Certification: Cisco Industrial Networking Specialist

Certification Full Name: Cisco Industrial Networking Specialist

Certification Provider: Cisco

Exam Code: 200-401

Exam Name: Managing Industrial Networks with Cisco Networking Technologies (IMINS)

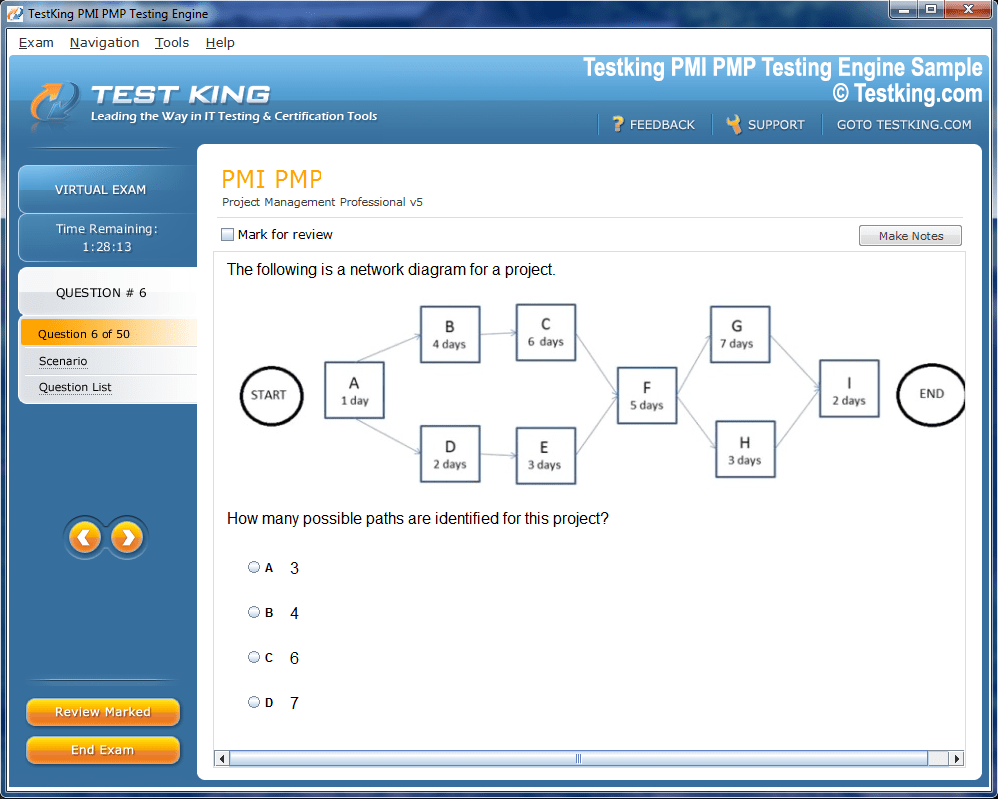

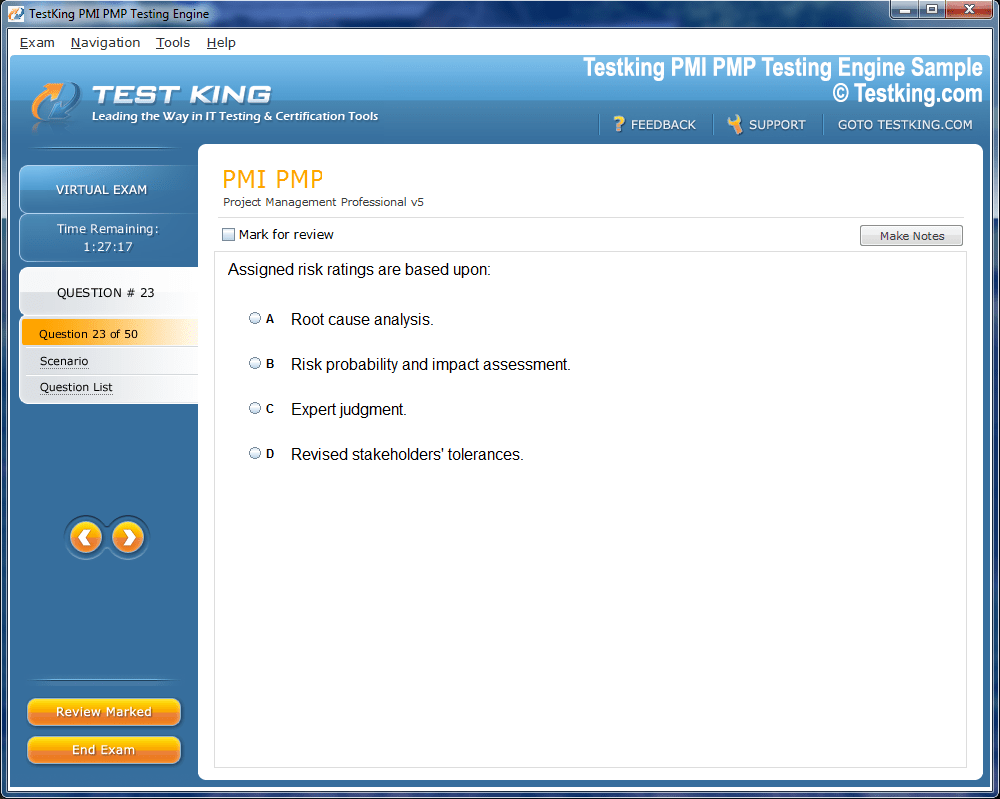

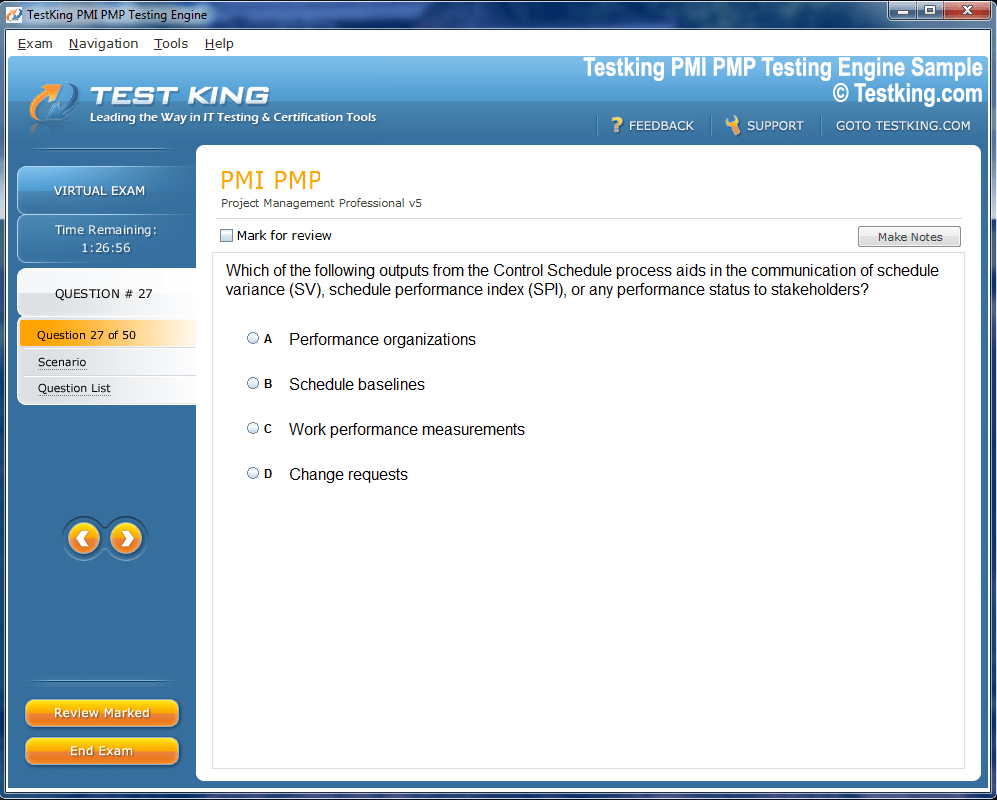

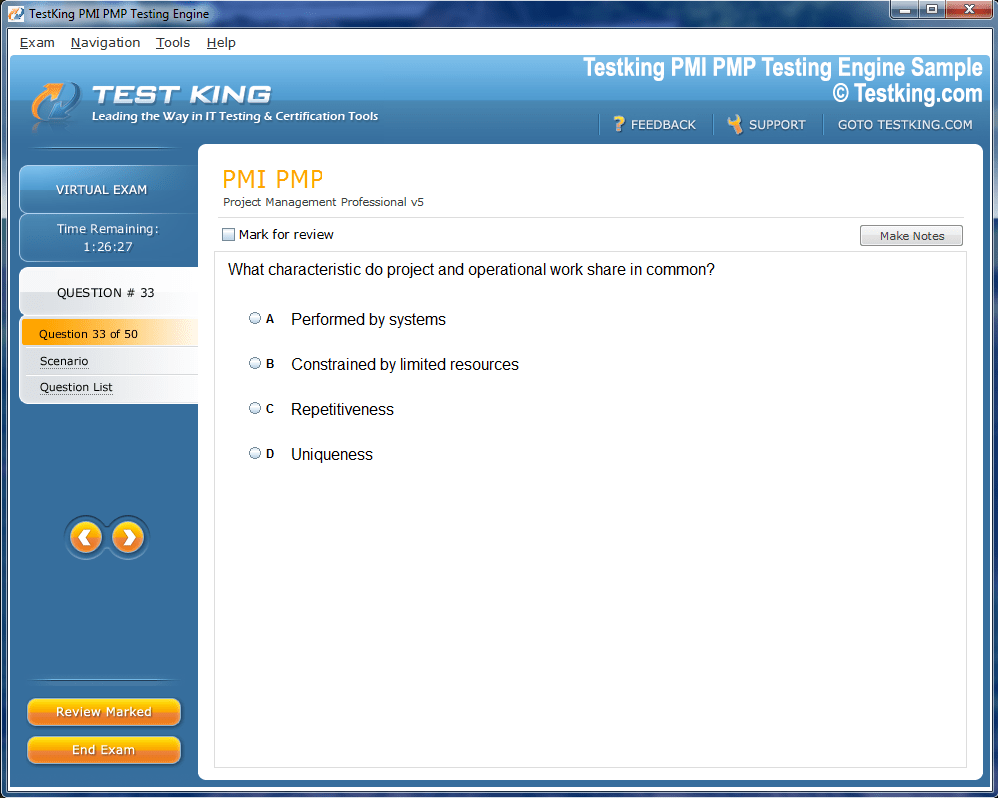

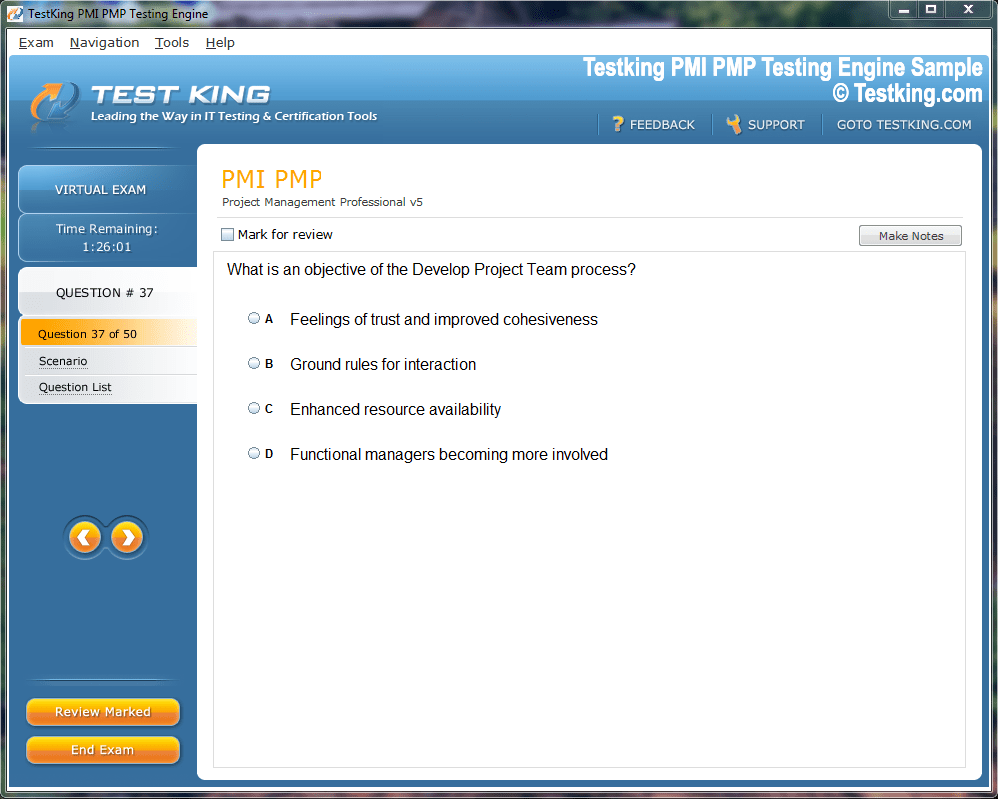

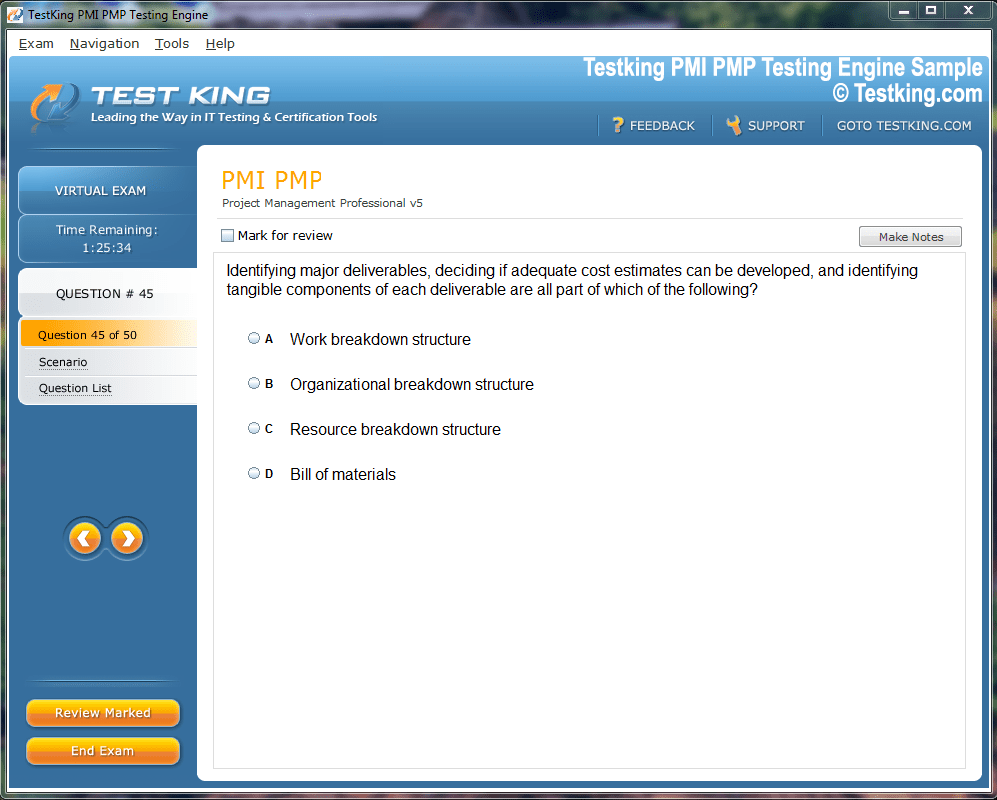

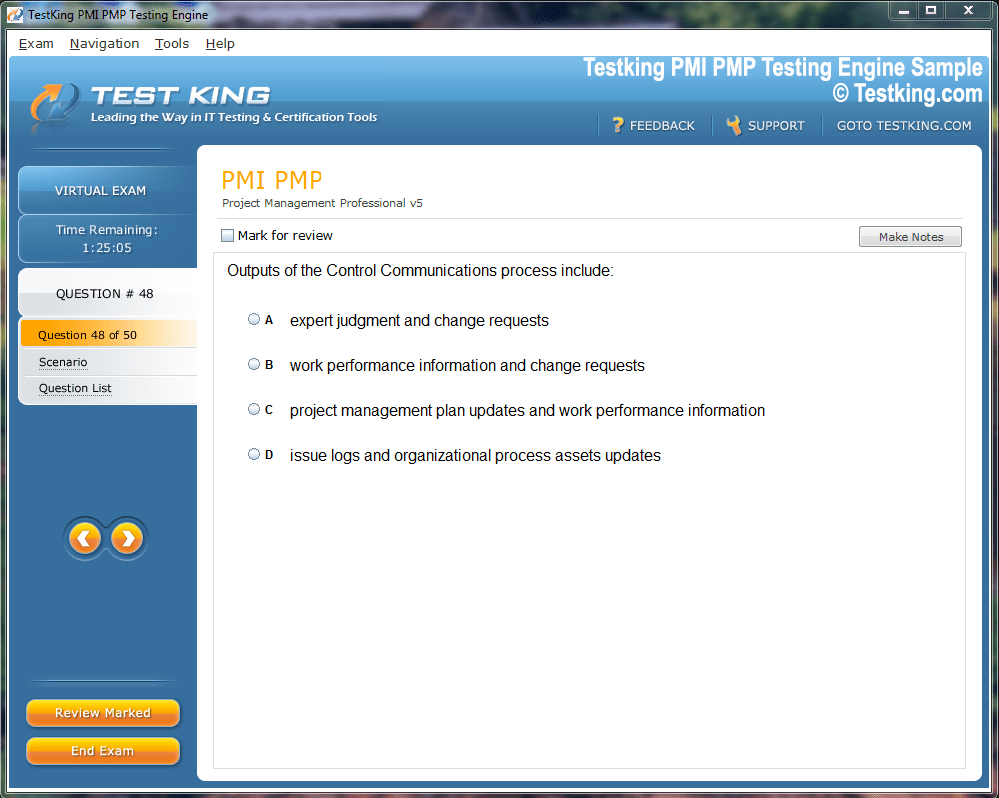

Product Screenshots

nop-1e =1

Elevating Your Professional Profile with Cisco Industrial Networking Specialist Certification

Industrial networking represents a paradigmatic shift from traditional enterprise networking paradigms. The convergence of operational technology with information technology creates unprecedented opportunities for organizations seeking to modernize their manufacturing processes. Industrial networks must withstand harsh environmental conditions while maintaining consistent performance levels that exceed conventional networking requirements.

The architectural foundation of industrial networking encompasses multiple layers of complexity. Physical layer considerations include ruggedized hardware capable of operating in extreme temperatures, electromagnetic interference resistance, and vibration tolerance. These networks frequently operate in environments where standard commercial equipment would fail catastrophically.

Network topology design principles differ significantly from enterprise implementations. Industrial networks often utilize redundant pathways to ensure continuous operation during equipment failures. Ring topologies, linear configurations, and star architectures each serve specific purposes within industrial environments. Understanding these topological variations enables network specialists to design resilient infrastructures that minimize downtime risks.

Protocol selection becomes critical when designing industrial networks. Ethernet-based protocols have gained prominence due to their compatibility with existing information technology infrastructure. However, legacy protocols continue operating in many industrial environments, requiring specialists to understand integration methodologies between disparate communication standards.

Bandwidth requirements in industrial networks vary dramatically based on application types. Real-time control systems demand minimal latency while historical data collection systems can tolerate higher latency in exchange for increased throughput capacity. Balancing these competing requirements necessitates sophisticated network design approaches that prioritize traffic according to business-critical functions.

Security considerations in industrial networking extend beyond traditional cybersecurity concerns. Physical security becomes paramount when network infrastructure exists in accessible industrial environments. Network segmentation strategies must prevent unauthorized access while maintaining operational efficiency. These security implementations require specialized knowledge of industrial protocols and their inherent vulnerabilities.

Exploring Cisco Industrial Solutions Portfolio

Cisco's industrial networking portfolio encompasses comprehensive solutions designed specifically for harsh operational environments. These solutions integrate seamlessly with existing enterprise infrastructure while providing specialized features necessary for industrial applications. The portfolio includes switching platforms, wireless solutions, security appliances, and management software designed for industrial deployments.

Industrial Ethernet switches form the backbone of modern industrial networks. These devices provide advanced features including precision time protocol synchronization, redundancy protocols, and environmental hardening. Switch selection criteria include port density requirements, power consumption limitations, and environmental specifications that match deployment conditions.

Wireless industrial networking solutions address mobility requirements in industrial environments. These systems must overcome significant radio frequency challenges including metallic interference, structural obstacles, and electromagnetic noise. Specialized antenna designs and frequency selection strategies become essential for reliable wireless connectivity in industrial settings.

Network management platforms specifically designed for industrial environments provide visibility into network performance metrics that matter most in operational contexts. These platforms monitor not only traditional networking parameters but also industrial-specific metrics such as temperature fluctuations, power consumption variations, and environmental sensor readings.

Integration capabilities with industrial automation systems distinguish Cisco's industrial portfolio from generic networking equipment. These integrations enable seamless data exchange between network infrastructure and operational systems including programmable logic controllers, human machine interfaces, and supervisory control systems.

The software-defined networking approach in industrial environments provides unprecedented flexibility for network configuration management. Centralized control mechanisms enable rapid deployment changes while maintaining security policies across distributed industrial facilities. This approach reduces configuration errors while improving operational efficiency.

Mastering Industrial Communication Protocols

Industrial communication protocols represent the linguistic foundation enabling diverse industrial systems to exchange information effectively. Understanding these protocols requires comprehensive knowledge of their technical specifications, implementation requirements, and interoperability considerations. Each protocol serves specific purposes within industrial environments, making protocol selection a critical design decision.

EtherNet/IP emerges as a predominant industrial Ethernet protocol, providing real-time communication capabilities while maintaining compatibility with standard Ethernet infrastructure. This protocol combines the Common Industrial Protocol with standard Ethernet technology, enabling seamless integration between industrial automation systems and enterprise networks. Understanding EtherNet/IP implementation requirements including multicast configuration, bandwidth allocation, and quality of service prioritization becomes essential for network specialists.

Profinet represents another significant industrial Ethernet protocol widely deployed in manufacturing environments. This protocol provides deterministic communication capabilities essential for precise industrial automation applications. Profinet implementation requires specialized knowledge of its real-time communication classes, network topology requirements, and device configuration procedures.

Modbus protocols, both serial and TCP variants, continue operating in numerous industrial installations despite their age. Understanding Modbus implementation enables specialists to integrate legacy industrial systems with modern networking infrastructure. This integration often requires protocol conversion techniques and bridge configurations that maintain communication reliability.

DeviceNet and ControlNet protocols remain prevalent in industrial automation systems, particularly in applications requiring intrinsic safety certifications. These protocols utilize specialized physical layer implementations designed for hazardous environments where spark prevention becomes critical for operational safety.

Foundation Fieldbus protocols provide advanced diagnostic capabilities and distributed control functionality. Understanding these protocols enables specialists to implement sophisticated industrial automation architectures where intelligence exists throughout the network rather than concentrated in central controllers.

Implementing Industrial Network Security Strategies

Industrial network security encompasses unique challenges that differentiate it from traditional enterprise security implementations. The convergence of operational technology with information technology creates attack vectors that require specialized security strategies. Understanding these unique security requirements enables specialists to implement comprehensive protection mechanisms without compromising operational efficiency.

Network segmentation strategies form the foundation of effective industrial security implementations. These strategies involve creating logical and physical boundaries between operational networks and enterprise systems. Proper segmentation prevents lateral movement of threats while maintaining necessary communication pathways for legitimate business functions.

Industrial firewall implementations require specialized knowledge of industrial protocols and their communication patterns. Traditional enterprise firewalls often lack the deep packet inspection capabilities necessary for industrial protocol analysis. Understanding industrial-specific firewall features including protocol validation, anomaly detection, and real-time monitoring capabilities becomes essential for effective security implementations.

Intrusion detection systems designed for industrial environments must understand normal operational patterns to distinguish between legitimate industrial communications and potential security threats. These systems require specialized signatures and behavioral analysis capabilities that account for the unique characteristics of industrial network traffic.

Authentication and authorization mechanisms in industrial networks must balance security requirements with operational accessibility. Traditional username and password authentication may prove inadequate for industrial devices that lack sophisticated user interfaces. Certificate-based authentication and role-based access control systems provide more appropriate security mechanisms for industrial environments.

Vulnerability management in industrial environments requires specialized approaches that consider operational continuity requirements. Traditional vulnerability scanning techniques may disrupt industrial operations, necessitating passive monitoring approaches and scheduled maintenance windows for security updates.

Designing Resilient Industrial Network Topologies

Network topology design in industrial environments requires careful consideration of reliability, performance, and maintainability requirements. Unlike enterprise networks where brief outages may cause inconvenience, industrial network failures can result in significant production losses and safety hazards. Understanding topology design principles enables specialists to create networks that meet stringent availability requirements.

Ring topologies provide inherent redundancy that enables rapid recovery from single points of failure. These topologies utilize specialized protocols such as Rapid Spanning Tree Protocol or proprietary recovery mechanisms that restore connectivity within milliseconds of detecting failures. Understanding ring topology implementation requirements including device placement, redundancy protocols, and recovery time optimization becomes essential for high-availability industrial networks.

Linear topology implementations often occur in industrial environments where physical constraints limit network infrastructure options. These topologies require careful planning to ensure adequate redundancy while minimizing infrastructure costs. Understanding linear topology limitations and mitigation strategies enables specialists to design networks that meet availability requirements within physical constraints.

Star topologies provide centralized management capabilities while offering scalability advantages for growing industrial facilities. However, these topologies create single points of failure that require careful mitigation through redundant infrastructure implementations. Understanding star topology design principles including switch redundancy, uplink diversity, and load distribution strategies becomes critical for reliable implementations.

Mesh topologies offer maximum redundancy but introduce complexity that may exceed management capabilities in some industrial environments. Understanding mesh topology benefits and limitations enables specialists to determine appropriate implementation scenarios while avoiding unnecessary complexity that could compromise network reliability.

Hybrid topology approaches combine elements from multiple topology types to address specific operational requirements. These approaches enable specialists to optimize network designs for particular industrial applications while maintaining overall system reliability and performance characteristics.

Optimizing Industrial Network Performance Parameters

Performance optimization in industrial networks requires understanding unique requirements that differ significantly from enterprise networking environments. Industrial applications often demand deterministic behavior, minimal latency, and consistent throughput characteristics that exceed typical enterprise requirements. Understanding these performance parameters enables specialists to design networks that meet stringent operational demands.

Latency optimization techniques in industrial networks focus on minimizing communication delays that could impact real-time control systems. These techniques include traffic prioritization, buffer management, and routing optimization strategies that ensure critical communications receive priority treatment. Understanding latency sources and mitigation techniques becomes essential for time-critical industrial applications.

Bandwidth management in industrial networks requires sophisticated understanding of traffic patterns and application requirements. Unlike enterprise networks where bandwidth usage may vary significantly throughout the day, industrial networks often maintain consistent traffic patterns aligned with production schedules. Understanding these patterns enables specialists to optimize bandwidth allocation for maximum efficiency.

Quality of service implementations in industrial networks must account for diverse application requirements ranging from real-time control to historical data collection. These implementations require comprehensive understanding of protocol priorities, traffic classification techniques, and queuing mechanisms that ensure appropriate service levels for different application types.

Network monitoring and performance analysis tools specifically designed for industrial environments provide insights into operational characteristics that impact production efficiency. These tools monitor industrial-specific metrics including protocol timing, device responsiveness, and environmental parameters that affect network performance.

Capacity planning for industrial networks requires understanding growth patterns and application evolution within industrial environments. Unlike enterprise networks where capacity requirements may increase gradually, industrial networks may experience sudden capacity demands due to production expansion or process modifications.

Implementing Industrial Wireless Solutions

Industrial wireless networking presents unique challenges that require specialized knowledge beyond conventional wireless implementations. Industrial environments introduce significant radio frequency interference, structural obstacles, and mobility requirements that demand sophisticated wireless solutions. Understanding these challenges enables specialists to implement reliable wireless connectivity in demanding industrial settings.

Frequency selection strategies in industrial wireless implementations must account for interference sources common in industrial environments. These sources include variable frequency drives, welding equipment, and other industrial machinery that generates electromagnetic emissions across wide frequency ranges. Understanding interference mitigation techniques including frequency hopping, channel bonding, and antenna diversity becomes essential for reliable wireless connectivity.

Antenna design and placement considerations in industrial environments differ significantly from office installations. Industrial antennas must withstand harsh environmental conditions while providing adequate coverage in areas with significant metallic interference. Understanding antenna types, radiation patterns, and mounting techniques enables specialists to optimize wireless coverage for specific industrial applications.

Wireless security implementations in industrial environments require specialized approaches that account for unique threat vectors and operational requirements. Traditional wireless security mechanisms may prove inadequate for industrial applications that require real-time communication with minimal latency overhead. Understanding industrial-specific wireless security techniques including certificate-based authentication and encrypted tunneling becomes critical for secure wireless implementations.

Mobility management in industrial wireless networks must support moving equipment and personnel while maintaining consistent connectivity. These implementations require sophisticated handoff mechanisms and roaming protocols that minimize communication interruptions during transitions between access points.

Wireless network monitoring and troubleshooting tools designed for industrial environments provide visibility into radio frequency conditions and interference sources that impact wireless performance. Understanding these tools and their capabilities enables specialists to maintain optimal wireless network performance in challenging industrial environments.

Integrating Legacy Industrial Systems

Legacy system integration represents one of the most challenging aspects of industrial networking implementations. Many industrial facilities operate equipment that has functioned reliably for decades, making complete system replacement economically unfeasible. Understanding integration techniques enables specialists to modernize industrial networks while preserving existing equipment investments.

Protocol conversion techniques enable communication between legacy industrial devices and modern networking infrastructure. These techniques often involve specialized gateway devices that translate between different communication protocols while maintaining message integrity and timing requirements. Understanding protocol conversion capabilities and limitations becomes essential for successful legacy integration projects.

Serial-to-Ethernet conversion implementations provide network connectivity for older industrial devices that utilize serial communication interfaces. These conversions must preserve communication characteristics including baud rates, parity settings, and flow control mechanisms that ensure proper device operation.

Bridge configurations enable integration between different network segments while maintaining protocol compatibility. These configurations require careful planning to ensure proper traffic flow and avoid communication bottlenecks that could impact industrial operations.

Data mapping techniques enable information exchange between systems using different data formats and addressing schemes. Understanding these techniques enables specialists to create seamless integration between legacy systems and modern industrial networks without compromising data integrity.

Migration strategies for legacy system modernization require careful planning to minimize operational disruptions while achieving modernization objectives. These strategies often involve phased approaches that gradually replace legacy components while maintaining operational continuity throughout the transition process.

Understanding Industrial Cybersecurity Frameworks

Industrial cybersecurity frameworks provide structured approaches for implementing comprehensive security programs that address unique industrial environment requirements. These frameworks recognize that industrial systems have different risk profiles, operational requirements, and security challenges compared to traditional enterprise environments. Understanding these frameworks enables specialists to develop security strategies that protect industrial operations while maintaining operational efficiency.

The NIST Cybersecurity Framework provides a foundation for industrial cybersecurity programs through its identify, protect, detect, respond, and recover functions. Industrial implementations of this framework require specialized understanding of operational technology assets, threat vectors, and recovery requirements that differ from information technology environments.

IEC 62443 standards series specifically addresses industrial automation and control system security throughout the entire system lifecycle. Understanding these standards enables specialists to implement security measures that meet international requirements for industrial cybersecurity while maintaining compatibility with existing operational systems.

Defense-in-depth strategies for industrial environments involve multiple layers of security controls that provide comprehensive protection against diverse threat vectors. These strategies must account for unique industrial requirements including real-time communication needs, legacy system limitations, and operational continuity demands.

Risk assessment methodologies for industrial environments require specialized approaches that consider both cybersecurity risks and operational safety implications. Understanding these methodologies enables specialists to prioritize security investments based on comprehensive risk analysis that accounts for all potential impacts.

Incident response procedures for industrial environments must balance cybersecurity response requirements with operational safety considerations. These procedures require specialized knowledge of industrial system recovery techniques and coordination between cybersecurity teams and operational personnel.

Deploying Industrial IoT Connectivity Solutions

Industrial Internet of Things implementations represent the convergence of traditional industrial automation with modern connectivity technologies. These implementations enable unprecedented visibility into industrial operations while creating new security and management challenges. Understanding IoT deployment strategies enables specialists to harness these technologies while mitigating associated risks.

Edge computing architectures in industrial environments provide local processing capabilities that reduce latency and bandwidth requirements for IoT applications. Understanding edge computing deployment strategies enables specialists to optimize system performance while maintaining security and reliability requirements.

Sensor integration techniques enable connection of diverse industrial sensors to network infrastructure through standardized communication protocols. These techniques must account for power limitations, environmental constraints, and communication requirements specific to different sensor types.

Data collection and analytics platforms designed for industrial IoT applications provide insights into operational performance that enable predictive maintenance and process optimization. Understanding these platforms enables specialists to implement comprehensive IoT solutions that deliver measurable business value.

Cloud connectivity strategies for industrial IoT implementations must balance the benefits of cloud-based analytics with security and reliability requirements of industrial operations. Understanding hybrid cloud architectures and edge processing techniques enables specialists to optimize IoT deployments for specific industrial applications.

Device management platforms for industrial IoT environments provide centralized control over distributed sensor networks and edge devices. Understanding these platforms enables specialists to maintain large-scale IoT deployments while ensuring security and operational reliability.

Maintaining Industrial Network Documentation Standards

Comprehensive documentation represents a critical foundation for successful industrial network implementations and ongoing maintenance operations. Industrial networks often operate in environments where downtime costs are extremely high, making accurate documentation essential for rapid troubleshooting and system modifications. Understanding documentation standards enables specialists to create and maintain information systems that support efficient network operations.

Network topology documentation for industrial environments must capture both logical and physical connectivity information while accounting for redundancy paths and emergency procedures. This documentation should include cable routing information, device specifications, and environmental considerations that impact network operations.

Configuration management documentation enables consistent device configurations across industrial networks while providing change tracking capabilities that support troubleshooting and compliance requirements. Understanding configuration management tools and procedures enables specialists to maintain accurate documentation throughout the network lifecycle.

Maintenance procedure documentation provides step-by-step guidance for routine maintenance tasks and emergency response procedures. This documentation must account for safety requirements, operational impacts, and coordination requirements specific to industrial environments.

Asset inventory documentation tracks network equipment throughout its operational lifecycle while providing information necessary for maintenance planning and replacement scheduling. Understanding asset management systems enables specialists to optimize equipment utilization and maintenance costs.

Compliance documentation demonstrates adherence to regulatory requirements and industry standards that govern industrial network operations. Understanding compliance documentation requirements enables specialists to maintain networks that meet all applicable regulatory standards.

Troubleshooting Industrial Network Issues

Industrial network troubleshooting requires specialized techniques that account for unique characteristics of industrial environments and applications. Unlike enterprise networks where performance degradation may be tolerable for short periods, industrial network issues can immediately impact production operations and safety systems. Understanding troubleshooting methodologies enables specialists to rapidly identify and resolve network problems with minimal operational impact.

Systematic troubleshooting approaches for industrial networks involve structured methodologies that prioritize potential causes based on their likelihood and operational impact. These approaches must account for interaction between network systems and industrial processes that may not be immediately obvious.

Network monitoring tools specifically designed for industrial environments provide real-time visibility into network performance metrics that correlate with industrial process parameters. Understanding these tools enables specialists to identify network issues before they impact industrial operations.

Protocol analysis techniques for industrial networks require specialized knowledge of industrial communication protocols and their expected behavior patterns. Understanding protocol analysis tools and techniques enables specialists to identify communication problems that may not be apparent through traditional network monitoring approaches.

Performance baseline establishment in industrial networks provides reference points for identifying abnormal behavior that may indicate developing problems. Understanding baseline establishment techniques enables specialists to implement proactive monitoring that identifies issues before they cause operational disruptions.

Root cause analysis methodologies for industrial network problems require comprehensive understanding of interaction between network infrastructure and industrial processes. Understanding these methodologies enables specialists to identify underlying causes rather than merely addressing symptoms of network problems.

Preparing for Professional Certification Success

Professional certification in industrial networking demonstrates specialized knowledge and skills that distinguish qualified specialists in this demanding field. Certification preparation requires comprehensive understanding of theoretical concepts combined with practical experience in industrial network implementations. Understanding certification requirements enables specialists to focus their professional development efforts effectively.

Study methodology development for industrial networking certification requires structured approaches that cover both theoretical knowledge and practical implementation skills. Effective study methods combine textbook learning with hands-on laboratory experience and real-world application scenarios.

Practice examination techniques enable specialists to become familiar with certification testing formats while identifying knowledge areas that require additional study attention. Understanding testing strategies helps maximize certification success probability while building confidence in professional capabilities.

Laboratory experience requirements for certification preparation involve hands-on work with industrial networking equipment and software platforms. Understanding laboratory setup requirements enables specialists to create learning environments that support practical skill development.

Professional development planning for industrial networking specialists involves continuous learning approaches that keep pace with rapidly evolving technology trends and industry requirements. Understanding professional development strategies enables specialists to maintain relevant skills throughout their careers.

Certification maintenance requirements ensure that certified professionals maintain current knowledge and skills as technology and industry practices evolve. Understanding maintenance requirements enables specialists to plan ongoing professional development activities that support long-term career success.

Architecting Scalable Industrial Network Infrastructure

Scalability represents a fundamental consideration in industrial network design, as manufacturing facilities frequently expand operations, integrate new production lines, or modify existing processes. Unlike enterprise networks that may accommodate growth through equipment upgrades, industrial networks must maintain operational continuity while supporting expansion requirements. Understanding scalability principles enables specialists to design networks that accommodate future growth without requiring complete infrastructure replacement.

Modular design approaches enable incremental network expansion that aligns with business growth patterns. These approaches utilize standardized building blocks that can be replicated across multiple facilities or production areas. Modular designs simplify troubleshooting, reduce spare parts inventory requirements, and accelerate deployment of new network segments.

Hierarchical network architectures provide scalability through well-defined layers that separate access, distribution, and core functions. Industrial implementations of hierarchical designs must account for unique requirements including environmental hardening, redundancy protocols, and real-time communication needs that differ from enterprise implementations.

Capacity planning methodologies for industrial networks require understanding of production patterns, seasonal variations, and expansion plans that influence network utilization over time. These methodologies must account for both current operational requirements and anticipated future demands to ensure adequate infrastructure investment.

Standardization strategies enable consistent network implementations across multiple facilities while reducing training requirements and operational complexity. Understanding standardization benefits and implementation challenges enables specialists to develop approaches that balance consistency with site-specific requirements.

Future-proofing techniques involve technology selection strategies that accommodate emerging requirements while protecting existing infrastructure investments. These techniques require understanding of technology evolution trends and migration strategies that minimize operational disruptions during upgrades.

Implementing Advanced Redundancy Mechanisms

Industrial network reliability requirements exceed typical enterprise standards due to potential production losses and safety implications associated with network failures. Advanced redundancy mechanisms provide multiple pathways for network communication while enabling rapid recovery from equipment failures. Understanding these mechanisms enables specialists to design networks that meet stringent availability requirements without excessive infrastructure costs.

High-availability clustering techniques enable redundant network services that provide seamless failover capabilities during equipment failures. These techniques require careful configuration of heartbeat mechanisms, shared storage systems, and automatic failover procedures that ensure minimal service interruption.

Link aggregation implementations combine multiple physical connections into logical channels that provide increased bandwidth and redundancy. Industrial implementations must account for environmental factors and physical routing constraints that may limit aggregation effectiveness in harsh environments.

Virtual Router Redundancy Protocol implementations provide gateway redundancy that ensures continuous network connectivity during router failures. Understanding VRRP configuration requirements and failover mechanisms enables specialists to implement reliable gateway services for industrial networks.

Spanning Tree Protocol optimizations for industrial environments require specialized configuration approaches that minimize convergence time while preventing broadcast loops. Understanding industrial-specific STP implementations enables rapid network recovery during topology changes.

Network interface bonding techniques provide redundancy at the server and device level by combining multiple network interfaces into fault-tolerant configurations. Understanding bonding modes and their appropriate applications enables specialists to implement device-level redundancy that complements network-level redundancy mechanisms.

Mastering Industrial Network Monitoring Systems

Comprehensive monitoring systems provide essential visibility into industrial network performance and health characteristics that enable proactive management and rapid problem resolution. Industrial monitoring requirements differ significantly from enterprise environments due to unique protocols, environmental factors, and operational criticality that demand specialized monitoring approaches.

Real-time monitoring platforms designed for industrial environments provide immediate notification of network conditions that could impact production operations. These platforms must monitor both traditional network metrics and industrial-specific parameters including protocol timing, device responsiveness, and environmental sensor data.

Historical data collection and analysis systems enable trend identification and capacity planning activities that support long-term network optimization. Understanding historical analysis techniques enables specialists to identify patterns that may indicate developing problems or optimization opportunities.

Alarm management systems for industrial networks must distinguish between informational events and conditions requiring immediate attention. These systems require sophisticated filtering and prioritization mechanisms that prevent alarm fatigue while ensuring critical issues receive appropriate attention.

Performance baseline establishment involves collecting normal operational data that serves as reference points for identifying abnormal network behavior. Understanding baseline collection techniques enables specialists to implement monitoring systems that accurately identify performance degradation.

Custom monitoring dashboard development enables tailored views of network performance data that align with specific operational requirements and organizational responsibilities. Understanding dashboard design principles enables specialists to create monitoring interfaces that effectively communicate network status to diverse audiences.

Optimizing Industrial Security Implementations

Industrial security implementations require sophisticated approaches that balance comprehensive protection with operational efficiency requirements. These implementations must address unique threat vectors present in industrial environments while maintaining the real-time communication characteristics essential for industrial operations. Understanding advanced security techniques enables specialists to implement robust protection without compromising operational performance.

Network micro-segmentation strategies create granular security zones that limit lateral movement of threats while maintaining necessary communication pathways. These strategies require detailed understanding of industrial communication patterns and application requirements to implement effective segmentation without disrupting operations.

Zero-trust security models for industrial environments challenge traditional perimeter-based security approaches by requiring verification of all network communications regardless of source location. Understanding zero-trust implementation techniques enables specialists to enhance security posture while accommodating industrial operational requirements.

Advanced threat detection systems specifically designed for industrial environments utilize behavioral analysis and machine learning techniques to identify suspicious activities that may indicate security threats. These systems require understanding of normal industrial communication patterns to distinguish between legitimate operations and potential threats.

Security orchestration and automated response systems enable rapid response to security incidents through predefined response procedures and automatic mitigation actions. Understanding SOAR implementation enables specialists to improve incident response effectiveness while reducing the burden on security personnel.

Certificate management systems for industrial environments provide automated certificate lifecycle management that ensures continuous security without operational disruptions. Understanding certificate management requirements enables specialists to implement robust authentication systems that scale to large industrial deployments.

Deploying Software-Defined Industrial Networks

Software-defined networking approaches in industrial environments provide unprecedented flexibility for network configuration and management while maintaining the reliability and performance characteristics required for industrial operations. Understanding SDN implementation techniques enables specialists to harness these benefits while addressing unique industrial requirements.

Centralized control plane implementations provide unified management of distributed industrial network infrastructure through software-based configuration and policy enforcement. These implementations require understanding of industrial communication requirements and latency sensitivities that influence controller placement and configuration strategies.

Network function virtualization in industrial environments enables flexible deployment of network services through software implementations rather than dedicated hardware appliances. Understanding NFV benefits and limitations enables specialists to optimize network service delivery while maintaining industrial reliability requirements.

Intent-based networking approaches enable high-level policy definitions that automatically translate into specific network configurations across distributed industrial infrastructure. Understanding IBN implementation enables specialists to simplify network management while ensuring consistent policy enforcement.

Edge orchestration platforms provide distributed control capabilities that enable local decision-making while maintaining centralized policy coordination. Understanding edge orchestration enables specialists to optimize network performance in distributed industrial environments.

Network automation frameworks enable programmatic configuration management that reduces manual errors while accelerating deployment and modification processes. Understanding automation techniques enables specialists to improve operational efficiency while maintaining configuration consistency across large industrial networks.

Managing Multi-Site Industrial Network Deployments

Multi-site industrial network deployments present unique challenges including diverse connectivity options, varying security requirements, and complex coordination requirements across distributed facilities. Understanding multi-site deployment strategies enables specialists to create cohesive network architectures that provide consistent functionality while accommodating site-specific requirements.

Wide area network connectivity strategies for industrial deployments must balance cost, performance, and reliability requirements across diverse geographic locations. Understanding WAN technology options and their appropriate applications enables specialists to select connectivity solutions that meet specific site requirements while maintaining overall network cohesion.

Network standardization across multiple sites provides operational benefits including simplified troubleshooting, reduced training requirements, and economies of scale in equipment procurement. Understanding standardization implementation enables specialists to balance consistency with site-specific adaptation requirements.

Centralized management platforms for multi-site deployments provide unified visibility and control across distributed industrial networks while accommodating local operational requirements. Understanding centralized management benefits and implementation challenges enables specialists to optimize multi-site network operations.

Disaster recovery planning for multi-site industrial networks requires sophisticated coordination between facilities to maintain operational continuity during major disruptions. Understanding disaster recovery strategies enables specialists to implement resilient multi-site architectures that protect against various failure scenarios.

Configuration synchronization techniques ensure consistent network settings across multiple sites while accommodating necessary site-specific variations. Understanding synchronization mechanisms enables specialists to maintain configuration consistency while supporting local operational requirements.

Integrating Industrial Analytics Platforms

Industrial analytics platforms transform raw network and operational data into actionable insights that enable optimization of manufacturing processes and network performance. These platforms require sophisticated data collection, processing, and visualization capabilities that can handle the unique characteristics of industrial data sources.

Data lake architectures for industrial environments provide scalable storage and processing capabilities for diverse data types including time-series sensor data, network performance metrics, and operational event information. Understanding data lake implementation enables specialists to create analytics foundations that support diverse analytical requirements.

Stream processing technologies enable real-time analysis of industrial data streams that can trigger immediate responses to operational conditions. Understanding stream processing capabilities enables specialists to implement analytics solutions that support real-time decision-making in industrial environments.

Machine learning applications in industrial networking enable predictive capabilities that can anticipate network performance issues and equipment failures before they impact operations. Understanding machine learning implementation enables specialists to harness these capabilities for proactive network management.

Visualization platforms specifically designed for industrial environments provide intuitive interfaces for monitoring network performance and operational metrics. Understanding visualization best practices enables specialists to create dashboards that effectively communicate complex information to diverse audiences.

Edge analytics implementations provide local processing capabilities that enable immediate response to operational conditions while reducing bandwidth requirements for centralized analytics platforms. Understanding edge analytics enables specialists to optimize system performance while maintaining analytical capabilities.

Implementing Industrial DevOps Practices

DevOps methodologies adapted for industrial environments enable more efficient development and deployment of network configurations and applications while maintaining the reliability and security standards required for industrial operations. Understanding industrial DevOps practices enables specialists to accelerate deployment cycles while maintaining operational excellence.

Infrastructure as code approaches for industrial networks enable version-controlled configuration management that provides consistency, traceability, and rapid deployment capabilities. Understanding IaC implementation enables specialists to improve configuration management while reducing deployment errors.

Continuous integration and deployment pipelines for industrial network configurations enable automated testing and deployment processes that ensure configuration quality while accelerating deployment timelines. Understanding CI/CD implementation enables specialists to implement robust deployment processes that maintain network reliability.

Configuration testing frameworks enable automated validation of network configurations before deployment to production environments. Understanding testing methodologies enables specialists to implement quality assurance processes that prevent configuration errors from impacting industrial operations.

Version control systems for industrial network configurations provide change tracking and rollback capabilities that support configuration management and compliance requirements. Understanding version control implementation enables specialists to maintain accurate configuration histories while supporting change management processes.

Collaborative development practices for industrial network teams enable efficient coordination between diverse team members while maintaining security and quality standards. Understanding collaborative practices enables specialists to optimize team productivity while ensuring appropriate oversight and control.

Advancing Professional Expertise Through Continuous Learning

Professional development in industrial networking requires continuous learning approaches that keep pace with rapidly evolving technology trends, changing industry requirements, and emerging threats. Understanding professional development strategies enables specialists to maintain relevant skills and advance their careers in this dynamic field.

Technology trend analysis enables specialists to identify emerging technologies and industry developments that may impact future network requirements. Understanding trend analysis techniques enables proactive skill development that maintains professional relevance in evolving markets.

Professional networking strategies enable specialists to build relationships with industry peers, vendors, and experts who can provide insights into best practices and emerging opportunities. Understanding networking approaches enables specialists to leverage collective industry knowledge for professional advancement.

Mentorship programs provide structured approaches for both receiving and providing professional guidance that accelerates skill development and career advancement. Understanding mentorship benefits enables specialists to participate effectively in programs that support professional growth.

Industry conference participation provides exposure to cutting-edge technologies, best practices, and industry leaders who shape the future of industrial networking. Understanding conference benefits enables specialists to maximize learning opportunities while building professional networks.

Vendor certification programs provide structured learning paths that demonstrate expertise in specific technologies while providing access to advanced training resources and professional recognition. Understanding certification strategies enables specialists to select programs that align with career objectives and market demands.

Evaluating Emerging Industrial Networking Technologies

Emerging technologies continue reshaping industrial networking landscapes through innovations in communication protocols, hardware capabilities, and software platforms. Understanding technology evaluation techniques enables specialists to assess new technologies effectively while making informed recommendations for industrial implementations.

5G wireless technologies for industrial applications provide unprecedented bandwidth and low-latency capabilities that enable new applications including augmented reality, real-time video analytics, and high-density sensor deployments. Understanding 5G implementation requirements enables specialists to evaluate opportunities for wireless infrastructure modernization.

Edge artificial intelligence platforms enable distributed processing capabilities that can analyze industrial data locally while providing immediate response to operational conditions. Understanding edge AI capabilities enables specialists to evaluate opportunities for intelligent network and process optimization.

Blockchain technologies for industrial applications provide secure, distributed ledger capabilities that can enhance supply chain transparency and equipment authentication. Understanding blockchain implementation enables specialists to evaluate potential applications in industrial environments.

Digital twin technologies create virtual representations of industrial networks and processes that enable simulation, optimization, and predictive analysis capabilities. Understanding digital twin implementation enables specialists to evaluate opportunities for advanced network modeling and optimization.

Quantum networking technologies represent emerging capabilities that may eventually provide unprecedented security and communication capabilities for industrial applications. Understanding quantum networking developments enables specialists to prepare for future technology transitions while evaluating current research directions.

Implementing Time-Sensitive Networking Solutions

Time-Sensitive Networking represents a revolutionary advancement in industrial Ethernet technology, providing deterministic communication capabilities essential for precision manufacturing and process control applications. TSN technologies enable standard Ethernet infrastructure to deliver guaranteed latency bounds and synchronized timing across distributed industrial networks. Understanding TSN implementation enables specialists to design networks that support the most demanding real-time applications while maintaining compatibility with existing Ethernet infrastructure.

TSN standardization efforts through IEEE 802.1 working groups have established comprehensive specifications for time synchronization, traffic scheduling, and network resource reservation. These standards enable interoperability between equipment from different vendors while providing the deterministic behavior required for critical industrial applications. Understanding TSN standards enables specialists to implement solutions that meet stringent timing requirements while maintaining vendor flexibility.

Precision Time Protocol implementation forms the foundation for TSN deployments by providing microsecond-level time synchronization across network infrastructure. PTP configuration requires understanding of master clock selection, boundary clock operation, and transparent clock functionality that maintains timing accuracy throughout the network. Proper PTP implementation enables applications that require precise coordination between distributed processes.

Traffic shaping mechanisms in TSN networks provide guaranteed bandwidth allocation and latency bounds for critical communications. These mechanisms utilize sophisticated queuing algorithms and admission control procedures that ensure real-time traffic receives priority treatment without completely blocking other network communications. Understanding traffic shaping enables specialists to optimize network performance for mixed-criticality applications.

Stream reservation protocols enable applications to request specific network resources including bandwidth, latency bounds, and delivery guarantees. These protocols require understanding of network topology, available resources, and application requirements to establish end-to-end communication paths that meet application demands. Proper stream reservation implementation ensures reliable real-time communication while preventing resource conflicts.

Network configuration for TSN deployments requires specialized tools and procedures that account for timing requirements and resource constraints across the entire network path. Understanding TSN configuration enables specialists to establish deterministic communication while maintaining network flexibility for non-real-time applications.

Designing Industrial Wireless Networks

Industrial wireless networking addresses unique challenges present in manufacturing and process control environments including electromagnetic interference, mobility requirements, and harsh environmental conditions. These challenges require specialized wireless technologies and deployment strategies that differ significantly from conventional wireless implementations. Understanding industrial wireless design enables specialists to implement reliable wireless connectivity that supports diverse industrial applications.

Frequency band selection for industrial wireless networks requires careful analysis of interference sources and regulatory constraints that vary by geographic region and application type. Industrial environments often contain significant interference sources including variable frequency drives, arc welding equipment, and high-power machinery that can disrupt wireless communications across multiple frequency bands. Understanding frequency selection strategies enables optimal wireless performance in challenging environments.

Mesh networking topologies provide redundant communication paths that improve wireless network reliability in industrial environments where line-of-sight connectivity may be compromised by equipment, structures, and environmental factors. Industrial mesh networks must handle mobility requirements while maintaining communication quality during topology changes caused by equipment movement or temporary obstructions.

Antenna system design for industrial wireless applications requires understanding of propagation characteristics in metallic environments, antenna mounting constraints, and coverage requirements for diverse application scenarios. Industrial antenna systems must withstand harsh environmental conditions including temperature extremes, chemical exposure, and mechanical vibration while maintaining consistent radio frequency performance.

Wireless security implementations for industrial environments must address unique threat vectors including physical access to wireless infrastructure, eavesdropping on unencrypted communications, and potential interference from malicious transmitters. Understanding industrial wireless security enables specialists to implement robust protection mechanisms without compromising communication performance or operational efficiency.

Mobile device management for industrial wireless networks requires specialized platforms that can handle ruggedized devices, application-specific requirements, and integration with industrial automation systems. Understanding industrial mobile device management enables specialists to deploy comprehensive wireless solutions that support diverse operational requirements while maintaining security and reliability standards.

Conclusion

Cloud integration for industrial networks enables access to advanced analytics capabilities, remote monitoring services, and scalable computing resources while maintaining the security and reliability requirements essential for industrial operations. Understanding cloud integration strategies enables specialists to harness cloud benefits while addressing unique industrial requirements including data sovereignty, latency sensitivity, and security concerns.

Hybrid cloud architectures provide optimal balance between local processing capabilities and cloud-based analytics services by maintaining critical operations locally while leveraging cloud resources for non-real-time functions. These architectures require sophisticated data flow management and security policies that determine which information can be transmitted to cloud services while maintaining operational independence for critical functions.

Edge computing platforms bridge the gap between industrial networks and cloud services by providing local processing capabilities that reduce latency and bandwidth requirements while enabling cloud connectivity for advanced analytics and management functions. Understanding edge computing deployment enables specialists to optimize system performance while maintaining cloud integration benefits.

Data pipeline architectures for industrial cloud integration must handle diverse data types including time-series sensor data, alarm information, and configuration data while maintaining data integrity and security throughout the transmission process. These pipelines require understanding of data transformation, filtering, and aggregation techniques that optimize cloud resource utilization while maintaining data quality.

Cloud security implementations for industrial environments require specialized approaches that address unique threat vectors and compliance requirements while maintaining operational efficiency. Understanding cloud security enables specialists to implement robust protection mechanisms that meet industrial security standards while leveraging cloud service benefits.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.