Exam Code: Cybersecurity Fundamentals Specialist

Exam Name: Cybersecurity Fundamentals Specialist

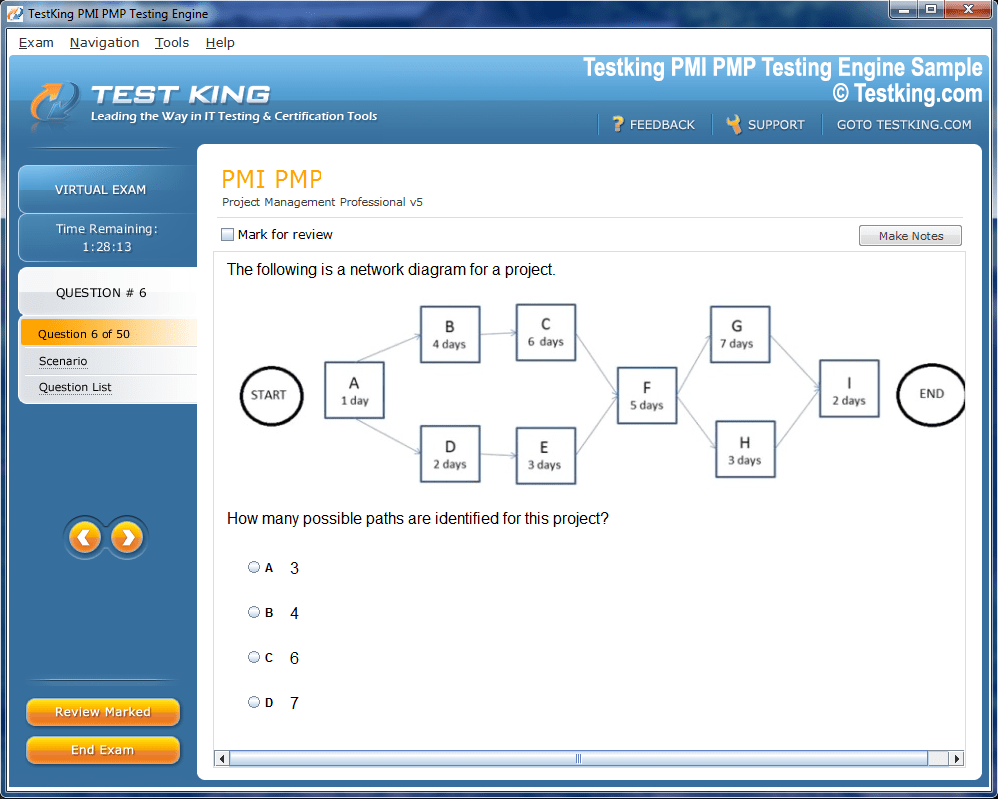

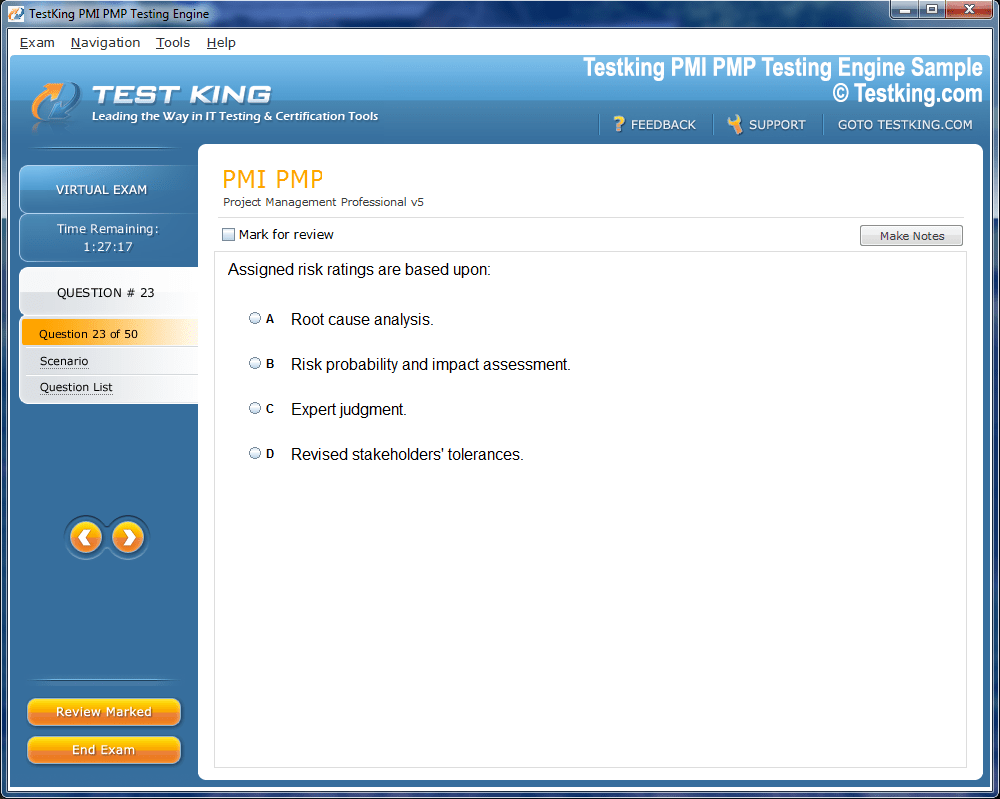

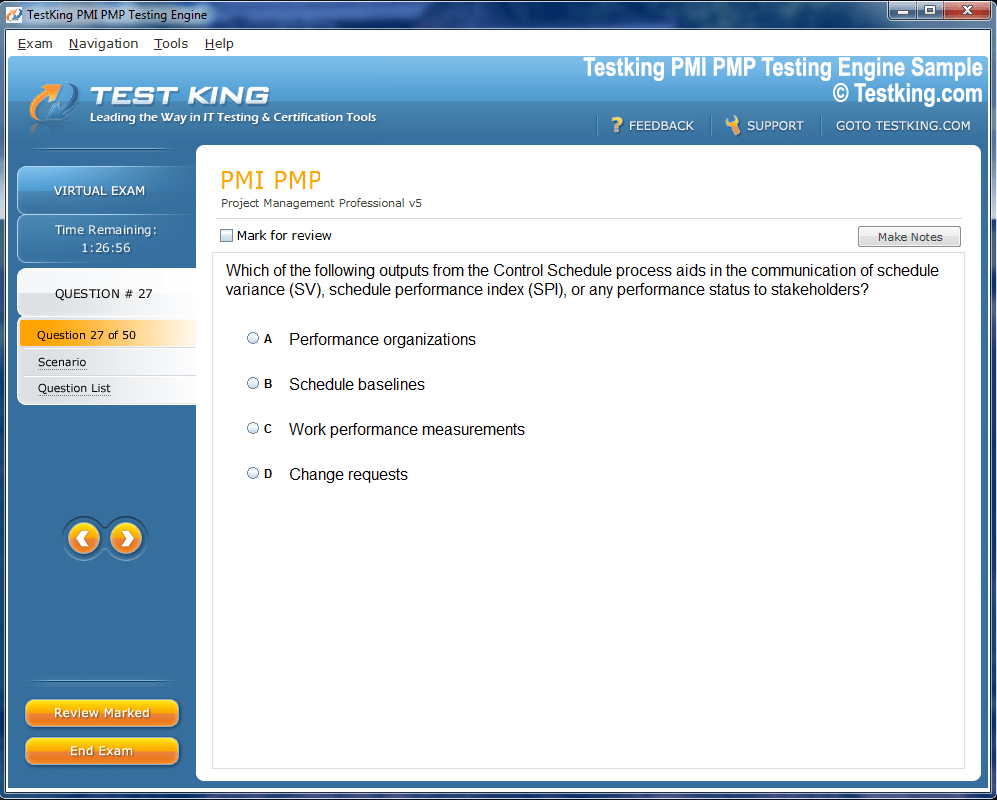

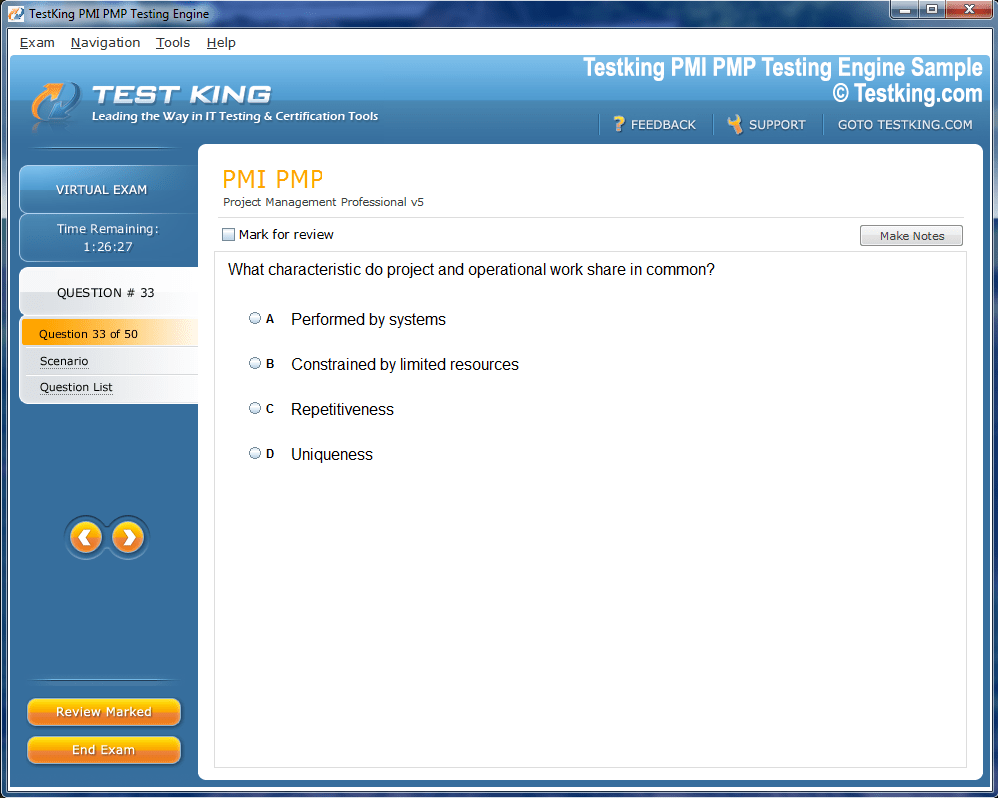

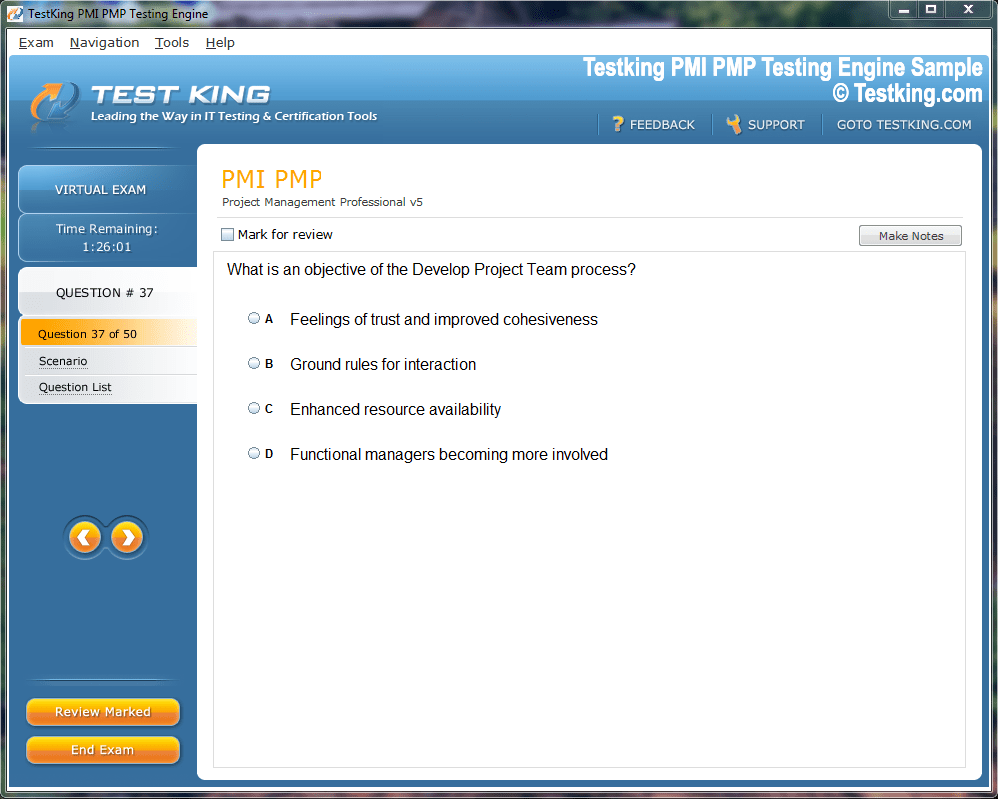

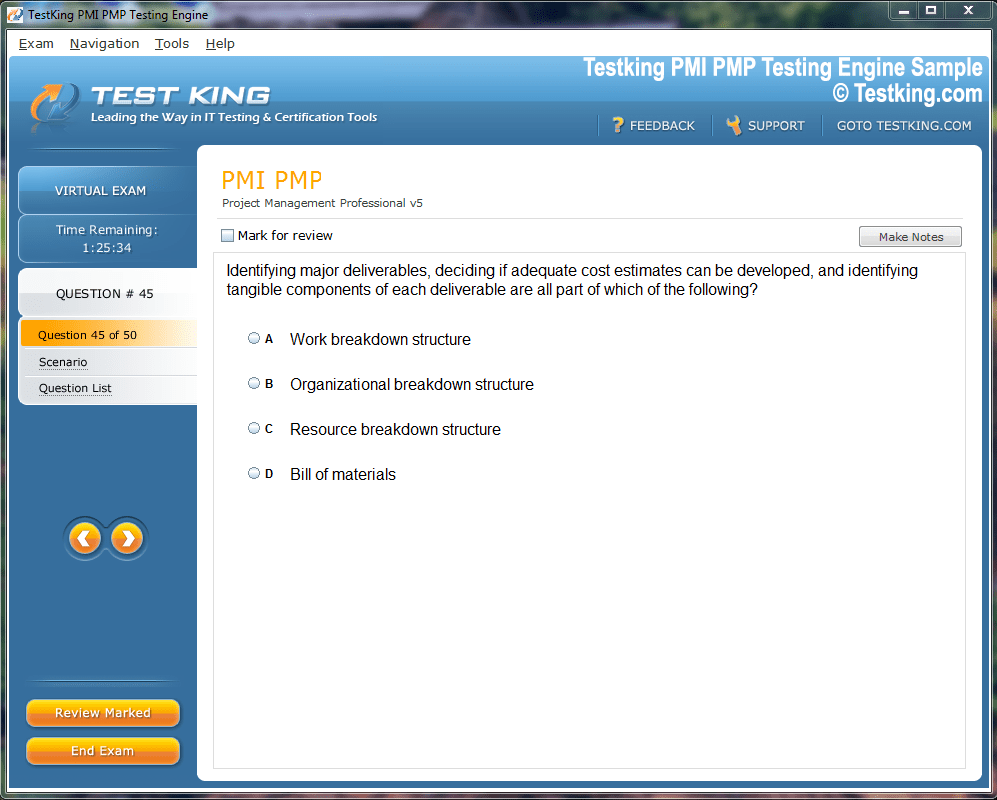

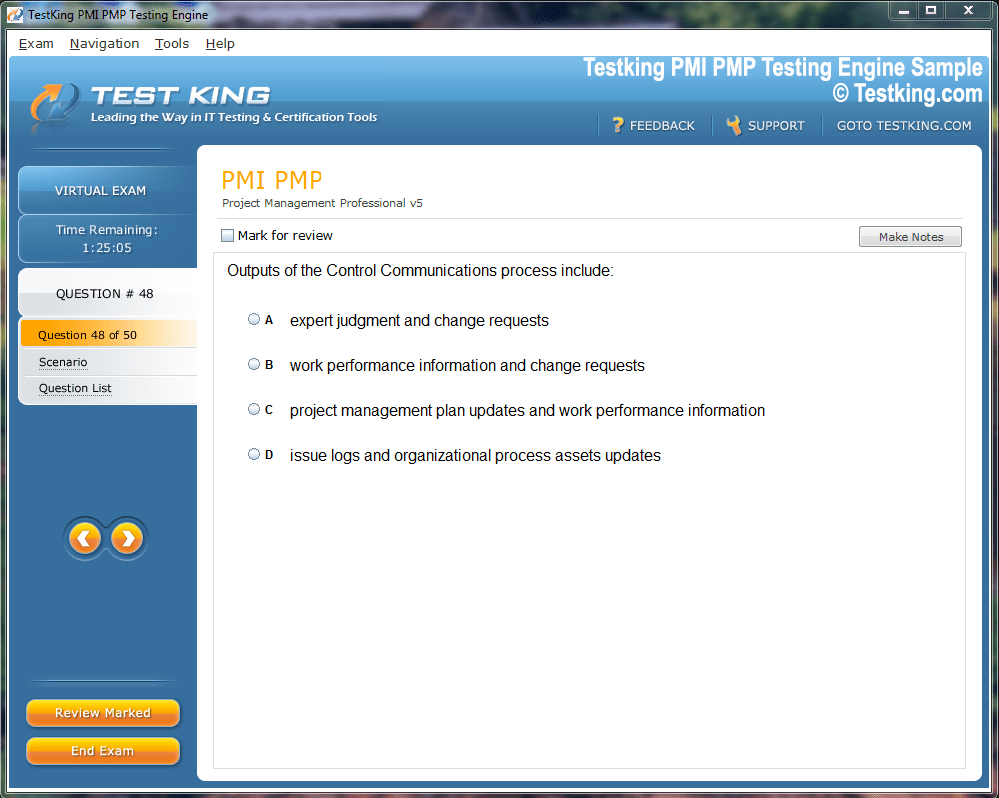

Product Screenshots

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our Cybersecurity Fundamentals Specialist testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.

Understanding Risk Assessment through ISA Cybersecurity Fundamentals Specialist

Industrial cybersecurity has emerged as a vital discipline within the modern landscape of automation and control systems. The increasing interconnectivity of industrial operations, combined with the proliferation of sophisticated cyber threats, has necessitated the development of robust security frameworks. Among these, the ISA/IEC 62443 standards have become the definitive benchmark, providing a globally recognized, consensus-based structure for safeguarding industrial automation and control systems (IACS). These standards offer a comprehensive approach, encompassing the full lifecycle of industrial systems—from initial assessment and design to implementation, operations, and maintenance.

The essence of industrial cybersecurity lies in understanding the unique vulnerabilities that industrial control systems present. Unlike conventional IT networks, industrial systems operate in real-time environments, where downtime or disruptions can have significant safety and financial repercussions. Consequently, cybersecurity measures must be meticulously designed to integrate with operational processes without impeding the efficiency or functionality of the system. ISA/IEC 62443 standards address this complexity by providing structured guidance on managing risk, implementing secure architectures, and maintaining resilient operations.

The ISA industrial cybersecurity training program and certificate recognition initiative are designed around these standards. This program equips professionals with the knowledge necessary to comprehend industrial cybersecurity terminology, assess vulnerabilities, and apply standardized practices effectively. Participants in this program engage with detailed curricula that cover a wide spectrum of topics, including network segmentation, secure configuration of industrial devices, authentication protocols, incident response, and ongoing maintenance practices. Each of these elements plays a crucial role in fortifying industrial environments against potential cyber intrusions.

The Role of ISA/IEC 62443 in Industrial Automation Security

ISA/IEC 62443 serves as a foundational pillar for cybersecurity in industrial automation. It is the only series of standards that has achieved global consensus, reflecting inputs from multiple stakeholders, including government agencies, industrial operators, and technology providers. This universality ensures that practices and guidelines derived from these standards are not only comprehensive but also adaptable across various industries, including energy, manufacturing, oil and gas, transportation, and critical infrastructure.

The framework of ISA/IEC 62443 is designed to address the entire industrial system lifecycle. During the assessment phase, organizations are guided to identify vulnerabilities in both existing and new systems. Risk assessment methodologies outlined in the standards provide a structured approach to quantify potential impacts, prioritize security measures, and allocate resources effectively. The design phase emphasizes the development of secure architectures, implementing measures such as network segmentation, access control mechanisms, and secure communication protocols.

The implementation and operations phases focus on the practical application of security measures. This includes configuring industrial devices securely, establishing robust authentication processes, deploying intrusion detection systems, and integrating monitoring tools to detect anomalies. Maintenance is equally critical, involving regular updates, patch management, and periodic audits to ensure ongoing compliance with security standards. By addressing each stage of the lifecycle, ISA/IEC 62443 fosters a holistic approach to industrial cybersecurity, minimizing the risk of both accidental and malicious disruptions.

Professional Development and Training Structure

The industrial cybersecurity training program is particularly suitable for professionals in IT and control system security roles. It is designed to cultivate expertise in managing cybersecurity risks specific to industrial environments. Participants develop proficiency in interpreting and applying the ISA/IEC 62443 standards, gaining insight into both theoretical frameworks and practical implementation strategies.

The program follows a structured progression through multiple certificate levels. The foundational course, Certificate 1, introduces participants to core principles of industrial cybersecurity, providing a grounding in terminology, concepts, and the structure of the ISA/IEC 62443 standards. Completion of this course is a prerequisite for subsequent levels, ensuring that all participants possess a uniform understanding before advancing to more specialized areas.

Subsequent certificates focus on distinct phases of the IACS lifecycle. The second certificate concentrates on risk assessment, enabling participants to evaluate vulnerabilities, identify critical assets, and develop strategies to mitigate threats. The third certificate emphasizes system design, guiding professionals in constructing secure architectures that integrate seamlessly with operational processes. The fourth certificate addresses maintenance and operational security, equipping participants to sustain resilient systems through ongoing monitoring, updates, and incident response measures.

The culmination of these four certificates confers the designation of ISA/IEC 62443 Cybersecurity Expert. This title signifies a comprehensive mastery of industrial cybersecurity principles, validated through rigorous training and examination. The certification process emphasizes not only theoretical understanding but also the practical ability to apply standards effectively within complex industrial environments.

Recommended Experience and Preparation

Although there are no mandatory prerequisites for enrolling in the training program, certain prior experiences are advantageous. Professionals with three to five years of IT cybersecurity experience, particularly those with exposure to industrial settings, are better positioned to engage with the material. A minimum of two years in a process control engineering environment provides valuable context, allowing participants to relate theoretical concepts to real-world operational scenarios.

Familiarity with the ISA/IEC 62443 standards can further enhance comprehension, although it is not required for entry. The advanced courses within the program do suggest prior knowledge or completion of foundational courses, ensuring participants are adequately prepared to tackle complex subjects. Certificate 1 serves as the gateway, establishing essential knowledge before progression to higher levels.

The recommended experience emphasizes both technical expertise and contextual awareness. Professionals who understand the intricacies of industrial operations, communication protocols, and control system architectures can more effectively integrate cybersecurity measures. This background facilitates a nuanced understanding of risk assessment, system design, and operational maintenance, all of which are central to the ISA/IEC 62443 framework.

Certificate Structure and Progression

The certification program is composed of four primary levels, each corresponding to a specific phase of industrial cybersecurity. Certificate 1, the Cybersecurity Fundamentals Specialist, introduces participants to the ISA/IEC 62443 standards, covering essential terminology, concepts, and general practices. It establishes the foundation for all subsequent certificates and ensures participants possess a comprehensive understanding of industrial cybersecurity principles.

Certificate 2 focuses on risk assessment, guiding participants to evaluate system vulnerabilities, analyze potential threats, and develop mitigation strategies. This stage emphasizes the application of structured methodologies to quantify risk, prioritize corrective measures, and implement safeguards effectively. Participants learn to perform detailed security assessments, integrate findings into operational strategies, and communicate risk insights to stakeholders.

Certificate 3 addresses system design, providing detailed instructions on constructing secure industrial architectures. Participants explore methods for segmenting networks, implementing secure access controls, deploying encryption, and ensuring reliable communication between devices. This phase integrates both theoretical frameworks and practical exercises, fostering the ability to design resilient systems capable of withstanding cyber threats.

Certificate 4 covers operations and maintenance, focusing on the sustainability of industrial cybersecurity practices. Participants learn to implement monitoring systems, perform routine audits, manage software updates, and respond to incidents. Emphasis is placed on continuity and resilience, ensuring that security measures remain effective throughout the operational lifespan of the industrial system.

Upon completion of all four certificates, professionals achieve the designation of ISA/IEC 62443 Cybersecurity Expert. This recognition reflects comprehensive expertise across assessment, design, implementation, operations, and maintenance of industrial cybersecurity measures. It signals readiness to manage complex security challenges within diverse industrial environments.

Training Delivery Formats

The industrial cybersecurity program offers multiple formats to accommodate different learning preferences and professional schedules. Classroom-based sessions provide an immersive environment with direct interaction with instructors and peers, facilitating hands-on exercises and collaborative problem-solving. Virtual classrooms replicate this interactive experience through online platforms, enabling remote participation without sacrificing engagement or instructional quality.

Instructor-guided online courses provide flexible learning while maintaining structured guidance, ensuring participants receive support while progressing through modules. Self-paced modular formats allow learners to control the pace of their study, revisiting content as needed and accommodating professional commitments. Each format includes access to the same core curriculum, exercises, and examination process, ensuring consistency in learning outcomes regardless of delivery method.

The diversity in delivery formats allows professionals to tailor their learning experience, balancing the demands of ongoing work responsibilities with the acquisition of advanced cybersecurity expertise. Regardless of the chosen format, the program emphasizes applied learning, with exercises and scenarios designed to mirror real-world industrial environments.

The Importance of Holistic Cybersecurity

Industrial cybersecurity is inherently interdisciplinary, requiring knowledge of IT networks, control systems, operational processes, and regulatory frameworks. The ISA/IEC 62443 standards address this complexity by promoting a lifecycle approach that integrates assessment, design, implementation, operations, and maintenance. Each stage reinforces the others, creating a comprehensive security posture that mitigates vulnerabilities, minimizes risk, and enhances operational resilience.

Holistic cybersecurity recognizes that vulnerabilities may exist at multiple levels, from network infrastructure and device configurations to human factors and procedural gaps. By systematically addressing each element, professionals can design and maintain systems that are robust against both internal errors and external attacks. The training program reinforces this philosophy, equipping participants to analyze industrial environments comprehensively, implement multi-layered defenses, and sustain security measures over time.

Risk Assessment and Threat Mitigation in Industrial Cybersecurity

Industrial cybersecurity is intrinsically tied to the principles of risk assessment and threat mitigation. Industrial automation and control systems (IACS) operate in environments where operational continuity is critical, and any disruption can lead to significant safety hazards, economic losses, and regulatory repercussions. The ISA/IEC 62443 standards provide a structured methodology for identifying, evaluating, and mitigating risks across the industrial system lifecycle. This approach ensures that both existing and emerging threats are addressed proactively, reinforcing the resilience of industrial operations.

The foundation of risk assessment in industrial cybersecurity involves the identification of critical assets and the evaluation of their susceptibility to cyber threats. Professionals are trained to analyze system components, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, actuators, and communication networks. Each component is examined for potential vulnerabilities, such as insecure configurations, outdated firmware, weak authentication protocols, and exposure to external networks. By systematically identifying weak points, cybersecurity specialists can prioritize remediation efforts, focusing on the most critical vulnerabilities first.

Threat modeling plays a pivotal role in industrial cybersecurity. This process involves anticipating potential attack vectors, understanding the tactics employed by malicious actors, and evaluating the potential impact of breaches. The ISA/IEC 62443 framework emphasizes the need for a structured, repeatable approach to threat analysis, incorporating both historical data and predictive modeling. By mapping threats against system vulnerabilities, organizations can develop targeted mitigation strategies, ensuring that defenses are both comprehensive and efficient.

Structured Approaches to Risk Mitigation

Once risks have been identified and evaluated, the next phase involves the implementation of mitigation measures. Risk mitigation in industrial cybersecurity often requires a combination of technical, procedural, and administrative controls. Technical measures include network segmentation, encryption of sensitive communications, deployment of firewalls, and intrusion detection systems. These measures are designed to prevent unauthorized access, detect suspicious activity, and maintain the integrity of operational processes.

Procedural controls involve the establishment of operational policies and best practices that minimize risk. Examples include strict change management protocols, secure configuration guidelines, and documented incident response procedures. Administrative controls encompass training programs, access management policies, and continuous monitoring initiatives. The synergy of technical, procedural, and administrative controls creates a multi-layered defense, often referred to as defense-in-depth, which enhances the resilience of industrial systems against cyber threats.

Regular audits and assessments are integral to effective risk mitigation. Industrial systems evolve, with new devices, software updates, and process changes introducing potential vulnerabilities. Continuous monitoring, combined with periodic audits, ensures that security measures remain current and effective. Professionals trained in ISA/IEC 62443 standards are equipped to conduct these assessments, analyzing both technical configurations and operational practices to ensure alignment with best practices and compliance requirements.

Cybersecurity Design for Industrial Systems

Designing secure industrial systems requires a deep understanding of both operational processes and cybersecurity principles. The ISA/IEC 62443 standards provide detailed guidance on constructing architectures that minimize vulnerabilities while maintaining operational efficiency. Network segmentation is a fundamental concept, separating critical systems from less sensitive areas to limit exposure in the event of a breach. This compartmentalization helps contain potential attacks and reduces the likelihood of cascading failures.

Access control mechanisms are another critical aspect of secure system design. Role-based access controls (RBAC) and identity management protocols ensure that only authorized personnel can interact with critical components. Authentication measures, such as multi-factor authentication (MFA) and cryptographic certificates, reinforce the integrity of access controls. These design elements are complemented by secure communication protocols, which safeguard data integrity and confidentiality during transmission between devices and control systems.

Secure design extends beyond technical configurations to include operational considerations. Professionals must consider maintenance schedules, firmware updates, and system redundancy to maintain continuity during both planned and unplanned events. The ISA/IEC 62443 standards emphasize the integration of security into every stage of the design process, ensuring that protections are not merely reactive but proactively embedded into the architecture of the system.

Operational Security and Maintenance Practices

The operational phase of industrial cybersecurity focuses on sustaining secure environments and minimizing the impact of potential incidents. Continuous monitoring is essential, with real-time data collection and analysis providing insights into system performance and potential threats. Intrusion detection systems, log analysis, and anomaly detection tools enable early identification of irregular activities, allowing for rapid intervention before incidents escalate.

Maintenance practices are equally important in preserving the security posture of industrial systems. Regular updates to software and firmware ensure that known vulnerabilities are addressed promptly. Patch management programs, combined with verification processes, help maintain system integrity while minimizing disruptions to operational processes. Periodic audits and inspections provide a mechanism to evaluate the effectiveness of security measures and identify areas for improvement.

Incident response planning is a crucial component of operational security. Well-defined procedures guide personnel through detection, containment, eradication, and recovery phases. By establishing clear roles, responsibilities, and communication channels, organizations can respond efficiently to cybersecurity events, minimizing downtime and mitigating potential losses. The ISA/IEC 62443 standards offer structured guidance for incident response, emphasizing preparedness, coordination, and continuous improvement.

Professional Expertise in Industrial Cybersecurity

The effectiveness of industrial cybersecurity measures relies heavily on the expertise of the professionals implementing them. The ISA/IEC 62443 training program is designed to cultivate this expertise, providing a blend of theoretical knowledge and practical skills. Participants develop a thorough understanding of terminology, standards, and best practices, enabling them to design, implement, and maintain secure industrial environments.

Certification progression ensures that participants acquire knowledge in a structured manner. Foundational training in Certificate 1 establishes essential concepts, terminology, and lifecycle considerations. Subsequent certificates build on this foundation, focusing on risk assessment, system design, and operational maintenance. Completion of all four certificates demonstrates comprehensive expertise, recognized through the ISA/IEC 62443 Cybersecurity Expert designation.

The training also emphasizes problem-solving and analytical skills. Professionals learn to assess complex systems, identify vulnerabilities, and develop effective mitigation strategies. Case studies, simulations, and practical exercises reinforce learning, bridging the gap between theoretical concepts and real-world application. This combination of knowledge and skill ensures that certified professionals can respond effectively to evolving cyber threats.

Fast-Track Training and Comprehensive Learning

To accommodate professionals seeking accelerated certification, the ISA/IEC 62443 program offers a fast-track course that consolidates key content from Certificates 2, 3, and 4. This intensive five-day program covers risk assessment, system design, and operational security, enabling participants to prepare for multiple certification exams simultaneously. Completion of the foundational Certificate 1 remains a prerequisite, ensuring that participants possess the necessary baseline knowledge.

The fast-track course emphasizes practical application, integrating assessment techniques, design principles, and operational practices into a cohesive learning experience. Participants engage with real-world scenarios, exploring vulnerabilities, analyzing threats, and implementing mitigation strategies in simulated environments. This approach reinforces critical thinking and decision-making skills, preparing professionals to address challenges across diverse industrial settings.

Upon completion of the fast-track course, participants may take individual certification exams in any order. This flexibility accommodates varying professional schedules and allows learners to focus on areas where additional mastery is required. Successful completion of all four certificates confers the Cybersecurity Expert designation, reflecting comprehensive knowledge and practical expertise across the industrial system lifecycle.

Industry Applications and Cross-Sector Relevance

The principles of industrial cybersecurity extend across multiple sectors, from energy and manufacturing to transportation and critical infrastructure. The ISA/IEC 62443 standards provide a universal framework that can be adapted to different operational contexts, addressing sector-specific threats while maintaining core security principles. This cross-sector relevance enhances the value of professional certification, equipping individuals with skills that are widely applicable and highly sought after.

In energy production and distribution, for example, secure system design and robust risk assessment are essential to prevent disruptions that could impact public safety and economic stability. In manufacturing, operational continuity depends on resilient automation systems that can withstand both accidental and malicious disruptions. Transportation systems require integrated cybersecurity measures to protect both operational technology and passenger safety. Across these sectors, the ability to apply standardized practices in contextually appropriate ways is a hallmark of professional expertise.

Integrating Security into Organizational Culture

Effective industrial cybersecurity extends beyond technical measures, requiring integration into organizational culture. Professionals trained in ISA/IEC 62443 standards are equipped to promote security awareness, establish operational policies, and foster a culture of vigilance. Organizational buy-in is critical, ensuring that security practices are consistently applied, supported by leadership, and reinforced through training and procedural compliance.

Cultivating a security-conscious culture involves regular communication, education, and collaboration. Employees at all levels must understand the importance of security practices, recognize potential threats, and follow established protocols. Professionals with certification are uniquely positioned to guide these initiatives, translating technical requirements into actionable organizational practices that enhance overall resilience.

Lifelong Learning and Continuous Improvement

The dynamic nature of cyber threats necessitates ongoing learning and adaptation. Industrial systems evolve, new vulnerabilities emerge, and attack methods become increasingly sophisticated. Professionals must continuously update their knowledge, review operational practices, and refine mitigation strategies to remain effective. The ISA/IEC 62443 certification framework encourages this mindset of continuous improvement, emphasizing the importance of staying current with standards, technologies, and industry best practices.

Participation in advanced courses, workshops, and professional communities supports lifelong learning. Engagement with peers, subject matter experts, and evolving research ensures that certified professionals maintain relevance and efficacy in their roles. This commitment to ongoing development reinforces the value of the ISA/IEC 62443 framework, fostering expertise that is resilient, adaptive, and aligned with the evolving landscape of industrial cybersecurity.

Designing Secure Industrial Systems with ISA/IEC 62443 Principles

Designing secure industrial automation and control systems requires a meticulous balance between operational efficiency and cybersecurity rigor. Industrial environments operate under stringent real-time constraints, where any disruption in communication or control can have cascading effects on safety, productivity, and financial outcomes. The ISA/IEC 62443 standards provide a robust framework for structuring secure system architectures, ensuring that protection mechanisms are integrated throughout the lifecycle of industrial systems.

The design process begins with a comprehensive understanding of the system’s operational requirements. Control engineers, IT security specialists, and system architects collaborate to map the flow of information, identify critical assets, and delineate potential points of vulnerability. Key elements include programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, human-machine interfaces (HMIs), sensors, and network infrastructures. Each of these components must be configured to resist both accidental misconfigurations and deliberate cyber attacks.

Network segmentation is a cornerstone of secure industrial design. By compartmentalizing systems according to criticality and function, organizations can limit the spread of malicious activity. For example, separating operational networks from enterprise IT networks reduces exposure to external threats, while isolating safety-critical processes ensures that security incidents do not compromise essential operations. ISA/IEC 62443 emphasizes the use of zones and conduits, which define boundaries and controlled pathways for communication between system components. These constructs allow for granular control of access and flow of data, enhancing the overall resilience of industrial systems.

Implementing Access Control and Authentication

Access control mechanisms are vital for preventing unauthorized access to industrial systems. The ISA/IEC 62443 framework advocates for role-based access control (RBAC), where users are granted permissions according to their responsibilities and operational needs. This principle reduces the likelihood of accidental or malicious interference, ensuring that personnel interact only with components relevant to their role.

Authentication processes further strengthen security by verifying the identity of users and devices. Multi-factor authentication (MFA), cryptographic certificates, and secure password management protocols help prevent unauthorized access. Device authentication ensures that only approved hardware can communicate within the network, minimizing the risk of rogue devices introducing vulnerabilities. These measures collectively reinforce the integrity of both operational and informational aspects of industrial systems.

Encryption of sensitive communications represents another critical safeguard. Industrial systems often exchange operational and control data that must remain confidential and unaltered. By employing end-to-end encryption, professionals can protect the integrity and privacy of transmitted data. ISA/IEC 62443 standards provide guidelines for selecting and implementing encryption algorithms, key management strategies, and secure communication protocols, ensuring that data security is maintained without compromising operational efficiency.

Integration of Security into System Design

Integrating security into industrial system design requires more than technical controls; it necessitates the consideration of human factors, operational procedures, and maintenance practices. Security should not be an afterthought or a separate layer; it must be embedded into the very architecture and culture of industrial operations. Professionals trained in ISA/IEC 62443 standards are adept at incorporating security into design workflows, ensuring that every system component, configuration, and process contributes to a resilient environment.

Operational procedures play a key role in secure design. For instance, change management protocols regulate modifications to system configurations, ensuring that updates are validated and documented before implementation. Configuration baselines establish approved settings for devices and systems, providing a reference point to detect deviations or unauthorized changes. These practices complement technical safeguards and help maintain the integrity of industrial systems over time.

Maintenance considerations are equally critical. Systems must accommodate updates, patches, and routine inspections without compromising security. Designing architectures with redundancy, fault tolerance, and modularity ensures that security interventions can be performed with minimal disruption to operations. The ISA/IEC 62443 framework emphasizes a lifecycle perspective, encouraging designers to anticipate future needs and potential vulnerabilities while crafting systems that are both secure and operationally sustainable.

Operational Security Measures

Once systems are designed and implemented, operational security practices become the primary mechanism for sustaining resilience. Continuous monitoring is essential to detect anomalies, unauthorized access, and performance deviations. Industrial environments generate large volumes of operational data, which can be analyzed to identify irregular patterns indicative of security threats. Intrusion detection systems, log management tools, and anomaly detection algorithms enable real-time identification of potential breaches.

Incident response planning complements monitoring by providing a structured approach to managing cybersecurity events. Well-defined procedures guide personnel through detection, containment, eradication, and recovery phases, ensuring that responses are swift, coordinated, and effective. Roles and responsibilities are clearly delineated, and communication channels are established to minimize confusion during crises. Professionals trained under the ISA/IEC 62443 standards are equipped to design and execute response plans that integrate technical, procedural, and organizational dimensions.

Regular audits and security reviews maintain operational integrity over time. As industrial systems evolve, new devices, software updates, and process changes may introduce vulnerabilities. Periodic audits help identify gaps, assess compliance with standards, and recommend corrective measures. These reviews are essential to sustain long-term resilience and ensure that security measures adapt to evolving operational conditions and threat landscapes.

Risk Assessment and Lifecycle Considerations

The concept of risk assessment permeates every stage of industrial cybersecurity. From initial design to operational maintenance, professionals must identify potential threats, evaluate their likelihood and impact, and implement measures to mitigate risk. The ISA/IEC 62443 standards provide structured methodologies for performing these assessments, enabling consistent, repeatable, and comprehensive evaluation of industrial systems.

Lifecycle considerations are integral to effective cybersecurity. Industrial systems are long-lived, often spanning decades, and their threat landscape evolves. Security measures must therefore be adaptable, supporting updates, patches, and architectural changes without compromising operational continuity. Professionals must anticipate potential vulnerabilities and integrate safeguards proactively, ensuring that systems remain robust against both emerging and existing threats.

Risk assessment also involves the prioritization of resources. Not all vulnerabilities carry equal significance, and not all mitigation measures carry equal cost or complexity. By evaluating potential impacts, organizations can allocate resources strategically, addressing the most critical risks first. This approach enhances efficiency while ensuring that essential protections are in place, reducing the likelihood of catastrophic failures or operational disruptions.

Certification and Professional Competence

Certification in industrial cybersecurity, based on the ISA/IEC 62443 framework, serves as a formal recognition of professional competence. The structured program includes multiple certificates, each addressing a specific aspect of the industrial system lifecycle. Certificate 1 establishes foundational knowledge, covering terminology, concepts, and standards. Subsequent certificates focus on risk assessment, secure design, and operational maintenance, culminating in the designation of Cybersecurity Expert for those who complete all levels.

Professional competence extends beyond technical proficiency. Certified individuals are trained to analyze complex industrial systems, identify vulnerabilities, and implement effective mitigation strategies. They develop the ability to communicate security requirements to diverse stakeholders, translate technical standards into operational practices, and integrate security into organizational workflows. This combination of knowledge, skill, and strategic insight equips professionals to address multifaceted challenges across diverse industrial environments.

Fast-Track Certification Programs

For professionals seeking accelerated achievement of certification, fast-track programs offer intensive learning pathways. These programs consolidate content from multiple certificate levels, covering risk assessment, system design, and operational security in a condensed format. While foundational knowledge remains a prerequisite, the fast-track approach allows participants to prepare for multiple certification exams simultaneously, streamlining the path to achieving the Cybersecurity Expert designation.

Fast-track programs emphasize practical application, engaging participants in scenario-based exercises that replicate real-world industrial challenges. This approach reinforces learning, ensuring that theoretical knowledge is translated into actionable skills. Participants gain experience in evaluating vulnerabilities, designing secure architectures, implementing operational safeguards, and responding to incidents, all within a controlled training environment.

Cross-Industry Relevance of Cybersecurity Practices

The principles of industrial cybersecurity are applicable across a wide range of sectors, including energy, manufacturing, transportation, and critical infrastructure. The ISA/IEC 62443 standards provide a flexible framework that can be adapted to diverse operational contexts. While specific threats and operational requirements may vary, the core practices of risk assessment, secure design, and operational maintenance remain consistent.

In energy systems, cybersecurity measures protect critical processes that ensure reliable power generation and distribution. In manufacturing, secure automation safeguards production continuity, reduces downtime, and mitigates financial losses. Transportation systems benefit from secure control networks that protect both operational efficiency and passenger safety. Across sectors, certified professionals apply standardized practices while tailoring solutions to the specific demands of each environment.

Embedding Security in Organizational Culture

Security is not solely a technical concern; it is a cultural imperative. Embedding security practices into organizational culture ensures that policies, procedures, and safeguards are consistently applied and reinforced. Certified professionals play a key role in fostering this culture, educating personnel, advocating for secure workflows, and integrating security awareness into daily operations.

Organizational culture encompasses leadership support, employee training, and procedural adherence. Personnel at all levels must understand the importance of cybersecurity, recognize potential risks, and adhere to established protocols. Professionals trained in ISA/IEC 62443 standards bridge the gap between technical requirements and operational practices, creating a culture where security is viewed as a collective responsibility rather than a separate function.

Continuous Improvement and Lifelong Learning

The dynamic nature of cyber threats necessitates ongoing learning and adaptation. Industrial systems evolve, vulnerabilities emerge, and attackers develop novel techniques. Professionals must continuously update their knowledge, reassess operational practices, and refine mitigation strategies to maintain resilience. Certification frameworks like ISA/IEC 62443 encourage a mindset of continuous improvement, emphasizing the importance of staying current with evolving standards, technologies, and best practices.

Participation in advanced courses, workshops, and professional networks supports lifelong learning. Engaging with peers, subject matter experts, and emerging research ensures that certified professionals maintain relevance and efficacy in their roles. This commitment to ongoing development enhances the long-term value of certification, reinforcing the ability to implement, manage, and sustain effective cybersecurity measures across complex industrial environments.

Operational Maintenance and Resilient Practices in Industrial Cybersecurity

Maintaining resilient industrial automation and control systems requires an intricate combination of technical proficiency, procedural rigor, and strategic foresight. Industrial environments are characterized by complex networks of programmable logic controllers (PLCs), human-machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, and interconnected sensors and actuators. Each component must operate harmoniously while remaining secure against an evolving landscape of cyber threats. The ISA/IEC 62443 standards provide comprehensive guidance for operational maintenance, emphasizing proactive risk management, continuous monitoring, and systematic updates across the industrial system lifecycle.

Operational maintenance encompasses both routine tasks and adaptive strategies that safeguard system integrity. Regular inspections, firmware updates, and configuration verifications ensure that devices remain compliant with security baselines and operational requirements. Industrial environments are dynamic, with ongoing changes in production schedules, process parameters, and equipment deployments, which necessitate continuous attention to cybersecurity. Certified professionals are trained to implement maintenance schedules that prioritize both functionality and security, minimizing downtime while preserving system resilience.

Monitoring and Anomaly Detection

Continuous monitoring represents a cornerstone of operational maintenance in industrial cybersecurity. Industrial control systems generate vast quantities of operational data, encompassing process variables, network traffic, device status, and system logs. Analyzing these data streams enables professionals to identify anomalies indicative of potential security incidents. Techniques such as pattern recognition, statistical analysis, and machine learning-based anomaly detection can detect deviations from expected behavior, signaling unauthorized access or system misconfigurations.

Intrusion detection systems (IDS) and intrusion prevention systems (IPS) serve as critical tools for monitoring and alerting. IDS identifies potential threats and suspicious activity, while IPS can actively block or contain malicious actions. Integration of these systems with operational dashboards provides real-time visibility into the security posture of industrial environments. ISA/IEC 62443 standards recommend layering monitoring tools with contextual intelligence, allowing alerts to be correlated with process-critical information for more accurate threat assessment.

Patch Management and System Updates

Regular patch management is essential for maintaining system security. Industrial devices, software applications, and network components are often exposed to vulnerabilities that can be exploited by malicious actors. Applying timely updates and patches mitigates these risks, ensuring that known weaknesses are addressed before they can be leveraged in attacks. Patch management in industrial systems must be carefully coordinated to avoid disrupting operational continuity, requiring meticulous planning, testing, and scheduling.

Updating industrial systems often involves collaboration between IT and operational technology (OT) teams. Certified professionals are trained to evaluate the criticality of patches, assess potential impacts on process control, and implement updates in a controlled manner. The ISA/IEC 62443 framework emphasizes the importance of version control, rollback procedures, and verification processes, ensuring that updates enhance security without introducing new vulnerabilities or operational risks.

Incident Response and Contingency Planning

Despite robust preventative measures, cyber incidents may still occur. Effective incident response plans are essential to minimize damage, restore operations, and prevent recurrence. ISA/IEC 62443 standards outline structured response procedures, guiding professionals through the stages of detection, containment, eradication, and recovery. Clear delineation of roles and responsibilities, combined with predefined communication protocols, ensures that incidents are managed efficiently and systematically.

Contingency planning complements incident response by preparing industrial systems for unexpected events, including cyberattacks, equipment failures, or natural disasters. Redundancy, failover mechanisms, and backup processes are integral components of resilient system design, enabling critical operations to continue even in adverse conditions. Professionals trained under ISA/IEC 62443 principles are equipped to implement contingency strategies that maintain operational continuity while safeguarding data integrity and process reliability.

Lifecycle Management and Continuous Improvement

Operational maintenance is not a static activity; it requires continuous assessment, refinement, and adaptation. Industrial systems evolve, incorporating new devices, software updates, and process modifications. Security measures must evolve accordingly, maintaining alignment with emerging threats, industry best practices, and regulatory requirements. Lifecycle management under ISA/IEC 62443 principles integrates proactive risk assessment, design review, and operational oversight, creating a dynamic framework for sustainable cybersecurity.

Periodic audits and vulnerability assessments are critical to continuous improvement. Certified professionals evaluate system configurations, network architectures, and operational procedures to identify areas for enhancement. These assessments may reveal gaps in access control, outdated firmware, or deficiencies in monitoring capabilities. By addressing these issues, organizations strengthen their security posture and enhance resilience against both known and emerging threats.

Professional Development and Expertise

The effectiveness of operational maintenance and security practices is intrinsically linked to the expertise of personnel. Professionals certified in ISA/IEC 62443 standards possess a structured understanding of industrial cybersecurity, encompassing risk assessment, system design, operational monitoring, and maintenance. This knowledge enables them to anticipate vulnerabilities, implement appropriate safeguards, and sustain secure operations across diverse industrial environments.

Certification progression emphasizes both theoretical knowledge and practical skills. Foundational training establishes terminology, concepts, and lifecycle principles, while advanced courses develop proficiency in risk assessment, secure design, and operational security. Through scenario-based exercises, simulations, and case studies, participants gain experience applying standards in realistic industrial contexts. This combination of knowledge and applied expertise ensures that certified professionals can manage complex systems with confidence and precision.

The Role of Automation and Artificial Intelligence

Emerging technologies, including automation and artificial intelligence (AI), are increasingly integrated into industrial cybersecurity practices. AI-powered monitoring tools enhance the detection of anomalies, predict potential failures, and optimize maintenance schedules. Automation facilitates routine tasks, such as patch deployment, configuration verification, and log analysis, reducing the risk of human error while improving efficiency.

Integration of AI and automation within the framework of ISA/IEC 62443 standards requires careful consideration. Professionals must ensure that automated processes align with security policies, maintain data integrity, and preserve operational continuity. Training programs emphasize the responsible deployment of these technologies, guiding monitoring, auditing, and adjusting AI-driven systems to support resilient industrial operations.

Cross-Sector Applications of Operational Maintenance

Operational maintenance practices outlined in ISA/IEC 62443 are applicable across a variety of industries. In energy production and distribution, continuous monitoring, redundancy, and rapid incident response protect critical infrastructure from both cyber and operational risks. Manufacturing environments benefit from predictive maintenance, automated monitoring, and secure control architectures that reduce downtime and enhance production efficiency. Transportation systems rely on secure operations to safeguard passenger safety, maintain network reliability, and mitigate the impact of potential cyber incidents.

The universality of these principles highlights the cross-sector relevance of industrial cybersecurity expertise. Certified professionals possess skills that can be adapted to diverse operational contexts, allowing them to implement best practices in multiple industries while maintaining compliance with evolving standards. The integration of operational maintenance and proactive security measures ensures that systems remain resilient, functional, and secure across a wide range of environments.

Embedding Security Awareness into Daily Operations

Effective operational maintenance requires more than technical expertise; it necessitates the cultivation of security awareness among all personnel. ISA/IEC 62443 standards emphasize the importance of embedding security practices into organizational culture. Employees at every level must understand potential threats, adhere to established protocols, and recognize their role in maintaining a secure environment.

Certified professionals play a pivotal role in fostering this culture. They provide training, guidance, and oversight, translating technical requirements into actionable operational practices. Security awareness campaigns, routine briefings, and procedural reminders reinforce vigilance, ensuring that personnel remain informed and engaged in maintaining secure industrial operations. Embedding security into daily workflows enhances overall resilience and reduces the likelihood of incidents caused by human error.

Advanced Strategies for Sustained Resilience

Sustaining resilient industrial systems requires the integration of advanced strategies beyond routine maintenance. Threat intelligence, predictive analytics, and scenario-based simulations enable organizations to anticipate potential risks and refine mitigation approaches. Risk-based prioritization ensures that critical vulnerabilities are addressed promptly, while continuous monitoring and auditing validate the effectiveness of implemented measures.

Redundancy and fault-tolerant designs are fundamental to maintaining operational continuity. Multiple layers of defense, including network segmentation, access control, and intrusion detection, create a robust security posture capable of withstanding diverse threats. Professionals trained under ISA/IEC 62443 standards are equipped to implement these strategies, balancing operational demands with security requirements to achieve sustained resilience.

Certification and Professional Recognition

The ISA/IEC 62443 certification framework validates expertise in operational maintenance and resilient practices. Completion of the four primary certificates—covering fundamentals, risk assessment, design, and operational maintenance—culminates in the designation of Cybersecurity Expert. This recognition demonstrates comprehensive competence in safeguarding industrial systems across their lifecycle.

Certified professionals are distinguished by their ability to integrate security into operational workflows, assess vulnerabilities, design robust architectures, and implement continuous monitoring. They are proficient in incident response planning, patch management, and risk mitigation, ensuring that industrial systems remain secure, efficient, and resilient. Certification not only signifies technical competence but also conveys strategic insight and operational acumen, positioning professionals as leaders in industrial cybersecurity.

Continuous Learning and Adaptation

The dynamic nature of industrial cybersecurity necessitates ongoing learning and adaptation. Emerging threats, evolving technologies, and regulatory changes require professionals to continuously update their knowledge and refine operational practices. ISA/IEC 62443 standards encourage a culture of continuous improvement, promoting the integration of lessons learned, best practices, and innovative solutions into daily operations.

Participation in advanced training, professional forums, and collaborative networks supports lifelong learning. Certified professionals engage with peers, subject matter experts, and industry developments to stay abreast of emerging trends. This proactive approach ensures that operational maintenance strategies remain effective, adaptive, and aligned with the evolving cybersecurity landscape.

Achieving Industrial Cybersecurity Expertise through ISA/IEC 62443 Certification

Industrial cybersecurity expertise is cultivated through structured education, practical application, and rigorous assessment. The ISA/IEC 62443 standards provide the foundation for training programs and certification pathways that develop professionals capable of managing complex industrial automation and control systems (IACS) securely and efficiently. Certification serves as a formal recognition of both knowledge and applied skills, reflecting a comprehensive understanding of risk assessment, system design, operational maintenance, and resilient practices.

The journey toward certification begins with foundational training, where participants acquire familiarity with industrial cybersecurity terminology, lifecycle principles, and the structure of the ISA/IEC 62443 standards. This initial stage establishes a common vocabulary, enabling professionals from IT, OT, and process control backgrounds to collaborate effectively. Understanding core concepts such as defense-in-depth, zones, and conduits, and secure device configuration forms the bedrock of expertise.

Certificate Progression and Specialization

The ISA/IEC 62443 certification program consists of four primary levels, each focusing on specific domains within industrial cybersecurity. Certificate 1, Cybersecurity Fundamentals Specialist, introduces essential principles, lifecycle considerations, andstandards-basedd terminology. Successful completion of this certificate is a prerequisite for advancing to higher levels, ensuring that participants possess a uniform foundation before pursuing specialization.

Certificate 2, Cybersecurity Risk Assessment Specialist, emphasizes the evaluation of vulnerabilities, identification of critical assets, and development of mitigation strategies. Professionals learn structured methods for quantifying risk, prioritizing corrective actions, and integrating findings into operational strategies. Certificate 3, Cybersecurity Design Specialist, focuses on constructing secure architectures that balance operational requirements with protective measures. Participants explore network segmentation, access control, secure communication protocols, and fail-safe configurations.

Certificate 4, Cybersecurity Maintenance Specialist, addresses the ongoing sustainment of secure systems. Operational monitoring, patch management, incident response planning, and continuous assessment are central themes. Completion of all four certificates culminates in the designation of ISA/IEC 62443 Cybersecurity Expert, signifying mastery across the entire industrial cybersecurity lifecycle.

Fast-Track Certification Programs

Recognizing the demands of modern industrial environments, fast-track certification programs offer accelerated pathways to expertise. These programs consolidate content from multiple certificate levels, covering risk assessment, secure design, and operational maintenance in intensive training formats. While foundational knowledge from Certificate 1 remains essential, fast-track programs allow professionals to prepare for several certification exams simultaneously, streamlining the process toward achieving Cybersecurity Expert status.

Fast-track courses emphasize practical application, utilizing scenario-based exercises and simulated industrial environments. Participants engage with real-world examples, evaluate potential vulnerabilities, design mitigation strategies, and execute operational safeguards. This experiential learning reinforces both theoretical concepts and practical skills, preparing professionals to apply standards effectively in diverse operational contexts.

The Role of Applied Knowledge and Analytical Skills

Expertise in industrial cybersecurity extends beyond theoretical understanding. Certified professionals must analyze complex systems, identify vulnerabilities, and develop solutions that integrate technical, procedural, and organizational considerations. Analytical skills are critical for interpreting operational data, recognizing anomalous patterns, and assessing the effectiveness of implemented security measures.

Scenario-based exercises within the ISA/IEC 62443 training framework cultivate these analytical capabilities. Participants encounter challenges such as network misconfigurations, unauthorized access attempts, and simulated attacks, requiring them to apply structured methodologies to mitigate risks. This practical exposure ensures that professionals can respond effectively to real-world threats while maintaining operational continuity.

Cross-Industry Applicability of Expertise

The principles of industrial cybersecurity, as codified in ISA/IEC 62443 standards, have broad applicability across sectors. Energy, manufacturing, transportation, and critical infrastructure industries all benefit from robust cybersecurity practices that protect operational continuity, ensure safety, and mitigate financial and regulatory risks. Certified professionals possess skills that can be adapted to these diverse operational contexts, applying standardized frameworks while addressing sector-specific challenges.

In energy systems, expertise in secure design and operational maintenance safeguards power generation, distribution, and grid reliability. In manufacturing, cybersecurity measures protect automated production lines, ensure product integrity, and reduce downtime. Transportation networks rely on resilient control systems to maintain service continuity, protect passengers, and mitigate potential disruptions. Across industries, certified professionals bring a standardized approach to industrial cybersecurity while tailoring solutions to operational nuances.

Integrating Cybersecurity into Organizational Culture

Technical proficiency alone is insufficient for achieving sustained industrial cybersecurity. Embedding security into organizational culture is critical for ensuring consistent application of standards, adherence to protocols, and vigilance across all levels of operations. Certified professionals act as catalysts, translating technical requirements into actionable practices, promoting awareness, and guiding operational staff in secure workflows.

Security-conscious organizations prioritize training, clear communication, and procedural reinforcement. Employees are educated on potential threats, operational risks, and the importance of adhering to established protocols. Professionals with ISA/IEC 62443 certification are well-positioned to lead these initiatives, fostering a culture where cybersecurity is a shared responsibility rather than an isolated function. Integrating cultural and procedural dimensions with technical controls enhances overall resilience and reduces the likelihood of human-error-induced incidents.

Advanced Monitoring and Predictive Maintenance

Continuous monitoring and predictive maintenance are essential components of sustained industrial cybersecurity. Operational data from sensors, devices, and networked systems can be analyzed to identify patterns, detect anomalies, and anticipate potential failures. Predictive analytics enable organizations to address vulnerabilities before they result in operational disruptions, enhancing both security and efficiency.

Artificial intelligence and automation further augment these capabilities. AI-driven monitoring tools can analyze vast datasets, recognize deviations from normal behavior, and prioritize alerts based on criticality. Automated maintenance processes streamline patch deployment, configuration verification, and log management, reducing human error while maintaining operational continuity. Professionals trained under ISA/IEC 62443 standards ensure that these technologies are deployed responsibly, aligned with both security and operational objectives.

Incident Response and Contingency Planning

Even with robust preventive measures, incidents may occur. Effective incident response and contingency planning are crucial for minimizing impact and restoring operations rapidly. ISA/IEC 62443 standards provide structured guidance for developing response protocols that encompass detection, containment, eradication, and recovery phases. Clear roles, communication channels, and predefined procedures ensure coordinated and efficient action.

Contingency planning complements incident response by preparing systems for unexpected disruptions, including cyberattacks, equipment failures, and natural events. Redundancy, failover mechanisms, and secure backup processes enable continuity of critical operations under adverse conditions. Certified professionals design, implement, and test these strategies, ensuring that industrial systems can withstand a wide array of operational and cyber-related challenges.

Conclusion

Industrial cybersecurity is a critical discipline that ensures the resilience, safety, and continuity of industrial automation and control systems. The ISA/IEC 62443 standards provide a globally recognized framework for securing industrial environments, guiding professionals through assessment, design, implementation, operations, and maintenance. Certification programs grounded in these standards cultivate expertise, equipping professionals with the knowledge and practical skills to identify vulnerabilities, mitigate risks, and implement robust security measures. From foundational principles to advanced strategies, certified individuals integrate technical controls, operational practices, and organizational culture to create secure, efficient, and adaptive industrial systems. Continuous monitoring, predictive maintenance, incident response, and lifecycle management reinforce resilience in dynamic operational contexts. Across diverse sectors—energy, manufacturing, transportation, and critical infrastructure—ISA/IEC 62443-certified professionals drive secure operations, informed decision-making, and long-term sustainability. Ultimately, mastery of these standards empowers organizations to navigate evolving threats, safeguard critical assets, and maintain operational excellence.