Exam Code: CPIM

Exam Name: Certified in Planning and Inventory Management

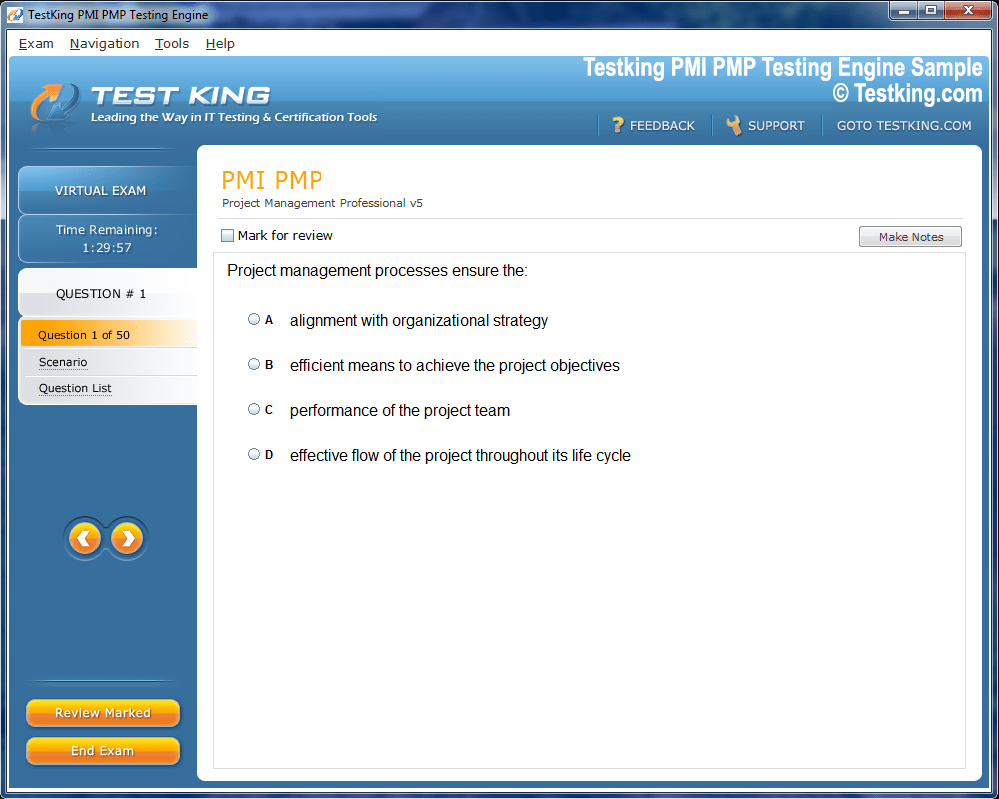

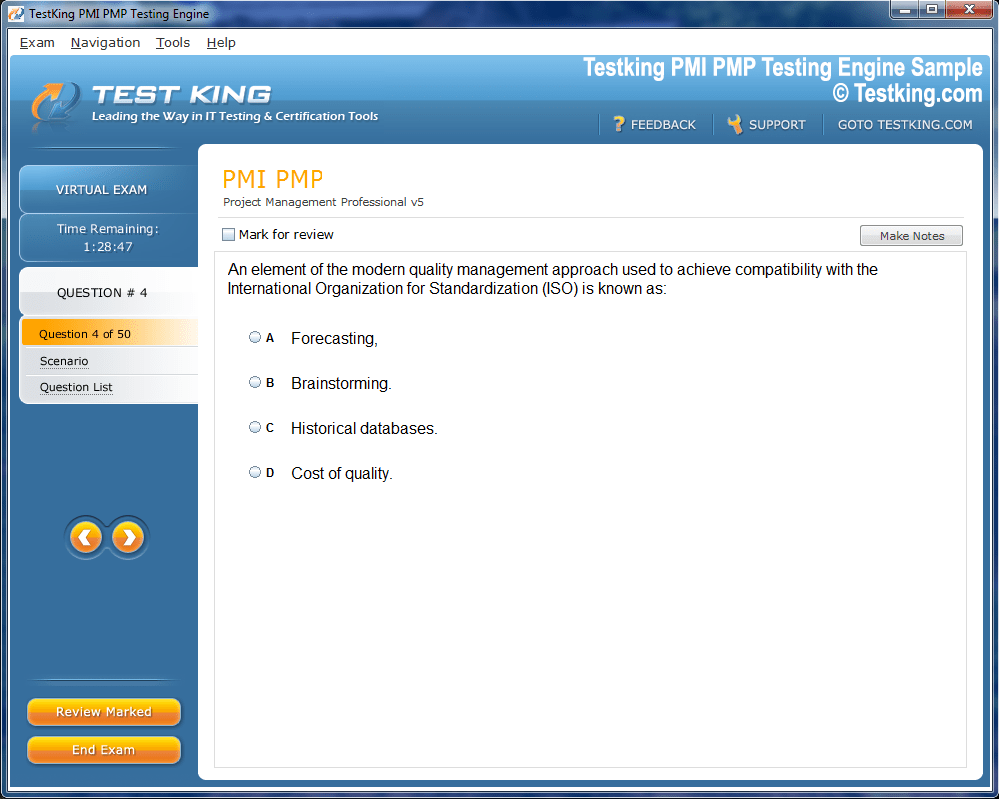

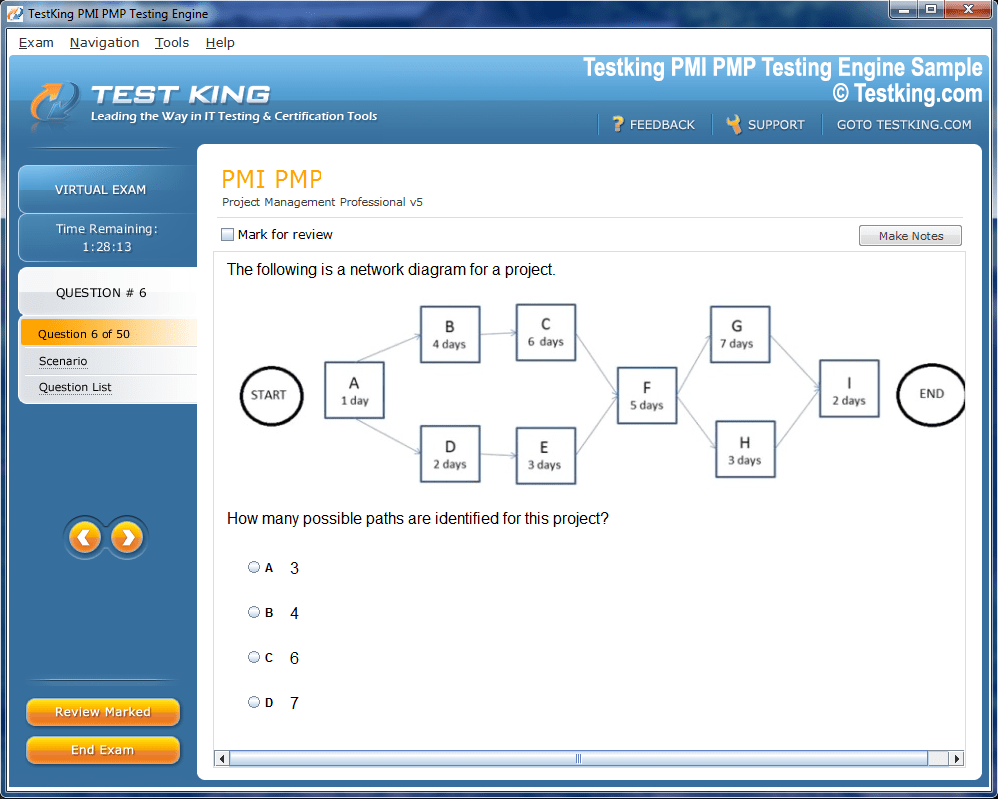

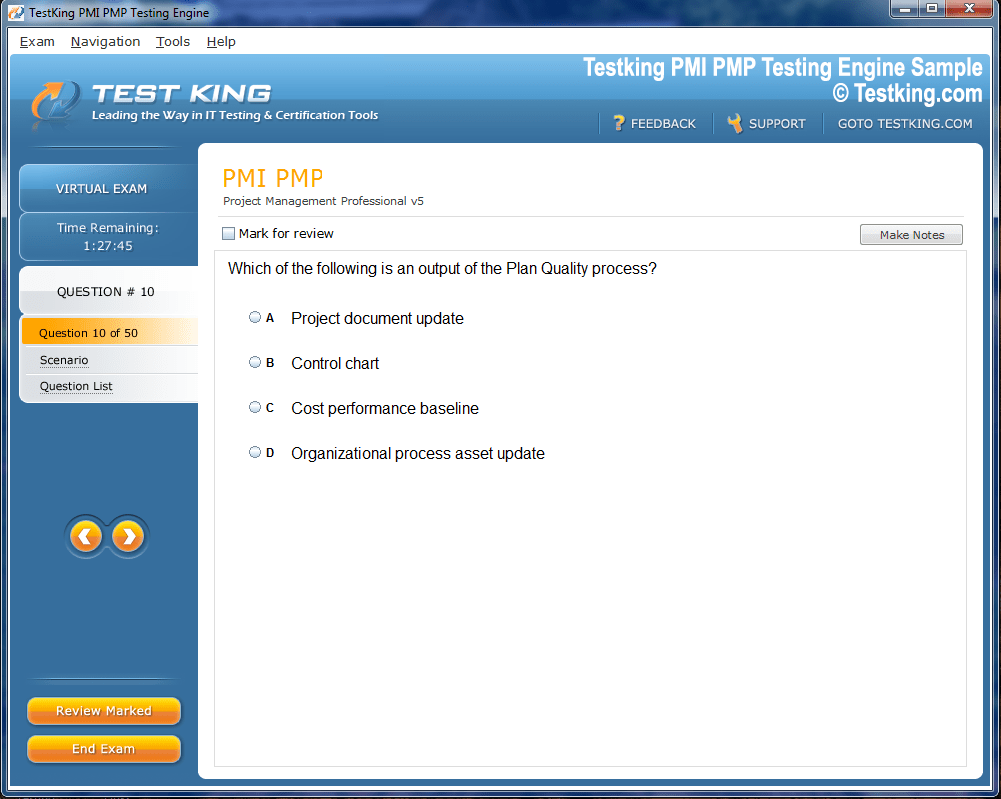

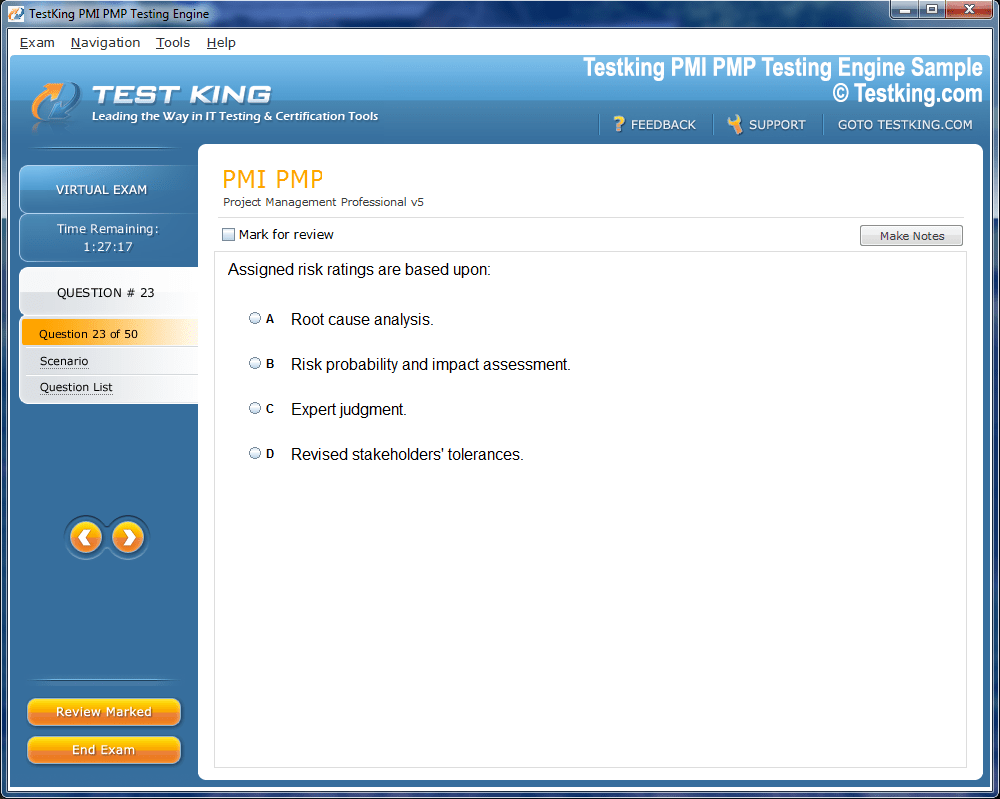

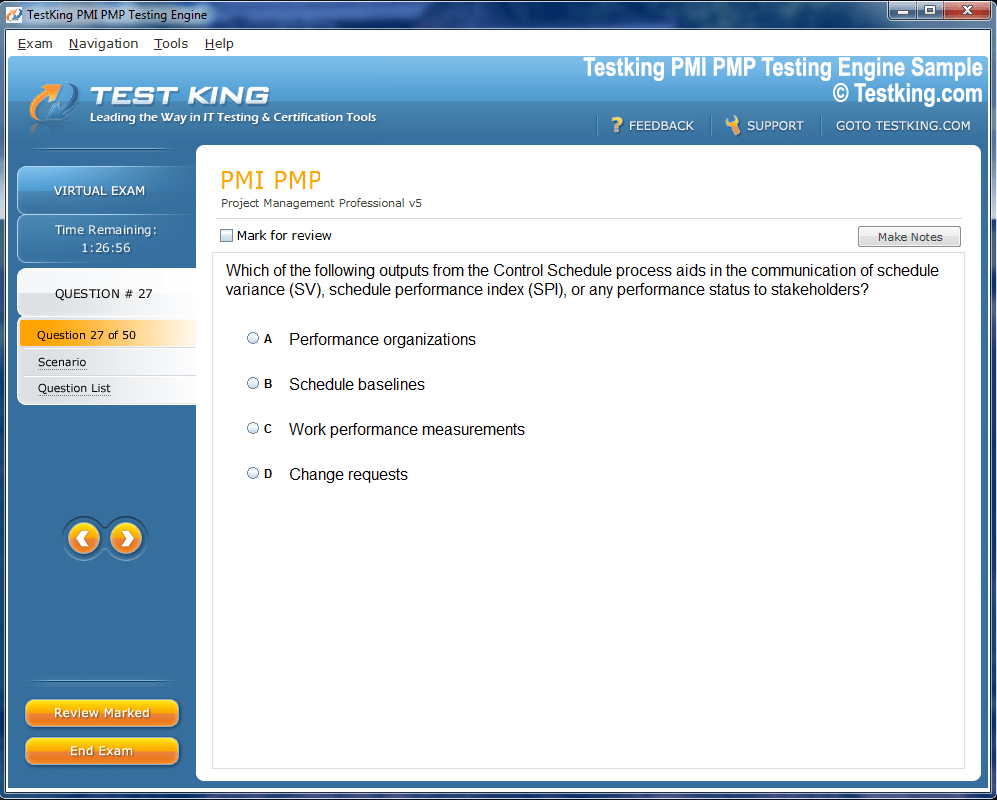

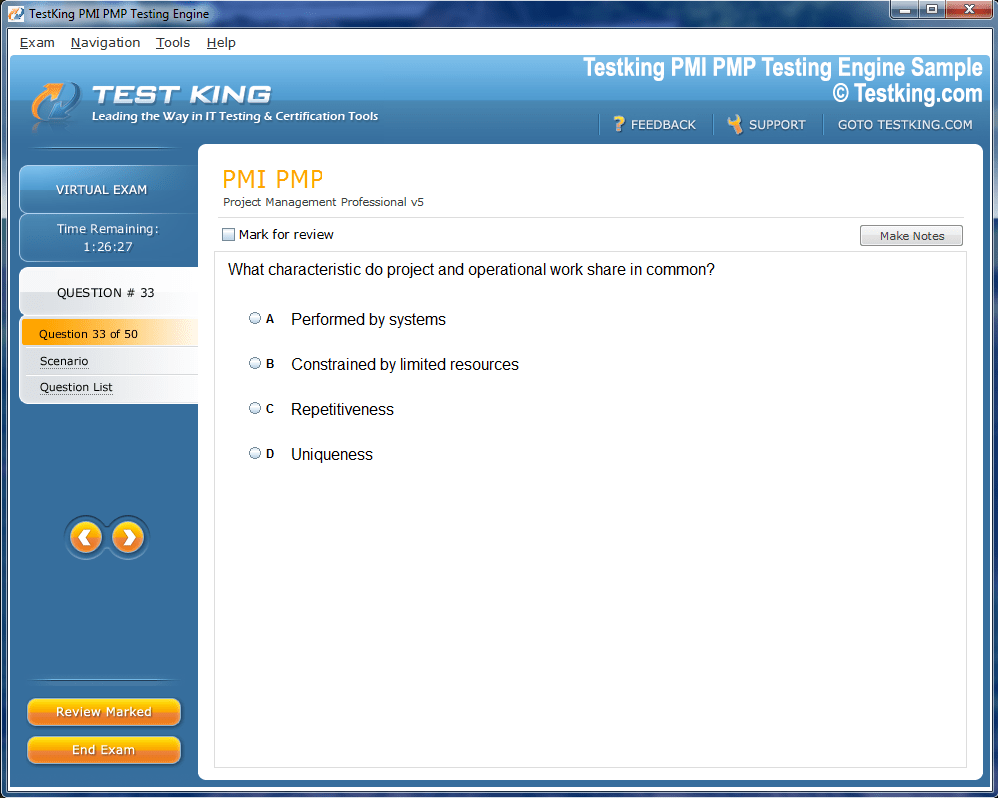

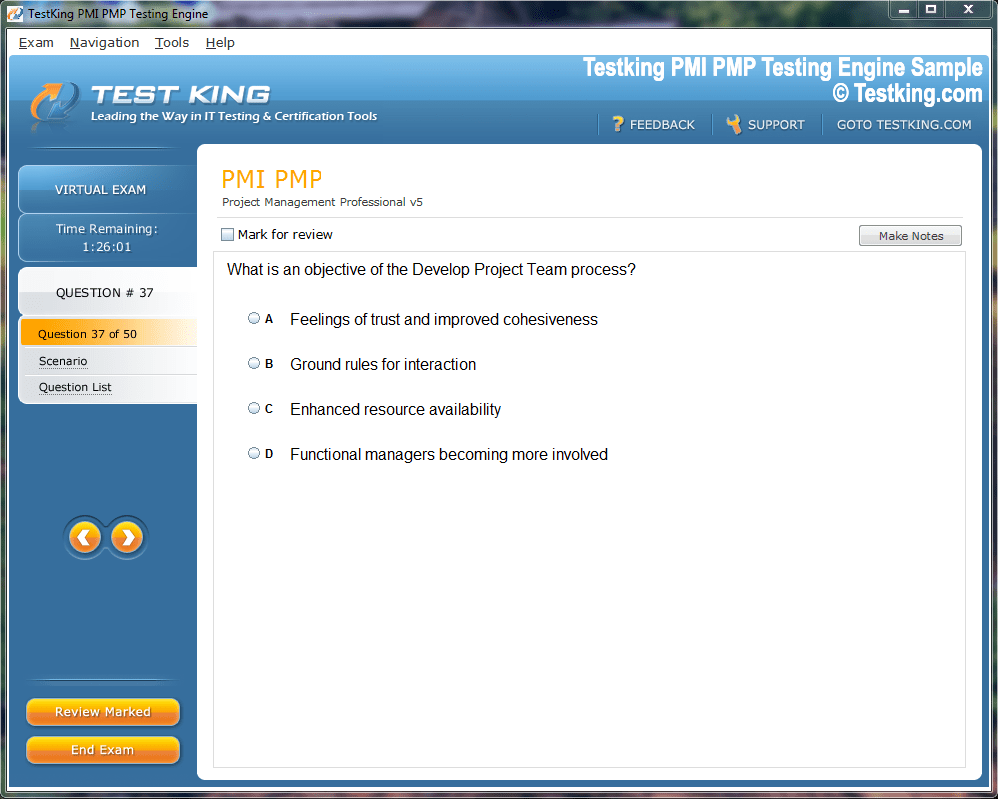

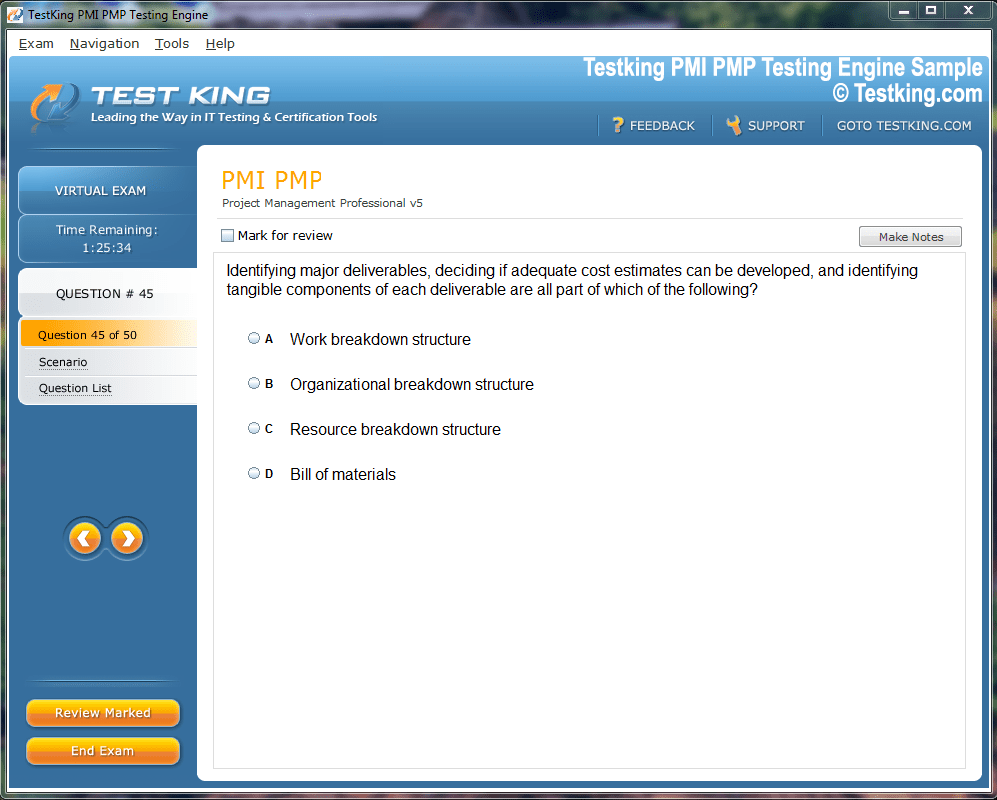

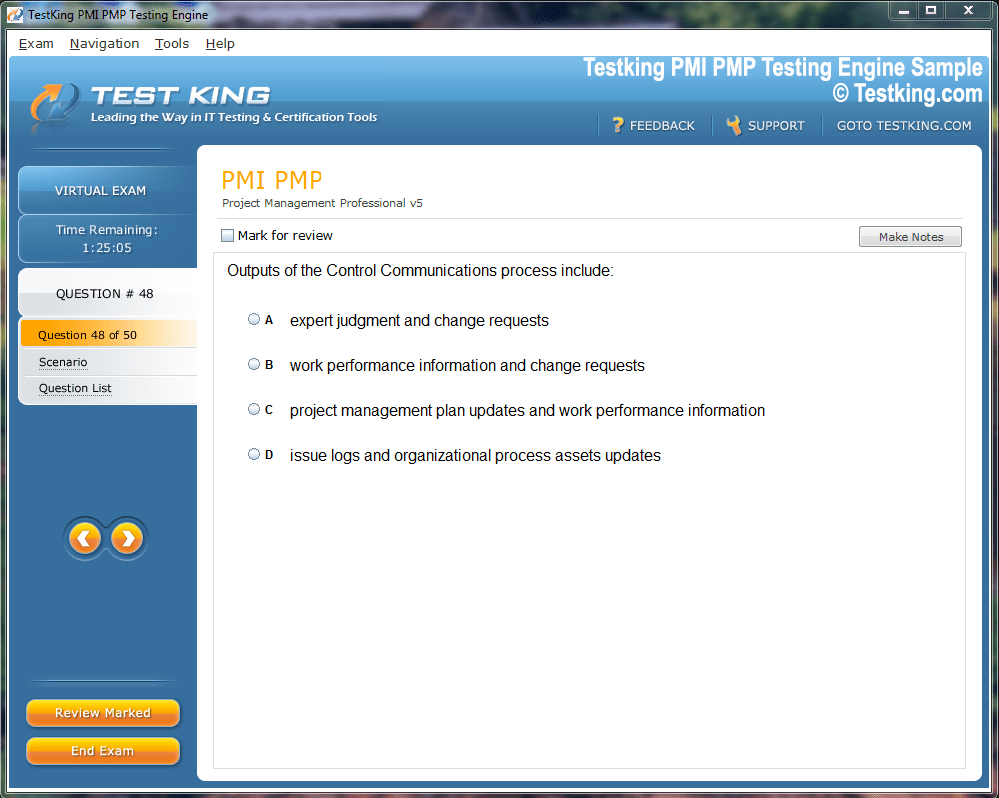

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our CPIM testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Top APICS Exams

APICS CPIM Certification Explained for Supply Chain Professionals

Global supply chains operate as intricate frameworks that interlace the creation, management, and delivery of goods across multiple geographies. These networks are not mere conduits of transportation; they encompass a sophisticated orchestration of resources, technologies, human expertise, and logistical foresight. In today’s interconnected economy, the efficacy of a supply chain can dictate the operational success or vulnerability of enterprises, transcending mere transactional exchanges to become a strategic imperative.

Consider the lifecycle of a wearable gadget, such as a smartwatch. Its journey begins with conceptualization, where engineers, designers, and marketers collaborate to define the product’s features, aesthetics, and technological capabilities. This phase requires an acute awareness of market trends, consumer preferences, and competitive intelligence. It is in this crucible of ideation that the foundational blueprint of the device emerges, setting the stage for all subsequent activities.

Once the conceptual framework is established, the procurement of materials becomes paramount. Global supply chains source components from myriad regions, often spanning continents. Microprocessors might originate from East Asia, while precision glass and polymer materials could be sourced from Europe or North America. Each supplier brings unique production methodologies, lead times, and quality standards. Ensuring seamless coordination among these suppliers demands not only technical acuity but also an understanding of geopolitical, economic, and environmental factors that influence material availability. This complexity underscores why supply chain management is more than logistical planning; it is an orchestration of interdependent systems that must operate in synchrony.

The assembly phase integrates these disparate components into a coherent, functional product. Highly skilled technicians, automated machinery, and meticulous quality assurance protocols converge to create a device that meets design specifications. Here, the concept of lean manufacturing is often employed to minimize waste, optimize throughput, and enhance operational efficiency. A delay or error in any segment of assembly can reverberate across the supply chain, highlighting the necessity for precision and adaptability at every juncture.

Quality control transcends simple defect detection; it encompasses comprehensive testing of functionality, durability, and safety. Standardized methodologies, such as Six Sigma and continuous improvement processes, are often utilized to maintain consistency across production batches. This rigorous attention to detail ensures that end users receive products that align with their expectations and comply with regulatory requirements. Consequently, quality management is intrinsically linked with inventory control, as faulty products or suboptimal processes can disrupt distribution schedules and inflate operational costs.

Distribution represents the culmination of the supply chain, wherein finished products are transported to retailers, warehouses, or directly to consumers. Global logistics networks, leveraging multimodal transport systems, ensure that products traverse complex geographic terrains efficiently. This stage is not merely about moving goods; it involves managing inventory levels, monitoring transit conditions, optimizing storage strategies, and ensuring timely delivery. Innovations in supply chain visibility, such as real-time tracking and predictive analytics, have enhanced the capability to anticipate disruptions and respond proactively.

The interconnectivity of global supply chains extends beyond physical goods to include information, financial transactions, and collaborative relationships. Suppliers, manufacturers, distributors, and end users operate within a dynamic ecosystem where communication and coordination are pivotal. Emerging technologies, including blockchain, artificial intelligence, and the Internet of Things, have introduced new dimensions of transparency, predictive modeling, and automated decision-making. These advancements allow supply chain professionals to detect inefficiencies, optimize routes, and anticipate market fluctuations with unprecedented accuracy.

Supply chains also play a critical role in risk management. Global disruptions, such as natural disasters, political instability, or pandemics, can impede material flow, compromise inventory integrity, and disrupt manufacturing schedules. To mitigate these vulnerabilities, organizations employ strategies such as dual sourcing, buffer inventory, and contingency planning. The ability to anticipate potential disruptions and implement corrective measures distinguishes resilient supply chains from those susceptible to volatility.

A central component of effective supply chain management is the integration of planning systems that align production with demand forecasts. Enterprise resource planning systems facilitate the orchestration of procurement, production scheduling, and distribution. These tools provide a holistic view of operations, enabling decision-makers to allocate resources efficiently, balance supply with demand, and optimize overall performance. Inventory management, a subdomain within supply chain operations, ensures that materials are available when needed while minimizing excess stock. Balancing these competing priorities requires a nuanced understanding of production cycles, lead times, and market dynamics.

The Certified in Planning and Inventory Management certification has emerged as a pivotal benchmark for professionals navigating this intricate landscape. CPIM certification validates expertise in planning, inventory control, and production operations, equipping individuals with the skills necessary to manage complex supply chain functions. Professionals who pursue this credential gain an understanding of demand forecasting, capacity planning, material requirements planning, and the optimization of production schedules. These competencies are not merely technical; they encompass strategic thinking, operational analysis, and the ability to coordinate multifaceted processes across organizational boundaries.

CPIM certification also emphasizes the harmonization of supply chain activities with organizational strategy. Strategic alignment ensures that operational decisions support broader corporate objectives, whether that involves reducing costs, enhancing customer satisfaction, or increasing market responsiveness. By linking planning and inventory management to enterprise strategy, professionals can transform supply chain operations from tactical exercises into sources of competitive advantage.

A defining feature of supply chain proficiency is the ability to navigate uncertainty. Volatility in customer demand, fluctuating raw material costs, and global economic shifts necessitate adaptive planning mechanisms. Scenario modeling, risk assessment, and contingency protocols enable supply chain professionals to respond to variability without compromising efficiency. This proactive approach fosters resilience and positions organizations to capitalize on emerging opportunities, whether through market expansion, product diversification, or operational innovation.

Collaboration is another cornerstone of effective supply chain management. Interactions among suppliers, manufacturers, logistics providers, and customers must be orchestrated to ensure the seamless flow of goods and information. Contractual arrangements, performance metrics, and partnership strategies all contribute to sustaining these relationships. Professionals with CPIM credentials are trained to evaluate supplier performance, coordinate production schedules, and implement continuous improvement initiatives that enhance overall operational coherence.

The importance of sustainability within global supply chains is increasingly recognized. Organizations are adopting environmentally responsible practices, such as optimizing transportation routes to reduce carbon emissions, implementing energy-efficient manufacturing processes, and sourcing materials ethically. Supply chain professionals must reconcile operational objectives with ecological stewardship, integrating sustainability considerations into planning and decision-making frameworks. This convergence of efficiency and responsibility reflects a sophisticated understanding of modern supply chain dynamics.

Technological innovation continues to redefine supply chain capabilities. Advanced analytics, predictive modeling, and automated inventory systems enable real-time decision-making and operational optimization. Artificial intelligence can forecast demand fluctuations, identify bottlenecks, and suggest corrective measures. Blockchain technology provides transparency and traceability, ensuring the authenticity and integrity of materials and products. Supply chain professionals equipped with CPIM certification are uniquely positioned to leverage these innovations, translating technological potential into practical operational improvements.

Finally, the human dimension remains an essential element of supply chain excellence. Leadership, communication, and collaborative skills enable professionals to coordinate complex processes, manage multidisciplinary teams, and negotiate with stakeholders across global contexts. The integration of technical expertise with managerial acumen is a hallmark of advanced supply chain practice, fostering environments in which efficiency, innovation, and adaptability converge.

Global supply chains are far more than the sum of their parts; they are dynamic, interconnected networks that underpin modern commerce. From conceptualization and material sourcing to assembly, quality control, and distribution, every stage demands strategic oversight, operational precision, and collaborative effort. Certifications such as CPIM codify this expertise, providing professionals with the knowledge and competencies necessary to navigate the complexities of planning, inventory management, and production operations. Mastery of these domains enables supply chain practitioners to drive efficiency, enhance resilience, and contribute meaningfully to organizational success in an increasingly competitive and volatile global marketplace.

Exploring CPIM Certification

The Certified in Planning and Inventory Management credential represents a globally recognized standard in supply chain expertise. Developed by the Association for Supply Chain Management, CPIM certification is designed to validate an individual's competence in planning, inventory management, production scheduling, and operational coordination. In a business environment where efficiency and precision are paramount, CPIM certification functions as both a mark of professional credibility and a practical toolkit for navigating complex supply chain systems.

CPIM certification emphasizes an integrated approach, combining technical knowledge with strategic insight. It is not solely about learning formulas or processes; it is about understanding how each element of the supply chain interrelates, how decisions ripple across production schedules, and how inventory policies impact overall operational efficiency. Professionals undertaking this certification are expected to develop a nuanced comprehension of supply chain strategy, demand forecasting, material requirements planning, and the synchronization of production resources.

The certification structure has evolved to accommodate the growing complexity of supply chain management. The latest iteration, CPIM 8.0, consolidates previous examinations into a single, comprehensive assessment. This approach ensures a unified evaluation of all essential competencies, covering topics that were previously divided into multiple exam modules. By integrating knowledge areas, CPIM 8.0 encourages professionals to adopt a holistic perspective, considering both operational details and strategic imperatives when making decisions.

Preparation for CPIM certification begins with an understanding of the exam content and format. The CPIM 8.0 exam consists of 150 questions, designed to assess mastery across key areas of supply chain management. Candidates are given three and a half hours to complete the assessment, demanding not only knowledge but also stamina, time management, and analytical thinking. The scoring scale ranges from 200 to 350, with a score of 300 or higher indicating successful completion. This scaled scoring methodology ensures consistency in evaluation, accommodating variations in question difficulty while maintaining rigorous standards.

The primary topics covered in the CPIM exam include supply chain strategy, sales and operations planning, demand management, supply management, detailed scheduling, inventory management, distribution, quality assurance, technology utilization, and continuous improvement processes. Each of these domains requires an in-depth understanding and the ability to apply principles to practical scenarios. For instance, demand management involves analyzing historical sales data, forecasting future requirements, and aligning production schedules to meet anticipated demand. Meanwhile, detailed scheduling focuses on allocating resources efficiently, coordinating production tasks, and mitigating bottlenecks that could disrupt the flow of goods.

Inventory management forms a critical component of the certification. Effective inventory control ensures that materials and products are available when needed without overstocking, which can lead to excessive holding costs or obsolescence. CPIM emphasizes methodologies such as just-in-time inventory, safety stock calculations, and reorder point analysis. Mastery of these techniques enables professionals to optimize the balance between supply availability and operational cost, enhancing the agility of the entire supply chain.

Supply management is another integral area of focus. This domain examines the procurement of materials, supplier evaluation, and coordination with external partners. Professionals are expected to assess supplier performance, manage lead times, and develop collaborative strategies that improve reliability and reduce risk. Understanding global sourcing dynamics, including geopolitical, economic, and environmental considerations, is essential for ensuring continuity and efficiency in the supply chain.

Sales and operations planning, often abbreviated as S&OP, is highlighted for its strategic significance. S&OP integrates data from multiple functions, including marketing, production, and finance, to develop synchronized plans that meet customer demand while optimizing resources. CPIM-certified professionals are trained to facilitate cross-functional collaboration, reconcile conflicting priorities, and develop actionable plans that enhance both operational performance and customer satisfaction.

Technology integration is emphasized throughout CPIM preparation. Modern supply chains rely on sophisticated systems for tracking inventory, managing production schedules, and analyzing performance metrics. Enterprise resource planning software, predictive analytics, and automated inventory systems are all within the scope of the certification. Professionals must understand how to leverage these tools to improve efficiency, identify trends, and anticipate disruptions, bridging the gap between data insights and operational action.

Continuous improvement processes are equally critical. CPIM certification encourages professionals to adopt a mindset of ongoing optimization, utilizing methodologies such as lean manufacturing and Six Sigma to reduce waste, enhance quality, and increase throughput. Candidates are trained to identify inefficiencies, implement corrective measures, and measure outcomes to ensure sustained improvement over time. These competencies contribute to both operational excellence and strategic competitiveness in increasingly dynamic markets.

Preparing for the CPIM exam requires a combination of structured study and practical application. The CPIM Learning System, developed by ASCM, provides a comprehensive self-study framework. This system includes detailed modules, practice questions, case studies, and simulations that replicate real-world supply chain challenges. Candidates are encouraged to allocate approximately 100 hours to study, though the exact duration varies depending on prior experience and familiarity with the subject matter. The system emphasizes iterative learning, allowing individuals to revisit challenging topics and reinforce key concepts.

Beyond self-study materials, additional resources can enhance preparation. Study groups, professional workshops, and online courses offer interactive opportunities to discuss complex topics, analyze scenarios, and clarify ambiguities. Engaging with peers and mentors provides insights into practical applications of theoretical concepts, bridging the gap between knowledge acquisition and operational execution. Professionals are encouraged to approach preparation with deliberate pacing, ensuring that understanding is deep rather than superficial.

Exam registration for CPIM certification is facilitated through Pearson VUE test centers or online proctoring systems. Candidates must obtain authorization to test before scheduling the exam, a process that ensures eligibility and confirms adherence to ASCM requirements. The examination environment emphasizes integrity, requiring adherence to protocols that preserve the credibility of the certification. Professionals are advised to simulate exam conditions during preparation, practicing time management, and question prioritization to optimize performance under actual test conditions.

The CPIM credential also encompasses ongoing professional development. Certification holders are required to earn professional development points every five years to maintain active status. These points can be earned through multiple avenues, including advanced coursework, attendance at workshops, publication of relevant articles, or participation in industry events. This requirement ensures that certified professionals remain current with evolving practices, technologies, and methodologies in supply chain management. The dynamic nature of global supply chains necessitates continuous learning, and CPIM provides a structured mechanism to encourage lifelong professional growth.

Earning CPIM certification offers tangible benefits beyond personal skill enhancement. Professionals with the credential are recognized for their ability to manage complex supply chain functions, optimize inventory, and contribute strategically to organizational objectives. Certification can enhance credibility in cross-functional teams, improve prospects for career advancement, and increase earning potential. Employers often view CPIM-certified individuals as capable of implementing best practices, reducing operational inefficiencies, and fostering innovation within supply chain operations.

The relevance of CPIM certification extends across industries. While commonly associated with manufacturing and logistics, the principles it encompasses apply to sectors as diverse as healthcare, retail, technology, and aerospace. Any organization that requires coordination of materials, resources, and production processes can benefit from personnel trained in planning, inventory management, and operational synchronization. This universality underscores the certification's value in equipping professionals with versatile, transferable competencies.

Finally, CPIM certification emphasizes strategic thinking. Professionals are encouraged to consider the broader implications of operational decisions, evaluating how inventory policies, production schedules, and supplier arrangements align with organizational goals. This strategic perspective fosters decision-making that balances efficiency, responsiveness, and risk mitigation, ensuring that supply chain operations contribute meaningfully to competitive advantage.

In summary, CPIM certification represents a comprehensive standard for expertise in supply chain planning and inventory management. Its integrated approach, encompassing operational detail, strategic alignment, technology utilization, and continuous improvement, equips professionals to navigate the intricacies of modern supply chains. Preparation for the exam involves structured study, practical application, and engagement with resources that replicate real-world scenarios. By earning and maintaining CPIM certification, professionals validate their competence, enhance their career trajectory, and contribute to the resilience, efficiency, and effectiveness of the organizations they serve.

CPIM Exam Structure and Preparation Strategies

The Certified in Planning and Inventory Management credential has evolved into a rigorous evaluation that reflects the complexities of contemporary supply chain operations. Understanding the structure of the CPIM exam is crucial for candidates seeking to achieve certification, as it provides a roadmap for both study and practical application. The CPIM 8.0 exam represents the most recent iteration, integrating topics previously distributed across multiple modules into a comprehensive assessment that evaluates proficiency in planning, inventory management, production scheduling, and operational efficiency.

The examination comprises 150 multiple-choice questions designed to test both conceptual understanding and practical problem-solving capabilities. Candidates are allocated three and a half hours to complete the exam, demanding not only technical knowledge but also time management skills, analytical reasoning, and strategic application of supply chain principles. The exam covers topics such as supply chain strategy, sales and operations planning, demand management, supply management, detailed scheduling, inventory management, distribution, quality assurance, technology utilization, and continuous improvement processes. Mastery of these domains enables professionals to make decisions that optimize performance across the supply chain ecosystem.

The scoring methodology for the CPIM exam employs a scaled system ranging from 200 to 350, with a passing score set at 300. This approach accounts for variations in question difficulty and ensures consistency in the evaluation process. Candidates must demonstrate not only an ability to recall information but also the capacity to apply knowledge in scenarios that replicate real-world operational challenges. The emphasis on applied understanding differentiates CPIM from purely theoretical assessments, highlighting the practical relevance of the credential for supply chain professionals.

A pivotal component of successful exam preparation is familiarity with the subject matter. The CPIM Learning System, developed by the Association for Supply Chain Management, provides a structured framework for study. This system includes detailed modules covering each exam topic, practice questions that simulate the exam environment, case studies reflecting real supply chain challenges, and interactive simulations that facilitate experiential learning. Candidates are encouraged to engage with the material iteratively, revisiting complex concepts and reinforcing knowledge through repeated practice and application.

Time management during preparation is critical. On average, candidates allocate approximately 100 hours to studying, though individual needs may vary based on prior experience and familiarity with supply chain concepts. A systematic approach is recommended, dividing study time across core domains while allowing for deeper focus on areas of personal challenge. Developing a study schedule that balances intensity with comprehension ensures that knowledge is retained rather than superficially memorized. Regular review sessions, coupled with practical exercises, enhance retention and application capabilities.

In addition to the Learning System, supplemental study resources can enrich preparation. Study groups and professional forums offer opportunities to discuss challenging topics, exchange problem-solving strategies, and gain insights from peers with diverse industry backgrounds. Mentorship from experienced supply chain professionals provides additional perspective, particularly in understanding how theoretical concepts translate into operational decisions. Engagement with multiple resources cultivates a multifaceted understanding, equipping candidates to navigate complex scenarios during the exam.

Simulation exercises constitute an essential component of practical preparation. By recreating supply chain scenarios, candidates develop skills in analyzing data, allocating resources, scheduling production, and managing inventory. These exercises promote critical thinking and reinforce the application of theoretical concepts to tangible operational challenges. For example, participants may be tasked with determining optimal reorder points for inventory or aligning production schedules with fluctuating demand forecasts. Such exercises mirror the types of problems encountered in real-world supply chain management, fostering both confidence and competence.

Technology plays an increasingly important role in preparation and professional practice. Familiarity with enterprise resource planning systems, predictive analytics tools, and automated inventory management platforms is advantageous. Candidates are encouraged to explore how these tools enhance decision-making, improve efficiency, and provide insights into supply chain performance. Integrating technological literacy with conceptual understanding ensures that professionals can navigate the digital complexities of modern operations effectively.

Exam-day strategies are equally critical. Candidates should familiarize themselves with the testing environment, whether at Pearson VUE centers or through online proctoring systems. Simulating exam conditions during practice sessions helps to acclimate to time constraints and the cognitive demands of sustained problem-solving. Strategic question management, including prioritization of complex items and efficient pacing, contributes to optimal performance. Attention to detail, careful reading of scenarios, and elimination of implausible options are fundamental techniques for enhancing accuracy under timed conditions.

Continuous assessment and feedback are integral to refining preparation. The CPIM Learning System includes diagnostic tools that highlight strengths and weaknesses across content areas. Regularly reviewing these diagnostics allows candidates to focus study efforts strategically, addressing gaps in knowledge while reinforcing areas of proficiency. This iterative approach fosters deeper comprehension, ensuring that understanding is both broad and nuanced. Additionally, engaging with practice exams under timed conditions cultivates endurance, decision-making speed, and confidence.

Maintaining motivation and focus during preparation is essential. The breadth of content can be daunting, encompassing topics ranging from supply chain strategy and sales and operations planning to inventory control, distribution, and continuous improvement methodologies. Setting incremental goals, monitoring progress, and celebrating milestones support sustained engagement. Visualization of the practical applications of CPIM knowledge—such as enhanced operational performance, strategic decision-making, and career advancement—reinforces commitment to the study process.

Resource management is another critical consideration. Candidates are encouraged to balance study with professional and personal responsibilities, ensuring that preparation is consistent but sustainable. Allocating specific periods for focused learning, free from distractions, maximizes cognitive absorption. Integrating practical exercises and scenario analysis into routine work tasks can also reinforce knowledge, providing immediate relevance and experiential reinforcement.

Collaboration enhances preparation effectiveness. Engaging in discussions with peers, mentors, and study groups facilitates exposure to diverse perspectives and problem-solving approaches. Supply chain challenges vary across industries, geographies, and organizational contexts; interacting with others broadens understanding and exposes candidates to alternative strategies and solutions. Collaborative learning fosters critical thinking, adaptability, and the ability to synthesize multiple sources of information—skills that are directly applicable to the CPIM exam and professional practice.

In addition to structured study materials, literature in supply chain management provides supplementary insights. Texts on lean manufacturing, Six Sigma methodologies, inventory optimization, and strategic sourcing enhance conceptual understanding. Case studies in diverse industries illuminate practical applications, demonstrating how principles are implemented in real-world operations. Engaging with such literature cultivates intellectual curiosity and encourages the development of problem-solving frameworks applicable both to the exam and professional environments.

Practical experience is invaluable. Candidates who apply supply chain concepts in their current roles gain an advantage in understanding the interconnectedness of planning, scheduling, inventory control, and distribution. Observing the effects of operational decisions on overall performance, evaluating process efficiencies, and experimenting with optimization strategies provide experiential learning that reinforces theoretical knowledge. Bridging practice and theory deepens comprehension, enhances retention, and develops the analytical skills required for success in the CPIM exam.

The integration of technology, practical application, and iterative study underscores the dynamic nature of CPIM preparation. Unlike rote memorization, certification emphasizes analytical reasoning, scenario evaluation, and strategic insight. Candidates are expected to interpret data, make informed decisions, and anticipate the effects of operational adjustments on the broader supply chain network. Preparation, therefore, is both cognitive and applied, blending knowledge acquisition with experiential engagement.

Finally, professional development continues beyond the exam. Certification holders are required to earn professional development points every five years to maintain active status. This requirement reinforces the principle that supply chain knowledge is not static; it evolves in response to technological advances, market dynamics, and organizational needs. Professionals are encouraged to pursue continuous learning through advanced courses, workshops, publications, and professional activities, ensuring that their expertise remains current and aligned with emerging best practices.

The CPIM exam represents a comprehensive evaluation of both technical knowledge and practical competence in supply chain management. Effective preparation involves understanding the exam structure, mastering the content domains, leveraging study systems, engaging in practical simulations, and integrating technological literacy. Time management, iterative learning, collaborative discussion, and practical application are essential components of readiness. By approaching preparation strategically, candidates not only enhance their likelihood of exam success but also cultivate enduring skills that elevate their professional capacity in planning, inventory management, and operational coordination within complex global supply chains.

Career Advantages and Professional Impact of CPIM Certification

Earning the Certified in Planning and Inventory Management credential opens a spectrum of opportunities for supply chain professionals, positioning them as highly capable individuals who can navigate complex operational landscapes. Beyond the acquisition of knowledge, CPIM certification functions as a tangible affirmation of professional competence, signaling mastery in planning, inventory control, production scheduling, and operational coordination. This credential not only enhances technical capability but also strengthens strategic influence within organizations.

A primary advantage of CPIM certification lies in its recognition of operational proficiency. Professionals holding this certification demonstrate an ability to optimize inventory accuracy, reduce stock levels, and ensure seamless synchronization between supply and demand. By improving the precision of demand forecasts and material requirement plans, CPIM-certified individuals contribute to more predictable production schedules, reduced wastage, and minimized operational disruption. These capabilities are essential in organizations where efficiency, responsiveness, and cost-effectiveness directly impact profitability and competitiveness.

The application of CPIM principles extends across a variety of functional areas. Sales and operations planning (S&OP) is one domain where certified professionals excel. Through S&OP, supply chain activities are aligned with business objectives, integrating input from marketing, production, and finance to develop actionable plans. CPIM-certified individuals facilitate cross-functional collaboration, reconcile conflicting priorities, and implement strategies that optimize resource allocation. The ability to translate analytical insights into practical operational improvements distinguishes professionals who have attained certification from their peers.

Inventory management, another central focus of CPIM, has far-reaching implications for operational efficiency. Proper inventory control ensures that materials are available to meet production schedules while avoiding excess holding costs or obsolete stock. CPIM-certified professionals employ methodologies such as just-in-time inventory, reorder point analysis, and safety stock optimization to balance these competing priorities. By applying these strategies, organizations achieve more predictable production flows, reduce capital tied up in inventory, and maintain responsiveness to market demand.

Material requirements planning (MRP) and capacity requirements planning (CRP) also benefit from CPIM expertise. These functions involve detailed analysis of production needs, resource allocation, and scheduling adjustments to align with fluctuating demand patterns. Professionals with certification understand how to coordinate these processes to prevent bottlenecks, optimize throughput, and maintain operational continuity. Their insights help organizations make informed decisions about production sequencing, resource utilization, and lead-time management, all of which contribute to higher efficiency and reliability.

The benefits of CPIM certification are not confined to operational performance alone. They extend into strategic decision-making and leadership within supply chain functions. Certified professionals are equipped to analyze complex scenarios, anticipate the implications of operational choices, and recommend actions that align with broader organizational objectives. This ability to bridge operational detail with strategic foresight enhances credibility in cross-functional teams, positioning CPIM-certified individuals as key contributors to organizational success.

Across industries, CPIM certification has broad applicability. While it is traditionally associated with manufacturing and logistics, its principles are relevant to healthcare, retail, technology, aerospace, and many other sectors. Any organization that coordinates materials, resources, and production processes can benefit from professionals trained in planning and inventory management. The universality of CPIM knowledge underscores its value in equipping professionals with adaptable, transferable competencies that transcend specific operational contexts.

In healthcare, for example, CPIM-certified professionals can optimize the inventory of pharmaceuticals, medical supplies, and equipment. Ensuring availability while minimizing waste is crucial in environments where supply shortages or overstocking can have significant consequences. Similarly, in retail, certified individuals contribute to inventory accuracy, product availability, and responsiveness to seasonal or fluctuating demand patterns. In technology and manufacturing, the expertise of CPIM professionals ensures that production schedules align with customer orders, minimizing delays and improving operational throughput.

Strategic sourcing and supplier relationship management are also enhanced through CPIM certification. Professionals learn to evaluate supplier performance, negotiate terms, and coordinate procurement activities to ensure reliability and efficiency. This expertise is particularly valuable in global supply chains, where sourcing decisions can be influenced by geopolitical, economic, or environmental factors. CPIM-certified individuals can anticipate disruptions, develop contingency strategies, and implement risk mitigation measures that preserve operational continuity.

CPIM certification also cultivates capabilities in quality management and continuous improvement. Professionals trained in these principles can identify inefficiencies, implement corrective measures, and monitor outcomes to ensure sustained improvement. Lean manufacturing and Six Sigma methodologies, often integrated into CPIM preparation, empower individuals to streamline processes, reduce waste, and enhance both product quality and operational efficiency. These competencies reinforce the credibility of certified professionals, positioning them as valuable assets in any supply chain context.

Career progression is another area positively influenced by CPIM certification. Certified professionals often experience accelerated advancement due to their validated expertise. By demonstrating competence in both operational detail and strategic planning, they become eligible for higher-responsibility roles, including production planning manager, supply chain manager, materials manager, or logistics coordinator. Employers recognize that CPIM-certified individuals possess the analytical skills, process knowledge, and strategic insight required to drive operational excellence and support organizational objectives.

Compensation is frequently correlated with certification attainment. CPIM-certified professionals typically earn higher salaries compared to non-certified peers, reflecting the value of their validated knowledge and demonstrated competencies. Average salaries in the United States for professionals holding CPIM credentials range broadly, depending on job title and responsibilities. Supply chain managers, for instance, can command substantial remuneration due to the critical impact of their role on operational efficiency, resource allocation, and organizational profitability. Production planners, materials managers, and supply chain analysts similarly benefit from increased earning potential, reflecting the enhanced operational value they bring to organizations.

The professional network gained through CPIM certification adds another dimension to career advancement. Engagement with other certified professionals, industry groups, and professional development forums provides access to diverse perspectives, best practices, and emerging trends. Networking opportunities foster collaboration, mentorship, and knowledge exchange, enriching the professional experience and enabling individuals to stay abreast of evolving practices in supply chain management. This network also supports career mobility, as professionals can leverage connections for opportunities in different industries, geographies, or functional areas.

In addition to individual career benefits, CPIM certification contributes to organizational success. Certified professionals enhance operational efficiency, reduce costs, and improve service levels, leading to better customer satisfaction and competitive positioning. Organizations that employ CPIM-certified personnel are better equipped to navigate supply chain disruptions, implement strategic initiatives, and adapt to market volatility. This dual benefit—personal career growth and organizational advantage—underscores the strategic value of the certification in contemporary business environments.

Decision-making within supply chains is profoundly impacted by CPIM knowledge. Certified professionals can analyze inventory data, interpret demand trends, and develop actionable plans that optimize production and distribution. Their understanding of interdependencies within supply chains allows them to anticipate bottlenecks, allocate resources effectively, and implement corrective actions before issues escalate. This proactive approach enhances operational stability, reduces waste, and increases responsiveness to changing market conditions.

The international recognition of CPIM certification enhances global mobility for professionals. As supply chains increasingly span multiple countries and continents, organizations value personnel who understand global sourcing, logistics coordination, and cross-cultural operational challenges. CPIM-certified individuals are equipped to navigate these complexities, facilitating seamless collaboration across geographic boundaries and contributing to efficient, resilient global supply chain networks.

Moreover, CPIM certification fosters a mindset of continuous improvement and lifelong learning. Certified professionals are encouraged to maintain an active status through professional development activities, ensuring that their knowledge remains current with evolving technologies, methodologies, and industry practices. This commitment to ongoing learning reinforces adaptability, analytical acuity, and operational competence, qualities that are increasingly essential in rapidly changing supply chain environments.

The practical applications of CPIM knowledge extend to process optimization, risk management, supplier collaboration, and operational strategy. By mastering planning, inventory control, production scheduling, and continuous improvement techniques, certified professionals enable organizations to operate more efficiently, reduce costs, enhance product quality, and improve delivery performance. These outcomes are critical in competitive industries where operational excellence and responsiveness to market dynamics confer a significant advantage.

Finally, CPIM certification instills confidence in professionals tasked with overseeing complex supply chain operations. The structured understanding of planning and inventory management principles empowers individuals to make informed decisions, communicate effectively with stakeholders, and contribute strategically to organizational objectives. This confidence is reinforced through practical experience, study preparation, and engagement with peers, culminating in a professional who is both technically proficient and strategically aware.

CPIM certification provides a multitude of career advantages, encompassing technical mastery, strategic insight, operational efficiency, and enhanced professional credibility. Certified individuals contribute to organizational performance by optimizing inventory management, improving production schedules, and facilitating cross-functional coordination. Their expertise is applicable across diverse industries, from manufacturing and retail to healthcare and technology, and is increasingly valued in global supply chains. The credential also supports career progression, higher earning potential, professional networking, and lifelong learning, making it a compelling investment for those seeking to excel in the multifaceted world of supply chain management.

Maintaining CPIM Certification and Future Trends in Supply Chain Management

Achieving the Certified in Planning and Inventory Management credential is a significant professional milestone, yet the journey does not end upon passing the exam. Maintaining CPIM certification requires ongoing engagement, continuous learning, and adaptation to the evolving dynamics of supply chain management. The credential is structured to ensure that certified professionals remain proficient in current practices, emerging technologies, and innovative methodologies that define modern operational excellence.

CPIM certification remains active for a five-year period, during which professionals must accrue professional development points to retain their credential. These points can be earned through a variety of activities designed to reinforce both theoretical knowledge and practical competence. Engagement in advanced coursework, participation in workshops and seminars, publication of industry-relevant articles, and contributions to professional forums all qualify as avenues for accumulating the requisite points. This structure fosters a culture of continuous improvement, encouraging professionals to remain at the forefront of supply chain best practices.

The requirement for ongoing professional development reflects the dynamic nature of supply chains themselves. Global supply chains are influenced by a multitude of factors, including technological advancements, shifting consumer behaviors, geopolitical considerations, and environmental sustainability imperatives. Certified professionals must therefore remain agile, incorporating new tools, strategies, and insights into their operational repertoire. By doing so, they ensure that their expertise continues to provide tangible value to organizations and enhances their strategic decision-making capabilities.

Technology plays an increasingly central role in the maintenance of supply chain expertise. Digital tools such as enterprise resource planning software, predictive analytics, artificial intelligence, and blockchain have transformed the ways in which inventory, production, and logistics are managed. CPIM-certified professionals must not only understand these technologies but also leverage them to optimize processes, anticipate disruptions, and enhance efficiency. Integration of technology into daily operations allows for more accurate demand forecasting, improved resource allocation, and real-time monitoring of supply chain performance.

Emerging trends in supply chain management underscore the importance of adaptability and forward-thinking. Sustainability has become a critical consideration, with organizations seeking to reduce their environmental footprint through responsible sourcing, energy-efficient manufacturing, and optimized transportation. Professionals with CPIM certification are well-positioned to contribute to these initiatives, applying inventory and planning expertise to minimize waste, enhance efficiency, and align operational practices with ecological objectives. Strategic decision-making that incorporates sustainability considerations is increasingly recognized as essential for long-term competitiveness.

Globalization continues to shape supply chain dynamics, presenting both opportunities and challenges. Cross-border procurement, multi-modal logistics, and international regulatory compliance require a sophisticated understanding of global operations. CPIM-certified individuals are equipped to navigate these complexities, ensuring that planning, inventory management, and production coordination are aligned with both local requirements and international standards. This global perspective enhances resilience, reduces risk, and supports seamless operational integration across diverse markets.

Risk management is another critical focus for maintaining CPIM relevance. Supply chain disruptions can result from natural disasters, political instability, economic fluctuations, or unforeseen operational issues. Certified professionals employ strategies such as dual sourcing, contingency planning, buffer inventory, and scenario analysis to mitigate risk. By anticipating potential challenges and implementing preemptive measures, they ensure continuity of operations, protect organizational resources, and maintain service levels even under adverse conditions. Continuous monitoring and adaptation are key components of effective risk management in complex supply chains.

Professional networking also contributes to the ongoing value of CPIM certification. Engagement with peers, mentors, and industry groups provides opportunities for knowledge exchange, collaborative problem-solving, and exposure to innovative practices. Networking facilitates professional growth, enabling individuals to share insights, learn from case studies, and remain informed about emerging trends. These interactions complement formal professional development activities, creating a comprehensive framework for sustained expertise and career advancement.

Mentorship and leadership development are increasingly recognized as integral aspects of maintaining supply chain proficiency. CPIM-certified professionals often assume roles that require guiding teams, influencing cross-functional decisions, and mentoring junior colleagues. The ability to convey knowledge effectively, foster collaboration, and develop talent within the organization amplifies the impact of the certification. Leadership in supply chain management involves both operational acumen and interpersonal skills, bridging technical expertise with strategic influence.

The CPIM framework also encourages the adoption of continuous improvement methodologies. Lean manufacturing, Six Sigma, and process optimization techniques remain central to professional practice. Certified individuals are expected to identify inefficiencies, implement corrective actions, and monitor outcomes to ensure sustained operational enhancement. Continuous improvement initiatives contribute to reduced waste, enhanced product quality, and improved throughput, reinforcing the credibility and value of CPIM-certified professionals within their organizations.

Education and professional growth are intertwined with the evolution of supply chain practices. Participation in industry conferences, webinars, and specialized training sessions allows professionals to stay abreast of innovations in logistics, inventory management, and production planning. Learning about novel approaches, such as predictive analytics in demand forecasting or advanced automation in manufacturing, equips CPIM-certified individuals to anticipate shifts in operational paradigms and adapt their strategies accordingly. This proactive engagement ensures that certification remains a marker of current, actionable expertise.

The future of supply chain management is increasingly influenced by data-driven decision-making. The ability to collect, analyze, and interpret vast amounts of operational data is transforming how organizations plan, execute, and optimize supply chain activities. CPIM-certified professionals leverage data analytics to forecast demand, streamline production schedules, reduce inventory holding costs, and enhance distribution efficiency. This analytical proficiency is critical in navigating the complexities of modern supply chains, where timely and accurate information directly impacts operational performance and strategic outcomes.

Integration of artificial intelligence and machine learning into supply chain processes represents another transformative trend. Predictive modeling, algorithmic optimization, and autonomous systems are reshaping production planning, logistics coordination, and inventory control. Professionals maintaining CPIM certification are encouraged to understand these emerging tools, assess their applicability, and incorporate them into operational workflows. By combining foundational planning expertise with advanced technological insights, certified individuals enhance organizational agility and competitive advantage.

Sustainability, resilience, and technological adaptation converge in the evolving landscape of supply chain management. CPIM certification equips professionals to address these multidimensional challenges, providing a foundation in planning, inventory control, and operational optimization while fostering strategic insight. Certified individuals are positioned to design supply chains that are efficient, responsive, and adaptable, aligning operational practices with organizational objectives, stakeholder expectations, and environmental considerations.

Continuous development also emphasizes soft skills, including communication, negotiation, and cross-functional collaboration. Managing complex supply chain operations requires not only technical competence but also the ability to coordinate with diverse teams, resolve conflicts, and influence decision-making. CPIM-certified professionals integrate these skills with operational knowledge, enhancing their effectiveness in guiding teams, implementing process improvements, and contributing strategically to organizational performance. Leadership, mentorship, and interpersonal acuity are therefore essential complements to technical expertise in maintaining certification relevance.

Professional development strategies for CPIM maintenance may include formal education, experiential learning, and participation in industry initiatives. Advanced courses in supply chain management, operational analytics, and strategic sourcing provide structured opportunities to deepen knowledge. Experiential learning, such as project leadership or cross-functional collaboration, reinforces practical application. Engagement in industry initiatives, such as standards committees or professional networks, enhances awareness of emerging trends and fosters thought leadership. Collectively, these approaches support a comprehensive and dynamic framework for sustaining CPIM proficiency.

The evolving nature of global supply chains requires continuous reflection and adaptation. Certified professionals are expected to monitor performance metrics, evaluate operational outcomes, and implement improvements in response to changing conditions. Scenario planning, predictive forecasting, and strategic analysis become routine components of practice, enabling organizations to anticipate disruptions, optimize resource utilization, and maintain service levels. CPIM certification provides the conceptual and practical foundation necessary to execute these responsibilities effectively.

Finally, maintaining CPIM certification ensures alignment with both professional and organizational objectives. Certified professionals contribute to operational excellence, strategic resilience, and sustainable practices, creating tangible value for employers and stakeholders. By engaging in ongoing professional development, adopting emerging technologies, and embracing continuous improvement, CPIM-certified individuals ensure that their expertise remains relevant, impactful, and aligned with the dynamic landscape of global supply chains. This commitment to growth, adaptation, and excellence defines the future of supply chain leadership.

CPIM certification is not merely an endpoint but a gateway to sustained professional development and operational mastery. Maintaining the credential requires ongoing education, practical application, engagement with emerging trends, and adaptation to evolving technologies and methodologies. Certified professionals are empowered to navigate complex global supply chains, optimize planning and inventory management, and contribute strategically to organizational success. By embracing continuous learning, technological innovation, and leadership development, CPIM-certified individuals remain at the forefront of supply chain excellence, prepared to meet the challenges and opportunities of an ever-changing operational landscape.

Conclusion

Global supply chains are intricate networks that connect suppliers, manufacturers, and consumers across regions, requiring precise coordination, strategic insight, and operational expertise. The Certified in Planning and Inventory Management credential embodies this mastery, validating skills in planning, inventory control, production scheduling, and process optimization. CPIM certification equips professionals to navigate the complexities of modern supply chains, from aligning demand and supply to implementing continuous improvement initiatives and leveraging emerging technologies. Beyond technical proficiency, the credential fosters strategic thinking, leadership, and adaptability, empowering professionals to drive operational efficiency and organizational success. Maintaining certification encourages continuous learning, integration of advanced tools, and responsiveness to evolving market and technological trends. Ultimately, CPIM provides a framework for building resilient, efficient, and sustainable supply chains while enhancing career prospects, professional credibility, and strategic impact. It stands as both a milestone and a gateway to lifelong growth in the dynamic field of supply chain management.