Certification: IBM Certified Deployment Professional - Maximo Asset Management v7.6 Functional Analyst

Certification Full Name: IBM Certified Deployment Professional - Maximo Asset Management v7.6 Functional Analyst

Certification Provider: IBM

Exam Code: C2010-555

Exam Name: IBM Maximo Asset Management v7.6 Functional Analyst

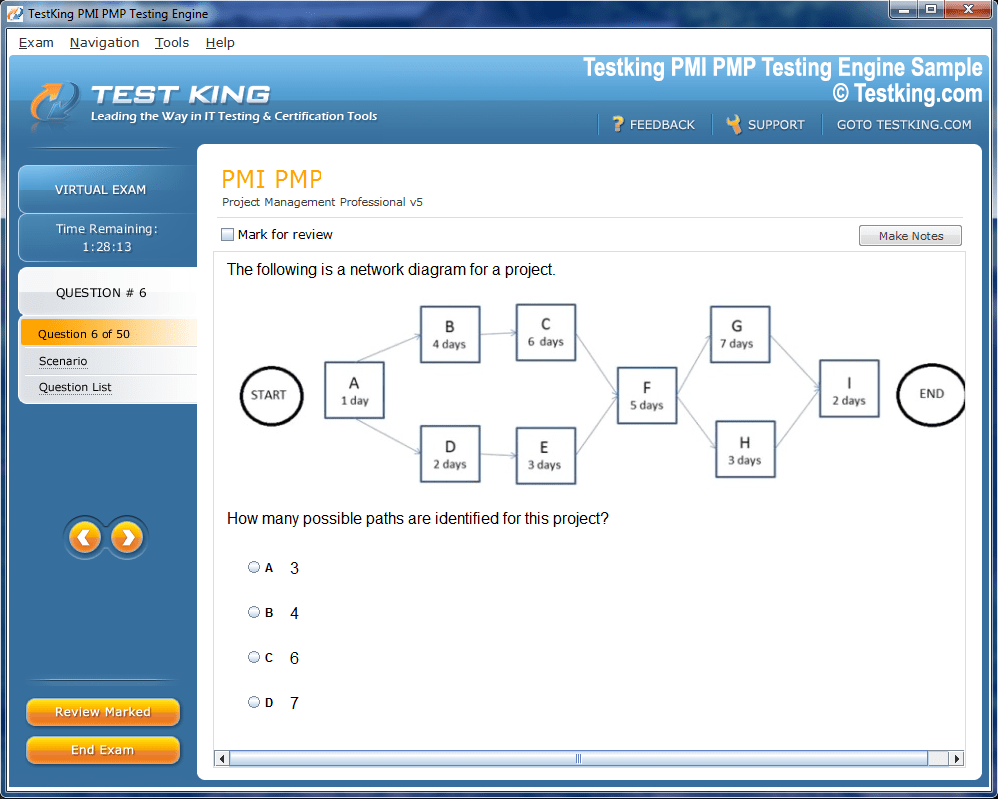

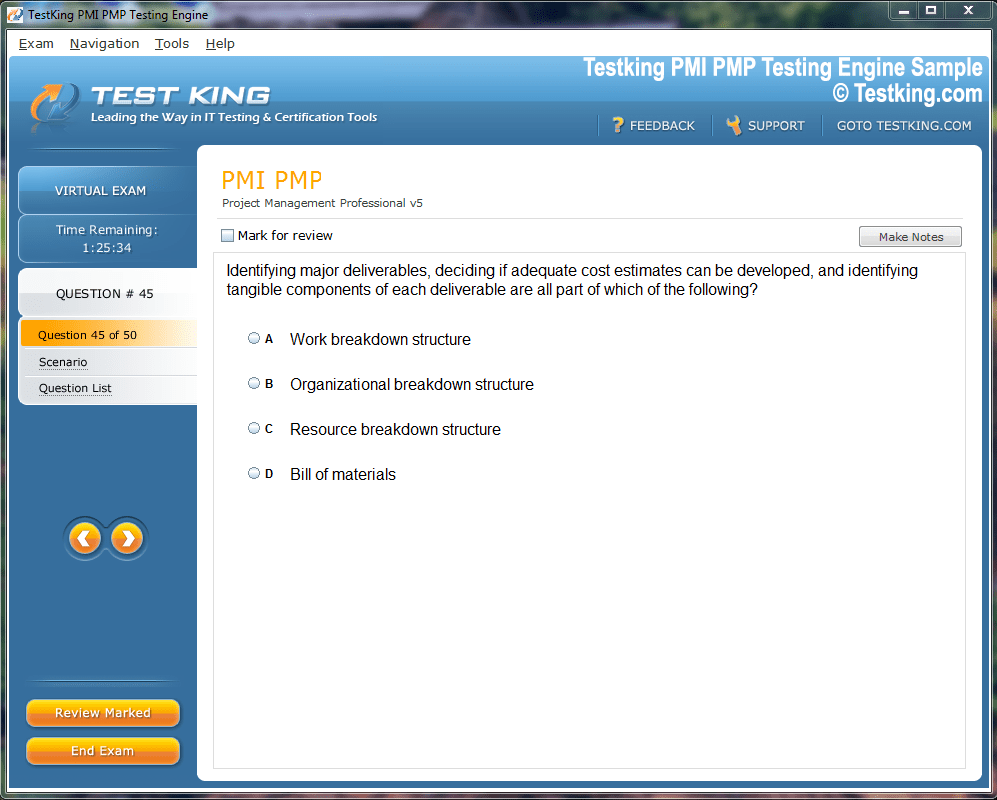

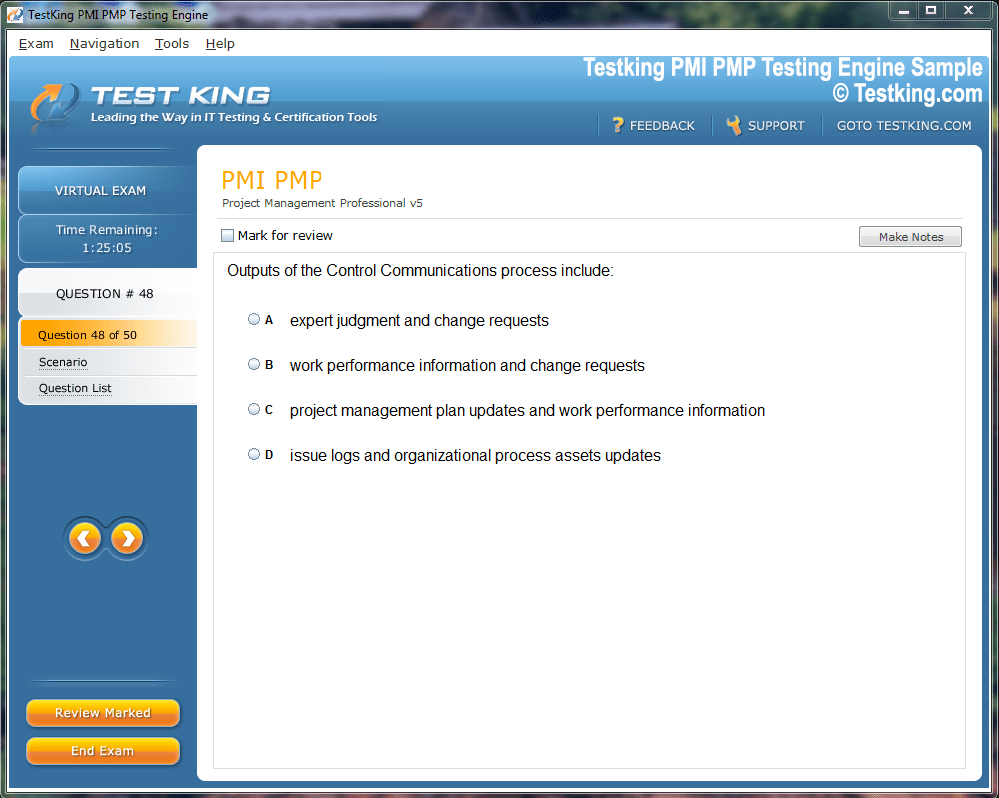

Product Screenshots

nop-1e =1

Advanced Techniques for IBM Certified Deployment Professional - Maximo Asset Management v7.6 Functional Analyst Certification

The IBM Maximo Asset Management Functional Analyst certification serves as a pivotal credential for professionals aiming to advance their expertise in asset management and business operations. This certification validates the candidate’s proficiency in handling the complexities of Maximo Asset Management v7.6, ensuring a thorough understanding of processes, workflows, and functional configurations. The C2010-555 exam specifically assesses the fundamental knowledge, analytical skills, and practical capabilities required to perform the duties of a functional analyst effectively within enterprise environments.

Candidates pursuing this certification are generally those who aspire to specialize in asset lifecycle management, predictive and preventive maintenance, and operational efficiency enhancement. The IBM Certified Deployment Professional credential not only establishes credibility in the asset management domain but also fosters a nuanced comprehension of Maximo's integrative functionalities. From work management to procurement, inventory oversight, and analytics, this certification emphasizes both conceptual clarity and practical application.

Overview of IBM Maximo Asset Management

IBM Maximo Asset Management is a comprehensive enterprise asset management (EAM) solution designed to optimize asset performance and lifecycle management. It encompasses an array of functionalities ranging from work order management to predictive maintenance and procurement, providing organizations with the tools to maintain operational continuity, reduce costs, and improve overall asset reliability. By leveraging Maximo, organizations can systematically monitor equipment, track resource utilization, and forecast potential failures with a high degree of precision.

The software’s architecture supports scalable deployment across industries such as manufacturing, energy, transportation, utilities, and pharmaceuticals, allowing businesses to manage assets efficiently while maintaining compliance with regulatory frameworks. Its robust configuration options enable administrators and functional analysts to tailor processes according to organizational requirements, incorporating asset hierarchies, failure codes, meters, and job plans. These capabilities allow for a granular approach to asset oversight, ensuring that both rotating and non-rotating assets are monitored and maintained according to best practices.

Understanding Maximo’s fundamental components is crucial for functional analysts, as it equips them to design, implement, and optimize asset management strategies. The system integrates seamlessly with enterprise resource planning (ERP) tools, facilitating a cohesive environment where data-driven decisions can be made with confidence. A thorough grasp of Maximo’s functionalities allows professionals to influence operational outcomes positively, ensuring assets are managed efficiently throughout their lifecycle.

Functional Analyst Role in Asset Management

The role of a functional analyst in IBM Maximo Asset Management involves translating organizational requirements into practical workflows and configurations within the software. Analysts are tasked with understanding business objectives and aligning Maximo functionalities to support these goals. This requires a combination of analytical reasoning, domain knowledge, and proficiency with the Maximo interface. Functional analysts are expected to configure asset hierarchies, failure codes, meters, and preventive maintenance schedules, ensuring that all asset management processes operate seamlessly.

Beyond configuration, analysts also evaluate asset relationships, define templates for consistent application, and ensure that work orders, job plans, and procurement processes are efficiently managed. They act as intermediaries between technical teams, such as system administrators or developers, and operational personnel, ensuring that business needs are effectively translated into actionable Maximo workflows. This role requires meticulous attention to detail, as well as the ability to foresee potential operational bottlenecks and mitigate risks associated with asset downtime or inefficiencies.

Functional analysts also play a key role in reporting and analytics, providing insights into asset performance, labor utilization, and maintenance effectiveness. By leveraging Maximo’s reporting tools, analysts can create custom reports and KPIs that guide strategic decisions, optimize resource allocation, and enhance overall asset productivity. The multifaceted responsibilities of a functional analyst make this certification particularly valuable for professionals seeking to establish a distinguished career in asset management.

Key Exam Details and Structure

The IBM Maximo Asset Management Functional Analyst exam (C2010-555) is designed to assess both theoretical understanding and practical application of Maximo functionalities. The exam comprises 72 questions to be completed within a 100-minute timeframe, requiring candidates to demonstrate knowledge across various modules such as asset management, predictive and preventive maintenance, work management, procurement, inventory, workflow, analytics, and administration.

A passing score of 64% reflects the minimum proficiency level required to achieve certification. The exam format includes multiple-choice questions, scenario-based queries, and problem-solving tasks that evaluate candidates’ ability to apply Maximo functionalities in real-world contexts. Sample questions and practice exams serve as effective preparatory tools, familiarizing candidates with the type of scenarios they may encounter and helping them manage time efficiently during the actual test.

Authorized training, hands-on experience, and focused study of the exam syllabus are recommended for successful outcomes. The C2010-555 exam not only validates technical knowledge but also underscores the candidate’s capability to integrate business requirements with Maximo’s functional features, ensuring that organizations derive maximum value from their asset management initiatives.

Asset Management Module

The asset management module in Maximo is the cornerstone of the functional analyst’s responsibilities. It encompasses tasks related to asset creation, maintenance, movement, and lifecycle management. Analysts must understand the nuances of rotating and non-rotating assets, asset relationships, and subassemblies. This includes configuring asset templates for uniformity, managing failure codes, and maintaining location hierarchies to ensure that each asset is correctly categorized and tracked.

Meters play a significant role in monitoring asset usage, enabling time-based and usage-based maintenance strategies. Warranty contracts are associated with assets to manage claims and reduce operational risks. Functional analysts also manage the swapping, modification, and relocation of assets to optimize resource allocation. Through careful configuration, analysts ensure that asset data remains accurate and actionable, facilitating proactive maintenance strategies that minimize unplanned downtime.

Understanding asset subassemblies and spare parts is critical, as it ensures that replacement components are readily available and properly tracked within the system. Analysts also ensure that asset hierarchies reflect the physical and functional structure of organizational equipment, enabling precise reporting and streamlined maintenance processes.

Predictive and Preventive Maintenance

Predictive and preventive maintenance (PM) is a core function of Maximo that allows organizations to anticipate asset failures and schedule timely interventions. Functional analysts configure master PMs and various types of preventive maintenance schedules, applying routes, sequences, and job plans to ensure systematic asset care. Condition monitoring is integrated to generate work orders automatically when specific thresholds are exceeded, enhancing operational reliability.

Time-based and meter-based PMs offer flexibility in maintenance planning, allowing organizations to tailor interventions according to asset usage and environmental conditions. Functional analysts must be adept at forecasting maintenance needs, modifying schedules, and applying job plan sequencing to optimize maintenance workflows. Proper configuration ensures that maintenance activities are both cost-effective and minimally disruptive to operations.

Predictive maintenance leverages historical data and real-time metrics to forecast potential failures, reducing the likelihood of unexpected downtime. This proactive approach supports operational continuity and extends asset longevity, demonstrating the critical value of a functional analyst in implementing sophisticated maintenance strategies.

Work Management and Planning

Work management and planning involve orchestrating work orders, tasks, and labor resources to ensure smooth operational performance. Functional analysts define work order structures, including child work orders, task assignments, and labor reporting. They oversee work order lifecycle management, from creation to completion, ensuring that each status change reflects actual progress and compliance with organizational procedures.

Job plans are integral to work management, providing step-by-step guidance for maintenance and operational tasks. Functional analysts ensure that plans are accurate, comprehensive, and accessible to field personnel. Labor reporting is configured to track hours, costs, and productivity, offering insights into workforce efficiency. Effective work management practices reduce operational bottlenecks, enhance asset uptime, and provide a measurable return on investment.

Planning also extends to resource allocation, scheduling, and coordination across departments, ensuring that preventive maintenance, reactive maintenance, and operational tasks are executed seamlessly. Functional analysts contribute to optimizing these workflows, translating operational requirements into actionable Maximo configurations.

Procurement Management

Procurement management in Maximo encompasses the entire lifecycle of purchasing, contracts, and inventory requisitions. Functional analysts manage procurement-related contracts, differentiate between companies and company masters, and oversee the processes of purchase requests, purchase orders, requests for quotations, direct receipts, and invoicing. Proper configuration ensures that procurement workflows are efficient, transparent, and compliant with organizational policies.

Receiving processes, returns of rotating assets, and direct issue items are meticulously managed within the system, ensuring that inventory levels remain accurate and that assets are accounted for at every stage. Functional analysts are responsible for aligning procurement operations with overall asset management strategies, reducing costs, and enhancing operational efficiency.

Effective procurement management supports predictive and preventive maintenance by ensuring that required parts, materials, and tools are available when needed. This module bridges asset management and inventory control, reinforcing the holistic approach of Maximo in enterprise asset management.

Inventory Management in Maximo

Inventory management constitutes a critical dimension of IBM Maximo Asset Management, facilitating precise control over materials, tools, and spare parts. Within this module, functional analysts are responsible for configuring and maintaining inventory balances, defining costing methods, and establishing item assembly structures. Each inventory item must be categorized correctly to ensure traceability and alignment with organizational processes. The software supports diverse item types, including rotating, non-rotating, and service items, allowing for nuanced tracking of resources across operational sites.

Functional analysts oversee both hard and soft inventory reservations, determining whether items are physically allocated or virtually earmarked for specific tasks. This enables organizations to minimize shortages and maintain optimal stock levels. Tool records and stocked tools are integrated into inventory workflows, allowing for comprehensive management of essential equipment. The addition of new units of measure and conversions ensures accurate calculation of quantities across varying operational contexts.

Item statuses are applied to monitor usability, condition, and compliance with operational requirements. The reorder process is configured to automate replenishment, preventing disruptions to maintenance schedules and operational continuity. By systematically managing inventory, functional analysts ensure that assets are adequately supported, contributing to cost reduction, operational efficiency, and enhanced asset reliability.

Workflow and Escalations

Workflows in Maximo provide a structured mechanism to automate business processes, reduce manual intervention, and ensure consistency in task execution. Functional analysts are tasked with constructing workflow processes that mirror organizational protocols, aligning system behavior with operational needs. These workflows encompass work order approvals, asset change requests, procurement authorizations, and maintenance notifications, among other processes.

Escalations complement workflows by automatically triggering actions when predefined conditions are met, such as overdue work orders, threshold breaches in meter readings, or non-compliance with scheduled maintenance. Analysts define escalation rules to maintain operational discipline, ensuring timely interventions and reducing the likelihood of asset failure or service disruptions. The seamless integration of workflows and escalations enhances operational predictability, improves communication across departments, and ensures that critical tasks are executed without delay.

Analytics and Reporting

Analytics is an indispensable module that empowers organizations to derive actionable insights from asset performance, maintenance activities, and operational data. Functional analysts construct ad hoc reports, providing customized visibility into specific operational parameters. The ability to generate real-time reports supports strategic decision-making and facilitates continuous improvement in asset management practices.

Key performance indicators (KPIs) are established to monitor critical metrics such as asset uptime, work order completion rates, labor efficiency, and inventory utilization. KPI templates are used to standardize reporting across departments, enabling consistent measurement and evaluation of performance outcomes. Analysts are responsible for selecting appropriate reporting options, running reports efficiently, and interpreting results to inform management decisions.

Reporting in Maximo is not limited to historical data; it encompasses predictive insights that guide maintenance planning, resource allocation, and procurement strategies. By integrating analytics with operational workflows, functional analysts enhance organizational agility, improve asset performance, and support long-term sustainability initiatives.

Administration and Configuration

The administration module in Maximo underpins the structural and functional integrity of the system. Functional analysts configure organizations, sites, and work centers, ensuring that operational hierarchies are accurately represented. Resource management includes assigning roles, defining responsibilities, and controlling access through security configurations. Proper administration safeguards the system’s integrity while providing the necessary flexibility for operational customization.

Business financials are configured to integrate cost tracking, budgeting, and financial reporting with asset management activities. Calendars and work periods are established to synchronize maintenance schedules, labor allocations, and operational timelines. Classification and attribute management allows for standardized categorization of assets, inventory, and work orders, facilitating precise reporting and analysis.

Edit mode is applied judiciously to manage updates and changes within the system. Functional analysts ensure that modifications are executed systematically, maintaining data consistency and operational accuracy. Robust administration supports all functional modules, enabling seamless execution of workflows, analytics, maintenance, procurement, and inventory processes.

Asset Hierarchies and Relationships

Understanding asset hierarchies and relationships is fundamental for effective asset management. Assets are organized into parent-child structures, subassemblies, and spares, allowing for a comprehensive view of dependencies and maintenance requirements. Functional analysts configure these hierarchies to reflect the physical and operational characteristics of organizational assets, ensuring that maintenance, reporting, and operational planning are accurately aligned.

Asset relationships extend beyond hierarchies, encompassing interdependencies such as shared usage, criticality, and lifecycle alignment. Analysts identify these connections to prevent operational conflicts, optimize resource allocation, and enhance predictive maintenance strategies. By maintaining precise asset relationships, organizations gain a holistic understanding of asset performance, reducing unplanned downtime and enabling more informed strategic planning.

Preventive Maintenance Strategies

Preventive maintenance (PM) strategies are designed to minimize asset failure, extend equipment life, and optimize resource utilization. Functional analysts configure time-based, meter-based, and condition-based PMs to ensure proactive maintenance scheduling. Master PMs are established to standardize recurring maintenance tasks across similar assets, enhancing operational efficiency and reducing administrative overhead.

Job plan sequencing is applied to ensure that maintenance tasks are performed in the correct order, minimizing operational disruptions and maximizing labor productivity. Condition monitoring thresholds trigger automatic work order generation, ensuring timely intervention before asset failure occurs. Analysts regularly review and update PM schedules based on historical performance data, operational changes, and predictive insights, maintaining alignment with organizational objectives.

Routes and locations are integrated into preventive maintenance plans to streamline field operations. Analysts assign assets to specific routes, enabling systematic inspections, servicing, and repairs. By meticulously configuring PMs, functional analysts enhance asset reliability, improve operational efficiency, and contribute to organizational resilience.

Work Order Lifecycle Management

Work orders are the operational backbone of Maximo, representing tasks ranging from routine maintenance to complex repair projects. Functional analysts define work order structures, including child work orders, tasks, and dependencies, ensuring clarity in execution and accountability. Assignments are configured to allocate labor, tools, and materials efficiently, while status changes track progress and compliance with organizational protocols.

The work order lifecycle encompasses creation, approval, execution, and closure, with each stage documented for reporting and analysis. Analysts monitor labor hours, materials usage, and task completion rates, providing management with accurate insights into operational efficiency. Integration with inventory and procurement modules ensures that resources are available when needed, preventing delays and maintaining continuity in maintenance operations.

Job plans associated with work orders provide standardized procedures, instructions, and safety guidelines, facilitating consistent execution. Analysts ensure that work orders are linked to assets, locations, and preventive maintenance schedules, creating a cohesive operational framework that maximizes asset performance.

Integration with Procurement and Inventory

Functional analysts play a vital role in integrating asset management with procurement and inventory processes. Proper alignment ensures that necessary materials, tools, and spare parts are available to support maintenance and operational activities. Analysts configure procurement workflows, manage receiving processes, and oversee returns of rotating assets or direct issue items.

Inventory management is synchronized with work orders, enabling real-time tracking of item usage, stock levels, and reservations. Hard and soft reservations are applied to secure critical items, while reorder processes automate replenishment to maintain optimal stock. Analysts ensure that costing methods, item statuses, and assembly structures reflect operational realities, providing accurate financial and operational visibility.

The integration of asset, procurement, and inventory modules enhances efficiency, reduces costs, and minimizes the risk of operational disruption. Functional analysts serve as the linchpin in coordinating these processes, ensuring that organizational objectives are met while maintaining high standards of asset reliability and performance.

Advanced Reporting in IBM Maximo

Advanced reporting within IBM Maximo Asset Management empowers organizations to transform raw operational data into actionable intelligence. Functional analysts construct complex reports that consolidate information from multiple modules, enabling a panoramic view of asset performance, maintenance activities, inventory usage, and work order efficiency. By synthesizing these data points, analysts provide management with insights that drive strategic decision-making, optimize resource allocation, and reduce operational inefficiencies.

Analytical sophistication in reporting involves the creation of custom queries, leveraging ad hoc reporting tools to address specific operational concerns. Reports may include metrics on downtime, asset utilization, preventive maintenance adherence, procurement timelines, and labor performance. Functional analysts ensure that these reports are aligned with organizational objectives, accurately reflecting operational realities and enabling data-driven management.

Effective reporting not only highlights historical performance but also supports predictive analysis. By examining trends, anomalies, and patterns in asset behavior, organizations can forecast maintenance requirements, identify potential bottlenecks, and preemptively address risks. Functional analysts play a pivotal role in designing and interpreting these reports, bridging the gap between data complexity and operational clarity.

Key Performance Indicators and Metrics

Key performance indicators (KPIs) are integral to monitoring organizational effectiveness in asset management. IBM Maximo allows functional analysts to define, track, and evaluate KPIs across a multitude of dimensions, including asset uptime, work order completion, labor efficiency, inventory turnover, and procurement lead times. KPI templates standardize measurement approaches, ensuring consistency across departments and reporting cycles.

Analysts configure dashboards and reporting interfaces to present KPIs in intuitive formats, allowing management and operational teams to quickly assess performance levels. These metrics facilitate informed decision-making, highlight areas requiring attention, and provide a benchmark for continuous improvement initiatives. In addition, KPIs can be linked to escalation processes, triggering alerts when performance thresholds are breached, thus reinforcing proactive management practices.

The precision and relevance of KPIs depend on accurate configuration of data sources, integration of modules, and alignment with organizational goals. Functional analysts ensure that KPIs are not only quantifiable but also meaningful, reflecting the strategic priorities of the business and providing actionable insights into operational efficiency.

Condition Monitoring and Predictive Maintenance

Condition monitoring is a critical component of predictive maintenance, enabling organizations to anticipate asset failures and schedule timely interventions. Functional analysts configure sensors, meters, and monitoring parameters to capture real-time data on asset health, performance, and utilization. This data is then analyzed to detect anomalies, wear patterns, and potential points of failure, allowing maintenance activities to be scheduled proactively.

Time-based and meter-based preventive maintenance is augmented by condition monitoring, providing a hybrid approach that balances scheduled interventions with predictive insights. Functional analysts define thresholds, alerts, and automated work order generation rules to ensure that deviations from normal operating conditions prompt immediate attention. This proactive approach reduces unplanned downtime, extends asset life, and optimizes resource deployment.

The integration of predictive maintenance with reporting and analytics enhances operational foresight. Analysts utilize historical data and trend analysis to refine maintenance schedules, update job plans, and adjust inventory and procurement requirements. By combining condition monitoring with structured workflows and asset hierarchies, organizations achieve a resilient and responsive maintenance ecosystem.

Job Plan Optimization

Job plans constitute the procedural backbone of maintenance activities within Maximo. They provide step-by-step guidance for executing tasks, ensuring consistency, safety, and efficiency. Functional analysts optimize job plans by sequencing tasks logically, allocating resources effectively, and incorporating condition-based triggers for specialized interventions.

Optimization includes defining task priorities, assigning labor skill requirements, and linking necessary tools and materials. By doing so, analysts enhance workflow efficiency, minimize downtime, and reduce the likelihood of errors during maintenance operations. Job plans can also be associated with multiple assets, master PMs, or specific routes, providing scalability and uniformity across the organization.

Continuous evaluation and refinement of job plans are essential. Analysts monitor task completion data, labor utilization, and maintenance outcomes, identifying opportunities for procedural improvements. This iterative approach ensures that job plans remain relevant, practical, and aligned with evolving operational demands, ultimately contributing to increased asset reliability and organizational performance.

Integration of Asset, Work, and Maintenance Data

Maximo excels in unifying asset, work order, and maintenance data into a cohesive operational framework. Functional analysts ensure that assets are linked to their respective work orders, preventive maintenance schedules, and inventory requirements. This integration allows for comprehensive tracking of resource utilization, task completion, and maintenance history.

Through effective integration, analysts can assess the lifecycle performance of assets, identify recurring issues, and recommend process improvements. The connection between asset data, predictive maintenance, and work order execution facilitates informed planning, minimizes redundancy, and reduces operational costs. Furthermore, integrated data supports advanced reporting, KPI measurement, and strategic decision-making, reinforcing the value of a well-configured Maximo environment.

Scenario-Based Application and Problem Solving

Functional analysts are often required to address complex operational scenarios that involve multiple interconnected modules. For instance, a failing asset may trigger a predictive maintenance alert, requiring immediate work order creation, inventory check for necessary spares, and procurement authorization for additional parts. Analysts must navigate these interdependencies efficiently, configuring Maximo to handle such scenarios automatically wherever possible.

Scenario-based problem solving requires not only technical knowledge but also a keen understanding of business processes, operational constraints, and organizational priorities. Analysts design workflows, escalations, and conditional rules that reflect real-world complexities, ensuring that Maximo functions as a reliable and intelligent operational tool. By simulating potential operational challenges and preemptively configuring system responses, analysts mitigate risks and maintain continuity in asset management activities.

Asset Subassemblies and Spare Parts Management

Managing asset subassemblies and spare parts is essential for maintaining operational readiness. Functional analysts configure subassemblies to represent the structural composition of complex assets, facilitating detailed tracking and maintenance planning. Spare parts are linked to specific assets or subassemblies, ensuring availability for preventive or corrective interventions.

The management of spare parts involves inventory oversight, reorder processes, and procurement coordination. Analysts define item statuses, categorize serviceable items, and track usage across work orders and maintenance tasks. By maintaining a comprehensive record of subassemblies and associated parts, organizations can reduce downtime, optimize stock levels, and improve the reliability of maintenance operations.

This level of granularity in asset and parts management supports predictive maintenance, informs procurement decisions, and enhances reporting accuracy. Functional analysts play a central role in configuring, monitoring, and refining these processes to align with organizational objectives and operational realities.

Warranty Contracts and Asset Lifecycle Management

Warranty management is another crucial aspect of IBM Maximo Asset Management. Functional analysts configure warranty contracts to track coverage periods, eligible parts, and service terms. By integrating warranty information with asset records, maintenance schedules, and procurement workflows, analysts ensure that organizations can leverage warranty provisions effectively, reducing repair costs and ensuring compliance with contractual obligations.

Lifecycle management extends beyond warranties to encompass acquisition, deployment, maintenance, and eventual retirement of assets. Analysts monitor asset usage, condition, and performance metrics to determine optimal replacement or refurbishment timelines. By aligning asset lifecycles with organizational goals, functional analysts contribute to sustainable resource management, cost control, and operational efficiency.

Location Hierarchies and Asset Categorization

The structuring of location hierarchies is fundamental for accurate asset tracking, reporting, and maintenance planning. Functional analysts configure locations to reflect physical, functional, or operational groupings, ensuring that assets are logically organized within Maximo. This enables efficient scheduling of preventive maintenance, targeted reporting, and streamlined workflow execution.

Asset categorization, in conjunction with location hierarchies, allows for nuanced reporting and KPI tracking. Analysts assign attributes, classifications, and subcategories to assets, facilitating granular analysis and strategic planning. Accurate hierarchies and categorizations enhance operational clarity, reduce maintenance errors, and provide a robust foundation for predictive and preventive maintenance initiatives.

Work Management and Planning Strategies

Effective work management and planning are pivotal in IBM Maximo Asset Management, ensuring that maintenance, operational, and procurement activities are coordinated with precision. Functional analysts oversee the creation, assignment, and execution of work orders, aligning tasks with preventive maintenance schedules, asset hierarchies, and operational priorities. This strategic orchestration minimizes downtime, optimizes labor utilization, and enhances asset reliability.

Work orders encompass multiple dimensions, including child work orders, task assignments, labor tracking, and resource allocation. Functional analysts define these elements to reflect organizational workflows, ensuring clarity and accountability. By configuring work order statuses and lifecycle stages, analysts monitor progress from creation to closure, maintaining alignment with operational objectives and regulatory standards.

Planning involves anticipating resource requirements, scheduling tasks according to priority, and coordinating multiple operational units. Analysts integrate preventive maintenance schedules with reactive maintenance requirements to balance operational demands, ensuring timely interventions without disrupting ongoing processes. Advanced planning also involves forecasting labor requirements, allocating skilled personnel efficiently, and synchronizing maintenance activities with inventory and procurement modules.

Labor Reporting and Resource Optimization

Labor reporting is a critical function within Maximo, providing insights into workforce utilization, task efficiency, and operational costs. Functional analysts configure labor tracking parameters, including hours worked, skills applied, task completion rates, and adherence to job plans. Accurate labor reporting enables management to evaluate performance, identify bottlenecks, and make data-driven decisions regarding staffing and operational assignments.

Resource optimization extends beyond labor to include tools, spare parts, and materials required for maintenance and operational tasks. Functional analysts ensure that these resources are allocated efficiently, minimizing downtime and preventing shortages. Integration with inventory management allows real-time visibility of resource availability, supporting proactive replenishment and cost-effective utilization. By optimizing labor and resource allocation, organizations achieve operational efficiency while maintaining high standards of asset performance and reliability.

Inventory Management and Reorder Strategies

Inventory management in Maximo encompasses more than stock tracking; it involves strategic planning, utilization analysis, and replenishment processes. Functional analysts configure inventory balances, item classifications, assembly structures, and costing methods to maintain accurate records. Proper categorization of items—rotating, non-rotating, service, and tool records—facilitates precise management and reporting.

Reorder strategies are integral to inventory optimization, preventing stockouts and ensuring that essential materials are available for scheduled maintenance and emergency interventions. Analysts establish minimum and maximum thresholds, define reorder points, and configure automatic replenishment processes. These strategies ensure that inventory aligns with operational demands, reduces holding costs, and minimizes waste.

Hard and soft reservations are employed to prioritize inventory usage, safeguarding critical items for essential work orders. Functional analysts monitor consumption patterns, identify trends, and adjust inventory policies to maintain operational continuity and cost efficiency. Integration with procurement and work management modules further ensures that inventory decisions are timely, informed, and aligned with broader organizational objectives.

Workflow Configuration and Process Automation

Workflows in Maximo provide a structured framework for automating routine processes, reducing manual intervention, and enhancing operational consistency. Functional analysts design workflows to mirror organizational policies, aligning system behavior with business requirements. These workflows encompass maintenance approvals, asset modifications, procurement authorizations, and exception handling, among other operational processes.

Automation within workflows reduces the likelihood of errors, ensures compliance with procedural standards, and accelerates task execution. Analysts define conditional rules, approvals, and escalations to handle deviations, ensuring that critical processes are executed without delay. By systematically mapping workflows, analysts create an operational blueprint that supports efficiency, accountability, and predictability across the organization.

Escalation rules complement workflows by automatically triggering actions when predefined conditions are met. Examples include overdue work orders, inventory shortages, or threshold breaches in asset condition monitoring. Functional analysts configure escalation parameters to ensure timely notifications, corrective actions, and managerial interventions. This proactive approach enhances operational resilience and maintains alignment with organizational goals.

Scenario-Based Workflow Optimization

Functional analysts frequently encounter complex scenarios that require sophisticated workflow configurations. For instance, a critical asset failure may necessitate simultaneous notifications to maintenance teams, inventory checks for spare parts, procurement of replacement items, and updates to reporting dashboards. Analysts design workflows that integrate these steps seamlessly, ensuring that responses are coordinated, timely, and efficient.

Scenario-based optimization involves simulating operational contingencies, identifying potential bottlenecks, and implementing automated responses. Analysts define parallel processing paths, conditional triggers, and escalation mechanisms to handle exceptions. By anticipating operational complexities, analysts enhance Maximo’s capacity to manage real-world challenges, ensuring minimal disruption and maximal asset uptime.

Advanced Asset Relationship Management

Understanding and managing complex asset relationships is central to effective asset management. Functional analysts define parent-child relationships, subassemblies, and interdependent assets, facilitating detailed tracking of maintenance requirements, lifecycle stages, and operational interconnections. Accurate representation of asset relationships supports preventive maintenance, predictive analysis, and resource allocation.

Asset relationship management also informs reporting, KPI development, and strategic planning. Analysts evaluate dependencies, criticality, and redundancy, ensuring that maintenance schedules and operational interventions are optimized. By maintaining precise records of asset interconnections, organizations gain enhanced visibility into operational risks, reduce unplanned downtime, and improve overall asset reliability.

Predictive and Preventive Maintenance Refinement

Functional analysts continually refine predictive and preventive maintenance strategies to enhance asset longevity and operational efficiency. Master PMs are updated based on historical data, condition monitoring insights, and operational feedback. Analysts adjust time-based and meter-based schedules to reflect actual asset usage and environmental conditions, ensuring that interventions occur precisely when needed.

Job plan sequencing, routes, and location-based maintenance strategies are evaluated for efficiency and effectiveness. Analysts assess the impact of preventive maintenance on labor resources, inventory utilization, and operational continuity. By fine-tuning maintenance processes, organizations achieve a balance between proactive care and resource optimization, minimizing both operational disruption and unnecessary expenditure.

Reporting Enhancements and KPI Integration

Advanced reporting is integrated with operational workflows to provide real-time visibility into maintenance activities, asset performance, and organizational efficiency. Functional analysts configure reports that combine data from multiple modules, allowing for comprehensive monitoring of KPIs such as downtime, work order completion, labor productivity, and inventory utilization.

KPI integration ensures that performance metrics are not isolated but linked to operational outcomes. Analysts configure dashboards and automated alerts to monitor critical parameters continuously, supporting proactive decision-making. This integration enables organizations to respond swiftly to operational anomalies, optimize maintenance strategies, and enhance overall asset performance.

Scenario Analysis and Problem Resolution

Functional analysts often employ scenario analysis to anticipate and resolve operational challenges. By modeling complex situations—such as simultaneous maintenance requirements across multiple sites, inventory shortages, or labor constraints—analysts develop contingency workflows, escalation protocols, and optimized task sequences.

Scenario analysis also informs training, resource allocation, and system configuration decisions. Functional analysts ensure that Maximo is configured to respond dynamically to operational disruptions, maintaining continuity and minimizing risks. The ability to preemptively address challenges enhances the organization’s resilience and demonstrates the strategic value of a well-configured Maximo environment.

Lifecycle Management and Strategic Planning

Lifecycle management extends beyond day-to-day maintenance to encompass the strategic planning of asset acquisition, deployment, utilization, and retirement. Functional analysts monitor asset performance, condition metrics, and maintenance history to determine optimal replacement cycles, refurbishment schedules, and investment priorities.

By aligning lifecycle decisions with organizational objectives, analysts contribute to sustainable resource management, cost control, and long-term operational efficiency. Integration with procurement, inventory, and reporting modules ensures that lifecycle strategies are actionable, measurable, and adaptable to changing operational conditions.

System Administration in IBM Maximo

System administration forms the backbone of efficient operations within IBM Maximo Asset Management. Functional analysts are responsible for configuring organizations, sites, and work centers to reflect the structural and operational hierarchies of the enterprise. Accurate administration ensures that assets, work orders, inventory, and maintenance tasks are properly aligned with organizational workflows, enabling smooth operations across multiple locations and departments.

Administrators configure roles, permissions, and security groups to regulate access to sensitive data and operational functionalities. Functional analysts manage these security configurations, ensuring that personnel can only access modules relevant to their responsibilities. This controlled access maintains data integrity, prevents operational discrepancies, and enhances accountability.

System configuration also encompasses business rules, operational parameters, and system defaults. Functional analysts fine-tune these settings to accommodate specific operational requirements, ensuring that Maximo functions seamlessly across diverse scenarios. Effective administration provides a stable and reliable environment that underpins all functional modules, from asset management to procurement and reporting.

Security Configuration and User Management

Security within Maximo is a multi-faceted domain that requires careful configuration by functional analysts. User groups, roles, and permissions are defined to control access to assets, work orders, inventory, and reporting functionalities. Analysts ensure that access controls are aligned with organizational policies, regulatory standards, and operational needs.

Security configuration extends to workflow approvals, escalation management, and maintenance execution. Analysts assign responsibilities in a way that enforces accountability while allowing operational efficiency. Role-based access prevents unauthorized modifications, protects sensitive data, and ensures that system changes are traceable. Functional analysts are instrumental in establishing these controls, providing a secure and auditable environment for enterprise asset management.

Business Financials Configuration

Business financials in Maximo connect asset management activities with cost tracking, budgeting, and financial reporting. Functional analysts configure accounts, cost centers, and financial controls to monitor expenditures associated with assets, maintenance tasks, procurement, and inventory. This configuration allows organizations to understand the financial implications of asset utilization and operational processes.

Integration between maintenance workflows and financial reporting enables analysts to allocate costs accurately, track labor expenses, and monitor material usage. By linking operational activities with financial metrics, organizations can assess return on investment, identify cost-saving opportunities, and make informed decisions about resource allocation. Functional analysts ensure that financial configurations are accurate, consistent, and adaptable to evolving operational and strategic requirements.

Calendars and Work Periods

Calendars and work periods define the temporal framework for maintenance activities, resource availability, and operational scheduling. Functional analysts configure calendars to reflect working hours, shifts, holidays, and exceptions, ensuring that preventive maintenance and work orders are planned with precision.

Work periods provide a structure for labor allocation, enabling accurate tracking of hours, productivity, and overtime. By aligning maintenance schedules with resource availability, functional analysts minimize operational conflicts and optimize workforce utilization. Calendars and work periods also facilitate compliance with labor regulations, safety protocols, and contractual obligations. This temporal structuring is critical for maximizing operational efficiency and ensuring that maintenance activities occur within planned timelines.

Classifications and Attribute Management

Asset and work order classifications allow for systematic categorization, facilitating reporting, analytics, and operational planning. Functional analysts configure classifications and attributes to capture detailed information about asset types, operational requirements, and maintenance priorities.

Attributes may include specifications, operational constraints, criticality levels, and maintenance guidelines. By applying standardized classifications and attributes, analysts ensure consistency across the organization, enabling accurate reporting, KPI measurement, and predictive maintenance strategies. Classifications also support scenario analysis, allowing organizations to identify patterns, optimize maintenance schedules, and anticipate operational challenges.

Edit Mode and Configuration Management

Edit mode in IBM Maximo serves as the central mechanism for implementing system-wide changes, updates, and enhancements. Functional analysts play a critical role in managing this mode to ensure that data accuracy, process integrity, and system stability are preserved. By carefully controlling edit mode activities, they prevent inconsistencies and ensure that daily operations continue smoothly without disruption.

Typical changes managed through edit mode include updates to asset records, revisions to preventive maintenance schedules, adjustments to inventory parameters, and modifications to workflow or approval rules. Analysts follow a structured process that involves designing, testing, and validating changes in controlled environments before deployment. This systematic approach reduces operational risks, minimizes system errors, and safeguards organizational data.

Configuration management, which complements edit mode, focuses on the continuous assessment and optimization of Maximo’s system settings. Functional analysts analyze performance metrics, user feedback, and operational outcomes to identify areas for improvement. They then implement targeted updates to enhance efficiency, ensure regulatory compliance, and strengthen reliability.

Through disciplined management of both edit mode and configuration processes, analysts maintain a balanced environment that supports system agility and business continuity. Their work ensures that Maximo remains aligned with evolving operational requirements while delivering consistent performance and data integrity. This proactive approach enables organizations to adapt effectively, optimize asset management practices, and sustain long-term operational excellence.

Integration of Administration with Operational Modules

Administration is not isolated; it intersects with all operational modules, including asset management, work management, procurement, inventory, analytics, and workflows. Functional analysts ensure that administrative configurations align with operational objectives, enabling seamless execution of preventive maintenance, work order management, inventory tracking, and reporting.

Security settings, calendars, classifications, and edit mode management influence workflows, KPI measurement, and predictive maintenance strategies. Analysts ensure that these administrative elements support operational continuity, enhance performance visibility, and maintain organizational compliance. By integrating administration with functional modules, Maximo becomes a cohesive, intelligent system capable of managing complex enterprise operations efficiently.

Scenario-Based Administrative Challenges

Functional analysts encounter complex administrative scenarios that require careful planning and configuration. For example, merging organizational sites, restructuring asset hierarchies, or updating security protocols across multiple departments involves coordination, validation, and rigorous testing. Analysts must anticipate operational impacts, ensure continuity, and maintain data integrity throughout the process.

Scenario-based challenges also include implementing new financial controls, modifying calendars to accommodate operational changes, or updating classifications for newly acquired assets. Functional analysts design workflows and edit mode strategies that enable smooth transitions, minimize disruption, and maintain alignment with strategic objectives. Effective administrative management ensures that Maximo continues to support operational, financial, and compliance requirements reliably.

Strategic Importance of Administration for Functional Analysts

Administration in IBM Maximo extends beyond technical configuration; it represents a strategic function that influences operational performance, resource optimization, and organizational resilience. Functional analysts leverage administrative capabilities to align system functionality with business goals, support predictive maintenance, and enhance reporting and analytics accuracy.

By configuring organizations, sites, security, calendars, classifications, and edit mode protocols effectively, analysts ensure that Maximo operates as a reliable, scalable, and responsive platform. Administrative expertise empowers organizations to anticipate operational challenges, respond proactively to maintenance requirements, and optimize resource utilization. This strategic integration of administration with operational modules underscores the critical role of functional analysts in enterprise asset management.

Preparing for the C2010-555 Exam Through Administration Expertise

Mastering administrative modules is essential for success in the IBM Maximo Asset Management Functional Analyst (C2010-555) Certification exam. Functional analysts must demonstrate proficiency in configuring organizations, managing users and security, setting up business financials, creating calendars and work periods, defining classifications and attributes, and applying edit mode changes.

Hands-on experience with these administrative functions, combined with scenario-based practice, ensures that candidates can navigate complex operational challenges efficiently. Understanding the strategic impact of administration on workflows, reporting, inventory management, and maintenance planning is crucial for both exam success and effective real-world application.

Integration Across Functional Modules

Integration is the cornerstone of effective asset management in IBM Maximo. Functional analysts ensure that modules—such as asset management, preventive maintenance, work management, procurement, inventory, analytics, and administration—operate cohesively. By establishing connections between assets, work orders, inventory items, and workflows, analysts create a seamless operational environment that enhances reliability and efficiency.

The ability to link preventive maintenance schedules with asset hierarchies, inventory availability, and labor resources ensures that maintenance tasks are executed accurately and on time. Procurement workflows are integrated with inventory levels and maintenance requirements, preventing stockouts and reducing operational delays. Analytics and reporting modules draw data from all functional areas, enabling comprehensive monitoring of KPIs and performance metrics.

Integration allows functional analysts to anticipate operational challenges, automate repetitive tasks, and implement scenario-based workflows that respond dynamically to real-world conditions. This holistic approach ensures that Maximo functions as a unified system, supporting strategic planning, operational efficiency, and continuous improvement.

Advanced Scenario Simulations

Functional analysts often encounter multifaceted operational scenarios that require sophisticated planning and configuration. Simulations of complex situations—such as simultaneous asset failures across multiple sites, labor shortages, or inventory constraints—enable analysts to refine workflows, escalations, and preventive maintenance strategies.

Scenario simulations involve mapping interdependencies among assets, work orders, and inventory, identifying potential bottlenecks, and defining contingency measures. Analysts apply predictive insights from condition monitoring to anticipate maintenance needs, adjust schedules, and allocate resources proactively. This approach enhances system responsiveness, mitigates operational risks, and ensures continuity in asset management activities.

By integrating simulations into training and system configuration, analysts prepare the organization to handle unplanned events efficiently. Scenario-based exercises also strengthen analytical skills, enabling functional analysts to optimize workflows, job plans, and preventive maintenance sequences under varying operational conditions.

Predictive Insights and Maintenance Optimization

Predictive insights are derived from condition monitoring, historical asset performance data, and preventive maintenance outcomes. Functional analysts leverage these insights to refine maintenance schedules, optimize resource utilization, and prevent unplanned downtime.

Time-based, meter-based, and condition-based preventive maintenance are continuously evaluated and adjusted based on predictive analytics. Functional analysts monitor trends, analyze deviations, and implement changes that enhance reliability while minimizing costs. Integration with work management ensures that resources are allocated efficiently, while alignment with inventory and procurement modules guarantees availability of necessary parts and tools.

Predictive insights also inform lifecycle management decisions, guiding asset replacement, refurbishment, and strategic investment. By using Maximo as a predictive tool, functional analysts empower organizations to transition from reactive maintenance to proactive, data-driven asset management strategies.

Exam Preparation Strategies

Preparation for the C2010-555 exam requires a comprehensive understanding of both conceptual knowledge and practical application. Functional analysts should focus on mastering all core modules, including asset management, preventive maintenance, work management, procurement, inventory, analytics, workflows, and administration. Hands-on practice with Maximo, scenario-based exercises, and configuration tasks are essential for building proficiency.

Reviewing sample questions and practice exams familiarizes candidates with the format, complexity, and time constraints of the certification test. Analysts should prioritize understanding inter-module integrations, workflows, KPI reporting, and scenario-based problem solving, as these are frequently assessed in the exam.

Effective study strategies include creating structured revision schedules, focusing on weak areas identified in practice tests, and reinforcing knowledge through real-world application. Scenario analysis, advanced reporting, and predictive maintenance simulations provide practical experience that enhances both exam performance and professional competency.

Consolidation of Knowledge

The IBM Maximo Asset Management Functional Analyst certification demonstrates a professional’s capability to manage, configure, and enhance enterprise asset management systems. Functional analysts integrate expertise across multiple Maximo modules to ensure operational excellence and system efficiency. This integration involves in-depth understanding and application of preventive maintenance, work management, procurement, inventory, reporting, administration, and system integration.

Proficiency in asset hierarchies, subassemblies, spare parts management, and lifecycle processes allows analysts to maintain optimal performance and reliability throughout the asset lifecycle. A firm grasp of workflows, escalations, job plan sequencing, and predictive maintenance strategies enables effective handling of complex operational environments. Furthermore, knowledge of administrative functions such as security configurations, business financials, calendar management, classifications, and edit modes ensures data integrity, compliance, and business continuity.

By consolidating technical and functional knowledge, professionals are equipped to excel in the IBM C2010-555 certification exam. More importantly, they become capable of implementing Maximo-based solutions that strengthen enterprise operations, enhance asset reliability, and align maintenance strategies with organizational goals. These capabilities empower organizations to operate with greater efficiency, optimize the use of resources, and support well-informed strategic decision-making.

Real-World Application of Functional Expertise

The value of a functional analyst extends far beyond certification. Their effectiveness is measured by how well they apply theoretical principles to real operational contexts. Analysts use their understanding of Maximo to monitor asset conditions, coordinate both preventive and predictive maintenance programs, oversee procurement activities, and maintain accurate inventory control.

Practical application requires problem-solving based on real scenarios, ongoing evaluation of job plans, and integration of multiple Maximo modules to promote operational synergy. By tracking performance indicators and analyzing key metrics, analysts identify trends, anticipate challenges, and adjust maintenance or resource allocation strategies as needed. Through the use of data-driven insights, they refine workflows and processes to enhance reliability and performance.

Maximo’s extensive functionality enables functional analysts to connect operational objectives with system capabilities. They continuously analyze operational data, detect inefficiencies, and introduce corrective measures that promote sustainable performance. This ability to merge analytics with functional processes allows organizations to maintain a proactive approach to maintenance and asset management. As a result, analysts contribute to improved operational continuity, stronger resource utilization, and long-term organizational sustainability.

Continuous Learning and Skill Enhancement

Enterprise asset management evolves continuously, driven by technological advancement and shifting business priorities. To remain effective, IBM Maximo functional analysts must engage in ongoing learning and professional development. Keeping pace with software updates, emerging functionalities, and evolving best practices ensures that analysts remain proficient in handling complex and dynamic asset management environments.

Continuous improvement involves delving into advanced analytical methods, innovative reporting techniques, and workflow optimization. Analysts expand their technical scope by exploring predictive analytics, scenario-based modeling, and simulation-driven analysis. Through experimentation with configurations and process improvements, they refine their understanding of how Maximo supports evolving business needs.

The emphasis on continuous learning extends beyond system knowledge to include developing analytical and strategic thinking skills. Analysts use operational data to assess system performance, identify patterns, and propose solutions for recurring challenges. This process fosters adaptability and enhances decision-making accuracy. The pursuit of ongoing skill enhancement ensures that organizations benefit from improved system utilization, efficient operations, and continuous process improvement.

A functional analyst who remains dedicated to learning not only keeps systems optimized but also drives innovation in maintenance management. This dedication reinforces the importance of the role, ensuring sustained growth and measurable improvements in enterprise asset management performance.

Strategic Impact of IBM Maximo Functional Analysts

Functional analysts occupy a critical position within the enterprise asset management ecosystem. They serve as the bridge between operational requirements and technological solutions, translating organizational objectives into efficient Maximo configurations. Their work ensures that business operations align with system capabilities, fostering an environment where data-driven decision-making supports overall strategic direction.

By integrating Maximo’s modules, analysts streamline maintenance planning, enhance scheduling accuracy, and ensure timely procurement and inventory management. Their use of analytics provides actionable insights into performance trends, allowing management teams to make informed decisions regarding maintenance priorities, resource deployment, and cost optimization.

Functional analysts play an essential role in promoting efficiency, compliance, and cost control. Through accurate configuration, scenario-based planning, and the use of predictive maintenance tools, they minimize downtime and reduce unexpected disruptions. Their ability to foresee operational risks and implement preventive strategies contributes significantly to organizational agility and resilience.

Beyond operational performance, functional analysts drive long-term value creation. Their insights support continuous improvement initiatives and align maintenance efforts with broader business objectives. They help organizations manage resources effectively, achieve compliance with industry standards, and improve return on investment. The strategic foresight they provide helps organizations anticipate future challenges and maintain a sustainable approach to asset management.

In essence, the influence of IBM Maximo Functional Analysts extends from system optimization to strategic leadership. Their mastery of Maximo functionalities not only ensures success in professional certification but also underpins their contribution to enterprise transformation. As organizations increasingly rely on data and automation to guide operations, the role of the functional analyst becomes indispensable.

Their expertise ensures that Maximo operates as an integrated solution rather than a collection of independent modules. Through careful planning, configuration, and analysis, they enable systems to function cohesively, delivering consistent value to business operations. Functional analysts thereby help organizations transition from reactive maintenance practices to proactive and predictive strategies, securing higher productivity and reduced operational costs.

Ultimately, the strength of an IBM Maximo Functional Analyst lies in their ability to combine technical precision with strategic insight. They not only manage and optimize asset systems but also support continuous growth through informed decision-making, efficient resource management, and sustainable operational practices. Their contributions uphold the principles of reliability, efficiency, and adaptability—key drivers of success in modern enterprise asset management.

Conclusion

The IBM Maximo Asset Management Functional Analyst (C2010-555) Certification represents a comprehensive evaluation of an individual’s ability to manage, configure, and optimize enterprise asset management processes. Mastery of this certification requires in-depth knowledge of asset hierarchies, preventive and predictive maintenance, work management, inventory control, procurement, workflows, analytics, and administration. Functional analysts are expected to integrate these modules seamlessly, ensuring operational efficiency, reliability, and cost-effectiveness across diverse organizational environments.

Functional analysts leverage Maximo’s capabilities to establish robust workflows, configure job plans, define KPIs, and implement escalation rules that enhance responsiveness to operational challenges. Predictive maintenance and condition monitoring enable proactive interventions, reducing unplanned downtime and extending asset lifecycles. Effective inventory management, spare parts oversight, and procurement integration ensure resources are available when needed, supporting continuity and operational resilience.

Administration and security configuration are critical to maintaining data integrity, controlling access, and aligning system functionalities with organizational objectives. Analysts also optimize labor utilization, track financial impacts, and apply classification systems to enable accurate reporting and actionable insights. Hands-on experience, scenario simulations, and practice exams strengthen proficiency, preparing candidates for both certification success and practical application in enterprise settings.

Ultimately, IBM Maximo Functional Analysts serve as strategic enablers, bridging operational processes with technological capabilities. By mastering Maximo’s integrated functionalities, analysts enhance decision-making, streamline asset management, and contribute significantly to organizational efficiency, reliability, and long-term sustainability.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.