Certification: ICS-SCADA Cybersecurity

Certification Full Name: ICS-SCADA Cybersecurity

Certification Provider: ECCouncil

Exam Code: ICS-SCADA

Exam Name: ICS-SCADA Cyber Security

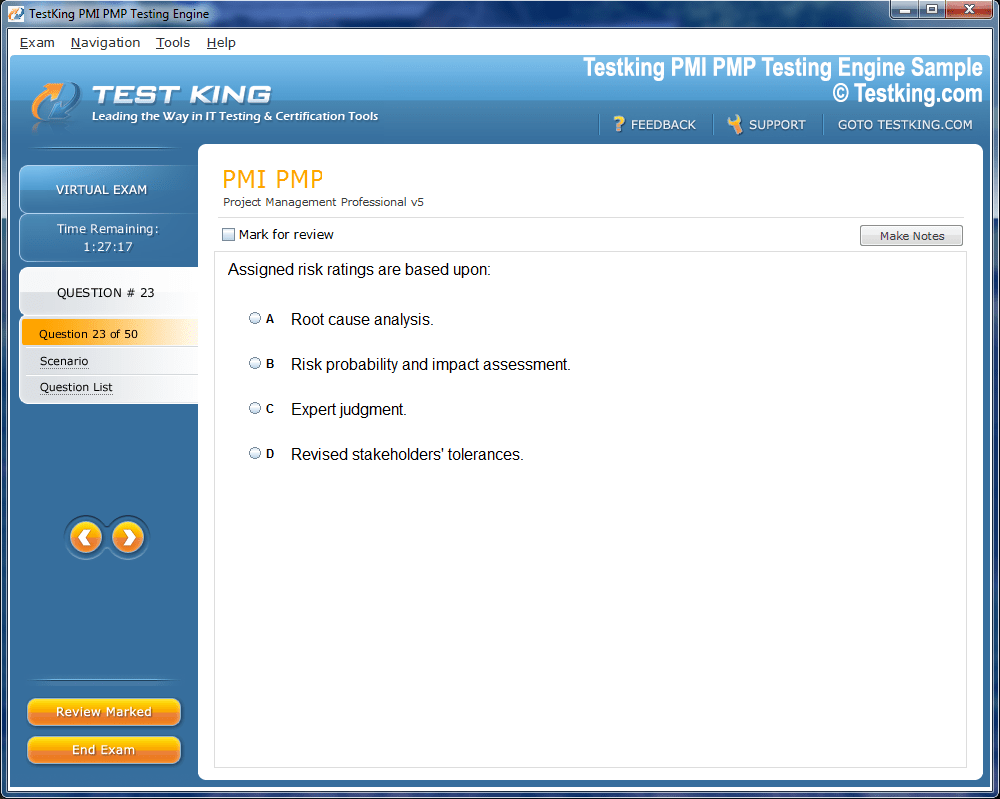

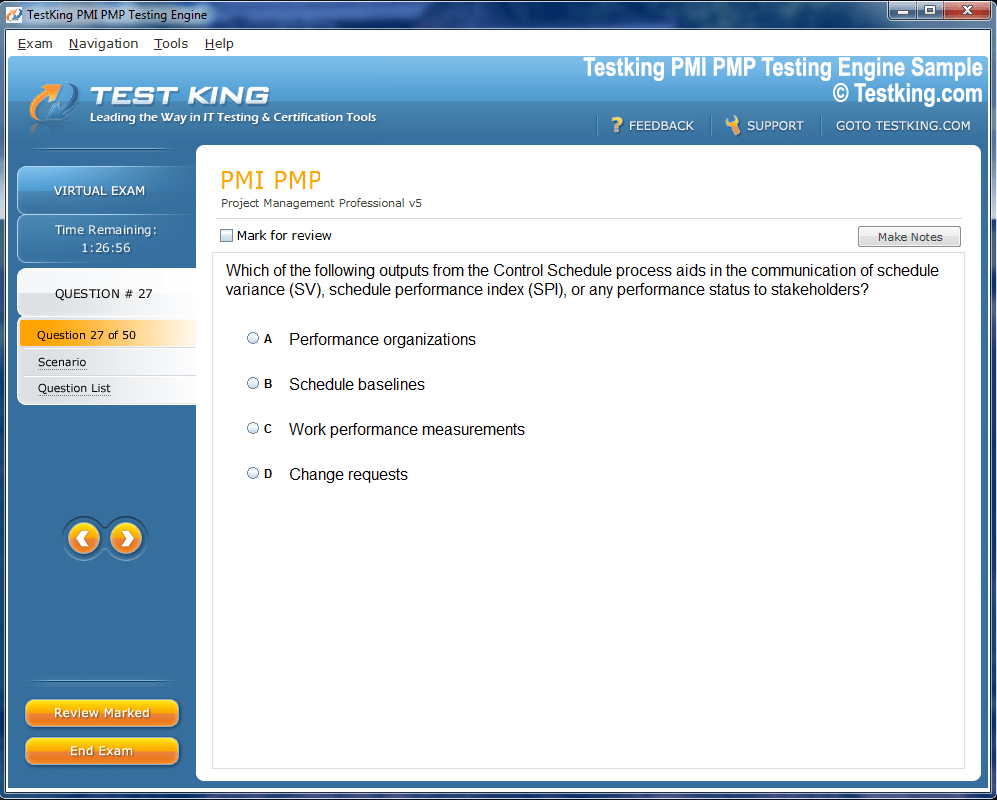

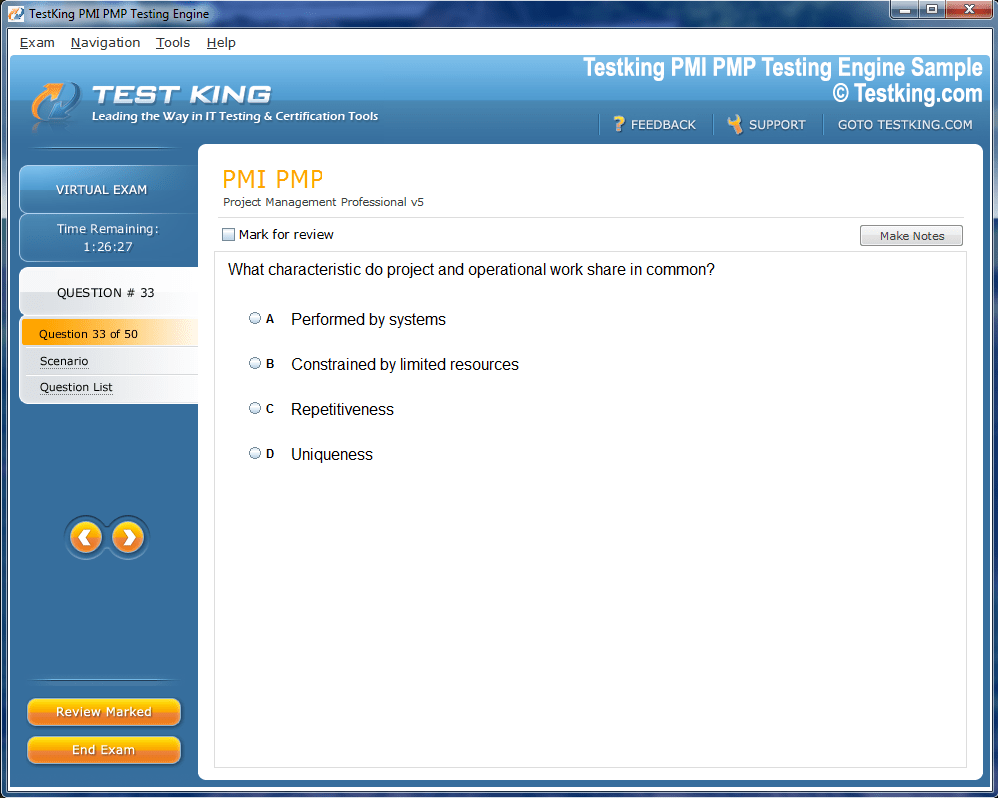

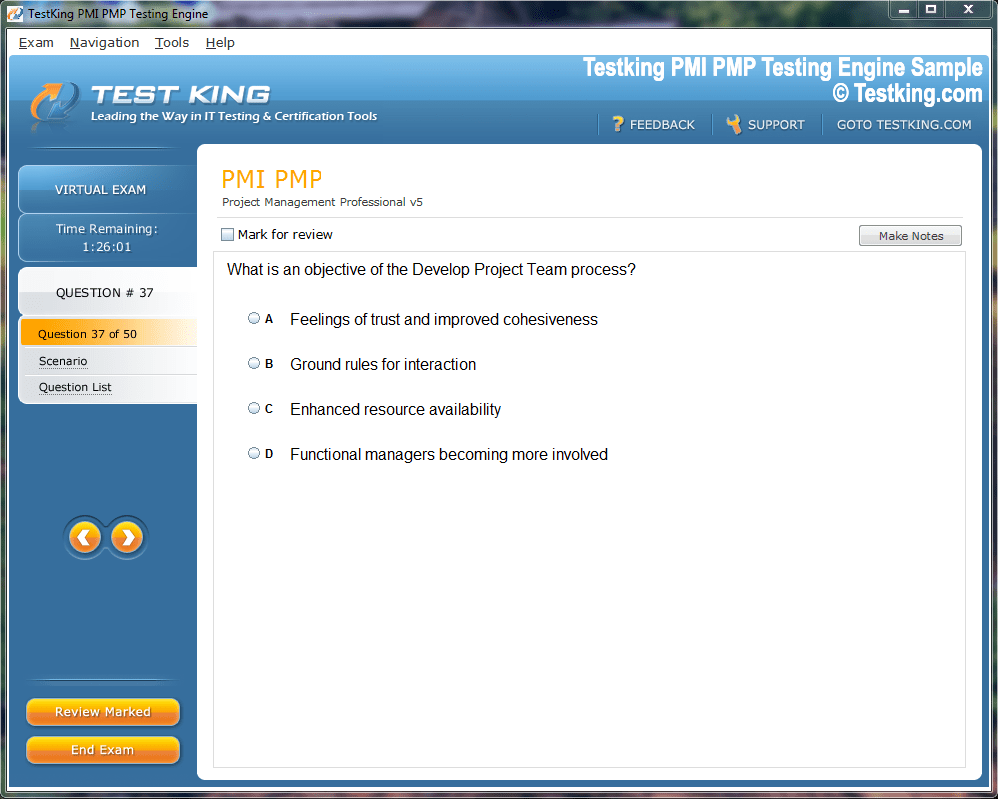

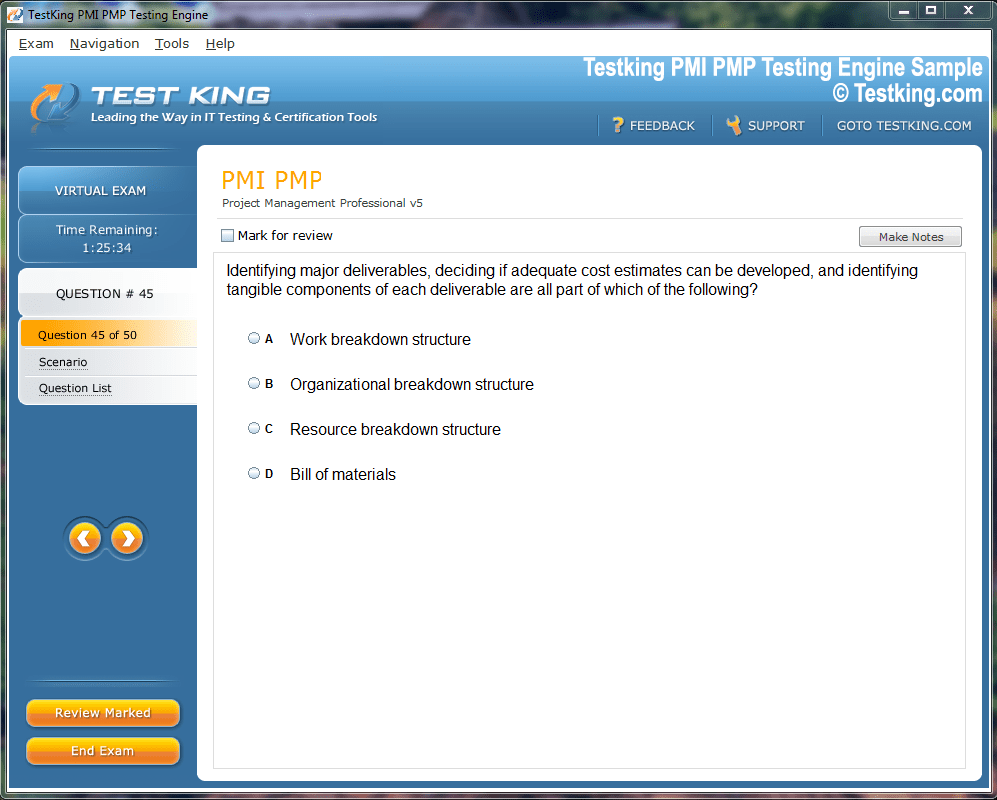

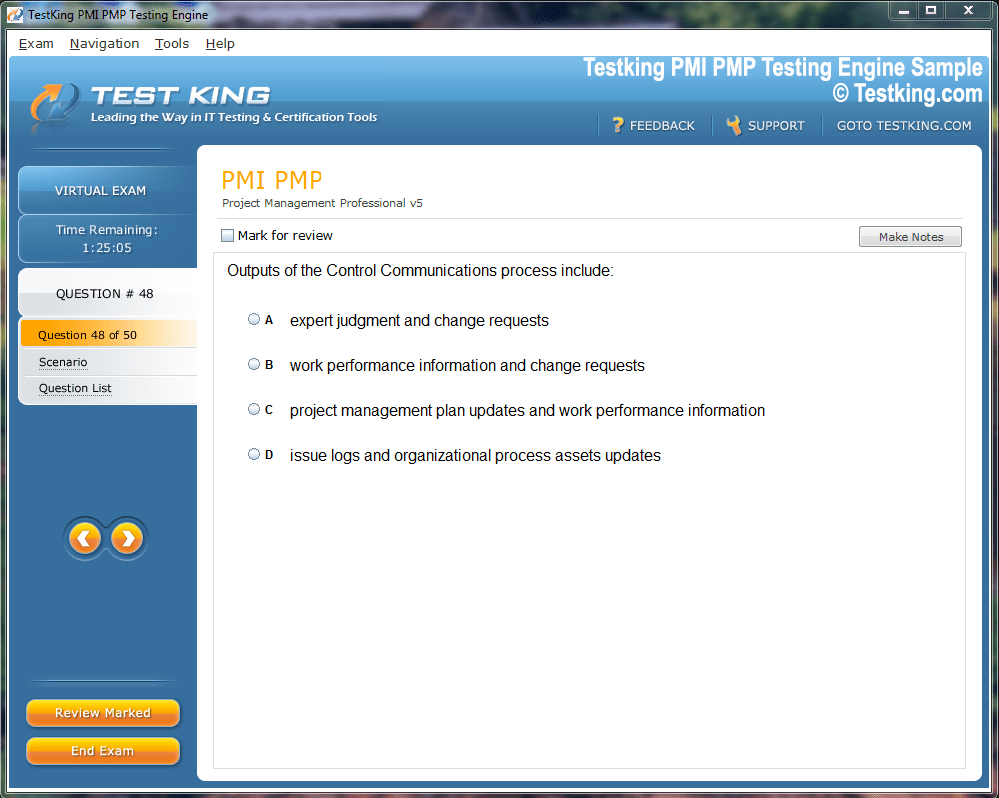

Product Screenshots

nop-1e =1

EC-Council ICS/SCADA Certification for Advanced Threat Mitigation in Industry

The ongoing digital metamorphosis of industries has not only transformed operations but has also brought a new dimension of vulnerability. Industrial Control Systems and Supervisory Control and Data Acquisition networks form the backbone of critical sectors such as energy distribution, water treatment, transportation, and manufacturing. These systems, historically isolated and insulated, are increasingly interconnected, exposing them to a proliferation of cyber threats. Unlike conventional IT networks, which primarily manage data, industrial control environments regulate tangible physical processes. This distinction makes them a unique target, as any compromise can precipitate cascading operational failures, financial repercussions, and potential hazards to human safety.

As the operational landscape evolves, the paradigm of cybersecurity in industrial environments must also adapt. Professionals working in this sphere must possess an intricate understanding of both technical and operational intricacies, merging knowledge from IT and operational technology spheres. This fusion of expertise ensures the development of defense strategies that are resilient, proactive, and capable of mitigating threats before they materialize into catastrophic outcomes. Industrial cybersecurity, therefore, is no longer merely a supplementary skill—it has become a strategic imperative for organizations that manage critical infrastructure.

Industrial control networks are often composed of legacy systems with limited inherent security features. These systems, designed primarily for reliability and operational efficiency, often lack encryption, authentication, and other fundamental cybersecurity mechanisms. The integration of modern protocols, IoT devices, and internet connectivity, while enhancing operational efficiency, simultaneously introduces vulnerabilities. Cyber adversaries exploit these gaps, leveraging sophisticated malware, phishing attacks, and advanced persistent threats to penetrate critical systems. Understanding the nuances of these threats is essential for any professional aspiring to secure industrial environments.

The Role of Industrial Control Systems in Critical Infrastructure

Industrial Control Systems govern processes that are fundamental to societal functioning. From regulating electrical grids and water purification plants to managing automated manufacturing lines, ICS and SCADA networks facilitate precision, efficiency, and reliability. Unlike conventional IT systems, where breaches primarily compromise data, attacks on ICS can result in tangible, physical consequences. A cyber intrusion into a power grid, for example, can induce widespread outages, disrupt transportation networks, and jeopardize public safety. Similarly, interference in water treatment systems could introduce contaminants or disrupt the flow of essential resources. These scenarios underscore the necessity of highly skilled professionals capable of anticipating and neutralizing threats.

The operational technology realm, which ICS and SCADA networks inhabit, is governed by real-time processes. Unlike IT environments, where latency can be tolerated, even minor disruptions in industrial networks can trigger substantial losses or unsafe conditions. Consequently, the cybersecurity strategies for ICS/SCADA systems must incorporate not only protective measures but also resilience mechanisms that ensure continuity and rapid recovery in the event of an incident. This requirement necessitates a hybrid skill set that blends conventional cybersecurity knowledge with a thorough comprehension of physical process control.

Why Specialized Training in ICS/SCADA Security Matters

The increasing sophistication of cyber threats demands professionals who do not merely respond to incidents but proactively fortify networks. Traditional IT security training, while foundational, is insufficient to address the unique challenges posed by industrial environments. Industrial networks are often subject to legacy protocols, proprietary technologies, and devices with limited computational capacity, all of which complicate conventional defense strategies. For instance, protocols such as Modbus, DNP3, and IEC 60870-5-104, widely used in ICS networks, were never designed with robust security in mind. They lack encryption, authentication, and integrity verification, making them particularly susceptible to exploitation.

Specialized certification programs provide a structured pathway for professionals to acquire this critical expertise. Such programs emphasize both theoretical knowledge and practical proficiency, equipping candidates with the skills to assess vulnerabilities, implement safeguards, and respond to incidents efficiently. Moreover, these programs encourage an offensive perspective, allowing practitioners to anticipate potential attack vectors by understanding the tactics and methodologies employed by adversaries. This dual approach—defensive and offensive—enables a more comprehensive security posture and positions certified professionals as indispensable assets in safeguarding industrial infrastructure.

Risk Analysis and Threat Anticipation

One of the foundational aspects of industrial cybersecurity is risk analysis. Unlike IT networks, where data loss is often the primary concern, industrial environments face a spectrum of risks that can impact physical operations. Evaluating potential threats requires an understanding of the interdependencies between devices, protocols, and processes. Professionals must identify vulnerabilities in both the network architecture and operational workflows, assess the probability of exploitation, and determine the potential impact on operational continuity and safety.

Advanced risk analysis involves a meticulous examination of system configurations, network topologies, and device interactions. It also considers external factors such as geopolitical tensions, supply chain vulnerabilities, and emerging cybercrime methodologies. By employing a structured risk assessment framework, cybersecurity professionals can prioritize protective measures, allocate resources effectively, and implement contingency plans that minimize the likelihood and severity of disruptive events. This proactive approach ensures that industrial networks remain resilient even in the face of sophisticated cyber threats.

Intrusion Detection and Real-Time Monitoring

Effective industrial cybersecurity depends on the ability to detect anomalies and intrusions in real time. Unlike conventional IT systems, where delayed responses might be tolerable, ICS and SCADA networks demand immediate action to prevent operational disruptions. Intrusion detection systems tailored for industrial environments monitor traffic patterns, protocol adherence, and device behavior to identify deviations that may indicate a security breach.

These systems rely on both signature-based and behavior-based detection methodologies. Signature-based techniques identify known attack patterns, while behavior-based approaches detect unusual activities that deviate from established operational norms. By combining these techniques, professionals can identify both familiar and novel threats. In addition to detection, real-time monitoring facilitates rapid response, enabling operators to isolate compromised components, prevent propagation, and maintain operational continuity. The integration of real-time analytics with automated response mechanisms further enhances the resilience of industrial networks.

Malware Analysis and Defensive Strategies

Industrial networks are increasingly targeted by sophisticated malware designed to disrupt operations, exfiltrate sensitive data, or compromise safety mechanisms. Malware such as Stuxnet, Triton, and Industroyer has demonstrated the devastating potential of cyberattacks on industrial infrastructure. Professionals tasked with securing these environments must possess the ability to detect, analyze, and neutralize malicious software.

Malware analysis involves dissecting the code, understanding its propagation methods, identifying indicators of compromise, and determining its potential impact on industrial processes. By comprehensively understanding malware behavior, cybersecurity specialists can develop targeted defense strategies, deploy countermeasures, and enhance system resilience. This process also informs the development of intrusion detection signatures, network segmentation strategies, and incident response protocols tailored to the unique requirements of ICS/SCADA systems.

Digital Forensics in Industrial Environments

In the event of a cyber incident, digital forensics plays a critical role in understanding the nature and extent of the breach. Industrial environments present unique challenges for forensic investigations, including proprietary protocols, real-time operational constraints, and a mix of legacy and modern devices. Forensic professionals must collect and analyze data without disrupting ongoing operations, ensuring that both evidence integrity and operational continuity are maintained.

The forensic process involves identifying compromised components, tracing attack vectors, reconstructing events, and documenting findings for operational, legal, and regulatory purposes. By understanding the attacker’s methods and motives, professionals can refine defensive strategies, close vulnerabilities, and prevent future incidents. This knowledge also supports compliance with regulatory requirements and enhances organizational readiness for emerging threats.

Incident Response and Recovery

Effective incident response is paramount in industrial cybersecurity. The ability to contain, mitigate, and recover from cyberattacks determines the overall resilience of the system. Response strategies must consider both digital and physical ramifications, ensuring that operations continue safely while addressing the breach.

Incident response in industrial environments includes immediate containment measures, such as isolating affected devices, blocking malicious traffic, and deploying backups or redundant systems. Recovery efforts focus on restoring normal operations, repairing compromised components, and validating system integrity. Professionals must also conduct post-incident analysis to identify lessons learned and refine response protocols. This continuous improvement cycle strengthens the organization’s defensive posture and ensures preparedness for future incidents.

Bridging IT and Operational Technology

A critical aspect of industrial cybersecurity is bridging the gap between IT and operational technology. Historically, IT and OT have operated in distinct domains, with separate teams, priorities, and protocols. However, the convergence of these spheres introduces both opportunities and challenges. While integration enhances operational efficiency and data visibility, it also expands the attack surface and introduces new vulnerabilities.

Cybersecurity professionals must navigate this convergence by understanding IT security principles such as network segmentation, access control, encryption, and endpoint protection, while simultaneously mastering OT-specific concepts such as process control logic, real-time system constraints, and device interoperability. This dual expertise allows for the development of holistic security strategies that safeguard the integrity, availability, and confidentiality of industrial systems.

The Strategic Imperative of ICS/SCADA Expertise

As industrial environments become increasingly interconnected, the demand for skilled cybersecurity professionals continues to rise. Organizations require experts who can not only manage existing vulnerabilities but also anticipate emerging threats. ICS/SCADA certification programs provide a structured pathway to acquire these capabilities, equipping professionals with the knowledge, skills, and mindset necessary to secure critical infrastructure.

Beyond operational and technical skills, certified professionals gain credibility in a competitive field. Their expertise signals to employers and stakeholders that they possess the competence to safeguard systems where cyberattacks could have far-reaching consequences. This recognition, combined with practical capabilities, positions them as indispensable assets in an era of escalating industrial cyber threats.

Preparing for a Career in Industrial Cybersecurity

Embarking on a career in industrial cybersecurity requires deliberate preparation and a commitment to continuous learning. Professionals should cultivate a comprehensive understanding of ICS/SCADA architectures, network protocols, and operational workflows. Hands-on experience with intrusion detection systems, malware analysis, and forensic investigations is invaluable in building practical proficiency.

Additionally, staying abreast of emerging threats and technological advancements is essential. Cyber adversaries continually refine their tactics, and industrial systems evolve with the adoption of IoT devices, cloud integration, and artificial intelligence. Professionals who engage in ongoing learning, participate in peer communities, and pursue specialized certifications remain at the forefront of industrial cybersecurity, capable of defending critical infrastructure against increasingly sophisticated threats.

The Evolving Threat Landscape in Industrial Environments

The modern industrial landscape is increasingly entwined with digital technologies, transforming traditional control systems into interconnected, high-speed networks. This evolution brings efficiency and precision but simultaneously expands the attack surface for cyber adversaries. Industrial Control Systems and Supervisory Control and Data Acquisition networks, once isolated and fortified through physical and network segmentation, now face a complex web of threats due to remote access, cloud integration, and the adoption of Internet of Things devices. These developments make industrial environments an attractive target for attackers seeking disruption, espionage, or financial gain.

Cyber threats targeting industrial networks differ significantly from conventional IT attacks. While IT attacks often focus on data theft or financial fraud, breaches in industrial environments can directly compromise physical operations, potentially endangering human safety and critical infrastructure. The consequences of such intrusions extend beyond monetary losses, affecting public trust, operational continuity, and national security. For example, targeted attacks on electrical grids, water treatment facilities, and transportation systems can cause widespread disruption with far-reaching societal impacts.

The sophistication of threats targeting industrial networks is continually increasing. Advanced persistent threats, state-sponsored actors, and organized cybercriminal groups employ specialized techniques to penetrate industrial networks. Malware such as Stuxnet, Industroyer, and Triton has demonstrated the potential for cyberattacks to manipulate industrial processes with precision, highlighting the need for a highly trained cybersecurity workforce capable of understanding both digital and physical dimensions of attacks.

Vulnerabilities Inherent in ICS/SCADA Systems

Industrial networks are inherently complex, often comprising a mixture of legacy and modern systems. Legacy protocols, such as Modbus, DNP3, and IEC 60870-5-104, were designed for operational reliability rather than security. They lack features such as encryption, authentication, and integrity verification, creating inherent vulnerabilities that adversaries can exploit. These protocols continue to be widely deployed, creating a persistent risk even as newer, more secure technologies emerge.

Another source of vulnerability arises from the convergence of information technology and operational technology. IT networks employ robust cybersecurity measures, while operational networks were historically designed for reliability and predictability. Integrating these two domains introduces new attack vectors, requiring professionals to navigate both IT security principles and OT-specific considerations. A misconfigured gateway, insecure remote access, or an unpatched device can serve as an entry point for cyberattacks, potentially compromising an entire industrial network.

Human factors also contribute to industrial cybersecurity risks. Operators and engineers may lack cybersecurity awareness or inadvertently engage in practices that expose systems to attacks, such as using default credentials, neglecting software updates, or connecting unauthorized devices to critical networks. Addressing these human-centric vulnerabilities requires comprehensive training programs, security policies, and an organizational culture that prioritizes cybersecurity alongside operational efficiency.

The Importance of Risk Analysis and Threat Modeling

Risk analysis is foundational to securing industrial environments. Unlike IT networks, where breaches often result in data loss, industrial systems face a spectrum of risks that can directly affect physical processes. Conducting a thorough risk assessment requires a deep understanding of network topology, device interdependencies, and operational workflows. Professionals must evaluate the likelihood of exploitation, potential impact on safety and operations, and the cascading consequences of a successful attack.

Threat modeling complements risk analysis by simulating potential attack scenarios. This proactive approach enables cybersecurity professionals to anticipate attacker strategies, identify critical vulnerabilities, and design mitigation strategies before an incident occurs. Threat models often consider multiple dimensions, including network access points, human factors, physical security, and regulatory constraints. By understanding how an attacker might navigate the system, professionals can implement layered defenses, including segmentation, access controls, and real-time monitoring.

Advanced risk analysis also incorporates emerging threats and geopolitical considerations. State-sponsored actors may target industrial infrastructure for espionage, sabotage, or economic disruption. Understanding these motivations helps professionals prioritize protective measures, allocate resources effectively, and develop contingency plans that maintain operational continuity even under sophisticated threat scenarios.

Intrusion Detection and Anomaly Monitoring

Intrusion detection is critical for safeguarding industrial networks, as timely identification of threats can prevent operational disruptions. Unlike traditional IT networks, where delayed response may be acceptable, ICS and SCADA networks operate in real time. A single compromised device can propagate disruptions rapidly, making continuous monitoring essential.

Intrusion detection systems for industrial environments rely on a combination of signature-based and behavior-based methodologies. Signature-based systems identify known attack patterns, while behavior-based systems detect deviations from normal operational processes. Advanced anomaly detection tools leverage machine learning to recognize subtle variations in device behavior, network traffic, and protocol adherence, enabling detection of novel threats.

The integration of real-time monitoring with automated response capabilities further enhances security. Automated alerts, isolation of compromised devices, and dynamic reconfiguration of network segments can prevent attackers from exploiting vulnerabilities or spreading malware. By combining proactive detection with rapid mitigation, cybersecurity professionals maintain operational continuity while minimizing the impact of incidents.

Malware and Attack Techniques Targeting Industrial Networks

Industrial networks face a growing variety of malware and attack techniques designed to manipulate operational processes, exfiltrate data, or disrupt services. Malware such as Stuxnet demonstrated the ability to target specific industrial processes with surgical precision, while Triton malware highlighted vulnerabilities in safety instrumented systems. Understanding the unique behavior of industrial malware is essential for designing effective defenses.

Malware analysis in industrial environments involves dissecting code, understanding propagation mechanisms, and evaluating potential impact on operational processes. Professionals must assess both direct effects on devices and indirect effects on interconnected systems. By identifying indicators of compromise, security teams can implement targeted countermeasures, refine intrusion detection signatures, and develop response strategies tailored to the operational context.

Attack techniques extend beyond malware. Adversaries exploit misconfigurations, unpatched devices, weak authentication, and insider vulnerabilities to gain unauthorized access. Social engineering, phishing, and supply chain compromises are increasingly common, emphasizing the need for comprehensive defense strategies that encompass technical, organizational, and human factors.

Digital Forensics in Industrial Contexts

Digital forensics is a critical component of industrial cybersecurity, enabling organizations to understand the nature and extent of breaches. Unlike IT environments, industrial networks require forensic analysis to be conducted without disrupting real-time operations. This presents unique challenges, as devices may operate under stringent timing constraints and often run proprietary software or legacy protocols.

Forensic investigations involve collecting and analyzing logs, device configurations, and network traffic to reconstruct the sequence of events leading to an incident. Understanding the attacker’s methods, entry points, and objectives informs the development of enhanced security measures, mitigating future risks. Additionally, forensic analysis supports regulatory compliance, incident reporting, and post-event review, ensuring organizations learn from each incident and strengthen resilience.

Incident Response and Recovery Strategies

Incident response in industrial environments demands careful coordination between IT and OT teams. The objective is not only to neutralize threats but also to preserve operational continuity. Response strategies include isolating compromised components, deploying redundant systems, and containing malware propagation. Effective incident response also requires post-event analysis to refine defensive protocols, patch vulnerabilities, and validate system integrity.

Recovery efforts focus on restoring normal operations while ensuring security. Backups, failover systems, and redundancy mechanisms are critical for minimizing downtime and maintaining operational safety. The iterative process of response and recovery strengthens an organization’s cybersecurity posture, enabling it to withstand future incidents with greater resilience.

Bridging IT and Operational Technology Expertise

The convergence of IT and OT domains necessitates a hybrid skill set for industrial cybersecurity professionals. IT expertise provides foundational knowledge in network security, encryption, authentication, and endpoint protection. OT expertise offers insight into process control, real-time system constraints, and industrial protocol behavior.

Bridging these domains enables professionals to implement comprehensive security strategies that address both digital and physical aspects of industrial operations. For example, network segmentation, access controls, and continuous monitoring can protect digital infrastructure, while secure configuration of programmable logic controllers, safety systems, and SCADA components ensures operational integrity. The integration of IT and OT security is essential for a robust defense against contemporary cyber threats.

Career Prospects in Industrial Cybersecurity

The demand for skilled professionals in ICS/SCADA security continues to rise as industrial networks become more interconnected. Specialized certifications provide a structured pathway for acquiring the knowledge and practical skills necessary to excel in this field. Certified professionals are well-positioned to occupy critical roles in sectors such as energy, utilities, transportation, and manufacturing.

The specialized nature of industrial cybersecurity often commands higher compensation compared to traditional IT security roles. Organizations recognize the criticality of securing operational networks and are willing to invest in professionals who can safeguard both digital and physical assets. Career growth in this domain is also accelerated by the relative scarcity of trained experts, creating opportunities for rapid advancement and specialization.

Beyond remuneration, professionals in industrial cybersecurity contribute to societal well-being. Protecting critical infrastructure ensures the uninterrupted delivery of essential services, safeguards public safety, and reinforces national security. This unique combination of technical challenge, societal impact, and career opportunity makes industrial cybersecurity a highly rewarding field for dedicated professionals.

Continuous Learning and Professional Development

The evolving threat landscape requires continuous learning and professional development. Cyber adversaries constantly refine their tactics, and industrial environments are subject to ongoing technological changes. Professionals must stay current with emerging threats, new protocols, and innovative security solutions to maintain an effective defense posture.

Participating in specialized training programs, certification courses, and professional communities provides opportunities to expand knowledge, exchange insights, and remain at the forefront of industrial cybersecurity. Continuous learning fosters both technical proficiency and strategic awareness, enabling professionals to anticipate threats, implement cutting-edge defenses, and adapt to an increasingly complex operational landscape.

Advanced Threats in Industrial Cybersecurity

Industrial Control Systems and Supervisory Control and Data Acquisition networks face an evolving array of threats that extend beyond conventional IT vulnerabilities. As these systems become increasingly digitized and interconnected, attackers exploit both technical and operational weaknesses to achieve strategic objectives. Advanced persistent threats, malware campaigns, and targeted intrusions now form part of a sophisticated threat landscape that demands specialized knowledge and anticipatory defense measures.

Unlike typical IT attacks, which primarily aim to exfiltrate data or disrupt online services, industrial cyberattacks often focus on manipulating physical processes. Malware can alter programmable logic controllers, disable safety systems, or disrupt critical operational workflows. The consequences of such attacks can range from temporary operational downtime to catastrophic system failures with human and environmental repercussions. This distinct risk profile underscores the need for professionals with hybrid expertise in digital security and process control.

ICS/SCADA Vulnerabilities and Exploitation

Industrial networks are composed of heterogeneous components, including legacy devices, modern automation systems, and interconnected sensors. Legacy protocols, such as Modbus, DNP3, and IEC 60870-5-104, are particularly susceptible to exploitation, as they were originally designed for operational efficiency rather than cybersecurity. These protocols often lack encryption, authentication, and integrity validation, making it easier for attackers to infiltrate systems, manipulate data, or disrupt processes.

Modernization efforts, including the integration of IoT devices, cloud-based monitoring, and remote management interfaces, create additional exposure points. While these advancements enhance operational insight and efficiency, they also expand the potential attack surface. Even minor misconfigurations or unpatched devices can serve as entry points for cyber intrusions, emphasizing the critical importance of comprehensive security measures that address both legacy and modern elements of industrial networks.

Human factors contribute further to ICS/SCADA vulnerabilities. Operators and engineers, while highly skilled in operational domains, may lack cybersecurity awareness. Practices such as reusing passwords, bypassing access controls, or introducing unverified devices into networks can inadvertently create exploitable weaknesses. Cultivating a culture of cybersecurity awareness and implementing rigorous operational policies are therefore essential complements to technical defenses.

Risk Assessment and Mitigation Strategies

A structured approach to risk assessment forms the cornerstone of industrial cybersecurity. Unlike conventional IT systems, industrial networks face multidimensional risks that encompass operational disruption, safety hazards, and environmental impact. Professionals must identify critical assets, evaluate potential vulnerabilities, and determine the probability and consequences of exploitation.

Advanced risk assessment techniques incorporate modeling of attack vectors, scenario analysis, and predictive simulations. These methodologies enable practitioners to anticipate potential intrusions, evaluate the systemic impact of an attack, and prioritize protective measures. Organizations can thereby allocate resources more efficiently, implement effective mitigations, and maintain resilience in the face of evolving threats. Risk assessment also supports regulatory compliance, ensuring that organizations meet industry standards and safeguard public safety.

Intrusion Detection Systems in Industrial Networks

Timely detection of anomalies is essential to maintaining the integrity and continuity of industrial operations. Intrusion detection systems designed for ICS/SCADA environments combine multiple approaches to identify both known and novel threats. Signature-based detection focuses on identifying patterns corresponding to previously recognized attacks, while behavior-based methods monitor deviations from normal operational patterns.

Sophisticated detection mechanisms incorporate machine learning and anomaly analytics to identify subtle or emerging threats. For example, unexpected variations in data flow, device responses, or protocol usage can signal an intrusion. By integrating real-time monitoring with automated alerting and response protocols, industrial cybersecurity teams can isolate compromised components, prevent lateral movement, and maintain operational continuity. Continuous improvement of detection algorithms ensures that systems remain responsive to emerging attack vectors.

Malware Targeting Industrial Systems

Industrial environments are increasingly targeted by malware specifically designed to compromise operational processes. Malware such as Stuxnet and Triton demonstrates the potential for attacks to alter physical systems with precision. These threats often exploit protocol vulnerabilities, manipulate control logic, or disable safety mechanisms, highlighting the unique challenges faced by industrial cybersecurity professionals.

Effective malware defense requires a multifaceted approach. Professionals must be able to detect malicious code, analyze its behavior, understand its propagation mechanisms, and implement mitigation strategies. Malware analysis informs intrusion detection, network segmentation, and operational safeguards. By understanding both the technical and operational dimensions of malware, professionals can anticipate attacks and fortify systems against exploitation.

Digital Forensics in Industrial Contexts

Digital forensics plays a pivotal role in understanding, mitigating, and preventing cyber incidents. In industrial environments, forensic analysis is complicated by real-time operational constraints, proprietary devices, and mixed legacy-modern systems. Professionals must conduct investigations without disrupting critical operations, preserving both evidence integrity and functional continuity.

Forensic activities include analyzing logs, tracing network traffic, examining device configurations, and reconstructing attack sequences. Insights gained from forensic investigations inform incident response, vulnerability remediation, and risk management strategies. Understanding attacker methodologies also supports proactive defense measures, enhancing the overall security posture of industrial networks. Forensics additionally assists organizations in meeting regulatory compliance requirements, ensuring accountability, and providing documentation for post-incident review.

Incident Response and Operational Recovery

Rapid and effective incident response is critical in industrial cybersecurity. Containing a threat and mitigating its impact requires precise coordination between IT and OT teams. Immediate actions include isolating affected devices, blocking malicious traffic, and deploying redundancies to maintain operations. Post-incident procedures involve recovery, system validation, and lessons-learned analysis to prevent future occurrences.

Recovery efforts must balance operational continuity with security assurance. Backups, redundant control systems, and failover mechanisms are essential to minimize downtime and maintain safe operations. Post-incident reviews inform policy refinement, update incident response playbooks, and enhance preparedness for subsequent attacks. The iterative process of response, recovery, and continuous improvement ensures that industrial systems are resilient and capable of withstanding evolving threats.

Integrating IT and OT Security Expertise

Industrial cybersecurity requires a synthesis of IT and OT knowledge. IT expertise provides foundational understanding of network security, encryption, access management, and endpoint protection. OT expertise offers insights into control processes, protocol behavior, and real-time system dynamics. Professionals who bridge these domains can implement comprehensive strategies that safeguard both digital and physical dimensions of industrial operations.

Effective integration involves network segmentation, access control policies, secure device configuration, and continuous monitoring. For example, segmenting IT and OT networks limits the potential spread of malware while preserving operational integrity. Secure configuration of programmable logic controllers, SCADA interfaces, and safety systems ensures that critical processes are protected even under cyber duress. The convergence of IT and OT knowledge is essential to designing robust defense architectures that can respond to multifaceted threats.

Industrial Cybersecurity as a Career Path

The growth of connected industrial environments has created a demand for professionals with specialized expertise in ICS/SCADA security. These individuals are positioned to take on roles in sectors such as energy, manufacturing, utilities, and transportation. Their responsibilities span threat analysis, network defense, incident response, and operational assurance, reflecting the multidimensional nature of industrial cybersecurity.

Specialized certification programs provide structured learning pathways to acquire the necessary skills and knowledge. Professionals gain both theoretical understanding and practical proficiency, preparing them to handle real-world challenges. The relative scarcity of trained experts in this niche field enhances career prospects, offering opportunities for accelerated growth, high compensation, and professional recognition.

Beyond financial rewards, careers in industrial cybersecurity provide societal impact. Protecting critical infrastructure ensures the uninterrupted delivery of essential services, preserves public safety, and reinforces national and organizational security. The combination of technical challenge, professional fulfillment, and societal contribution makes this a compelling career trajectory.

Emerging Technologies and Their Impact on Industrial Security

The adoption of emerging technologies such as artificial intelligence, machine learning, and predictive analytics is transforming industrial cybersecurity. AI-powered monitoring systems can detect anomalies in real time, anticipate potential threats, and recommend proactive interventions. Predictive maintenance and automated diagnostics enhance operational reliability while reducing human error, which is a common source of vulnerability.

Cloud integration and remote monitoring, while beneficial for operational efficiency, introduce new security considerations. Professionals must ensure secure authentication, encrypted communication, and rigorous access controls to prevent unauthorized intrusion. Blockchain and distributed ledger technologies are also being explored for their potential to enhance transactional integrity, supply chain security, and data provenance in industrial networks.

Staying abreast of technological advancements is essential for professionals seeking to maintain an effective security posture. Continuous learning ensures that defensive strategies evolve in tandem with operational and technological innovations, enabling industrial networks to remain resilient against emerging threats.

Governance, Compliance, and Security Policies

Industrial cybersecurity is governed by a combination of internal policies, regulatory requirements, and international standards. Compliance with these frameworks ensures that organizations implement consistent security practices, conduct risk assessments, and maintain operational accountability. Certified professionals are often tasked with translating regulatory mandates into actionable policies, auditing network configurations, and ensuring adherence to best practices.

Security policies in industrial environments encompass access control, network segmentation, patch management, incident response, and employee awareness training. Integrating governance and operational considerations ensures that security measures are both enforceable and practical, maintaining the balance between operational efficiency and risk mitigation. Professionals with expertise in policy implementation and compliance play a crucial role in sustaining resilient and secure industrial systems.

Continuous Learning and Professional Development

Industrial cybersecurity is an evolving field, with adversaries constantly refining their tactics and technological environments continuously advancing. Professionals must engage in lifelong learning to remain effective. Participation in specialized training programs, certification courses, professional forums, and knowledge-sharing networks enables practitioners to stay current with emerging threats, novel defense strategies, and operational innovations.

Continuous development fosters both technical and strategic competence, allowing professionals to anticipate risks, implement innovative defenses, and maintain the integrity and continuity of critical infrastructure. A commitment to learning and adaptation is therefore indispensable for success in this dynamic and high-stakes domain.

Industrial Cybersecurity and the Escalation of Threats

The industrial sector, characterized by its reliance on operational technologies and interconnected networks, faces a continuously escalating spectrum of cyber threats. Industrial Control Systems and Supervisory Control and Data Acquisition networks have traditionally been designed for reliability and operational continuity rather than cybersecurity. The rapid integration of digital technologies, remote access, and internet-connected devices has exponentially increased the attack surface, making industrial networks prime targets for cyber adversaries.

Threat actors range from opportunistic cybercriminals to highly sophisticated state-sponsored groups. While conventional IT attacks often focus on data exfiltration or financial disruption, industrial cyberattacks can manipulate physical systems, causing operational shutdowns, safety hazards, and environmental consequences. This distinct risk profile demands that professionals in industrial cybersecurity possess a nuanced understanding of both digital and physical domains to anticipate and counter multifaceted threats effectively.

Unique Vulnerabilities in ICS/SCADA Networks

Industrial environments exhibit unique vulnerabilities that differentiate them from conventional IT networks. Legacy protocols such as Modbus, DNP3, and IEC 60870-5-104, while integral to operational efficiency, were never designed with robust security in mind. These protocols lack encryption, authentication, and data integrity measures, making them inherently susceptible to exploitation. Cyber adversaries can manipulate device commands, intercept data, or inject malicious instructions, potentially leading to operational disruptions or unsafe conditions.

The integration of Internet of Things devices, cloud-based monitoring, and remote access further compounds these vulnerabilities. While such technologies enhance operational insight and efficiency, they also introduce new attack vectors. Even minor configuration errors, unpatched devices, or unauthorized access points can serve as entry points for cyber intrusions, necessitating meticulous security planning and continuous monitoring to maintain resilience.

Human factors contribute significantly to industrial cybersecurity risks. Operators, engineers, and maintenance personnel, although highly proficient in process control, may inadvertently create vulnerabilities. Practices such as reusing passwords, bypassing security protocols, or introducing unverified devices can compromise system integrity. Addressing these risks requires a combination of organizational policies, awareness programs, and technical controls to foster a security-conscious culture within industrial environments.

Comprehensive Risk Analysis for Industrial Systems

Risk analysis in industrial environments extends beyond conventional IT considerations, encompassing operational, safety, and environmental dimensions. Effective risk assessment requires a thorough understanding of network architecture, device interdependencies, and process workflows. Professionals must evaluate the likelihood of exploitation, potential consequences of attacks, and cascading effects on interconnected systems.

Advanced risk analysis involves the simulation of attack scenarios, threat modeling, and predictive evaluation. By anticipating potential intrusions, organizations can prioritize critical assets, implement targeted countermeasures, and allocate resources efficiently. Incorporating external factors such as geopolitical threats, supply chain vulnerabilities, and evolving adversary tactics enhances the accuracy of risk assessments and informs the design of resilient defensive architectures.

Intrusion Detection and Continuous Monitoring

Intrusion detection systems tailored for industrial environments are essential for maintaining operational integrity. Unlike conventional IT networks, industrial systems operate in real time, where even minimal disruptions can have severe consequences. Continuous monitoring allows for the early identification of anomalies, enabling rapid response before minor issues escalate into major incidents.

Detection methodologies combine signature-based recognition with behavior analysis to identify both known and unknown threats. Machine learning algorithms enhance these systems by detecting subtle deviations in network traffic, device communication, and protocol usage patterns. Integration with automated response mechanisms enables swift isolation of compromised components, minimizing disruption and maintaining operational continuity. Continuous refinement of detection capabilities ensures that industrial networks remain adaptive to emerging threats.

Malware Threats in Industrial Environments

Industrial networks are increasingly targeted by sophisticated malware designed to compromise operational processes. Malware such as Stuxnet, Industroyer, and Triton has demonstrated the potential for precision attacks on critical infrastructure, manipulating control systems, disabling safety mechanisms, or exfiltrating sensitive information. Understanding the behavior, propagation methods, and impact of industrial malware is essential for designing effective defensive strategies.

Malware analysis involves dissecting code, identifying indicators of compromise, and assessing potential operational impacts. Insights from analysis inform intrusion detection signatures, network segmentation strategies, and incident response protocols. By anticipating attacker behavior and the potential effects of malware, cybersecurity professionals can develop resilient defense mechanisms capable of mitigating both known and emerging threats.

Digital Forensics for Industrial Systems

Digital forensics is a critical discipline in industrial cybersecurity, enabling organizations to understand and respond to security incidents without compromising operational continuity. Industrial networks present unique challenges for forensic investigations due to real-time operational constraints, legacy systems, and proprietary devices. Professionals must gather and analyze evidence while ensuring that critical processes remain uninterrupted.

Forensic activities encompass log analysis, network traffic reconstruction, device examination, and identification of attack vectors. Understanding the methods and objectives of attackers enables organizations to remediate vulnerabilities, enhance defensive measures, and improve resilience against future incidents. Forensics also supports regulatory compliance and organizational accountability, ensuring that incidents are documented and analyzed to inform continuous improvement.

Incident Response and Recovery Protocols

Effective incident response is paramount in industrial environments, where operational continuity and safety are critical. Incident response protocols focus on containing threats, mitigating damage, and restoring normal operations. Immediate actions include isolating affected devices, blocking malicious traffic, and deploying redundant systems to maintain functionality. Post-incident measures involve system validation, remediation, and refinement of response procedures.

Recovery strategies balance operational continuity with security assurance. Backup systems, redundant control mechanisms, and failover protocols are critical for minimizing downtime and maintaining safety. Post-incident analysis provides insights into vulnerabilities, informs updates to security policies, and strengthens preparedness for subsequent attacks. Iterative response and recovery cycles are essential for enhancing the resilience of industrial networks.

Bridging IT and Operational Technology Security

Industrial cybersecurity requires a synthesis of IT and OT expertise. IT knowledge encompasses network security, access control, encryption, and endpoint protection. OT expertise includes process control, device communication protocols, and real-time operational constraints. Bridging these domains enables professionals to develop holistic security strategies that protect both digital and physical aspects of industrial operations.

Integrated security measures include network segmentation, secure device configuration, access management, and continuous monitoring. Segmentation limits the spread of potential intrusions, while secure configuration ensures the reliability of control systems. Continuous monitoring and anomaly detection provide early warning of potential attacks. Professionals who can navigate both IT and OT domains are essential for defending industrial networks against complex, multifaceted threats.

Career Opportunities in Industrial Cybersecurity

The growing complexity and connectivity of industrial systems have created a high demand for cybersecurity professionals with specialized expertise in ICS/SCADA environments. Roles span threat analysis, network defense, incident response, risk assessment, and operational continuity management. Certified professionals are particularly valued for their ability to integrate technical, operational, and strategic considerations.

Industrial cybersecurity offers competitive compensation due to the specialized skill set required and the criticality of protecting operational infrastructure. Professionals can find opportunities in energy, utilities, manufacturing, transportation, and other sectors reliant on industrial networks. The scarcity of trained experts in this field also accelerates career advancement and provides opportunities for specialization and leadership roles.

Beyond financial and professional incentives, industrial cybersecurity professionals contribute directly to public safety and national security. Securing critical infrastructure ensures the continuity of essential services, mitigates operational risks, and enhances societal resilience. The combination of technical challenge, societal impact, and career growth makes industrial cybersecurity an increasingly attractive domain for skilled professionals.

Emerging Technologies in Industrial Security

The adoption of emerging technologies, including artificial intelligence, machine learning, predictive analytics, and automation, is reshaping industrial cybersecurity. AI-driven monitoring systems can detect anomalies in real time, anticipate potential threats, and recommend proactive interventions. Predictive analytics and automated diagnostics enhance operational reliability while minimizing human error, a common source of vulnerability.

Cloud-based integration and remote monitoring, while enhancing operational visibility, introduce additional security challenges. Professionals must implement secure authentication, encrypted communications, and rigorous access controls to prevent unauthorized access. Distributed ledger technologies, such as blockchain, are being explored to improve data integrity, supply chain security, and operational transparency.

Remaining informed about technological trends is critical for professionals seeking to maintain resilient industrial networks. Continuous learning ensures defensive strategies evolve alongside emerging operational and digital technologies, mitigating the risk of exploitation by increasingly sophisticated adversaries.

Governance, Policy, and Compliance in Industrial Cybersecurity

Industrial cybersecurity operates within a framework of organizational governance, industry standards, and regulatory requirements. Compliance ensures that organizations implement consistent security practices, conduct regular risk assessments, and maintain operational accountability. Certified professionals play a pivotal role in translating regulations into actionable policies, auditing networks, and ensuring adherence to best practices.

Security policies cover access management, network segmentation, patching, incident response, and employee training. Effective governance balances operational efficiency with risk mitigation, ensuring that security measures are practical, enforceable, and adaptive to evolving threats. Professionals adept at policy implementation and compliance contribute to the sustainable security of industrial systems.

Lifelong Learning and Professional Growth

Industrial cybersecurity is a dynamic field, where adversaries continually refine tactics and technology evolves rapidly. Professionals must engage in lifelong learning to remain effective. Participation in certification programs, specialized training, professional networks, and knowledge-sharing initiatives is critical for staying current with emerging threats, evolving technologies, and best practices.

Continuous professional development fosters technical proficiency, strategic awareness, and operational insight. It empowers professionals to anticipate risks, implement innovative defenses, and maintain resilient infrastructure. A commitment to ongoing learning is essential for long-term success in industrial cybersecurity, enabling practitioners to navigate an increasingly complex threat landscape effectively.

The Strategic Significance of ICS/SCADA Security

Industrial Control Systems and Supervisory Control and Data Acquisition networks are essential to the functioning of modern industrial infrastructure. They manage processes that sustain energy distribution, water treatment, transportation, and manufacturing operations. With the growing integration of digital technologies, these systems have become increasingly connected, exposing them to a spectrum of cyber threats that can compromise both operational integrity and safety.

The strategic significance of ICS/SCADA security extends beyond organizational concerns. Disruptions in critical industrial networks can have far-reaching implications, affecting public safety, environmental stability, and national security. Cyberattacks targeting operational technologies are often calculated, sophisticated, and capable of exploiting both technical and human vulnerabilities. These attacks underscore the necessity of skilled cybersecurity professionals who can safeguard industrial processes and ensure the continuity of essential services.

Identifying Industrial Network Vulnerabilities

Industrial networks consist of a heterogeneous mix of devices, including legacy controllers, modern automation equipment, and networked sensors. Legacy protocols such as Modbus, DNP3, and IEC 60870-5-104, while integral to operational reliability, lack robust security mechanisms such as encryption, authentication, and data integrity checks. These vulnerabilities are particularly concerning because many industrial environments continue to rely on these protocols due to operational constraints or compatibility requirements.

The convergence of operational technology and information technology further exacerbates network vulnerabilities. While IT networks typically employ advanced security measures, OT systems have traditionally prioritized reliability over cybersecurity. Integration introduces potential attack vectors, including misconfigured gateways, unsecured remote access points, and unpatched devices. Professionals tasked with securing these networks must address both legacy and modern vulnerabilities while maintaining operational continuity.

Human factors also play a significant role in industrial security risks. Operators and engineers, although skilled in process control, may inadvertently create vulnerabilities through unsafe practices such as sharing credentials, connecting unauthorized devices, or bypassing security protocols. Cultivating a security-conscious organizational culture, coupled with training and stringent operational policies, is critical to mitigating human-centric risks.

Comprehensive Risk Assessment in Industrial Environments

Risk assessment is the foundation of industrial cybersecurity, as it allows organizations to identify, quantify, and prioritize threats to operational systems. Unlike IT networks, industrial networks face risks that can have immediate physical, environmental, and societal consequences. Risk assessment methodologies encompass network topology analysis, device interdependencies, process flow evaluations, and potential attack vectors.

Advanced techniques include threat modeling, predictive simulations, and scenario-based analyses. These approaches allow cybersecurity professionals to anticipate attacker strategies, assess the impact of potential intrusions, and design resilient mitigation measures. Considering external factors, such as geopolitical risks, supply chain vulnerabilities, and emerging malware, further enhances the efficacy of risk assessments. The ultimate goal is to implement proactive defenses that maintain operational integrity and mitigate both technical and operational risks.

Intrusion Detection and Real-Time Monitoring

Timely detection of threats is critical in industrial environments where even minimal disruptions can have significant consequences. Intrusion detection systems tailored for ICS/SCADA networks combine signature-based and behavior-based approaches to identify known and unknown threats. Signature-based detection identifies patterns associated with prior attacks, while behavior-based detection monitors deviations from expected operational norms.

Advanced intrusion detection leverages machine learning to detect subtle anomalies in device communication, network traffic, and protocol behavior. Automated alerts and response mechanisms allow rapid isolation of compromised components, limiting potential damage and maintaining operational continuity. Continuous refinement of detection algorithms ensures that industrial networks remain adaptive and resilient against emerging cyber threats.

Malware and Exploit Techniques in Industrial Systems

Industrial networks are frequently targeted by malware specifically designed to disrupt operational processes or compromise control systems. Notable examples such as Stuxnet, Triton, and Industroyer illustrate the potential for malware to manipulate industrial processes with precision, bypass safety systems, and compromise critical infrastructure. Professionals must possess the skills to analyze malware behavior, identify propagation mechanisms, and assess operational impacts.

Effective malware defense in industrial environments combines proactive monitoring, behavioral analysis, network segmentation, and rapid incident response. Understanding both the technical and operational dimensions of malware allows professionals to anticipate attacks, implement targeted countermeasures, and strengthen overall network resilience. Defense strategies must be dynamic, continuously evolving to address emerging threats and novel attack techniques.

Digital Forensics and Incident Analysis

Digital forensics is integral to understanding and mitigating industrial cyber incidents. Conducting forensic investigations in industrial networks presents unique challenges, including real-time operational constraints, proprietary protocols, and legacy systems. Professionals must gather evidence without disrupting ongoing operations, ensuring that both investigative and operational objectives are met.

Forensic analysis involves examining logs, network traffic, device configurations, and attack signatures to reconstruct events. Insights gained inform incident response, remediation strategies, and preventive measures. Understanding attacker tactics also supports proactive defenses, helping organizations anticipate future threats. Additionally, forensics ensures regulatory compliance, accountability, and documentation for post-incident review.

Incident Response and Operational Recovery

Effective incident response requires a coordinated approach that balances security, operational continuity, and safety. Response protocols in industrial environments include isolating affected components, blocking malicious traffic, deploying redundant systems, and validating device integrity. Post-incident activities focus on remediation, lessons learned, and refinement of security policies and protocols.

Recovery strategies aim to restore normal operations while maintaining system security. Redundant systems, failover mechanisms, and secure backups minimize downtime and ensure process reliability. Iterative post-incident analysis strengthens network resilience, improves preparedness for future attacks, and supports continuous enhancement of defensive strategies.

Integrating IT and OT Security

Industrial cybersecurity demands the integration of IT and OT expertise. IT knowledge includes network security, encryption, access management, and endpoint protection. OT expertise encompasses process control, device behavior, real-time operational constraints, and industrial protocols. Professionals capable of bridging these domains can implement comprehensive defense strategies that protect both digital and physical systems.

Security measures include network segmentation to prevent lateral movement of threats, secure configuration of controllers and SCADA devices, access controls to manage user permissions, and continuous monitoring for anomalies. Integration of IT and OT knowledge is essential for designing resilient infrastructures capable of withstanding complex cyberattacks.

Career Advancement in ICS/SCADA Security

The increasing complexity of industrial networks has created a high demand for professionals with specialized ICS/SCADA cybersecurity skills. Career opportunities span threat analysis, incident response, vulnerability assessment, risk management, and operational assurance. Certified professionals possess a blend of technical and operational knowledge that makes them highly valued in sectors such as energy, manufacturing, utilities, and transportation.

Industrial cybersecurity offers competitive remuneration due to the specialized skill set required and the criticality of protecting operational networks. Career progression is accelerated by the relative scarcity of qualified professionals in this niche field, offering opportunities for specialization, leadership, and strategic influence. Beyond financial incentives, professionals contribute to public safety and national security by protecting essential infrastructure from cyber threats.

Emerging Technologies Shaping Industrial Security

Emerging technologies are reshaping industrial cybersecurity strategies. Artificial intelligence and machine learning enable real-time anomaly detection, predictive threat modeling, and proactive defense measures. Predictive maintenance, automated diagnostics, and operational analytics reduce human error and enhance system resilience.

Cloud integration and remote monitoring, while providing operational advantages, introduce additional security considerations. Professionals must implement encrypted communications, secure authentication, and access controls to prevent unauthorized intrusion. Distributed ledger technologies, including blockchain, offer potential for enhanced data integrity, supply chain security, and operational transparency. Keeping pace with technological evolution is crucial for maintaining effective industrial cybersecurity defenses.

Governance, Policy, and Regulatory Compliance

Industrial cybersecurity operates within a framework of organizational governance, industry standards, and regulatory requirements. Compliance ensures consistent implementation of security measures, regular risk assessments, and operational accountability. Professionals often translate regulatory mandates into actionable policies, conduct audits, and ensure adherence to best practices.

Security policies encompass access management, network segmentation, patch management, incident response, and personnel training. Effective governance balances operational efficiency with security imperatives, ensuring measures are practical, enforceable, and adaptive to evolving threats. Skilled professionals in policy and compliance contribute to the sustainable and secure operation of industrial networks.

Lifelong Learning and Professional Development

The dynamic nature of industrial cybersecurity necessitates continuous learning. Threat actors continuously refine techniques, and technological innovation introduces new operational risks. Professionals must engage in ongoing training, certifications, knowledge-sharing forums, and industry events to remain proficient and effective.

Continuous professional development fosters technical expertise, operational insight, and strategic foresight. It empowers professionals to anticipate risks, deploy innovative defenses, and maintain resilient industrial infrastructures. Commitment to lifelong learning ensures relevance and effectiveness in a field characterized by rapid technological evolution and persistent threats.

The Rising Importance of Industrial Cybersecurity

Industrial cybersecurity has emerged as a critical domain as industrial environments increasingly rely on digital technologies. Modern Industrial Control Systems and Supervisory Control and Data Acquisition networks are no longer isolated; they are interconnected, leveraging cloud systems, IoT devices, and remote access. While these integrations improve operational efficiency and real-time monitoring, they also broaden the attack surface, making these networks attractive targets for cyber adversaries.

The threats faced by industrial networks are complex and diverse. Unlike traditional IT breaches, attacks in industrial environments can disrupt physical operations, endanger lives, and compromise public safety. Consequently, industrial cybersecurity professionals require a multifaceted skill set that combines knowledge of IT security principles, operational technology protocols, and real-time process management. The role demands not only technical expertise but also strategic foresight to anticipate and mitigate emerging threats.

Understanding Industrial Network Vulnerabilities

Industrial networks are a mosaic of legacy systems, modern automation platforms, and interconnected sensors. Many legacy protocols, including Modbus, DNP3, and IEC 60870-5-104, were engineered for reliability and operational continuity rather than security. These protocols lack encryption, authentication mechanisms, and data integrity safeguards, leaving critical systems vulnerable to intrusion and manipulation.

The integration of IT and OT networks introduces additional vulnerabilities. While IT systems employ robust cybersecurity measures, OT systems traditionally emphasize operational stability over security. The convergence of these domains creates potential attack vectors, such as insecure remote access, unpatched devices, or misconfigured gateways. Human factors, such as operator errors or inadvertent policy violations, further exacerbate these risks. Addressing these vulnerabilities requires a combination of technical defenses, organizational policies, and workforce training.

Comprehensive Risk Assessment and Threat Modeling

Risk assessment in industrial environments involves more than evaluating digital security threats; it must account for physical processes, environmental hazards, and operational continuity. Cybersecurity professionals identify critical assets, analyze potential vulnerabilities, and determine the likelihood and impact of different attack scenarios.

Advanced threat modeling techniques simulate attack vectors, evaluate potential consequences, and prioritize mitigation strategies. Predictive analyses consider not only technical risks but also external factors such as geopolitical threats, supply chain vulnerabilities, and emerging malware campaigns. Comprehensive risk assessment and threat modeling provide a roadmap for implementing layered defenses, ensuring that industrial networks remain resilient under a range of adverse scenarios.

Intrusion Detection and Anomaly Identification

Intrusion detection is paramount in industrial cybersecurity because even minor disruptions can have catastrophic operational consequences. Effective systems combine signature-based detection, which identifies known threats, with behavior-based monitoring, which detects deviations from normal operational patterns.

Machine learning and advanced analytics enhance detection capabilities, identifying subtle anomalies in network traffic, device communication, and protocol behavior. Coupled with real-time monitoring and automated response mechanisms, intrusion detection allows cybersecurity professionals to isolate compromised components, mitigate potential damage, and maintain uninterrupted operations. Continuous refinement of detection systems ensures responsiveness to new and sophisticated threats.

Malware and Exploit Techniques

Industrial networks face increasingly sophisticated malware designed to disrupt operational processes or compromise control systems. Notable cases such as Stuxnet, Triton, and Industroyer illustrate the potential for malware to manipulate industrial processes with precision, bypass safety mechanisms, and endanger critical infrastructure.

Professionals must possess expertise in malware analysis, including understanding propagation techniques, assessing operational impacts, and identifying indicators of compromise. Defense strategies include proactive monitoring, network segmentation, behavioral analysis, and rapid incident response. By comprehensively understanding both technical and operational dimensions, professionals can design resilient defenses capable of mitigating evolving malware threats.

Digital Forensics in Industrial Environments

Digital forensics is essential for analyzing incidents, understanding attacker behavior, and strengthening defenses. In industrial networks, forensic investigations must be conducted without disrupting real-time operations. This is particularly challenging due to legacy systems, proprietary protocols, and complex interdependencies between devices.

Forensic procedures include log analysis, traffic reconstruction, device examination, and identification of attack vectors. Insights from forensic investigations inform incident response, remediation, and proactive threat mitigation. Forensics also ensures compliance with regulatory standards, provides documentation for organizational accountability, and supports lessons-learned processes to improve security posture over time.

Incident Response and Operational Recovery

Effective incident response in industrial environments requires careful coordination between IT and OT teams. Immediate actions involve isolating compromised components, blocking malicious traffic, and activating redundant systems to maintain operational continuity. Post-incident activities include system validation, remediation, and refinement of security policies.

Recovery strategies emphasize restoring operations while ensuring security integrity. Redundant control systems, failover protocols, and secure backups minimize downtime and operational disruption. Post-incident analysis strengthens network resilience, informs policy adjustments, and enhances preparedness for future threats. Iterative response and recovery cycles are vital to sustaining industrial network security in the face of sophisticated adversaries.

Integrating IT and OT Security Expertise

Industrial cybersecurity requires a hybrid skill set encompassing both IT and OT domains. IT expertise includes network security, endpoint protection, encryption, and access management. OT expertise encompasses process control, industrial protocol understanding, and real-time operational constraints.

Professionals who bridge IT and OT can implement comprehensive security architectures that safeguard both digital and physical systems. Integration strategies include network segmentation, secure device configuration, access management, and continuous monitoring. Such integration ensures that threats are mitigated while maintaining operational continuity, particularly in environments where physical processes are directly linked to digital control systems.

Career Prospects in Industrial Cybersecurity

The industrial cybersecurity field offers growing opportunities due to increasing network connectivity and escalating threats. Roles include threat analysis, vulnerability assessment, incident response, risk management, and operational security oversight. Professionals with specialized skills and certifications are highly sought after in sectors such as energy, utilities, manufacturing, and transportation.

Industrial cybersecurity offers competitive compensation owing to the critical nature of the work and the scarcity of qualified professionals. Career advancement is accelerated by the specialized skill set required, and opportunities exist for leadership, strategic influence, and subject matter expertise. Beyond professional growth, individuals contribute directly to societal safety and national security by safeguarding critical infrastructure.

Emerging Technologies in Industrial Security

Emerging technologies are transforming industrial cybersecurity practices. Artificial intelligence and machine learning enable predictive threat modeling, real-time anomaly detection, and proactive defense. Predictive maintenance and automated diagnostics reduce operational risks and minimize human error.

Cloud computing and remote monitoring enhance operational visibility but introduce new security challenges. Securing cloud communications, managing access control, and encrypting data are essential to prevent exploitation. Distributed ledger technologies such as blockchain offer potential for enhancing data integrity, supply chain transparency, and operational accountability. Continuous engagement with emerging technologies is essential for professionals seeking to maintain resilient industrial networks.

Governance, Policy, and Compliance

Industrial cybersecurity operates within a framework of organizational governance, industry standards, and regulatory compliance. Security policies include access management, network segmentation, patching, incident response, and personnel training. Professionals ensure that these policies are enforceable, practical, and adaptive to evolving threats.

Compliance with regulatory standards guarantees that organizations implement consistent security practices, conduct routine risk assessments, and maintain accountability. Professionals skilled in policy translation, auditing, and compliance support sustainable security practices, reinforcing both operational reliability and organizational reputation.

Continuous Learning and Professional Development

Industrial cybersecurity is a rapidly evolving field, demanding continuous learning. Threat actors continually refine attack methods, while technological innovations introduce new vulnerabilities. Professionals must participate in training, certification programs, industry forums, and knowledge-sharing communities to maintain proficiency and awareness.

Lifelong learning enhances technical competence, operational insight, and strategic foresight. It enables professionals to anticipate threats, implement innovative defenses, and preserve the integrity of industrial networks. Continuous professional development ensures relevance, effectiveness, and resilience in a domain characterized by evolving challenges and high stakes.

Conclusion

Industrial cybersecurity has become a critical discipline as industrial networks evolve in complexity and connectivity. The convergence of operational technology and information technology introduces unparalleled efficiency, yet it also expands the attack surface, exposing Industrial Control Systems and Supervisory Control and Data Acquisition networks to sophisticated cyber threats. Unlike conventional IT networks, these systems govern physical processes, making breaches potentially catastrophic, affecting operational continuity, safety, and environmental stability.

Protecting industrial environments requires a specialized combination of technical, operational, and strategic expertise. Professionals must master risk assessment, intrusion detection, malware analysis, digital forensics, incident response, and the integration of IT and OT knowledge. They must understand legacy protocols, modern automation systems, and emerging technologies such as AI, predictive analytics, cloud integration, and blockchain to anticipate and mitigate threats. Continuous monitoring, policy enforcement, and compliance with governance frameworks are essential to ensure resilience and reliability.

Industrial cybersecurity is a high-demand field with lucrative and diverse career opportunities. Certified professionals are uniquely positioned to protect critical infrastructure across sectors such as energy, manufacturing, utilities, and transportation. Their work safeguards public safety, supports national security, and ensures operational stability, reflecting the societal significance of the discipline.

Certification programs offer structured learning paths to acquire both theoretical and practical skills, fostering an offensive mindset that anticipates and neutralizes emerging threats. As industrial systems continue to digitize and cyber adversaries grow more sophisticated, skilled and certified professionals will remain indispensable, securing the backbone of modern society. Industrial cybersecurity is not only a career but a responsibility, blending technical mastery with strategic foresight to defend the infrastructure that powers our world.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?