Certification: CPIM-BSP

Certification Full Name: CPIM - Basics of Supply Chain Management

Certification Provider: APICS

Exam Code: CPIM-BSP

Exam Name: CPIM - Basics of Supply Chain Management

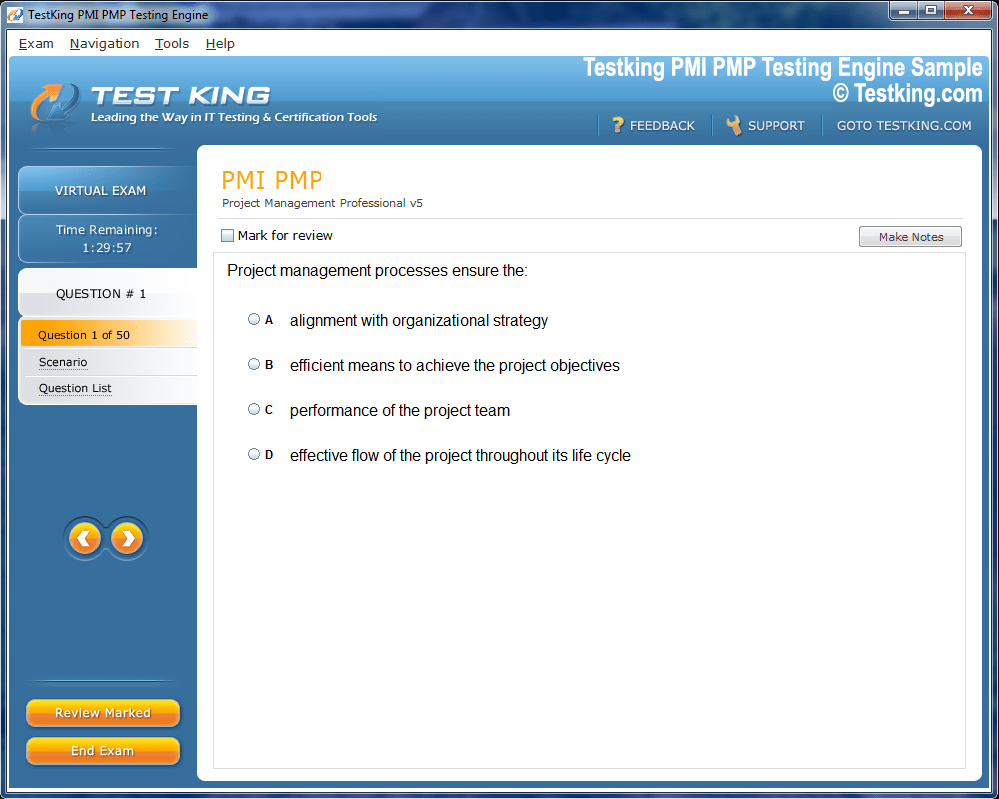

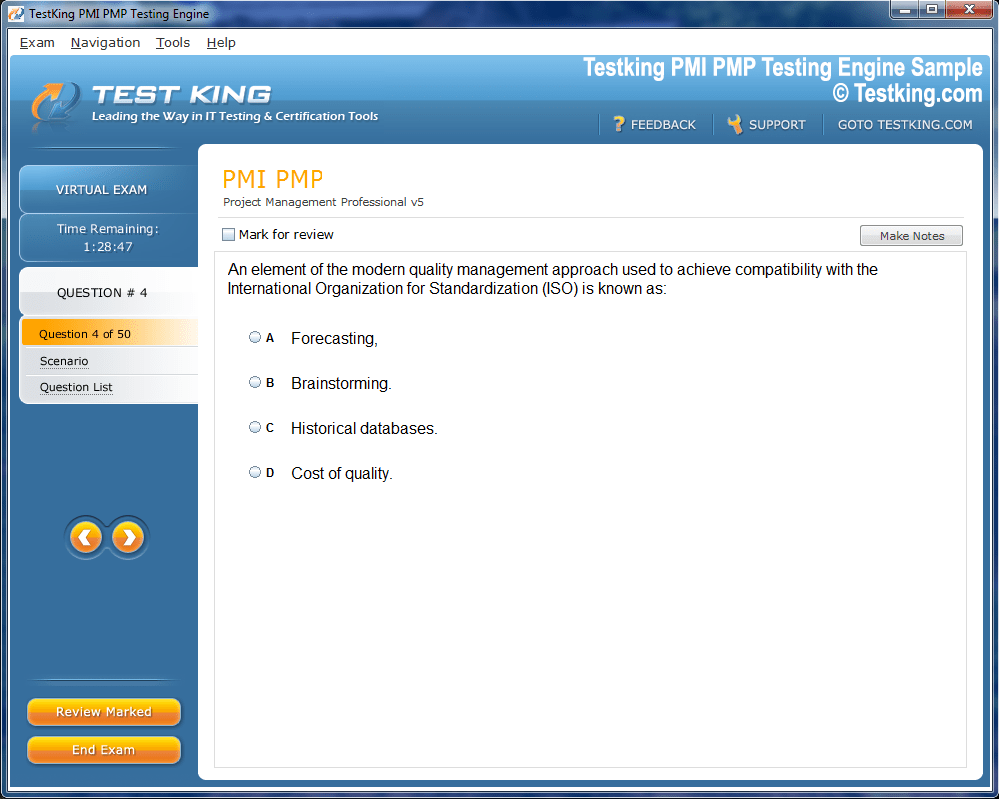

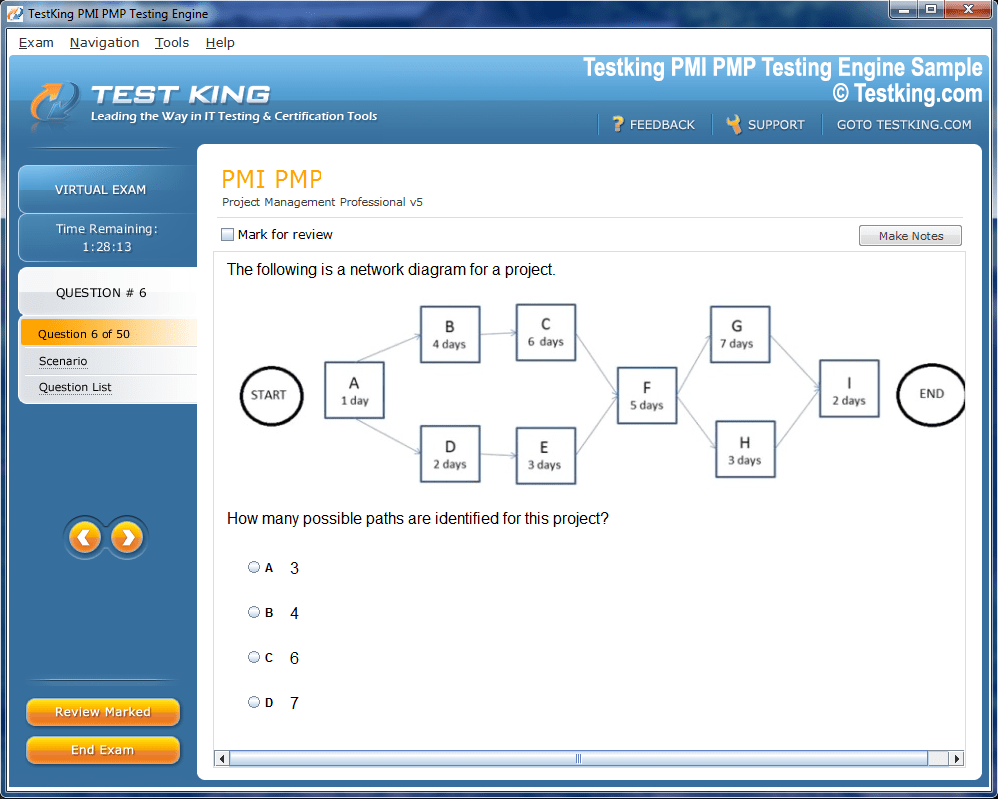

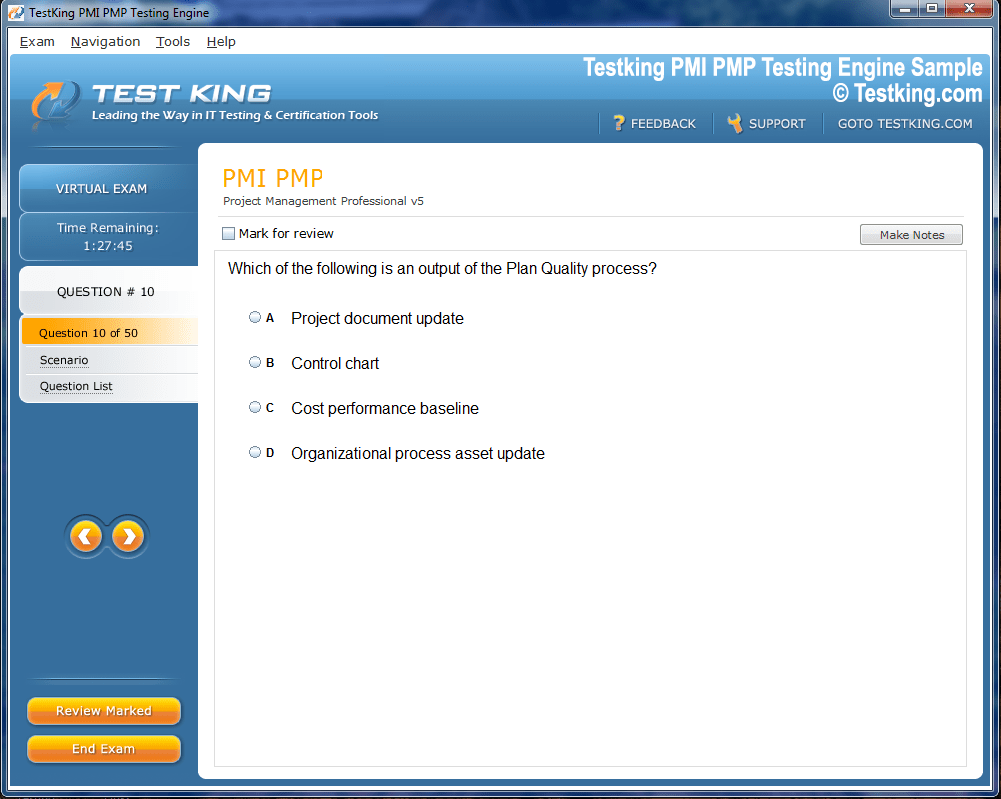

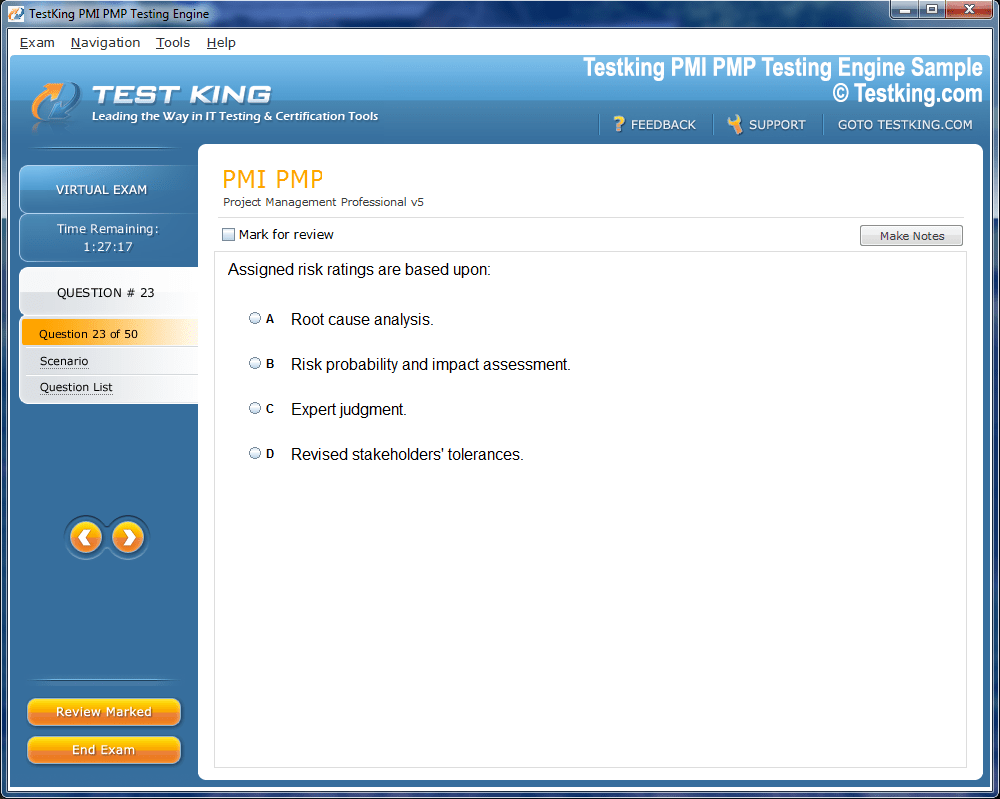

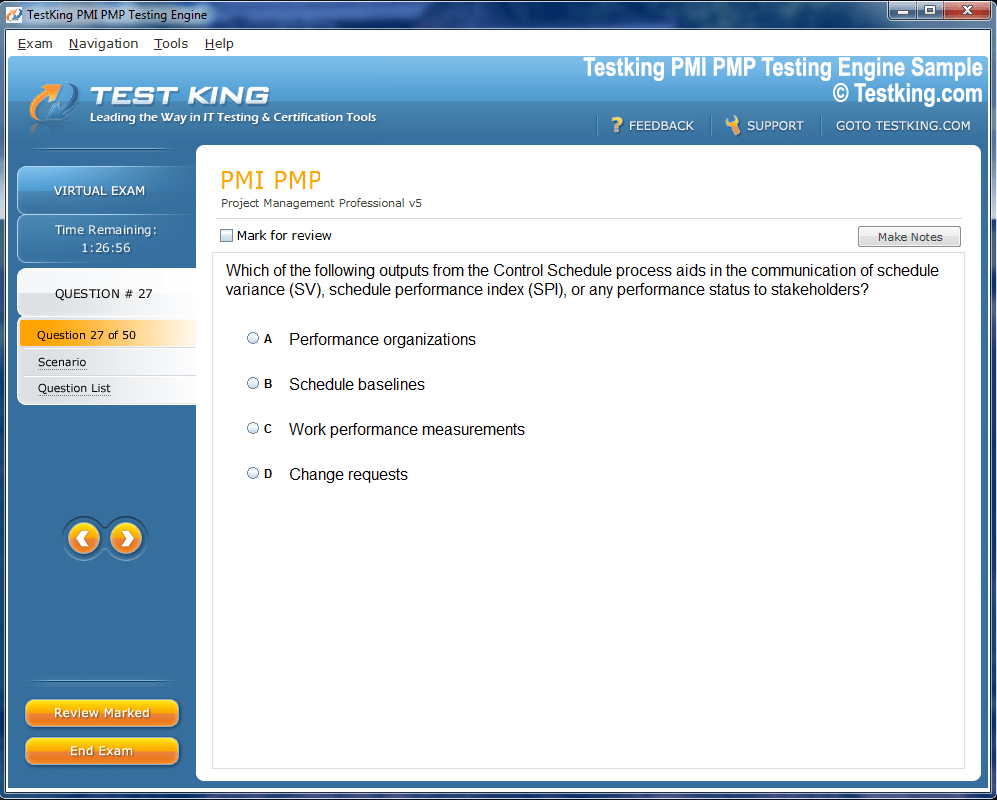

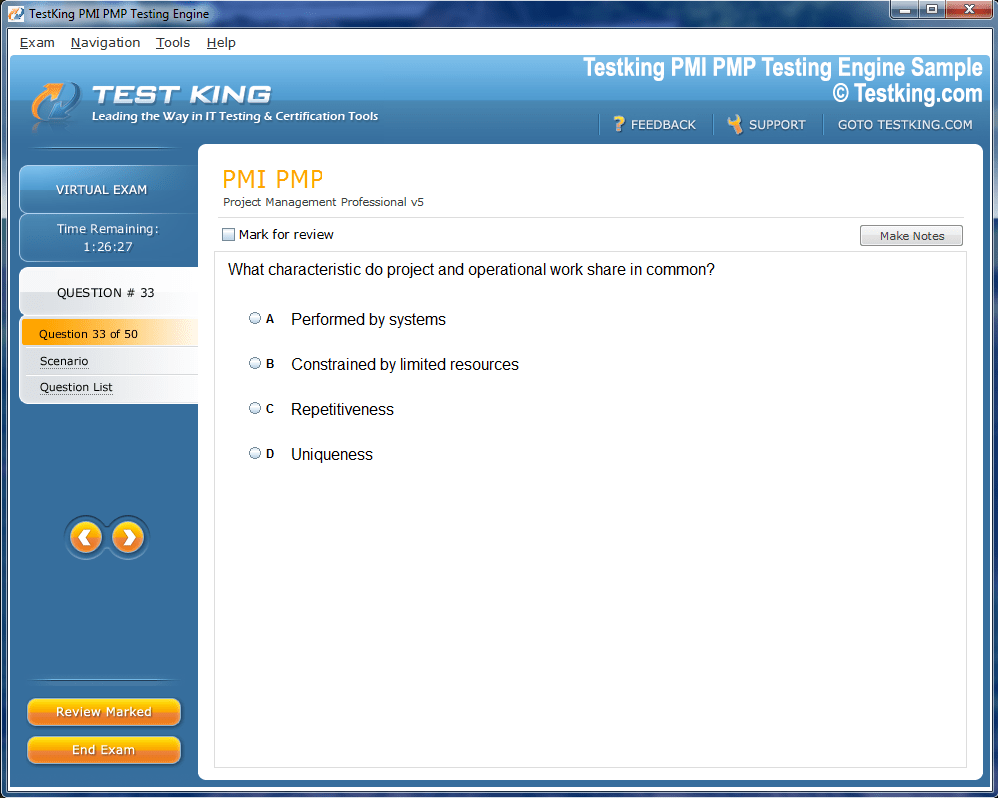

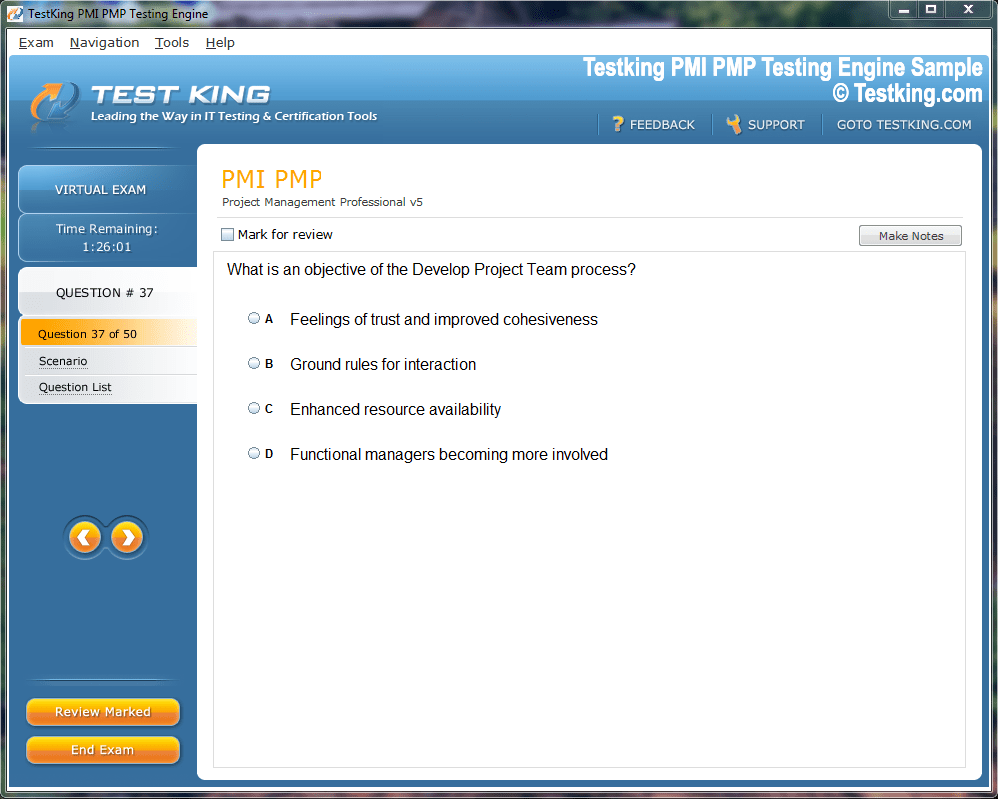

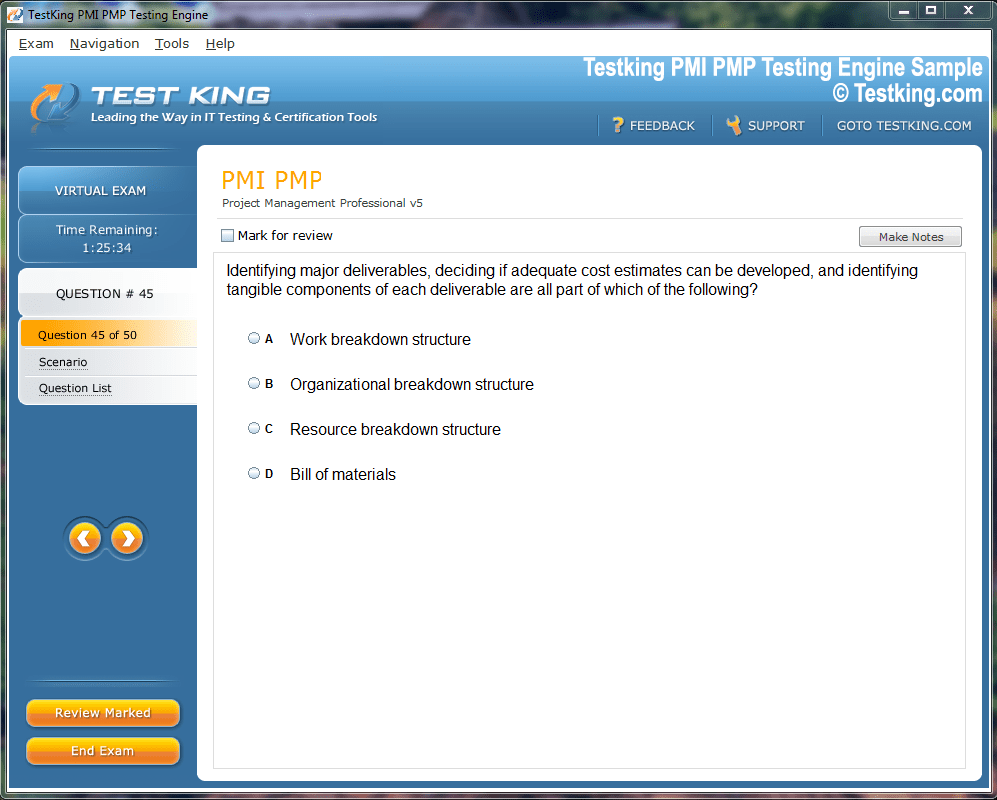

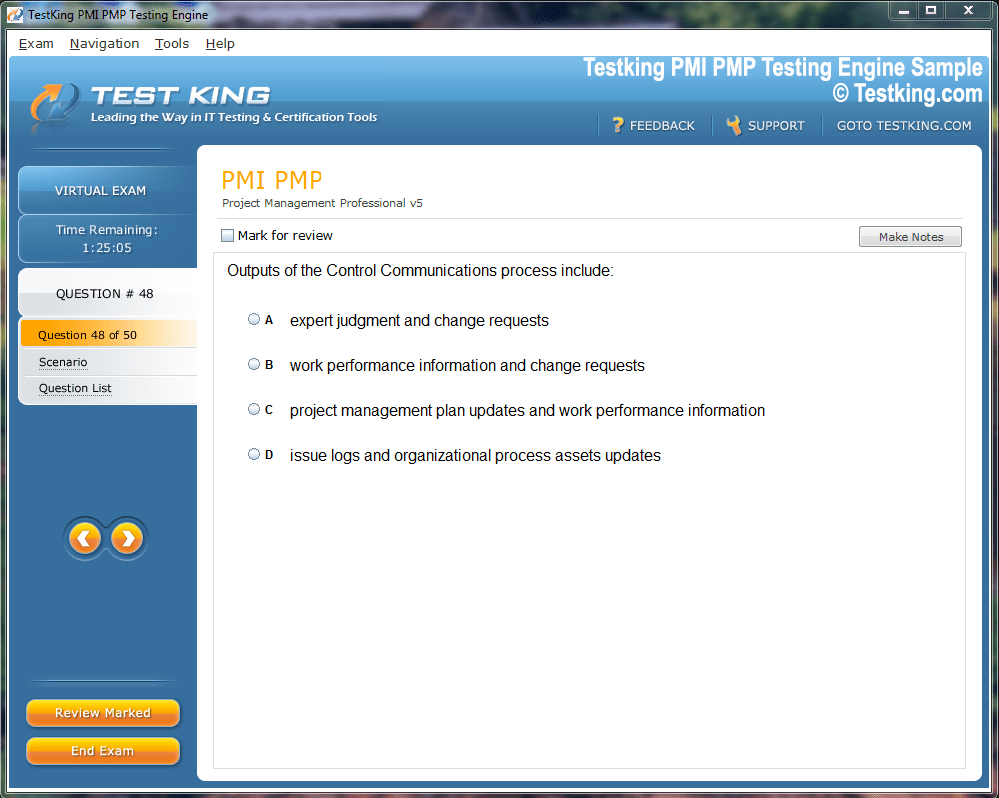

Product Screenshots

nop-1e =1

Strategic Approaches to Conquer the CPIM-BSP Certification

Acquiring superior quality APICS CPIM BSP exam dumps represents a pivotal strategy for aspirants seeking excellence in the CPIM Basics of Supply Chain Management certification examination. Contemporary professionals recognize that thorough preparation requires exceptional resources that address every facet of supply chain fundamentals, inventory management principles, and operational excellence concepts. The sophisticated CPIM-BSP certification dumps available through premium platforms provide comprehensive coverage of all examination domains, ensuring candidates develop robust knowledge foundations while simultaneously building confidence for examination day success.

Modern certification preparation transcends mere memorization, demanding deep comprehension of supply chain dynamics, procurement strategies, production planning methodologies, and distribution network optimization techniques. The meticulously crafted CPIM BSP pdf questions serve as navigational instruments that illuminate the pathway toward certification achievement, offering strategic insights into examination patterns, question structures, and content emphasis areas that distinguish successful candidates from those who struggle.

Premium study materials incorporate real-world scenarios that mirror actual workplace challenges faced by supply chain professionals daily, thereby bridging theoretical knowledge with practical application capabilities. This pedagogical approach ensures candidates not only pass examinations but also acquire competencies immediately applicable within organizational contexts, delivering tangible value to employers while accelerating career trajectory progression.

Revolutionary Methodology for CPIM-BSP Examination Preparation Excellence

The journey toward CPIM BSP certification mastery demands strategic utilization of cutting-edge preparation methodologies that align with contemporary learning science principles. Advanced APICS CPIM-BSP questions and answers incorporate spaced repetition algorithms, adaptive difficulty progression, and comprehensive performance analytics that enable candidates to identify knowledge gaps precisely while optimizing study time allocation for maximum retention efficiency.

Successful candidates recognize that excellence emerges from systematic preparation rather than haphazard study approaches. Premium APICS CPIM BSP braindumps provide structured learning pathways that progressively build competency across fundamental supply chain concepts including demand forecasting, capacity planning, materials requirement planning systems, and just-in-time inventory methodologies. This scaffolded approach ensures candidates develop comprehensive understanding rather than superficial familiarity with examination topics.

Contemporary preparation resources leverage multimedia integration, incorporating visual diagrams, process flowcharts, and interactive simulations that enhance comprehension of complex supply chain relationships and interdependencies. Such multisensory learning experiences significantly improve information retention while making preparation more engaging and sustainable throughout extended study periods.

Comprehensive Analysis of CPIM Basics of Supply Chain Management Examination Structure

The CPIM Basics of Supply Chain Management certification examination encompasses diverse content domains that collectively assess candidate proficiency across essential supply chain management competencies. Understanding examination architecture represents crucial preparatory knowledge that enables strategic study planning and efficient resource allocation. The assessment evaluates knowledge spanning supply chain strategy development, demand management techniques, procurement optimization, production scheduling, inventory control methodologies, warehouse management systems, and distribution network design principles.

Premium APICS CPIM-BSP pdf dumps provide granular coverage of each content domain, ensuring candidates encounter representative question types while developing familiarity with examination terminology, scenario presentation formats, and response selection strategies. This comprehensive exposure eliminates surprise elements during actual examination experiences, allowing candidates to focus cognitive resources on demonstrating knowledge rather than navigating unfamiliar question formats.

Sophisticated preparation materials incorporate difficulty calibration that mirrors actual examination challenge levels, ensuring candidates develop realistic performance expectations while building confidence through progressively challenging practice experiences. This graduated difficulty approach prevents both overconfidence from excessively simple materials and discouragement from unrealistically difficult resources that misrepresent actual examination requirements.

Strategic Advantages of Premium CPIM-BSP Certification Preparation Resources

Distinguishing characteristics of exceptional APICS CPIM BSP exam questions extend far beyond mere content coverage, encompassing pedagogical sophistication, content currency, and alignment with current examination blueprints. Premium resources undergo continuous validation processes that ensure accuracy, relevance, and consistency with official examination standards, eliminating the risks associated with outdated or inaccurate preparation materials that proliferate across unregulated platforms.

Expert-curated CPIM-BSP dumps incorporate explanatory rationales for both correct and incorrect response options, transforming each practice question into a comprehensive learning experience. This approach ensures candidates understand underlying principles rather than simply memorizing answer patterns, developing transferable knowledge applicable across diverse question variations that may appear during actual examinations.

Advanced preparation platforms provide performance tracking dashboards that visualize progress across content domains, identify persistent knowledge gaps, and recommend targeted remediation activities. This data-driven approach optimizes preparation efficiency by directing study efforts toward areas requiring additional reinforcement while avoiding redundant review of already-mastered content.

Foundational Supply Chain Management Concepts Within CPIM BSP Curriculum

The CPIM Basics of Supply Chain Management certification curriculum establishes foundational knowledge across interconnected supply chain domains that collectively enable organizational competitiveness through operational excellence. Mastery begins with comprehensive understanding of supply chain strategy formulation, encompassing competitive positioning analysis, value proposition definition, and strategic alignment between supply chain capabilities and organizational objectives.

Demand management represents another critical curriculum component, requiring candidates to demonstrate proficiency in forecasting methodologies, demand pattern recognition, forecast accuracy measurement, and collaborative planning processes. Premium APICS CPIM-BSP practice questions extensively cover these concepts through realistic scenarios that mirror actual business challenges, ensuring candidates develop practical application capabilities alongside theoretical knowledge.

Procurement and supplier relationship management constitute essential curriculum elements, addressing sourcing strategy development, supplier evaluation criteria, contract negotiation principles, and performance monitoring frameworks. Comprehensive preparation materials explore these topics through case-based scenarios that require candidates to analyze complex procurement situations and select optimal strategies based on multiple competing considerations.

Advanced Inventory Management Principles and Optimization Techniques

Inventory management sophistication distinguishes exceptional supply chain professionals from mediocre practitioners, making this domain particularly emphasized within CPIM BSP certification examinations. Candidates must demonstrate comprehensive understanding of inventory classification systems including ABC analysis, inventory carrying cost calculations, economic order quantity determinations, safety stock optimization, and reorder point establishment methodologies.

Premium CPIM-BSP exam dumps provide extensive coverage of inventory management concepts through quantitative problems requiring mathematical calculations alongside conceptual questions assessing theoretical understanding. This balanced approach ensures candidates develop both computational proficiency and strategic thinking capabilities necessary for real-world inventory optimization challenges.

Advanced preparation materials address contemporary inventory management approaches including vendor-managed inventory systems, consignment arrangements, just-in-time methodologies, and lean inventory principles. Understanding these modern approaches alongside traditional inventory management techniques enables candidates to demonstrate comprehensive knowledge spanning historical evolution and current best practices within the supply chain management discipline.

Production Planning and Control Systems Mastery

Production planning and control represents another cornerstone domain within CPIM Basics of Supply Chain Management curriculum, requiring candidates to demonstrate proficiency across diverse planning methodologies and execution control systems. Comprehensive understanding begins with master production scheduling concepts, encompassing demand prioritization, capacity availability assessment, production smoothing techniques, and schedule stability considerations.

Material requirements planning systems constitute complex curriculum components demanding detailed understanding of bill of materials structures, inventory record accuracy requirements, lead time determination methodologies, and lot sizing techniques. Premium APICS CPIM BSP braindumps provide extensive practice with MRP logic through realistic scenarios requiring candidates to trace material requirements through multi-level product structures while accounting for existing inventory balances and scheduled receipts.

Capacity requirements planning extends production planning concepts by addressing resource availability constraints, load leveling techniques, and capacity adjustment strategies. Sophisticated preparation materials explore these concepts through integrated scenarios that require simultaneous consideration of material availability and capacity constraints, mirroring real-world planning complexity faced by supply chain professionals daily.

Quality Management Integration Within Supply Chain Operations

Quality management principles permeate contemporary supply chain operations, requiring CPIM BSP candidates to demonstrate understanding of quality philosophy evolution, statistical process control methodologies, and continuous improvement frameworks. Certification preparation must address quality concepts spanning prevention approaches, detection systems, and corrective action protocols that collectively ensure product and service excellence throughout supply chain processes.

Premium CPIM-BSP certification dumps incorporate quality management scenarios requiring candidates to analyze process capability indices, interpret control chart patterns, and recommend appropriate quality improvement interventions. This comprehensive coverage ensures candidates appreciate quality management not as isolated discipline but rather as integral component of supply chain excellence that influences every operational decision and process design consideration.

Total quality management principles including customer focus orientation, continuous improvement philosophy, and employee empowerment approaches represent additional curriculum elements requiring conceptual understanding and practical application capabilities. Sophisticated preparation materials explore these concepts through organizational scenarios that require candidates to evaluate quality culture development strategies and recommend implementation approaches appropriate for diverse organizational contexts.

Warehouse Management and Distribution Network Optimization

Warehouse management systems and distribution network design constitute increasingly important curriculum domains reflecting contemporary supply chain complexity and customer expectation evolution. Candidates must demonstrate understanding of warehouse layout optimization principles, material handling equipment selection criteria, picking strategy alternatives, and inventory accuracy maintenance protocols that collectively determine warehouse operational efficiency.

Premium APICS CPIM-BSP exam questions address warehouse management through realistic operational scenarios requiring candidates to evaluate alternative layout configurations, assess material handling technology options, and recommend appropriate picking methodologies based on order profile characteristics. This applied approach ensures candidates develop practical decision-making capabilities rather than merely memorizing theoretical concepts disconnected from operational realities.

Distribution network design extends warehouse management concepts by addressing facility location optimization, transportation mode selection, route planning methodologies, and network configuration strategies that balance cost efficiency with customer service requirements. Comprehensive preparation materials explore these strategic considerations through case studies requiring multi-criteria analysis and trade-off evaluation skills essential for effective supply chain network design.

Performance Measurement and Metrics Development for Supply Chain Excellence

Performance measurement frameworks enable objective assessment of supply chain effectiveness and efficiency while providing actionable insights for continuous improvement initiatives. CPIM BSP curriculum requires candidates to demonstrate proficiency in key performance indicator development, balanced scorecard construction, and performance benchmarking methodologies that collectively enable data-driven supply chain management.

Premium CPIM-BSP dumps extensively cover performance measurement concepts through scenarios requiring metric selection, target establishment, and performance interpretation capabilities. Candidates must understand relationships between operational metrics and strategic objectives, ensuring measurement systems drive behaviors aligned with organizational priorities rather than creating unintended consequences through poorly designed incentive structures.

Advanced preparation materials address contemporary performance measurement approaches including supply chain operations reference model frameworks, activity-based costing methodologies, and total cost of ownership calculations. Understanding these sophisticated measurement approaches enables candidates to demonstrate knowledge currency and appreciation for evolving best practices within supply chain performance management discipline.

Technology Integration and Information Systems Within Modern Supply Chains

Information technology represents critical enabler of contemporary supply chain excellence, requiring CPIM BSP candidates to demonstrate understanding of enterprise resource planning systems, warehouse management systems, transportation management platforms, and supply chain visibility technologies. Certification preparation must address technology capabilities, implementation considerations, and organizational change management requirements associated with supply chain technology adoption.

Premium APICS CPIM BSP exam questions explore technology concepts through implementation scenarios requiring candidates to evaluate system requirements, assess alternative solutions, and recommend appropriate technologies based on organizational characteristics and strategic objectives. This practical approach ensures candidates appreciate technology not as end itself but rather as means toward achieving operational excellence and competitive advantage.

Advanced preparation materials address emerging technologies including artificial intelligence applications, machine learning algorithms, blockchain implementations, and Internet of Things sensor networks that increasingly shape supply chain capabilities. Understanding these frontier technologies alongside established systems enables candidates to demonstrate forward-looking knowledge that positions them as strategic contributors within evolving organizational contexts.

Risk Management and Business Continuity Planning Strategies

Supply chain risk management has emerged as critical competency area reflecting increasing disruption frequency and magnitude across global supply networks. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of risk identification methodologies, probability and impact assessment techniques, mitigation strategy development, and business continuity planning approaches that collectively enhance supply chain resilience.

Premium CPIM-BSP certification dumps address risk management through realistic disruption scenarios requiring candidates to evaluate vulnerability exposures, recommend appropriate mitigation strategies, and develop contingency plans that ensure business continuity despite adverse events. This comprehensive coverage ensures candidates appreciate risk management as proactive discipline rather than reactive crisis response approach.

Advanced preparation materials explore diverse risk categories including supply disruptions, demand volatility, quality failures, transportation interruptions, and information system outages. Understanding this risk taxonomy enables candidates to develop comprehensive risk management frameworks that address multiple threat vectors rather than focusing narrowly on single risk categories while ignoring others.

Sustainability and Environmental Considerations in Supply Chain Management

Environmental sustainability has transitioned from peripheral concern to central strategic imperative within contemporary supply chain management, requiring CPIM BSP candidates to demonstrate understanding of circular economy principles, carbon footprint reduction strategies, sustainable sourcing practices, and reverse logistics system design. Certification preparation must address both business case justifications and operational implementation approaches for sustainability initiatives.

Premium APICS CPIM-BSP practice questions incorporate sustainability scenarios requiring candidates to evaluate environmental impact alternatives, assess trade-offs between sustainability objectives and cost considerations, and recommend balanced approaches that advance environmental goals while maintaining economic viability. This nuanced approach recognizes sustainability as complex domain requiring sophisticated analysis rather than simplistic prioritization.

Advanced preparation materials address emerging sustainability frameworks including lifecycle assessment methodologies, extended producer responsibility concepts, and stakeholder engagement approaches that collectively enable organizations to navigate increasing environmental expectations from customers, regulators, and society broadly. Understanding these frameworks positions candidates as knowledgeable contributors to organizational sustainability strategy development and implementation.

Global Supply Chain Management and International Trade Considerations

Globalization has fundamentally transformed supply chain management, requiring professionals to demonstrate understanding of international trade regulations, customs procedures, import and export documentation requirements, and cross-cultural management considerations. CPIM Basics of Supply Chain Management curriculum addresses these global dimensions through content covering Incoterms applications, foreign exchange risk management, and global sourcing strategy development.

Premium CPIM-BSP exam dumps explore global supply chain concepts through international scenarios requiring candidates to navigate regulatory requirements, evaluate international sourcing decisions, and recommend appropriate risk mitigation strategies for global operations. This comprehensive coverage ensures candidates develop capabilities necessary for success within increasingly internationalized supply chain environments.

Advanced preparation materials address contemporary globalization challenges including trade policy uncertainty, geopolitical risk assessment, and nearshoring versus offshoring trade-off analysis. Understanding these complex considerations enables candidates to demonstrate sophisticated thinking about global supply chain strategy that transcends simplistic cost minimization approaches while appreciating multifaceted factors influencing international operations success.

Organizational Change Management for Supply Chain Transformation Initiatives

Successful supply chain improvement initiatives require effective change management approaches that address human dimensions alongside technical considerations. CPIM BSP curriculum requires candidates to demonstrate understanding of stakeholder analysis techniques, communication strategy development, resistance management approaches, and training program design principles that collectively enable successful transformation initiatives.

Premium APICS CPIM BSP braindumps incorporate change management scenarios requiring candidates to evaluate organizational readiness, identify potential resistance sources, and recommend appropriate intervention strategies that facilitate change adoption. This comprehensive coverage recognizes that technical excellence proves insufficient without complementary attention to organizational and human factors influencing implementation success.

Advanced preparation materials explore change management frameworks including Kotter's eight-step process, ADKAR model applications, and participative change approaches that leverage employee involvement to enhance change initiative success rates. Understanding these structured methodologies enables candidates to approach organizational change systematically rather than relying on intuition alone when navigating complex transformation challenges.

Leadership and Team Development Within Supply Chain Organizations

Supply chain excellence depends fundamentally upon effective leadership and high-performing teams, requiring CPIM BSP candidates to demonstrate understanding of leadership style alternatives, team development stages, conflict resolution approaches, and motivation theory applications. Certification preparation must address both leadership competencies and team dynamics that collectively determine organizational capability to execute supply chain strategies effectively.

Premium CPIM-BSP certification dumps explore leadership concepts through organizational scenarios requiring candidates to evaluate leadership approach appropriateness, recommend team composition strategies, and suggest intervention approaches for team dysfunction situations. This practical orientation ensures candidates develop applicable leadership insights rather than merely memorizing theoretical constructs disconnected from organizational realities.

Advanced preparation materials address contemporary leadership challenges including virtual team management, cross-functional collaboration facilitation, and talent development strategies that enhance organizational capability over time. Understanding these modern leadership dimensions positions candidates to contribute effectively within evolving organizational structures that increasingly emphasize collaboration across traditional functional boundaries.

Strategic Sourcing and Supplier Relationship Management Excellence

Strategic sourcing transcends traditional purchasing approaches by emphasizing total cost of ownership optimization, supplier capability development, and collaborative relationship structures that create mutual value for buying organizations and suppliers. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of category management approaches, should-cost analysis methodologies, and supplier performance measurement systems.

Premium APICS CPIM-BSP exam questions address strategic sourcing through procurement scenarios requiring candidates to evaluate make-versus-buy decisions, assess supplier qualification criteria, and recommend appropriate relationship structures based on purchase category characteristics. This comprehensive coverage ensures candidates appreciate sourcing as strategic activity rather than tactical transaction processing function.

Advanced preparation materials explore contemporary sourcing approaches including low-cost country sourcing considerations, supplier development program design, and supplier integration strategies that leverage external capabilities to enhance organizational competitiveness. Understanding these sophisticated sourcing concepts enables candidates to contribute strategically to procurement excellence rather than merely executing established purchasing procedures.

Demand Planning and Forecasting Methodology Sophistication

Accurate demand planning represents foundational requirement for supply chain excellence, requiring CPIM BSP candidates to demonstrate proficiency across diverse forecasting methodologies including time series analysis, causal modeling, qualitative techniques, and collaborative forecasting approaches. Certification preparation must address both quantitative calculation capabilities and conceptual understanding of forecast method selection criteria appropriate for different demand pattern characteristics.

Premium CPIM-BSP dumps extensively cover forecasting concepts through quantitative problems requiring forecast calculations alongside conceptual questions assessing understanding of forecast accuracy measurement, forecast bias detection, and forecast improvement strategies. This balanced approach ensures candidates develop comprehensive forecasting competencies applicable across diverse organizational contexts and product categories.

Advanced preparation materials address contemporary forecasting challenges including demand sensing technologies, machine learning applications, and demand shaping strategies that proactively influence demand patterns rather than passively forecasting future requirements. Understanding these frontier approaches positions candidates as knowledgeable contributors to demand planning excellence within increasingly sophisticated organizational contexts.

Lean Manufacturing Principles and Continuous Improvement Methodologies

Lean manufacturing philosophy has profoundly influenced contemporary supply chain management, requiring CPIM Basics of Supply Chain Management candidates to demonstrate understanding of waste elimination principles, value stream mapping techniques, pull system implementations, and continuous improvement frameworks. Certification preparation must address both lean concepts and practical implementation approaches that enable organizations to achieve operational excellence through systematic waste reduction.

Premium APICS CPIM BSP exam questions explore lean principles through operational scenarios requiring candidates to identify waste categories, recommend improvement interventions, and evaluate implementation approaches for lean initiatives. This applied orientation ensures candidates develop practical capabilities to contribute meaningfully to organizational lean transformation efforts rather than merely discussing theoretical lean concepts.

Advanced preparation materials address contemporary lean approaches including lean six sigma integration, lean service applications, and lean supply chain extensions that apply lean principles beyond traditional manufacturing contexts. Understanding these expanded lean applications enables candidates to demonstrate versatility in applying lean thinking across diverse organizational settings and industry sectors.

Capacity Planning and Resource Optimization Strategies

Effective capacity planning ensures organizations maintain appropriate resource levels to meet demand requirements while avoiding costly excess capacity that undermines profitability. CPIM BSP curriculum requires candidates to demonstrate understanding of capacity measurement approaches, capacity planning time horizons, capacity adjustment alternatives, and capacity utilization optimization techniques.

Premium CPIM-BSP certification dumps address capacity planning through scenarios requiring candidates to calculate capacity requirements, evaluate capacity expansion alternatives, and recommend appropriate capacity strategies based on demand forecasts and strategic considerations. This comprehensive coverage ensures candidates develop both analytical capabilities and strategic thinking skills necessary for effective capacity management.

Advanced preparation materials explore sophisticated capacity considerations including theory of constraints applications, bottleneck identification methodologies, and flexible capacity strategies that enable rapid adjustment to demand fluctuations. Understanding these advanced concepts positions candidates to contribute strategically to capacity planning excellence that balances efficiency objectives with flexibility requirements.

Master Scheduling and Production Control Execution

Master production scheduling translates demand requirements into specific production plans that guide daily operational execution while balancing multiple competing objectives including customer service, inventory investment, and production efficiency. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate proficiency in master schedule development, available-to-promise calculations, and schedule stability management approaches.

Premium APICS CPIM-BSP practice questions extensively cover master scheduling through realistic scenarios requiring candidates to develop schedules, resolve scheduling conflicts, and make trade-off decisions that balance competing priorities. This practical approach ensures candidates develop applicable scheduling capabilities rather than merely understanding theoretical scheduling concepts.

Advanced preparation materials address contemporary scheduling challenges including mixed-model scheduling approaches, level loading techniques, and advanced planning system applications that leverage optimization algorithms to enhance scheduling effectiveness. Understanding these sophisticated approaches positions candidates to contribute effectively within increasingly complex production planning environments.

Material Requirements Planning System Logic and Applications

Material requirements planning systems represent foundational planning technology within manufacturing organizations, requiring CPIM BSP candidates to demonstrate detailed understanding of MRP logic, system inputs, calculation processes, and output interpretations. Certification preparation must provide extensive practice with MRP mechanics to ensure candidates can accurately trace material requirements through multi-level product structures.

Premium CPIM-BSP exam dumps incorporate numerous MRP scenarios requiring candidates to perform net requirements calculations, determine planned order releases, and identify system nervousness causes. This quantitative emphasis ensures candidates develop computational proficiency necessary for MRP system success alongside conceptual understanding of planning logic.

Advanced preparation materials address MRP system enhancements including distribution requirements planning extensions, closed-loop MRP implementations, and manufacturing resource planning evolution. Understanding this systems evolution enables candidates to appreciate MRP within broader enterprise resource planning context rather than viewing it as isolated planning tool.

Just-In-Time Manufacturing and Pull System Implementations

Just-in-time manufacturing represents alternative production philosophy emphasizing flow optimization, inventory minimization, and quality perfection rather than traditional batch manufacturing approaches. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of JIT prerequisites, kanban system mechanics, and implementation challenges that organizations encounter when transitioning from traditional push systems to pull-based approaches.

Premium APICS CPIM BSP braindumps explore JIT concepts through implementation scenarios requiring candidates to evaluate organizational readiness, design appropriate kanban systems, and recommend transition strategies that minimize disruption risks. This practical orientation ensures candidates appreciate JIT implementation complexity rather than viewing it as simple inventory reduction initiative.

Advanced preparation materials address JIT evolution including lean manufacturing integration, synchronous manufacturing concepts, and quick response manufacturing approaches. Understanding these related methodologies enables candidates to demonstrate comprehensive knowledge of pull-based manufacturing philosophies that collectively advance operational excellence objectives.

Total Quality Management and Statistical Process Control Applications

Quality excellence requires systematic approaches encompassing prevention philosophies, statistical monitoring techniques, and continuous improvement cultures that permeate organizational operations. CPIM BSP curriculum requires candidates to demonstrate understanding of quality cost categories, control chart applications, process capability analysis, and quality improvement methodologies including Six Sigma approaches.

Premium CPIM-BSP certification dumps incorporate quality management scenarios requiring candidates to interpret control charts, calculate process capability indices, and recommend appropriate quality improvement interventions. This quantitative and qualitative coverage ensures candidates develop comprehensive quality management capabilities applicable across diverse operational contexts.

Advanced preparation materials address contemporary quality approaches including design for six sigma methodologies, quality function deployment techniques, and statistical sampling plan design. Understanding these sophisticated quality tools positions candidates to contribute strategically to organizational quality excellence rather than merely performing quality control inspections.

Distribution Requirements Planning and Transportation Management

Distribution requirements planning extends material requirements planning logic into distribution network contexts, requiring CPIM Basics of Supply Chain Management candidates to demonstrate understanding of DRP mechanics, safety stock positioning strategies, and distribution network inventory optimization. Certification preparation must address both DRP calculations and strategic distribution network design considerations that collectively determine distribution system effectiveness.

Premium APICS CPIM-BSP exam questions explore distribution planning through scenarios requiring candidates to perform DRP calculations, evaluate inventory positioning alternatives, and recommend appropriate distribution strategies based on customer service requirements and cost considerations. This comprehensive coverage ensures candidates develop both analytical and strategic capabilities necessary for distribution excellence.

Advanced preparation materials address transportation management topics including mode selection criteria, route optimization techniques, and freight consolidation strategies that minimize transportation costs while meeting delivery commitments. Understanding these transportation considerations enables candidates to appreciate distribution planning within broader logistics optimization context.

Project Management Applications Within Supply Chain Contexts

Supply chain improvement initiatives frequently require project management capabilities to ensure successful implementation within time, budget, and scope constraints. CPIM BSP curriculum requires candidates to demonstrate understanding of project planning techniques, network diagram construction, critical path identification, and project control approaches that enable effective initiative management.

Premium CPIM-BSP dumps incorporate project management scenarios requiring candidates to develop project schedules, identify critical paths, and recommend appropriate control approaches for supply chain projects. This practical orientation ensures candidates develop applicable project management skills relevant for supply chain improvement initiative leadership.

Advanced preparation materials address contemporary project management approaches including agile methodologies, program management frameworks, and portfolio management concepts. Understanding these evolved project approaches positions candidates to manage supply chain initiatives effectively within increasingly complex organizational environments that demand both structure and flexibility.

Financial Analysis and Cost Management for Supply Chain Decisions

Sound financial analysis capabilities enable supply chain professionals to evaluate alternatives objectively and make decisions that optimize organizational profitability. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of relevant cost concepts, financial metric calculations, and investment evaluation techniques applicable to supply chain decisions.

Premium APICS CPIM BSP exam questions address financial analysis through scenarios requiring candidates to calculate inventory carrying costs, evaluate make-versus-buy decisions using financial criteria, and assess capital investment alternatives using return on investment calculations. This quantitative emphasis ensures candidates develop financial literacy necessary for effective supply chain decision-making.

Advanced preparation materials explore sophisticated financial concepts including activity-based costing applications, total cost of ownership analysis, and working capital optimization strategies. Understanding these advanced financial tools positions candidates to contribute strategically to organizational profitability through financially sound supply chain decisions.

Information Technology Foundations for Supply Chain Systems

Effective supply chain management increasingly depends upon sophisticated information systems requiring CPIM BSP candidates to demonstrate foundational understanding of database concepts, system integration requirements, and technology implementation considerations. Certification preparation must address both technical system capabilities and organizational factors influencing system success.

Premium CPIM-BSP certification dumps explore information technology through system selection scenarios requiring candidates to evaluate system requirements, assess alternative solutions, and recommend implementation approaches. This comprehensive coverage ensures candidates appreciate technology within organizational context rather than viewing systems solely through technical lens.

Advanced preparation materials address emerging technologies including cloud computing applications, mobile technology enablement, and advanced analytics capabilities. Understanding these technology trends positions candidates to contribute knowledgeably to organizational technology strategy discussions rather than merely using existing systems without strategic perspective.

Professional Ethics and Responsibility Within Supply Chain Management

Ethical conduct represents foundational expectation for supply chain professionals who frequently encounter situations involving conflicts of interest, confidential information, and decisions affecting multiple stakeholders. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of professional ethics principles, ethical decision-making frameworks, and corporate social responsibility considerations.

Premium APICS CPIM-BSP practice questions incorporate ethical scenarios requiring candidates to identify ethical issues, evaluate alternative courses of action, and recommend appropriate responses consistent with professional standards. This coverage ensures candidates appreciate ethical dimensions of supply chain management rather than focusing exclusively on technical competencies.

Advanced preparation materials address contemporary ethics challenges including corruption prevention, transparency expectations, and stakeholder management approaches that navigate competing interests ethically. Understanding these complex ethical considerations positions candidates as trusted professionals who can navigate difficult situations while maintaining integrity.

Career Development Pathways and Professional Growth Strategies

CPIM BSP certification represents important career milestone that opens doors to diverse supply chain opportunities spanning operations management, procurement, planning, and strategic roles. Candidates benefit from understanding career pathways, complementary certifications, and professional development strategies that maximize certification investment returns.

Premium CPIM-BSP exam dumps support career development by ensuring certification success that validates competency to employers and enhances professional credibility. This certification foundation enables candidates to pursue progressively responsible supply chain positions while building expertise that distinguishes them within competitive employment markets.

Advanced preparation materials address broader professional development considerations including networking strategies, continuing education opportunities, and career transition approaches. Understanding these career dimensions enables candidates to leverage certification strategically within broader professional development plans that accelerate career progression toward desired objectives.

Examination Day Success Strategies and Performance Optimization

Certification examination success requires not only content knowledge but also effective test-taking strategies, anxiety management techniques, and performance optimization approaches. Premium preparation resources provide comprehensive guidance spanning content mastery, examination logistics, and psychological preparation that collectively enhance examination performance.

Candidates benefit from understanding examination format, question types, time management approaches, and response selection strategies that maximize scoring potential. Premium APICS CPIM BSP braindumps provide authentic examination experience through realistic practice questions that familiarize candidates with actual examination characteristics, eliminating surprise factors that undermine performance.

Advanced preparation includes practice examination experiences that simulate actual testing conditions, enabling candidates to refine pacing strategies, identify stamina requirements, and build confidence through successful practice performances. This comprehensive preparation approach transforms examination day from anxious ordeal into confident demonstration of earned competency.

Technological Advancements Shaping Future Supply Chain Practices

Supply chain management continues evolving rapidly through technological innovations including artificial intelligence, machine learning, robotics, autonomous vehicles, and blockchain implementations. CPIM BSP candidates benefit from understanding these emerging technologies alongside traditional concepts, positioning themselves as forward-thinking professionals prepared for future supply chain environments.

Premium CPIM-BSP certification dumps incorporate emerging technology concepts where relevant to certification content, ensuring candidates demonstrate knowledge currency alongside foundational competencies. This balanced approach prepares candidates for both current organizational realities and future supply chain transformations increasingly influenced by technological capabilities.

Advanced preparation materials explore potential technology impacts including automation effects on workforce requirements, data analytics applications for decision enhancement, and digital twin implementations for simulation-based planning. Understanding these frontier developments positions candidates as strategic contributors to organizational technology adoption discussions rather than passive recipients of technology-driven changes.

Cross-Functional Collaboration Excellence in Supply Chain Operations

Contemporary supply chain excellence requires effective collaboration across organizational functions including sales, marketing, finance, engineering, and operations. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of cross-functional integration requirements, collaborative planning processes, and communication strategies that facilitate effective coordination across organizational boundaries.

Premium APICS CPIM-BSP exam questions incorporate cross-functional scenarios requiring candidates to navigate competing functional priorities, recommend collaborative approaches, and resolve conflicts that inevitably arise when diverse perspectives intersect. This realistic coverage ensures candidates develop collaboration capabilities necessary for supply chain success within complex organizational environments.

Advanced preparation materials address contemporary collaboration enablers including sales and operations planning processes, integrated business planning frameworks, and collaborative forecasting approaches. Understanding these structured collaboration methodologies enables candidates to facilitate effective cross-functional coordination that optimizes organizational performance beyond what isolated functional excellence could achieve.

Regulatory Compliance and Standards Adherence Requirements

Supply chain operations face increasing regulatory scrutiny spanning product safety, environmental standards, labor practices, and trade compliance requirements. CPIM BSP curriculum requires candidates to demonstrate awareness of regulatory landscape, compliance management approaches, and audit preparation strategies that ensure organizations meet legal obligations while maintaining operational efficiency.

Premium CPIM-BSP dumps address regulatory topics through compliance scenarios requiring candidates to identify regulatory requirements, evaluate compliance status, and recommend remediation approaches for deficiencies. This coverage ensures candidates appreciate regulatory dimensions of supply chain management that extend beyond operational efficiency considerations.

Advanced preparation materials explore industry-specific regulations including pharmaceutical supply chain requirements, food safety standards, and hazardous materials handling regulations. Understanding these specialized requirements positions candidates for success within regulated industries where compliance expertise represents differentiating capability valued by employers.

Customer Service Excellence and Demand Fulfillment Optimization

Superior customer service represents ultimate supply chain objective, requiring organizations to balance service level commitments with cost efficiency realities. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of service level metrics, order fulfillment processes, and customer service strategy development that creates competitive advantage through supply chain excellence.

Premium APICS CPIM BSP exam questions explore customer service through scenarios requiring candidates to evaluate service level alternatives, calculate fill rate metrics, and recommend appropriate service strategies based on customer segmentation approaches. This comprehensive coverage ensures candidates appreciate customer service as strategic supply chain outcome rather than operational afterthought.

Advanced preparation materials address omnichannel fulfillment challenges, last-mile delivery optimization, and returns management processes that collectively determine customer experience quality. Understanding these contemporary service delivery dimensions positions candidates to contribute effectively within evolving retail and distribution environments increasingly shaped by e-commerce growth.

Data Analytics and Business Intelligence Applications

Data-driven decision making has become supply chain management cornerstone, requiring professionals to demonstrate proficiency in data analysis techniques, visualization methods, and insight generation approaches. CPIM BSP curriculum requires candidates to understand key performance indicators, dashboard design principles, and analytical methodologies that transform raw data into actionable supply chain intelligence.

Premium CPIM-BSP certification dumps incorporate analytical scenarios requiring candidates to interpret performance data, identify trends, and recommend data-driven improvements. This analytical emphasis ensures candidates develop capabilities to leverage organizational data assets effectively rather than relying solely on intuition for supply chain decisions.

Advanced preparation materials explore sophisticated analytics including predictive modeling, prescriptive analytics, and artificial intelligence applications. Understanding these advanced analytical approaches positions candidates to contribute strategically to organizational analytics capability development that enhances decision quality through data science applications.

Organizational Culture and Change Readiness Assessment

Successful supply chain transformation initiatives require organizational cultures that embrace change, continuous improvement, and innovation. CPIM Basics of Supply Chain Management curriculum requires candidates to understand culture assessment approaches, change readiness evaluation techniques, and cultural transformation strategies that enable sustainable organizational improvement.

Premium APICS CPIM-BSP practice questions incorporate organizational scenarios requiring candidates to assess cultural barriers, recommend culture change initiatives, and evaluate organizational readiness for supply chain transformations. This comprehensive coverage ensures candidates appreciate cultural dimensions that profoundly influence supply chain initiative success rates.

Advanced preparation materials address culture development strategies including leadership modeling, reward system alignment, and communication approaches that reinforce desired cultural attributes. Understanding these culture change methodologies enables candidates to contribute effectively to organizational transformation efforts that require cultural evolution alongside process improvements.

Negotiation Skills and Relationship Management Competencies

Effective negotiation capabilities enable supply chain professionals to secure favorable commercial terms while maintaining constructive supplier relationships essential for long-term success. CPIM BSP curriculum requires candidates to demonstrate understanding of negotiation preparation approaches, negotiation tactics, and relationship management strategies that balance immediate transaction optimization with relationship preservation.

Premium CPIM-BSP exam dumps explore negotiation through procurement scenarios requiring candidates to evaluate negotiation positions, recommend negotiation strategies, and assess negotiation outcomes against multiple criteria. This practical orientation ensures candidates develop applicable negotiation skills rather than merely understanding theoretical negotiation concepts.

Advanced preparation materials address sophisticated negotiation approaches including collaborative negotiation methodologies, multi-party negotiation complexities, and cultural considerations in international negotiations. Understanding these advanced negotiation dimensions positions candidates for success in increasingly complex procurement environments requiring sophisticated relationship management capabilities.

Disaster Recovery and Emergency Response Planning

Supply chain resilience depends upon robust disaster recovery planning and effective emergency response capabilities that minimize disruption impacts when adverse events occur. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of business continuity planning approaches, emergency response protocols, and recovery strategy development that ensures organizational survival during crisis situations.

Premium APICS CPIM BSP braindumps incorporate disaster scenarios requiring candidates to evaluate vulnerability exposures, recommend preparedness investments, and design response protocols appropriate for diverse disruption types. This comprehensive coverage ensures candidates appreciate resilience as proactive investment rather than reactive crisis management approach.

Advanced preparation materials address contemporary resilience challenges including pandemic response planning, cyber security incident management, and climate change adaptation strategies. Understanding these evolving threat landscapes positions candidates to contribute knowledgeably to organizational resilience enhancement initiatives that address emerging risks alongside traditional disruption categories.

Intellectual Property Protection and Competitive Intelligence Management

Supply chain operations frequently involve proprietary information requiring protection while simultaneously demanding competitive intelligence gathering to inform strategic decisions. CPIM BSP curriculum requires candidates to demonstrate understanding of intellectual property concepts, confidentiality management approaches, and ethical intelligence gathering techniques that navigate tension between information protection and acquisition needs.

Premium CPIM-BSP certification dumps address intellectual property through scenarios requiring candidates to identify protection requirements, evaluate security measures, and recommend appropriate safeguards for proprietary information. This coverage ensures candidates appreciate information security dimensions of supply chain management extending beyond operational efficiency considerations.

Advanced preparation materials explore contemporary intellectual property challenges including trade secret protection, patent strategy considerations, and technology transfer agreements. Understanding these sophisticated intellectual property topics positions candidates to contribute effectively within knowledge-intensive industries where intellectual property represents core organizational asset requiring diligent protection.

Workforce Planning and Talent Development Strategies

Supply chain excellence ultimately depends upon skilled workforce capable of executing sophisticated processes and contributing to continuous improvement initiatives. CPIM Basics of Supply Chain Management curriculum requires candidates to demonstrate understanding of workforce planning approaches, competency development strategies, and succession planning methodologies that ensure organizational capability sustainability.

Premium APICS CPIM-BSP exam questions incorporate workforce scenarios requiring candidates to evaluate staffing requirements, recommend training initiatives, and design development programs that enhance organizational capability.

Conclusion

Successfully achieving the CPIM-BSP (Certified in Production and Inventory Management – Basics of Supply Planning) certification is more than just memorizing concepts; it requires a comprehensive, strategic approach that balances knowledge acquisition, practical application, and exam readiness. The strategies outlined in this guide emphasize a structured study plan, consistent practice, and a deep understanding of supply chain fundamentals, all of which are critical for not only passing the exam but also applying these principles effectively in real-world scenarios. By adopting a methodical preparation strategy, candidates can transform what may initially seem like a daunting challenge into a manageable and rewarding journey.

One of the most important aspects of exam preparation is creating a personalized study plan. Understanding your strengths and weaknesses allows you to allocate time efficiently, ensuring that complex topics receive sufficient attention while reinforcing foundational knowledge. Utilizing a combination of official study materials, supplementary resources, and practice exams can provide a well-rounded approach that addresses both theoretical concepts and practical applications. This ensures familiarity with the exam format, improves time management skills, and builds confidence when confronting challenging questions.

Another key element is active engagement with the material. Passive reading is rarely sufficient for mastery. Techniques such as summarizing chapters in your own words, creating visual aids like flowcharts or mind maps, and discussing topics with peers or mentors help reinforce learning. Additionally, frequent self-assessment through quizzes and mock tests not only identifies areas that need improvement but also helps in retaining information over the long term. Consistency and discipline in following a study schedule play a pivotal role in maintaining progress and avoiding last-minute stress.

Equally important is developing an analytical mindset. The CPIM-BSP exam tests the ability to apply supply chain principles to real-life scenarios rather than just recall facts. Approaching problems logically, understanding the cause-and-effect relationships within supply planning, and evaluating multiple solutions critically will help you tackle situational questions with confidence.

Finally, maintaining a positive attitude and resilience throughout the preparation process cannot be overstated. A balanced approach that includes adequate rest, stress management, and healthy routines ensures that mental sharpness and focus are sustained until exam day.

Conquering the CPIM-BSP certification is achievable through a blend of structured planning, active learning, analytical thinking, and consistent practice. By integrating these strategies, candidates not only increase their chances of success but also gain a solid foundation for long-term career growth in supply chain management. Strategic preparation turns the CPIM-BSP journey from a test of memory into a transformative professional milestone.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.