industrial processes.

Mitigating these threats requires a combination of technical remediation, system restoration, and preventive strategies. Security professionals remove malicious code, restore affected components, and implement safeguards to prevent future incidents. The capacity to anticipate attack methodologies, understand threat behavior, and respond swiftly is a hallmark of effective industrial cybersecurity practice.

Digital Forensics in Industrial Contexts

Digital forensics plays a pivotal role in understanding and responding to cyber incidents in industrial environments. Forensic investigations reconstruct attack sequences, identify exploited vulnerabilities, and assess the scope of compromise. In ICS and SCADA systems, forensic analysis may involve examining network traffic, control logic, sensor data, and system logs to develop a comprehensive understanding of the incident.

The insights gained from forensic investigations inform immediate remediation efforts and long-term security planning. By understanding attacker strategies, organizations can refine detection systems, enhance incident response protocols, and bolster overall resilience. In industrial settings, where operational continuity is paramount, effective forensic analysis minimizes downtime and ensures that critical processes remain secure.

Incident Response and Resilience Planning

Incident response in industrial environments is both complex and high-stakes. Unlike conventional IT breaches, which primarily impact data availability, cyber incidents in ICS and SCADA systems can disrupt physical processes, compromise safety systems, and produce cascading operational effects. A well-structured incident response framework encompasses preparation, detection, containment, eradication, and recovery phases.

Preparation involves establishing response protocols, training personnel, and ensuring redundancy measures. Detection and containment focus on identifying threats promptly and limiting their operational impact. Eradication and recovery entail removing malicious elements, restoring system integrity, and validating process stability. Effective incident response in industrial contexts requires seamless integration of cybersecurity principles with operational expertise, ensuring resilient and uninterrupted functionality.

The Increasing Complexity of Industrial Threats

Industrial cyber threats are evolving in complexity and sophistication. Nation-state actors, criminal organizations, and hacktivists target ICS and SCADA systems due to their strategic importance and potential for high-impact disruption. Attacks may exploit zero-day vulnerabilities, manipulate control logic, or leverage advanced malware capable of remaining undetected for extended periods. These threats necessitate continuous vigilance, advanced technical knowledge, and proactive defense strategies.

Emerging attack vectors also include supply chain vulnerabilities, IoT-enabled devices, and remote access points. Each of these vectors introduces additional layers of risk that require specialized expertise to manage. Industrial cybersecurity professionals must continually adapt to new threat landscapes, integrating evolving defensive techniques into operational protocols to safeguard critical infrastructure.

Career Opportunities in Industrial Cybersecurity

The specialized nature of ICS and SCADA security has created a growing demand for skilled professionals. Industries such as energy, manufacturing, transportation, and utilities require experts capable of safeguarding essential infrastructures from cyber threats. Certified professionals are sought after for their unique combination of technical acumen, operational insight, and practical experience in securing industrial systems.

This demand translates into lucrative career opportunities and high earning potential. Industrial cybersecurity roles often command salaries significantly higher than general cybersecurity positions due to the specialized knowledge and responsibility involved. Professionals may pursue positions such as ICS security analyst, SCADA security engineer, incident response specialist, or risk assessment consultant, each contributing to the protection and resilience of critical infrastructure.

Skill Development Through Certification Programs

Certification programs in industrial cybersecurity provide a structured pathway for professionals to acquire essential skills. These programs combine theoretical knowledge with practical training, emphasizing hands-on experience in risk analysis, intrusion detection, malware examination, digital forensics, and incident response. Participants learn to navigate the unique challenges of ICS and SCADA systems, including legacy technologies, proprietary protocols, and high-stakes operational environments.

By completing certification programs, professionals gain the expertise required to anticipate threats, implement effective defenses, and respond decisively to incidents. The structured curriculum ensures that participants develop a comprehensive understanding of industrial systems and the cyber threats they face, positioning them as valuable assets in securing critical infrastructure.

Cross-Industry Relevance of Industrial Cybersecurity Skills

The competencies acquired through industrial cybersecurity training are applicable across multiple sectors. Energy production, water treatment, transportation networks, and manufacturing operations all rely on ICS and SCADA systems for efficient functioning. Certified professionals can apply their expertise to diverse industrial contexts, enhancing operational security, continuity, and resilience across various domains.

This cross-industry applicability provides professionals with flexibility in career advancement. By leveraging their specialized skill set, they can transition between sectors, contribute to national security initiatives, and influence operational standards for industrial cybersecurity. The versatility of these competencies underscores the strategic value of pursuing focused training and certification in industrial system security.

Recognition and Professional Credibility

Certification in industrial cybersecurity provides recognition and credibility within the professional community. Employers, peers, and stakeholders view certified individuals as competent experts capable of securing critical infrastructures. This recognition facilitates career growth, enhances professional reputation, and establishes individuals as trusted authorities in the field.

The credibility associated with certification also reinforces organizational confidence in cybersecurity measures. Certified professionals contribute to the establishment of robust security practices, instill operational confidence, and serve as role models for industry standards. Their expertise becomes integral to both organizational resilience and the broader cybersecurity ecosystem within industrial sectors.

Contributing to National and Global Security

Industrial cybersecurity professionals play a direct role in safeguarding infrastructures that underpin public safety and economic stability. Securing ICS and SCADA systems telp prevent cyber incidents that could disrupt essential services, compromise safety systems, or create environmental hazards. The work of these professionals has a profound impact on national security, public welfare, and global operational continuity.

Beyond organizational contributions, certified professionals participate in shaping industry best practices, advising on regulatory frameworks, and supporting the development of resilient infrastructure standards. Their expertise ensures that industrial operations remain secure, reliable, and capable of withstanding the evolving cyber threat landscape.

Career Pathways and Professional Growth in Industrial Cybersecurity

The field of industrial cybersecurity presents expansive opportunities for professionals seeking to specialize in securing critical infrastructures. As organizations increasingly rely on interconnected systems to manage industrial processes, the demand for experts in ICS and SCADA security continues to grow. Career pathways in this sector are distinguished by a combination of technical proficiency, operational knowledge, and strategic insight, offering professionals both responsibility and recognition.

Individuals pursuing careers in industrial cybersecurity may occupy roles such as ICS security analysts, SCADA engineers, incident response coordinators, risk assessment consultants, and cybersecurity architects. These positions require an intricate understanding of operational technologies, control logic, network security, and threat intelligence. Unlike traditional IT roles, industrial cybersecurity professionals must anticipate attacks that could disrupt physical processes, manipulate machinery, or compromise safety protocols. This combination of skills and responsibility makes these positions both challenging and highly rewarding.

The Rising Demand for Skilled Professionals

The increasing digitization of industrial operations has expanded the attack surface, making ICS and SCADA systems more vulnerable to cyber threats. The convergence of IT and OT environments has exposed legacy components to sophisticated attacks, amplifying the need for professionals who can navigate both technological domains. Global trends indicate a growing scarcity of experts equipped with the knowledge required to safeguard industrial infrastructures, creating an environment where certified professionals are in high demand.

Industries such as energy, manufacturing, water treatment, transportation, and critical utilities rely heavily on operational continuity. Cybersecurity breaches in these sectors can result in widespread disruption, environmental hazards, financial losses, and reputational damage. Organizations recognize the necessity of recruiting, retaining, and developing talent capable of mitigating these risks. As a result, the labor market rewards professionals with specialized expertise through competitive salaries, leadership opportunities, and strategic influence within their organizations.

Enhancing Operational Security Through Certification

Certification programs tailored to ICS and SCADA security provide professionals with structured learning and hands-on experience essential for industrial cybersecurity. These programs cover critical areas such as risk assessment, intrusion detection, malware analysis, digital forensics, and incident response. By integrating theoretical understanding with practical application, certifications ensure that professionals are prepared to address real-world industrial threats.

Hands-on training is particularly valuable, as it exposes candidates to simulated attacks and operational scenarios that mirror challenges faced in industrial environments. Practical exercises may include configuring network defenses, analyzing malware specific to control systems, reconstructing cyber incidents, and implementing strategic response protocols. Such experience develops the confidence, competence, and analytical skills required to protect critical infrastructure effectively.

Risk Management and Strategic Planning

A central focus of industrial cybersecurity is proactive risk management. Risk management involves identifying vulnerabilities, assessing potential impacts, and implementing measures to reduce exposure to cyber threats. Industrial systems are complex, comprising legacy devices, sensors, controllers, and networked components, each with distinct security considerations. Effective risk management requires a deep understanding of these elements, their interactions, and the potential operational consequences of compromise.

Strategic planning complements risk management by establishing policies, frameworks, and response protocols that guide organizational actions in the event of cyber incidents. This includes contingency planning, redundancy implementation, network segmentation, access control policies, and regular security audits. By integrating these measures, organizations not only minimize the likelihood of attacks but also enhance their resilience and capacity to maintain operational continuity under adverse conditions.

Intrusion Detection and Anomaly Monitoring

Monitoring for unauthorized activity is critical in industrial cybersecurity, as early detection can prevent significant operational disruptions. Intrusion detection systems analyze network traffic, system logs, and process signals to identify deviations from established norms. These systems employ techniques ranging from signature-based detection to machine learning algorithms capable of identifying anomalies and emerging threats.

Industrial environments present unique challenges for intrusion detection, including deterministic traffic patterns, proprietary protocols, and the necessity of uninterrupted operations. Security professionals must distinguish between benign deviations and indicators of compromise, ensuring that detection mechanisms are precise and actionable. Real-time monitoring and accurate anomaly identification enable swift response to incidents, reducing potential downtime and operational impact.

Malware Analysis and Defense Mechanisms

Malware targeting industrial systems is often tailored to manipulate control logic, disrupt operations, or compromise safety mechanisms. Logic bombs, trojans, and ransomware can infiltrate ICS and SCADA environments through multiple vectors, including network connections, infected devices, or software vulnerabilities. Malware analysis in industrial cybersecurity involves dissecting malicious code, understanding its propagation, and assessing its potential impact on processes and infrastructure.

Effective defense against malware requires coordinated strategies that encompass technical remediation, system restoration, and preventive measures. Professionals remove harmful code, restore compromised systems, and implement security enhancements to prevent recurrence. This approach ensures that industrial processes remain operational while minimizing exposure to ongoing and future threats.

Digital Forensics in Industrial Operations

Digital forensics provides critical insights into cyber incidents, enabling organizations to understand attack methodologies and implement corrective measures. Forensics in ICS and SCADA contexts involves examining system logs, control sequences, sensor data, and network activity to reconstruct incidents and determine their scope. The findings of forensic investigations inform immediate responses, long-term security enhancements, and policy adjustments.

The application of digital forensics in industrial environments is particularly vital due to the tangible consequences of cyber attacks. Accurate forensic analysis allows organizations to not only restore operations efficiently but also fortify systems against subsequent attempts, enhancing overall resilience. Professionals trained in forensic methodologies are equipped to navigate these complex investigations with precision and strategic foresight.

Incident Response and Recovery Strategies

Incident response in industrial cybersecurity is a dynamic and high-stakes process. Unlike IT systems, where breaches may primarily affect data, industrial systems are responsible for controlling physical operations. Consequently, incident response protocols must address both cyber threats and their potential operational impact. Effective strategies encompass preparation, detection, containment, eradication, and recovery.

Preparation involves developing response plans, training personnel, and establishing redundant systems to maintain operational continuity. Detection and containment require real-time monitoring, anomaly identification, and swift mitigation of threats. Eradication focuses on removing malicious elements and restoring system integrity, while recovery ensures that processes resume normal operation with minimal disruption. Professionals adept in these strategies protect both infrastructure and the people dependent on it.

Industry Applications and Cross-Sector Relevance

The principles and practices of industrial cybersecurity apply across diverse sectors. Energy production, water treatment, transportation networks, manufacturing, and healthcare all depend on ICS and SCADA systems for efficient operation. Professionals trained in these systems can apply their expertise in multiple contexts, enhancing operational security, continuity, and resilience.

The cross-sector relevance of industrial cybersecurity amplifies career flexibility and impact. Professionals can move between industries, adapt strategies to varying operational requirements, and contribute to standardizing security practices across multiple domains. Their role in shaping robust infrastructures is both strategic and influential, emphasizing the significance of specialized training and certification.

Earning Potential and Professional Recognition

Industrial cybersecurity professionals often command higher compensation than those in traditional IT security roles. The specialized knowledge, operational responsibility, and strategic importance associated with ICS and SCADA security justify premium remuneration. Certified professionals frequently access lucrative opportunities in energy, utilities, defense, and large-scale manufacturing, reflecting the high value placed on their expertise.

Certification also enhances professional recognition and credibility. Employers and peers regard certified individuals as capable experts in industrial security, fostering trust and facilitating career advancement. This recognition extends beyond immediate organizational contexts, positioning professionals as authorities in the broader cybersecurity community.

Contributing to Public and National Safety

Securing ICS and SCADA systems has a direct impact on public safety and national stability. Industrial cybersecurity professionals prevent attacks that could compromise essential services, endanger communities, or disrupt critical infrastructure. Their work contributes to safeguarding electricity grids, water treatment systems, transportation networks, and other vital operations.

The strategic importance of these contributions underscores the societal value of industrial cybersecurity. Professionals not only protect organizational assets but also help maintain social stability and economic resilience. By mitigating cyber threats to essential infrastructure, these experts play a pivotal role in ensuring that modern societies function safely and efficiently.

Staying Ahead of Emerging Threats

The cyber threat landscape is continuously evolving, with adversaries developing increasingly sophisticated tactics. Industrial systems face targeted attacks from advanced persistent threats, nation-state actors, and organized criminal networks. Professionals must remain vigilant, update their skills, and adapt strategies to counteract these evolving risks.

Continuous learning is essential for industrial cybersecurity experts. Participation in professional communities, engagement with ongoing training programs, and exposure to the latest technological developments enable professionals to anticipate threats and implement proactive defenses. This commitment ensures operational resilience and reinforces the security of critical infrastructures.

Strategic Advantages of Certification

Certification in ICS and SCADA security offers a structured pathway to acquire these essential skills. Beyond knowledge acquisition, certification programs foster practical competence, analytical thinking, and strategic planning. Participants develop the ability to assess risks, respond to incidents, and implement preventive measures that enhance operational security.

Certified professionals also gain exposure to a network of peers, instructors, and practitioners. This professional ecosystem facilitates knowledge sharing, collaboration, and mentorship, further strengthening the capacity to address complex industrial cybersecurity challenges. The combination of expertise, experience, and professional connectivity positions certified individuals as indispensable assets in safeguarding critical infrastructure.

Integration of IT and OT Security Practices

Industrial cybersecurity uniquely integrates IT and OT security considerations. Unlike conventional IT environments, where the primary focus is on data protection, industrial systems must balance data integrity with operational reliability. Security measures must accommodate the deterministic nature of control systems, ensure safety compliance, and maintain uninterrupted production processes.

This integration requires specialized methodologies, including network segmentation, access controls, real-time monitoring, and predictive analytics. Professionals trained in these techniques can effectively bridge the gap between IT and OT domains, ensuring that cybersecurity measures complement operational objectives rather than hinder them. The ability to harmonize these domains is a defining trait of successful industrial cybersecurity practice.

Advanced Strategies for Industrial Cybersecurity

The complexity of industrial cybersecurity requires more than basic protective measures; it demands advanced strategies that integrate technical proficiency, operational understanding, and proactive threat management. Industrial Control Systems and Supervisory Control and Data Acquisition systems are at the forefront of critical infrastructure operations. Their interconnectivity with modern networks, IoT devices, and remote monitoring platforms has expanded operational capabilities while introducing novel vulnerabilities. Cybersecurity strategies must therefore be sophisticated, multifaceted, and adaptable to evolving threats.

Advanced industrial cybersecurity strategies begin with comprehensive threat modeling and risk analysis. Professionals evaluate each component within the ICS and SCADA ecosystems, including legacy devices, programmable logic controllers, sensors, actuators, and network interfaces. This holistic perspective allows the identification of weak points, potential attack vectors, and systemic interdependencies that could amplify the impact of a cyber incident. By understanding the operational context and technical architecture, security teams can implement targeted defenses that reduce exposure and enhance resilience.

Layered Defense and Network Segmentation

A fundamental principle in industrial cybersecurity is the implementation of layered defense. Multi-tiered security architectures mitigate risk by compartmentalizing operations, limiting the spread of malicious activity, and ensuring that protective mechanisms operate across different levels of the infrastructure. Network segmentation, for instance, divides the industrial network into isolated zones, preventing intruders from gaining unrestricted access to critical systems.

In practice, network segmentation may involve separating IT and OT domains, isolating high-risk devices, and implementing strict access controls. Firewalls, intrusion detection systems, and authentication mechanisms work in concert to enforce these boundaries. Layered defense also includes endpoint protection, secure communication protocols, and continuous monitoring, creating multiple barriers that adversaries must navigate to compromise industrial operations.

Predictive Analytics and Anomaly Detection

Predictive analytics and anomaly detection are critical components of advanced industrial cybersecurity strategies. These approaches utilize historical data, behavioral models, and real-time monitoring to identify deviations from normal operational patterns. In ICS and SCADA environments, anomaly detection can reveal early signs of malware infiltration, unauthorized access, or process manipulation.

Machine learning algorithms and statistical models enhance predictive capabilities by continuously refining baselines and identifying subtle patterns that may escape human observation. By leveraging predictive analytics, security professionals can detect threats before they escalate, proactively adjust defense mechanisms, and maintain operational continuity. This proactive posture is essential in environments where delays or errors in response could have severe physical and financial consequences.

Threat Intelligence and Adversary Profiling

Threat intelligence is a cornerstone of contemporary industrial cybersecurity. By collecting, analyzing, and disseminating information about emerging threats, organizations gain insights into attacker techniques, tactics, and motivations. Adversary profiling allows security teams to anticipate potential attack scenarios, evaluate vulnerabilities, and deploy countermeasures in advance.

In industrial settings, threat intelligence includes monitoring nation-state activities, cybercriminal operations, and malware developments specifically targeting ICS and SCADA systems. Security professionals synthesize this intelligence to adjust protective strategies, update detection algorithms, and inform operational protocols. A robust threat intelligence program enables organizations to stay ahead of adversaries, reducing the likelihood of successful cyber attacks.

Incident Response Orchestration

Incident response in industrial cybersecurity is a meticulously coordinated endeavor. Unlike conventional IT breaches, industrial incidents often involve physical processes, safety systems, and operational continuity considerations. Effective response requires predefined protocols, clear communication channels, and rapid decision-making to contain and neutralize threats.

Incident response orchestration includes preparation, real-time monitoring, containment, eradication, recovery, and post-incident analysis. Security teams conduct simulations and tabletop exercises to refine response plans, ensuring readiness for high-impact events. Additionally, integration with operational personnel is critical, as collaboration between cybersecurity specialists and process engineers ensures that interventions maintain process stability while mitigating threats.

Security Monitoring and Continuous Improvement

Continuous monitoring is essential for maintaining industrial cybersecurity. This involves real-time observation of network traffic, control processes, system logs, and endpoint activity to detect anomalies, intrusion attempts, and performance deviations. Advanced monitoring solutions incorporate automated alerting, threat correlation, and incident tracking to streamline detection and response.

Continuous improvement is equally important. Security strategies must evolve alongside technological advancements, emerging threats, and operational changes. Regular audits, vulnerability assessments, and penetration testing provide feedback for refining defense mechanisms. By adopting a cycle of monitoring, assessment, and enhancement, organizations can maintain resilient and adaptive industrial security postures.

Sector-Specific Defense Methodologies

Different industries present unique cybersecurity challenges, necessitating sector-specific defense methodologies. For example, energy infrastructures such as power generation and distribution systems require protection against attacks targeting programmable logic controllers and supervisory networks. Manufacturing operations emphasize securing automation systems, robotics, and supply chain integration. Water treatment facilities prioritize safeguarding process control systems that manage chemical dosing, filtration, and distribution.

Tailored defense strategies account for operational priorities, regulatory requirements, and potential safety implications. Sector-specific methodologies may involve specialized intrusion detection rules, protocol validation, safety interlocks, and redundancy measures. Professionals trained in these approaches can implement nuanced security solutions that align with industry-specific operational and regulatory frameworks.

Redundancy and Operational Resilience

Redundancy is a critical element in ensuring operational resilience in industrial environments. Redundant systems, backup controllers, and failover mechanisms provide continuity in the event of a cyber incident or technical failure. Redundancy also supports rapid recovery, minimizing downtime and maintaining critical services during remediation efforts.

Implementing redundancy requires careful planning and coordination, ensuring that backup systems mirror operational processes accurately and can be activated seamlessly. Professionals integrate redundancy with monitoring, anomaly detection, and incident response protocols to create a resilient industrial ecosystem capable of withstanding cyber disruptions.

Integration of Emerging Technologies

Emerging technologies such as artificial intelligence, blockchain, and edge computing offer new opportunities for industrial cybersecurity. AI-driven analytics can detect sophisticated threats, optimize network defenses, and anticipate potential vulnerabilities. Blockchain technology provides tamper-evident audit trails, enhancing system integrity and accountability. Edge computing facilitates real-time processing and localized security enforcement at operational nodes, reducing latency and improving resilience.

Integrating these technologies requires specialized knowledge and careful deployment to ensure compatibility with legacy systems and operational requirements. Professionals adept at leveraging emerging solutions can enhance detection capabilities, streamline incident response, and reinforce overall industrial security frameworks.

Supply Chain and Third-Party Risk Management

Supply chain vulnerabilities are a significant concern in industrial cybersecurity. External vendors, contractors, and third-party systems can introduce hidden risks, ranging from compromised software to insecure network connections. Effective supply chain risk management involves vetting vendors, enforcing security standards, and monitoring third-party interactions continuously.

By integrating supply chain oversight into industrial cybersecurity strategies, organizations can reduce exposure to indirect threats, strengthen operational resilience, and maintain control over critical processes. Professionals trained in supply chain risk management play a pivotal role in fortifying industrial environments against both direct and indirect cyber threats.

Regulatory Compliance and Governance

Compliance with industry regulations, standards, and governance frameworks is an integral component of industrial cybersecurity. Regulations such as critical infrastructure protection guidelines and sector-specific security mandates establish baseline requirements for securing ICS and SCADA systems. Adherence to these standards ensures operational safety, legal compliance, and alignment with best practices.

Professionals must navigate complex regulatory landscapes, integrating compliance measures with technical security protocols and operational procedures. This dual focus enhances organizational credibility, reduces legal and financial risks, and promotes a culture of proactive security governance.

Emerging Threats and Adaptive Defense

The industrial cyber threat landscape is constantly evolving, with adversaries developing increasingly sophisticated attack techniques. Emerging threats include advanced persistent threats targeting specific industries, malware designed to manipulate physical processes, and coordinated attacks on interconnected infrastructures. Professionals must anticipate these threats, continuously update defensive strategies, and adopt adaptive security frameworks.

Adaptive defense involves dynamic threat modeling, continuous monitoring, and real-time mitigation. It emphasizes resilience, flexibility, and rapid response to minimize operational disruption. By cultivating adaptive capabilities, industrial cybersecurity professionals ensure that critical systems remain protected against evolving threats, maintaining reliability and operational integrity.

Holistic Approaches to Industrial Cybersecurity

As industrial systems continue to evolve and integrate with modern digital technologies, a holistic approach to cybersecurity becomes essential. Industrial Control Systems and Supervisory Control and Data Acquisition environments are at the intersection of physical processes and digital management, necessitating a comprehensive strategy that addresses technical, operational, and organizational dimensions simultaneously. Holistic industrial cybersecurity emphasizes the interconnection of people, processes, and technology, ensuring that every facet of industrial operations is fortified against cyber threats.

At the core of this approach is the recognition that security cannot be compartmentalized. A breach in a single subsystem, whether a sensor, controller, or communication node, can propagate across the network and compromise operational continuity. Holistic strategies incorporate cross-functional collaboration, integrating cybersecurity professionals, process engineers, IT specialists, and management teams into a unified security framework. This cohesion ensures that both digital assets and physical processes receive coordinated protection.

Organizational Culture and Security Awareness

The human element is a critical factor in industrial cybersecurity. Employees, contractors, and operators often interact with ICS and SCADA systems daily, and inadvertent actions can create vulnerabilities. Cultivating a culture of security awareness involves regular training, policy enforcement, and the promotion of vigilant operational behavior.

Security-conscious culture encourages personnel to identify potential risks, report anomalies, and adhere to established protocols. Awareness programs may include simulations of cyber incidents, tabletop exercises, and scenario-based learning to reinforce the importance of security in day-to-day operations. By embedding cybersecurity principles into organizational culture, companies enhance their resilience and reduce the likelihood of breaches caused by human error.

Integration of Cybersecurity and Operational Objectives

Industrial cybersecurity is most effective when seamlessly integrated with operational objectives. Security measures must align with process continuity, safety standards, and production efficiency. For example, intrusion detection systems, access controls, and network segmentation should complement operational workflows rather than impede them.

Integration requires collaboration between cybersecurity teams and operational staff to understand process dependencies, safety requirements, and critical thresholds. By designing security protocols that account for operational realities, organizations achieve a balance between protection and functionality, ensuring that critical systems remain both secure and productive.

Continuous Risk Assessment and Adaptive Strategies

The dynamic nature of industrial operations and cyber threats necessitates continuous risk assessment and adaptive strategies. Regular evaluation of system components, network connections, and process dependencies identifies evolving vulnerabilities and informs mitigation efforts. Adaptive strategies allow organizations to respond effectively to emerging threats, integrating lessons learned from past incidents and current threat intelligence.

Continuous risk assessment may involve vulnerability scanning, penetration testing, and scenario modeling. These activities enable proactive identification of weak points and facilitate the deployment of targeted defenses. Adaptive strategies ensure that industrial cybersecurity measures remain relevant and effective, maintaining operational integrity in the face of increasingly sophisticated adversaries.

Collaborative Defense and Industry Partnerships

Collaboration extends beyond the organizational level to encompass industry-wide partnerships. Industrial systems are often interconnected through supply chains, utility networks, and critical infrastructure ecosystems. Threats targeting one entity can have cascading effects, underscoring the importance of shared intelligence, best practices, and coordinated defense strategies.

Industry partnerships allow organizations to exchange threat intelligence, coordinate incident response, and establish standardized security protocols. These collaborations strengthen collective resilience and ensure that industrial cybersecurity evolves in tandem with emerging threats. Professionals participating in such networks gain insights into broader risk landscapes, enhancing their capacity to protect interconnected infrastructures.

Emerging Technologies and Innovation in Industrial Security

The integration of emerging technologies offers new avenues for strengthening industrial cybersecurity. Artificial intelligence enables predictive analytics, real-time anomaly detection, and automated threat mitigation. Edge computing enhances local processing capabilities, reducing latency and improving responsiveness to operational deviations. Blockchain technology provides tamper-evident records and secure communication channels, enhancing transparency and accountability.

Innovation extends to threat simulation, automated response frameworks, and dynamic network reconfiguration. By leveraging these technologies, industrial cybersecurity professionals can enhance detection accuracy, accelerate response times, and implement proactive defense measures. Effective application requires understanding both the technical potential and operational implications of these solutions to maintain process stability.

Regulatory Compliance and Standards Evolution

Industrial cybersecurity is governed by a complex landscape of regulations, standards, and best practices. Compliance ensures operational safety, legal accountability, and alignment with industry benchmarks. Regulatory frameworks guide risk management, incident response, access control, and infrastructure resilience, forming the foundation for structured cybersecurity programs.

As technologies and threats evolve, regulatory standards are continually updated to reflect emerging challenges. Organizations must adapt policies, processes, and technical measures to remain compliant, integrating these requirements into holistic cybersecurity strategies. Professionals must stay informed of regulatory developments and align organizational practices with evolving standards to maintain both security and legal integrity.

Future Trends in Industrial Cybersecurity

The future of industrial cybersecurity is shaped by technological advancement, threat evolution, and operational complexity. Key trends include increased adoption of AI-driven monitoring, greater emphasis on predictive risk modeling, integration of cybersecurity into digital twins, and enhanced collaboration across industrial ecosystems. Cyber threats are expected to become more targeted, persistent, and sophisticated, necessitating adaptive strategies and continuous skill development.

Professionals must anticipate these trends by cultivating expertise in emerging technologies, threat intelligence, and operational integration. Preparing for future challenges involves not only technical proficiency but also strategic foresight, critical thinking, and the ability to coordinate multi-disciplinary defense efforts.

Professional Development and Lifelong Learning

Sustaining expertise in industrial cybersecurity requires ongoing professional development. The rapidly changing landscape demands continuous education in threat intelligence, technological innovation, operational risk, and regulatory compliance. Lifelong learning enables professionals to maintain relevance, adapt strategies, and implement state-of-the-art solutions for protecting ICS and SCADA environments.

Development avenues include formal certification programs, advanced training courses, workshops, professional communities, and scenario-based simulations. Engagement with these resources ensures that professionals remain informed of emerging threats, evolving defense mechanisms, and best practices for safeguarding critical infrastructure.

Impact of Industrial Cybersecurity on Society

Industrial cybersecurity extends its influence beyond organizational boundaries to impact society at large. Reliable ICS and SCADA systems underpin essential services, from electricity and water supply to transportation and healthcare. Cyber incidents affecting these systems can disrupt daily life, compromise public safety, and cause economic instability.

By securing industrial environments, cybersecurity professionals contribute to societal resilience, ensuring that critical infrastructure operates reliably and safely. Their work mitigates risks that could otherwise result in widespread disruption, environmental hazards, and public harm. The societal significance of their role underscores the importance of expertise, vigilance, and strategic intervention.

Strategic Integration of Security Frameworks

Holistic industrial cybersecurity integrates technical solutions, operational procedures, organizational policies, and regulatory compliance into a unified security framework. This integration allows organizations to manage risk comprehensively, respond to threats efficiently, and maintain continuity across complex operational networks.

Strategic frameworks include layered defense architectures, continuous monitoring systems, incident response protocols, redundancy planning, and adaptive security strategies. Integration ensures that each component supports the others, creating a cohesive and resilient environment capable of withstanding diverse cyber threats. Professionals skilled in this integration are able to orchestrate security measures that align with both operational goals and industry standards.

Collaboration Between Cybersecurity and Operational Teams

Effective industrial cybersecurity relies on the collaboration between cybersecurity specialists and operational personnel. Process engineers, operators, and control system technicians possess critical knowledge of system behavior, operational constraints, and safety requirements. Cybersecurity professionals bring expertise in threat detection, risk assessment, and response strategies.

By fostering collaboration, organizations ensure that security measures enhance operational safety and efficiency without impeding processes. Joint planning, shared simulations, and coordinated response protocols enable teams to anticipate threats, implement preventive measures, and respond to incidents with minimal disruption. This partnership strengthens organizational resilience and promotes a culture of integrated security.

Conclusion

The field of industrial cybersecurity has grown into a critical discipline, driven by the increasing digitization and interconnectivity of Industrial Control Systems and Supervisory Control and Data Acquisition environments. Protecting these systems requires a unique blend of technical expertise, operational knowledge, and strategic foresight. Professionals equipped with specialized training and certification are prepared to assess risks, detect anomalies, analyze threats, respond to incidents, and maintain operational resilience across diverse industrial sectors. Their work safeguards essential infrastructure, from energy grids and water treatment facilities to transportation networks and manufacturing processes, ensuring public safety, economic stability, and societal continuity. As cyber threats become increasingly sophisticated, holistic strategies integrating advanced technologies, cross-functional collaboration, regulatory compliance, and continuous learning are essential. Industrial cybersecurity specialists remain at the forefront of defense, enabling secure, reliable, and resilient operations, and reinforcing the vital role of skilled professionals in sustaining modern industrial ecosystems.