Certification: CLSSGB

Certification Full Name: Certified Lean Six Sigma Green Belt

Certification Provider: GAQM

Exam Code: CLSSGB

Exam Name: Certified Lean Six Sigma Green Belt - GAQM

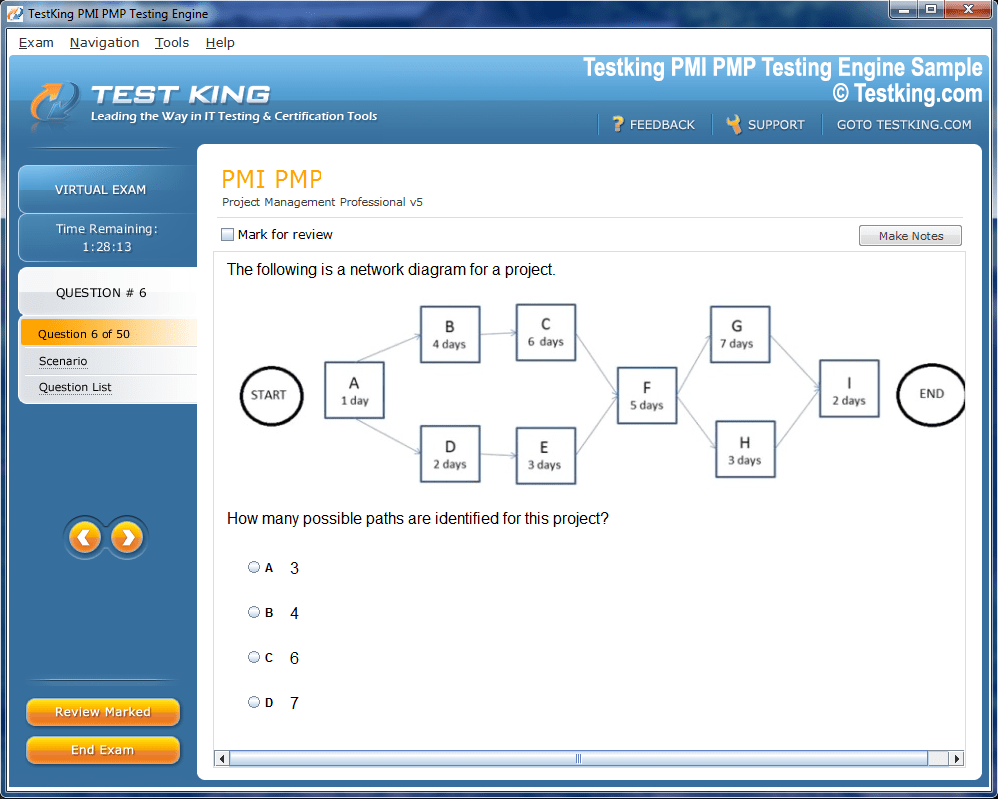

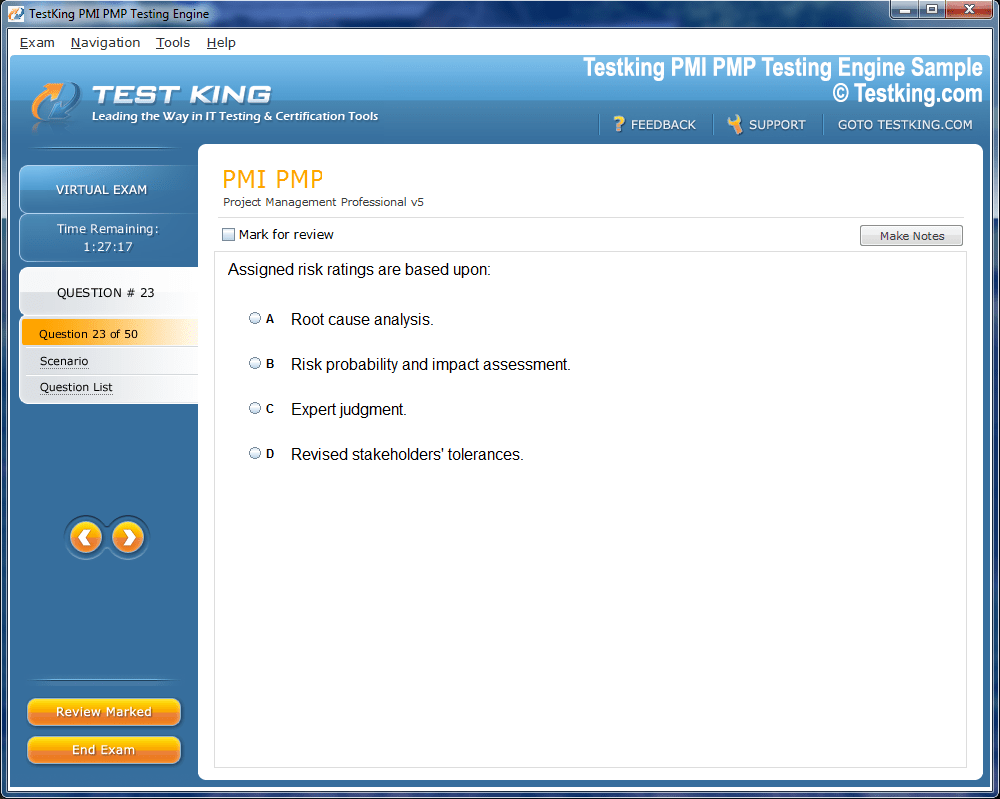

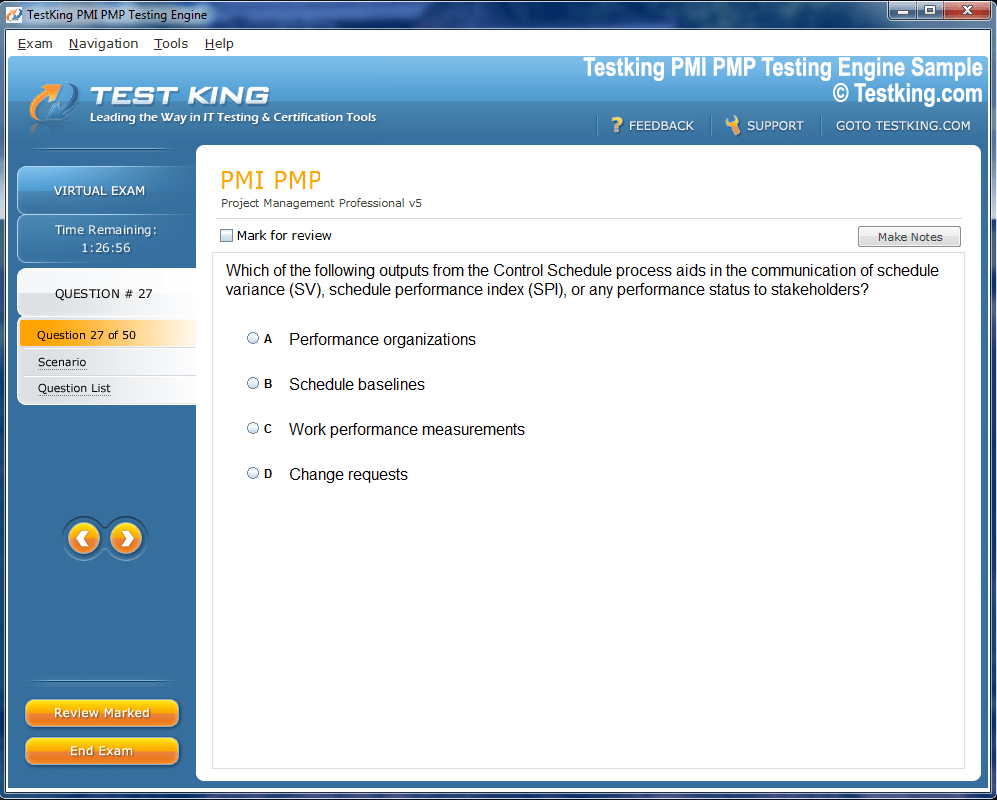

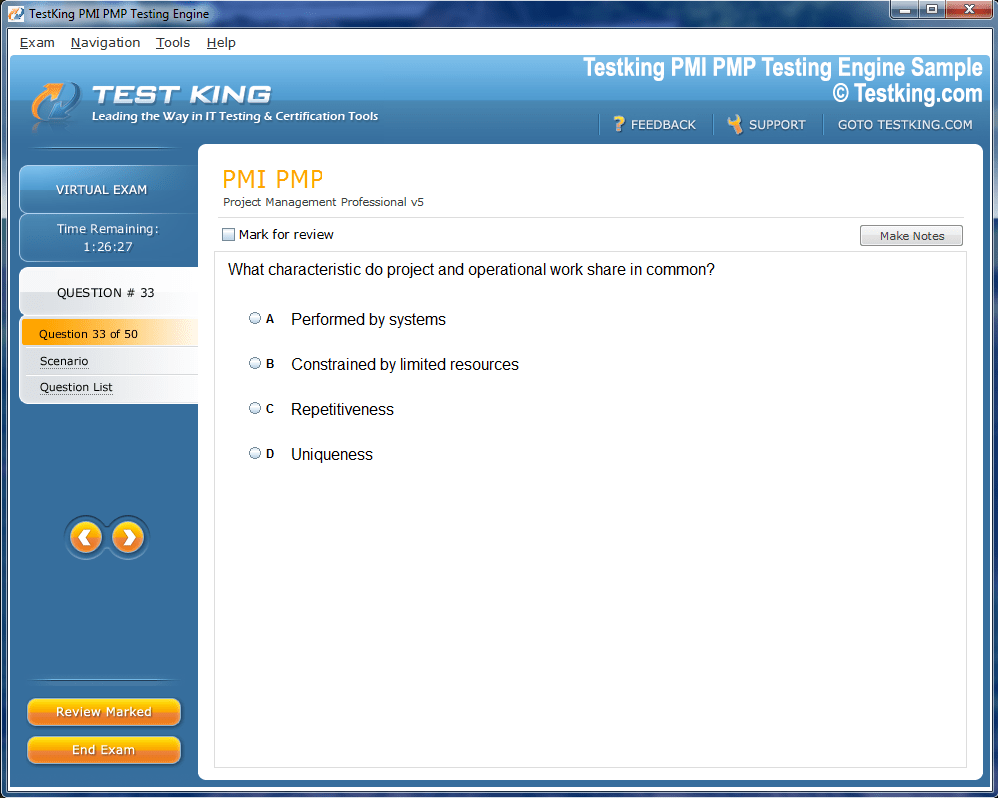

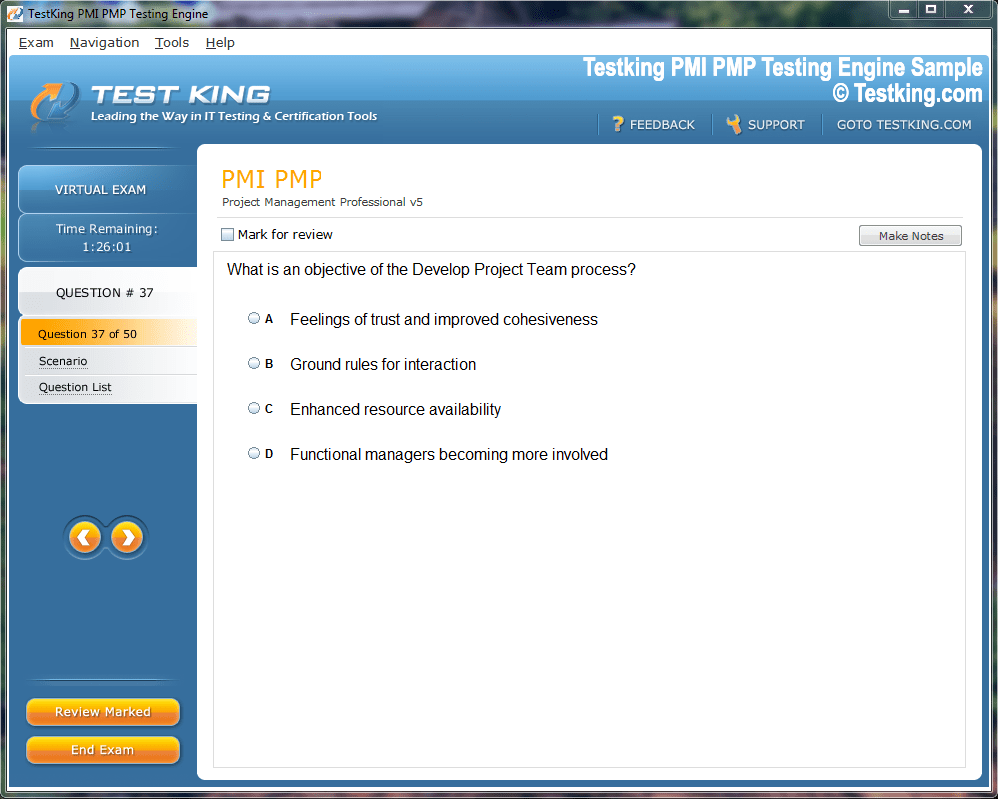

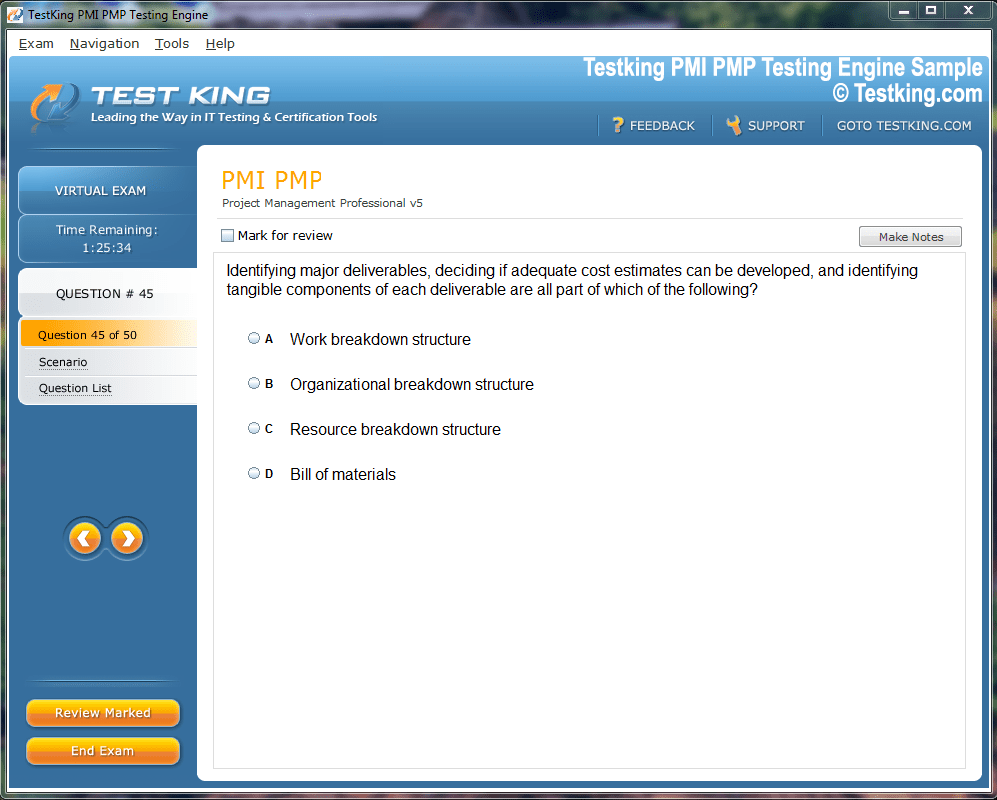

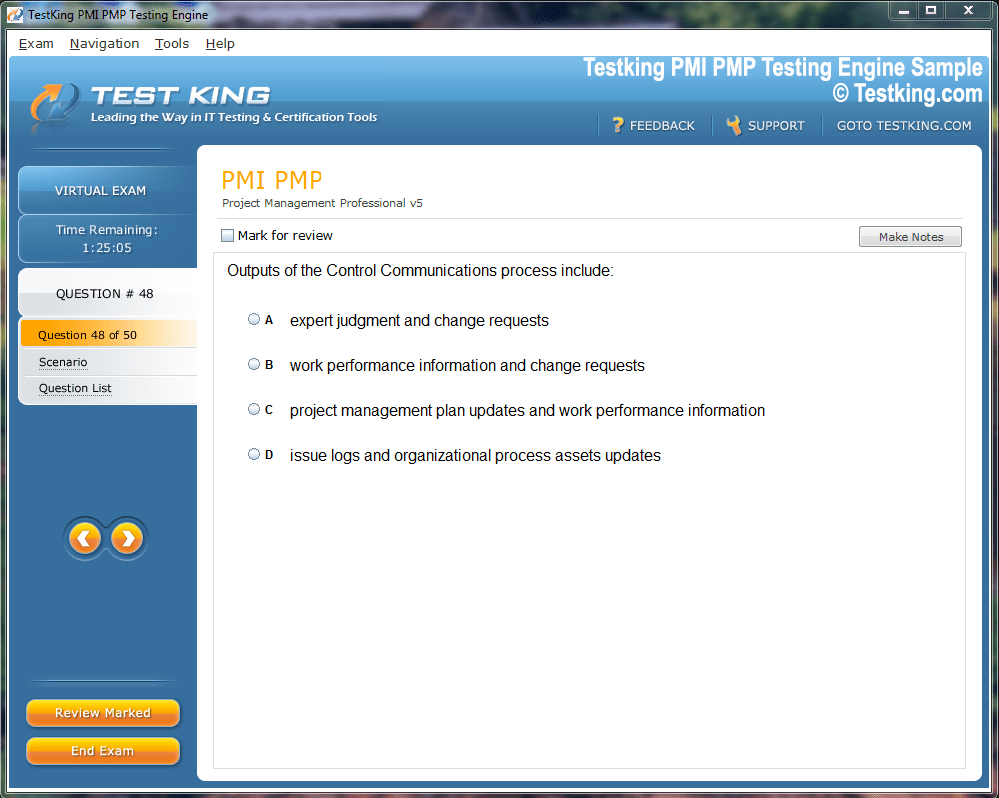

Product Screenshots

nop-1e =1

Becoming a Lean Six Sigma Expert through CLSSGB Certification

In 1980, Bill Smith, an American industrialist, conceptualized the Six Sigma methodology, a rigorous approach aimed at optimizing organizational processes and minimizing defects in products and services. This methodology, now ubiquitous across diverse industries, provides a systematic framework for identifying inefficiencies, reducing variability, and enhancing profitability. Six Sigma emphasizes precision and consistency, aspiring to achieve a defect rate no greater than 3.4 per million opportunities. Its adoption by corporations worldwide is rooted in the methodology's ability to foster operational excellence, streamline workflows, and enhance customer satisfaction through quantifiable process improvement.

Lean Six Sigma, an amalgamation of Lean management principles and Six Sigma techniques, extends the philosophy of process optimization. Lean focuses on the elimination of waste, whether it be excess motion, redundant processes, or unnecessary inventory, thereby enhancing value creation for the end consumer. When integrated with Six Sigma’s statistical rigor and structured problem-solving approach, Lean Six Sigma provides organizations with a powerful arsenal to address inefficiencies, minimize delays, and sustain consistent revenue streams. For organizations navigating increasingly complex competitive landscapes, Lean Six Sigma serves as a strategic instrument to harmonize operational efficiency with quality assurance.

The conceptual underpinning of Lean Six Sigma revolves around the notion of continuous improvement. It is predicated upon the belief that processes are malleable and can be refined through meticulous measurement, disciplined analysis, and targeted interventions. By employing data-driven decision-making and fostering a culture of accountability, organizations can systematically identify sources of variation and implement robust corrective measures. The methodology’s people-centric orientation underscores that successful process improvement is contingent not only on analytical acumen but also on the commitment, expertise, and collaboration of the team involved.

Role of Lean Six Sigma Green Belts

Lean Six Sigma Green Belts occupy a critical niche within organizational improvement initiatives. Unlike Black Belts, who often spearhead projects with full-time dedication, Green Belts typically engage in process improvement efforts on a part-time basis while maintaining their primary professional responsibilities. Despite this distinction, Green Belts are instrumental in executing process enhancement strategies, supporting Black Belts in data collection, analysis, and implementation of corrective actions, and ensuring that projects align with organizational objectives.

The responsibilities of a Green Belt extend beyond mere assistance; they encompass a thorough understanding of statistical tools, problem-solving methodologies, and process optimization techniques. Green Belts are adept at interpreting data, identifying process bottlenecks, and recommending solutions that reduce variability and enhance efficiency. Their contributions are particularly vital in cross-functional teams where collaboration and precise execution determine the success of improvement projects. By developing expertise in both Lean principles and Six Sigma techniques, Green Belts bridge the gap between strategic project leadership and operational implementation.

The presence of Green Belts within an organization augments the effectiveness of Lean Six Sigma projects. While Black Belts provide advanced analytical guidance and oversee complex projects, Green Belts facilitate the dissemination of knowledge throughout the organization, enabling broader participation in process improvement initiatives. This dual-tiered approach ensures that improvement efforts are both technically rigorous and operationally practical, promoting a culture of continuous learning and proactive problem-solving.

Advantages of Lean Six Sigma Certification

Achieving Lean Six Sigma Green Belt certification confers numerous professional and organizational benefits. For individuals, the certification validates proficiency in process improvement methodologies, statistical analysis, and project management. It enhances employability, providing recognition as a competent practitioner capable of driving tangible business outcomes. For organizations, having certified Green Belts contributes to higher efficiency, reduced operational costs, and improved quality control. The implementation of Lean Six Sigma strategies often translates into measurable gains in customer satisfaction, as defect-free processes yield products and services that consistently meet or exceed expectations.

Certification also equips candidates with the skills necessary to contribute meaningfully to team-based projects. Green Belts learn to navigate project dynamics, manage stakeholder expectations, and communicate analytical findings effectively. These competencies are crucial for ensuring that improvement initiatives are both technically sound and organizationally relevant. Moreover, certification serves as a foundation for further professional development, enabling candidates to advance to Black Belt or Master Black Belt levels, where they can assume greater responsibility for strategic process improvement initiatives.

Beyond professional recognition, the certification fosters cognitive and analytical growth. The rigorous training exposes candidates to statistical methods, problem-solving frameworks, and quality management tools that enhance critical thinking and decision-making capabilities. Green Belts develop the ability to synthesize complex information, identify root causes of inefficiencies, and design solutions that optimize processes while minimizing resource expenditure. These cognitive skills, coupled with practical expertise, create versatile professionals capable of driving continuous improvement across a wide spectrum of operational contexts.

Eligibility Criteria and Candidate Profile

While the Lean Six Sigma Green Belt certification does not impose stringent prerequisites, certain attributes and experiences can significantly enhance a candidate’s likelihood of success. Typically, candidates with a minimum of three years of professional experience in relevant fields demonstrate greater readiness for the rigorous analytical and project management demands of the certification. Although a graduate degree is advantageous, it is not mandatory, emphasizing the accessibility of the certification to professionals from diverse educational backgrounds.

The ideal candidate exhibits analytical acuity, meticulous attention to detail, and a propensity for structured problem-solving. Familiarity with organizational processes, quality management principles, and data interpretation techniques is beneficial, as these competencies facilitate a smoother learning curve during exam preparation. Moreover, candidates who cultivate a mindset oriented toward continuous improvement and evidence-based decision-making are better positioned to leverage the full spectrum of Lean Six Sigma methodologies in practical scenarios.

Candidates must achieve a minimum score of 70 percent in the Certified Lean Six Sigma Green Belt examination to earn the credential. This benchmark ensures that certified professionals possess a robust understanding of both theoretical frameworks and practical applications. The exam evaluates proficiency in core areas such as process mapping, statistical analysis, root cause identification, project management, and Lean principles. Successful candidates demonstrate the ability to integrate these competencies into actionable strategies that enhance operational performance.

Exam Structure and Preparation

The Lean Six Sigma Green Belt exam, administered by the International Association for Six Sigma Certification, encompasses a structured assessment designed to evaluate both theoretical understanding and applied problem-solving skills. The examination is typically conducted in a proctored environment and may be taken online or at authorized testing centers. It consists of 100 questions, with formats including multiple-choice, true/false, and descriptive items, providing a comprehensive evaluation of candidate knowledge.

The examination duration is three hours, challenging candidates to apply analytical reasoning efficiently under time constraints. While formal training is recommended, candidates may prepare independently using study guides, practice exams, and other resources that familiarize them with exam content and question patterns. A non-proctored evaluation, such as a preliminary Green Belt assessment, can serve as a diagnostic tool to gauge readiness and identify areas requiring further study.

Preparation for the exam involves mastering a variety of analytical and statistical tools, including process mapping, cause-and-effect analysis, failure mode and effects analysis, and hypothesis testing. Candidates also develop competence in Lean techniques, such as value stream mapping, waste identification, and process flow optimization. By integrating these methodologies, candidates acquire a holistic understanding of process improvement, equipping them to contribute effectively to organizational initiatives.

Examination Policies and Procedures

To ensure the integrity and standardization of the Lean Six Sigma Green Belt exam, candidates must adhere to specific policies and procedures. Identification verification is mandatory, requiring an official photo ID that matches the application submitted to the testing authority. Personal items are secured in temporary storage during the examination to maintain a controlled environment conducive to fair assessment.

Candidates are advised to arrive at least 30 minutes prior to the scheduled exam to complete check-in procedures. Late arrivals may forfeit their opportunity to test, with the associated examination fee non-refundable. Calculator policies stipulate that only non-programmable, battery-operated devices are permitted, precluding the use of devices with memory or graphing functions to prevent unfair advantages.

The exam is strictly closed-book, with no reference materials allowed within the testing area. Items such as unbound notes, slide charts, and writing tablets containing blank pages are prohibited to maintain uniform testing conditions. Candidates must also adhere to specified procedures for rescheduling, cancellation, or absence, ensuring that administrative protocols are followed consistently.

Application and Scheduling

The application process for the Lean Six Sigma Green Belt certification is conducted through the official IASSC platform. Candidates submit their applications online, which are typically reviewed within one to two business days. Paper-based applications undergo a longer review period of three to five days. During this review, eligibility is verified, and applicants who do not meet the criteria are refunded their application fees.

Testing options include on-demand, web-based examinations, which allow candidates to take the proctored exam from home or another secure location at a time of their choosing. Alternatively, candidates may opt to take the exam at a Pearson-Vue authorized testing center, providing a traditional, in-person testing environment. Once the application is approved, candidates can schedule their examination within the designated testing window, selecting a date and time that aligns with their preparedness and convenience.

Understanding Six Sigma Methodology

Six Sigma methodology operates as a structured approach for problem-solving and process improvement, grounded in statistical analysis and data-driven decision-making. The fundamental goal is to identify and eliminate variations in processes that result in defects or inefficiencies. By striving for near-perfection—measured as no more than 3.4 defects per million opportunities—organizations can consistently deliver products and services that meet or exceed customer expectations.

Central to Six Sigma is the DMAIC framework: Define, Measure, Analyze, Improve, and Control. This systematic process ensures that project objectives are clearly delineated, relevant data is collected and scrutinized, root causes of defects are identified, solutions are implemented, and improvements are sustained over time. The methodology emphasizes not only the elimination of waste but also the enhancement of value for both the organization and its customers. DMAIC serves as the backbone of Lean Six Sigma projects, providing practitioners with a repeatable and scalable methodology for continuous improvement.

The integration of Lean principles within Six Sigma amplifies its effectiveness. While Six Sigma focuses on precision and defect reduction, Lean emphasizes the removal of non-value-adding activities and the optimization of workflow. By combining these approaches, organizations can achieve a dual objective: increased efficiency and enhanced quality. Lean Six Sigma practitioners, particularly Green Belts, play a pivotal role in identifying redundant processes, streamlining operations, and fostering a culture of proactive problem-solving.

The Role of Green Belts in Process Improvement

Lean Six Sigma Green Belts are integral to the execution of process improvement initiatives. They often operate part-time on projects while fulfilling their regular professional responsibilities. Despite this, their contribution is substantial, encompassing data collection, statistical analysis, and the implementation of process improvements. Green Belts serve as the connective tissue between operational teams and project leaders, ensuring that improvement strategies are effectively translated into tangible results.

Green Belts are trained to apply a variety of tools and techniques, such as process mapping, cause-and-effect analysis, control charts, and hypothesis testing. These tools enable them to diagnose inefficiencies, quantify process variability, and recommend interventions that minimize defects and enhance efficiency. Their role extends to facilitating team collaboration, communicating findings to stakeholders, and supporting the execution of solutions recommended by Black Belts. By doing so, Green Belts ensure that Lean Six Sigma projects maintain both analytical rigor and operational relevance.

Moreover, Green Belts contribute to knowledge dissemination within the organization. Their involvement in projects fosters a culture of continuous improvement, encouraging colleagues to embrace analytical problem-solving and adopt Lean principles in daily operations. Through mentorship, collaboration, and hands-on engagement, Green Belts amplify the impact of Six Sigma initiatives beyond individual projects, promoting systemic organizational transformation.

Benefits of Lean Six Sigma Green Belt Certification

Obtaining Lean Six Sigma Green Belt certification provides a multitude of professional and organizational advantages. For individuals, certification signifies proficiency in statistical analysis, process optimization, and project management. It serves as a testament to one’s ability to lead and support improvement initiatives, enhancing credibility and employability. Certified Green Belts often experience increased opportunities for career advancement, as organizations value professionals capable of driving measurable improvements.

From an organizational perspective, having certified Green Belts enhances operational performance by reducing process variability, minimizing defects, and improving efficiency. Implementation of Lean Six Sigma strategies leads to cost savings, accelerated cycle times, and heightened customer satisfaction. Certified professionals contribute to the organization’s capacity to meet market demands consistently, ensuring that products and services are delivered with high quality and reliability.

Certification also promotes cognitive and analytical development. Candidates acquire the ability to interpret complex data sets, identify trends, and apply statistical methodologies to solve practical problems. They learn to synthesize information, diagnose root causes, and design interventions that enhance process performance. These competencies cultivate versatile professionals capable of addressing challenges across multiple operational domains and fostering a culture of evidence-based decision-making.

Exam Structure and Requirements

The Certified Lean Six Sigma Green Belt exam, administered by the International Association for Six Sigma Certification (IASSC), is a structured assessment designed to evaluate both theoretical knowledge and applied proficiency. The exam consists of 100 questions, including multiple-choice, true/false, and descriptive formats, and must be completed within three hours. Candidates must achieve a minimum score of 70 percent to earn the credential, ensuring a rigorous standard of competency.

Although there are no mandatory prerequisites, it is recommended that candidates have a minimum of three years of professional experience in relevant fields. A graduate degree can be advantageous but is not compulsory. Prior exposure to project management, quality management, or operational roles can enhance preparedness for the exam, as it provides practical context for theoretical concepts.

Preparation for the exam involves mastery of statistical tools, Lean principles, and process improvement methodologies. Candidates typically engage in structured training programs, independent study using books and guides, and practice exams. These activities familiarize candidates with the exam format, question types, and core concepts, providing a comprehensive understanding of the Lean Six Sigma framework.

Exam Preparation Strategies

Effective preparation for the Lean Six Sigma Green Belt exam involves a multifaceted approach. Candidates benefit from structured study plans that incorporate both theoretical learning and practical application. Core areas of study include process mapping, root cause analysis, hypothesis testing, statistical process control, and Lean methodologies such as value stream mapping and waste reduction techniques.

Practice exams and sample questions are invaluable for developing familiarity with the format and identifying areas that require further study. Engaging in simulations or non-proctored evaluation tests allows candidates to gauge their readiness and refine their understanding of complex concepts. Additionally, participating in group study sessions or discussion forums can enhance comprehension through collaborative learning and peer feedback.

Time management is another critical aspect of exam preparation. Candidates must allocate sufficient time to cover each domain comprehensively while allowing for review and reinforcement of key concepts. Consistent practice and disciplined study routines cultivate confidence, reduce exam anxiety, and improve the likelihood of achieving the required passing score.

Policies and Procedures for Examination

To maintain examination integrity, candidates must comply with IASSC policies and procedures. Identification verification is mandatory, with an official photo ID required to match the exam application. Candidates’ personal belongings are stored securely during the examination to prevent unauthorized access to materials.

Arriving at the testing center at least 30 minutes early is essential to complete check-in procedures. Late arrivals may be denied entry, forfeiting their exam fee. Calculators permitted during the exam must be non-programmable and battery-operated, excluding devices with memory, graphing, or programmable functionalities.

The exam is closed-book, prohibiting reference materials, notes, or electronic devices. Unpermitted items, including slide charts, unbound tablets, and writing materials with blank pages, are strictly forbidden. Candidates must also adhere to protocols for rescheduling or canceling exams, ensuring fair and standardized administration.

Application and Testing Options

Candidates may apply for the Lean Six Sigma Green Belt exam through the official IASSC platform. Online applications are typically processed within one to two business days, while paper submissions require three to five days. During the review process, eligibility is verified, and ineligible applicants are refunded their application fees.

Testing options include on-demand, web-based proctored exams that allow candidates to complete the test remotely at a secure location. Alternatively, candidates may take the exam at a Pearson-Vue authorized testing center for a traditional in-person experience. Once approved, candidates select a suitable date and time within the testing window to schedule their examination.

Continuous Improvement and Organizational Impact

Lean Six Sigma Green Belts contribute significantly to organizational continuous improvement initiatives. By identifying inefficiencies, analyzing data, and implementing corrective actions, they help streamline operations, reduce variability, and enhance quality. Their role extends beyond project-specific contributions, influencing broader organizational culture by promoting analytical thinking, data-driven decision-making, and collaborative problem-solving.

Organizations benefit from the widespread application of Lean Six Sigma principles, achieving operational efficiency, cost reduction, and enhanced customer satisfaction. Green Belts serve as catalysts for change, facilitating the dissemination of best practices and fostering a proactive approach to process improvement. Their involvement ensures that Lean Six Sigma methodologies are embedded into organizational routines, driving sustainable performance improvements.

Lean Six Sigma Principles and Philosophies

Lean Six Sigma is anchored in a philosophy that emphasizes efficiency, precision, and continuous improvement. At its core, it seeks to eliminate defects and redundancies while optimizing workflows to enhance overall productivity. The methodology merges Lean’s focus on waste reduction with Six Sigma’s statistical rigor, creating a synergistic framework that addresses both efficiency and quality. By adhering to these principles, organizations can cultivate a culture of accountability, data-driven decision-making, and persistent refinement.

The philosophy underlying Lean Six Sigma champions the notion that processes are not static but dynamic systems subject to analysis, adjustment, and enhancement. Practitioners are encouraged to continually seek improvement opportunities, whether by reducing variability, streamlining workflows, or optimizing resource allocation. This mindset fosters operational resilience and positions organizations to respond effectively to evolving market demands and technological advancements.

Green Belts embody these philosophies within project teams. They are trained to scrutinize processes, uncover inefficiencies, and implement practical solutions. Their work ensures that improvement initiatives are both analytically robust and operationally feasible. By bridging strategic objectives with day-to-day operations, Green Belts facilitate the alignment of organizational goals with actionable process enhancements, thereby sustaining long-term improvements.

Statistical Tools and Techniques for Green Belts

A cornerstone of Lean Six Sigma proficiency is the mastery of statistical tools and analytical techniques. Green Belts utilize a variety of instruments to measure process performance, identify deviations, and evaluate potential solutions. Tools such as control charts, Pareto analysis, histograms, and scatter plots enable practitioners to interpret data systematically, revealing patterns and trends that inform decision-making.

Root cause analysis is another critical component, allowing Green Belts to diagnose underlying issues that contribute to inefficiencies or defects. Techniques such as the 5 Whys, fishbone diagrams, and failure mode and effects analysis facilitate a structured approach to problem identification and solution development. These methodologies empower Green Belts to implement targeted interventions that enhance process reliability and reduce variability.

In addition to traditional statistical methods, Green Belts employ Lean tools to eliminate non-value-adding activities. Value stream mapping, process flow analysis, and waste identification strategies allow practitioners to visualize workflows, detect bottlenecks, and optimize operations. The integration of statistical analysis with Lean practices enables a holistic approach to process improvement, ensuring that both quality and efficiency are addressed in tandem.

Project Management and Leadership Skills

Green Belts are not only analytical practitioners but also vital contributors to project management and team leadership. Their responsibilities often involve coordinating tasks, monitoring progress, and communicating findings to stakeholders. Effective project management ensures that improvement initiatives adhere to timelines, resource allocations, and organizational objectives.

Leadership skills are essential for fostering collaboration and motivating team members. Green Belts facilitate discussions, mediate conflicts, and encourage adherence to Lean Six Sigma methodologies. By guiding project teams and supporting Black Belts in strategy execution, they ensure that process improvement initiatives achieve their intended outcomes. These leadership competencies enhance both individual performance and organizational effectiveness.

Green Belts also cultivate change management skills, recognizing that successful process improvement involves both technical and human dimensions. They anticipate resistance, communicate the benefits of improvement initiatives, and engage team members in the implementation of solutions. This holistic approach ensures that Lean Six Sigma projects are embraced by stakeholders and integrated seamlessly into organizational practices.

Exam Preparation and Study Techniques

Preparing for the Lean Six Sigma Green Belt exam requires a comprehensive and disciplined approach. Candidates benefit from combining theoretical study with practical application, ensuring mastery of both statistical tools and Lean principles. Study guides, reference books, and online courses provide foundational knowledge, while practice exams and sample questions reinforce understanding and exam readiness.

Time management and structured study schedules are crucial. Candidates should allocate dedicated periods for reviewing core concepts, practicing problem-solving, and simulating exam conditions. Regular self-assessment through quizzes and evaluation tests enables learners to identify gaps in knowledge and target areas that require further study.

Collaborative learning can also enhance preparation. Engaging with peers, participating in discussion forums, and exchanging case studies allow candidates to explore diverse perspectives and deepen comprehension. Practical application of Lean Six Sigma tools within real or simulated projects further solidifies understanding, enabling candidates to translate theoretical concepts into actionable skills.

Exam Policies and Proctoring

To ensure fairness and integrity, the Lean Six Sigma Green Belt exam is governed by strict policies and proctoring procedures. Candidates must present a valid photo ID that matches the application, and all personal items are stored securely during the examination. This controlled environment minimizes the risk of unauthorized assistance and maintains standardized testing conditions.

Calculators used during the exam must be non-programmable and battery-operated, excluding devices capable of storing information or performing graphing functions. The examination is strictly closed-book, prohibiting reference materials, notes, or electronic devices. Adherence to these policies ensures that candidates are assessed solely on their knowledge and analytical capabilities.

Candidates are encouraged to arrive at the testing center well before the scheduled time to complete check-in procedures. Late arrivals may forfeit their exam opportunity, with fees non-refundable. Procedures for rescheduling or canceling the exam are clearly defined, providing candidates with structured options while maintaining the integrity of the certification process.

Certification Application Process

Application for the Lean Six Sigma Green Belt certification is conducted through the official IASSC platform. Online submissions are typically processed within one to two business days, while paper-based applications may take three to five days. During the review, eligibility is verified, and applicants who do not meet the criteria are refunded the application fees.

Candidates may select from multiple testing options, including on-demand, web-based proctored exams and in-person testing at authorized Pearson-Vue centers. On-demand testing provides flexibility, allowing candidates to complete the exam remotely at a secure location of their choice. In-person testing offers a traditional examination environment, facilitating standardized administration and oversight.

Scheduling is determined once the application is approved. Candidates select a suitable date and time within the available testing window, balancing exam readiness with convenience. Adhering to scheduling guidelines ensures a smooth and efficient testing process, enabling candidates to focus on demonstrating their knowledge and skills.

Professional Advantages of Certification

Achieving Lean Six Sigma Green Belt certification yields substantial professional benefits. Certified practitioners are recognized for their expertise in process improvement, statistical analysis, and project management. This credential enhances career prospects, signaling to employers that the individual possesses the analytical and operational skills necessary to contribute meaningfully to organizational improvement initiatives.

Certification also cultivates cognitive and analytical growth. Green Belts develop the ability to synthesize complex information, identify root causes of inefficiencies, and implement effective solutions. These skills are transferable across industries and functional domains, providing a versatile foundation for professional advancement. Additionally, certification fosters confidence in executing Lean Six Sigma methodologies, enabling practitioners to lead and support improvement projects with competence.

For organizations, certified Green Belts contribute to measurable enhancements in efficiency, quality, and customer satisfaction. Their expertise in process analysis and improvement translates into reduced defects, optimized workflows, and lower operational costs. By integrating Lean Six Sigma principles into organizational practices, Green Belts help create a culture of continuous improvement, resilience, and innovation.

Continuous Improvement and Organizational Transformation

Lean Six Sigma Green Belts are agents of organizational transformation. Their work ensures that process improvement initiatives are implemented effectively and sustainably. By identifying inefficiencies, reducing variability, and fostering data-driven decision-making, Green Belts enhance organizational performance across multiple dimensions.

The impact of Green Belts extends beyond individual projects. They facilitate the dissemination of best practices, mentor colleagues, and encourage adoption of Lean Six Sigma methodologies throughout the organization. This systemic approach promotes a culture of continuous improvement, ensuring that operational enhancements are maintained, replicated, and scaled across departments and functions.

Organizations that embrace Lean Six Sigma principles benefit from a dual focus on efficiency and quality. By leveraging the analytical and operational expertise of Green Belts, companies can optimize resources, minimize waste, and consistently deliver products and services that exceed customer expectations. This integrated approach positions organizations to achieve sustainable growth and competitive advantage.

Lean Six Sigma Implementation in Organizations

Implementing Lean Six Sigma within an organization requires strategic alignment, structured methodologies, and committed personnel. The philosophy emphasizes that process improvement is a continuous endeavor rather than a one-time intervention. By embedding Lean Six Sigma principles into organizational culture, companies can foster resilience, optimize operations, and ensure sustained excellence. Implementation begins with identifying key areas of inefficiency, followed by defining measurable objectives and deploying Green Belts and Black Belts to lead improvement initiatives.

Green Belts play a pivotal role during implementation. They serve as both analysts and facilitators, applying statistical tools and Lean techniques to scrutinize workflows and uncover inefficiencies. Through meticulous data analysis, Green Belts can identify bottlenecks, sources of variation, and wasteful practices that impede productivity. Their insights are crucial in guiding corrective actions and ensuring that project objectives align with broader organizational goals.

The DMAIC framework—Define, Measure, Analyze, Improve, and Control—forms the structural backbone of Lean Six Sigma implementation. Green Belts actively participate in each phase, from defining project goals and collecting relevant data to analyzing root causes and implementing solutions. They also help in establishing control mechanisms to sustain improvements, ensuring that operational gains are maintained over time.

Tools and Techniques for Process Optimization

Lean Six Sigma Green Belts employ a comprehensive toolkit to analyze, diagnose, and optimize processes. Statistical tools such as control charts, Pareto analysis, and hypothesis testing facilitate precise evaluation of process performance and defect rates. These instruments enable practitioners to identify variations, quantify inefficiencies, and prioritize interventions based on data-driven insights.

Root cause analysis is a fundamental technique used by Green Belts to uncover the underlying factors contributing to defects or delays. Methods like the 5 Whys, fishbone diagrams, and failure mode and effects analysis allow for structured investigation, ensuring that solutions address the true sources of problems rather than superficial symptoms. This analytical rigor is essential for sustainable process improvement.

Lean techniques complement statistical methods by targeting waste elimination and value stream optimization. Value stream mapping, process flow analysis, and time-motion studies enable Green Belts to visualize workflows, detect inefficiencies, and recommend practical interventions. By integrating statistical analysis with Lean methodologies, Green Belts can ensure that improvements enhance both quality and efficiency.

Developing Analytical and Critical Thinking Skills

A central component of Lean Six Sigma Green Belt training is the cultivation of analytical and critical thinking skills. Green Belts learn to interpret complex datasets, identify trends, and assess process performance objectively. This analytical capability allows practitioners to make informed decisions, prioritize improvement opportunities, and design interventions that are both effective and feasible.

Critical thinking extends beyond data analysis. Green Belts must evaluate the potential impact of proposed changes, anticipate challenges, and balance multiple constraints, including time, cost, and resource availability. By applying logical reasoning and systematic evaluation, Green Belts ensure that process improvements are robust, sustainable, and aligned with organizational objectives.

Practical application of these skills occurs through participation in real-world projects. By analyzing actual workflows, implementing corrective actions, and monitoring outcomes, Green Belts translate theoretical knowledge into actionable insights. This hands-on experience reinforces analytical acumen, enhances problem-solving abilities, and builds confidence in leading process improvement initiatives.

Exam Preparation and Study Strategies

Preparing for the Lean Six Sigma Green Belt certification requires a methodical approach that combines theoretical understanding with practical application. Candidates benefit from a structured study plan, allocating dedicated time to review core concepts, practice problem-solving, and simulate exam conditions. Study resources, including guides, reference books, and online courses, provide foundational knowledge, while practice exams enhance familiarity with question formats and difficulty levels.

Effective preparation involves understanding both Lean and Six Sigma methodologies, including process mapping, statistical analysis, root cause identification, and waste elimination. Candidates should focus on mastering analytical tools such as control charts, histograms, and scatter plots, as well as Lean techniques like value stream mapping and process flow optimization. Integrating these competencies enables candidates to approach exam questions with confidence and precision.

Self-assessment is a valuable strategy for exam readiness. Taking diagnostic tests or non-proctored evaluation exams allows candidates to gauge their knowledge, identify weaknesses, and prioritize areas for review. Collaborative learning, including group discussions or peer feedback sessions, can further deepen understanding and reinforce concepts through practical examples and case studies.

Policies and Procedures for Certification

The Lean Six Sigma Green Belt exam is administered under strict policies and procedures to ensure fairness, integrity, and standardized evaluation. Candidates are required to present a valid photo ID that matches their application, and all personal items are stored securely during the examination. Compliance with these policies is essential to maintain the credibility of the certification process.

Candidates must arrive at the testing center at least 30 minutes prior to the scheduled exam to complete check-in procedures. Late arrivals may forfeit the exam, with fees non-refundable. Calculators permitted in the exam hall must be non-programmable and battery-operated, excluding devices capable of storing or processing data. The exam is strictly closed-book, with no reference materials allowed within the testing environment.

Procedures for rescheduling or canceling exams are clearly defined by IASSC, providing candidates with structured options while preserving the integrity of the certification. Adherence to these policies ensures a controlled and fair testing environment, allowing all candidates to demonstrate their knowledge and skills under standardized conditions.

Application Process and Testing Options

Candidates apply for the Lean Six Sigma Green Belt exam through the official IASSC platform. Online applications are processed within one to two business days, while paper-based applications may take three to five days. During the review process, eligibility is verified, and applicants who do not meet criteria are refunded application fees.

Testing options include on-demand, web-based proctored exams and in-person exams at authorized Pearson-Vue testing centers. On-demand testing offers flexibility, allowing candidates to complete the exam remotely at a secure location, while in-person testing provides a traditional examination environment. Once the application is approved, candidates can schedule the exam within the designated testing window, selecting a date and time that aligns with their preparedness.

The examination assesses both theoretical knowledge and practical application of Lean Six Sigma principles. Questions cover topics such as DMAIC methodology, Lean tools, statistical analysis, process optimization, and project management. Candidates must achieve a minimum score of 70 percent to earn the certification, ensuring that only proficient practitioners are recognized as Green Belts.

Professional Advantages and Career Development

Lean Six Sigma Green Belt certification confers significant professional advantages. Certified Green Belts are recognized for their expertise in process improvement, statistical analysis, and project execution. This recognition enhances career prospects, providing access to roles that require analytical rigor, operational acumen, and collaborative problem-solving skills.

Certification also equips professionals with transferable competencies. Analytical thinking, critical evaluation, and structured problem-solving skills are applicable across industries and functions. Green Belts gain the ability to influence organizational decision-making, contribute to strategic initiatives, and implement sustainable process improvements.

Organizations benefit from the deployment of certified Green Belts by achieving measurable improvements in quality, efficiency, and customer satisfaction. Certified professionals help optimize workflows, reduce defects, and implement data-driven solutions that enhance operational performance. Their contributions foster a culture of continuous improvement, ensuring that Lean Six Sigma principles are embedded into organizational practices and sustained over time.

Continuous Improvement and Organizational Excellence

Lean Six Sigma Green Belts are instrumental in advancing organizational excellence through continuous improvement initiatives. Their analytical expertise, practical skills, and collaborative approach enable organizations to identify inefficiencies, reduce variability, and enhance process performance. By implementing systematic interventions, Green Belts ensure that operational improvements are sustained, scalable, and aligned with strategic objectives.

The influence of Green Belts extends beyond individual projects. They mentor colleagues, facilitate knowledge sharing, and promote adoption of Lean Six Sigma methodologies across departments. This broader impact fosters a culture of accountability, data-driven decision-making, and proactive problem-solving, ensuring that organizational improvements are pervasive and enduring.

Organizations that embrace Lean Six Sigma principles and leverage the expertise of Green Belts benefit from optimized resource utilization, reduced waste, and enhanced customer satisfaction. The combination of efficiency and quality positions companies to maintain a competitive edge, adapt to evolving market conditions, and achieve sustainable growth.

Advanced Concepts in Lean Six Sigma

Lean Six Sigma Green Belts are not only versed in foundational methodologies but also gain exposure to advanced concepts that enhance their ability to drive process improvement. These concepts include statistical process control, advanced hypothesis testing, and complex root cause analysis. Mastery of these techniques enables Green Belts to address intricate operational challenges and implement solutions that yield measurable improvements.

Statistical process control provides Green Belts with tools to monitor process performance over time, detect anomalies, and prevent defects before they propagate. Control charts, for example, allow practitioners to visualize process stability and identify trends that require intervention. By applying these techniques, Green Belts can ensure that processes remain within defined performance limits, minimizing variability and enhancing quality.

Hypothesis testing and inferential statistics equip Green Belts to make data-driven decisions with confidence. These methods allow for comparison of process variations, evaluation of potential solutions, and determination of statistically significant improvements. By integrating these approaches with Lean principles, Green Belts can optimize workflows while ensuring that improvements are both effective and sustainable.

Lean Techniques for Operational Efficiency

Lean principles complement Six Sigma by focusing on the elimination of non-value-adding activities. Green Belts employ techniques such as value stream mapping, process flow analysis, and waste reduction strategies to enhance operational efficiency. These tools enable practitioners to visualize processes, identify bottlenecks, and implement interventions that reduce delays and improve throughput.

Value stream mapping, for instance, provides a comprehensive view of the entire workflow, highlighting areas where resources are underutilized or processes are redundant. By identifying these inefficiencies, Green Belts can propose changes that streamline operations, reduce cycle time, and increase overall productivity. Process flow analysis further allows for the examination of sequential steps, ensuring that each activity contributes to the value delivered to customers.

Waste reduction strategies target various forms of inefficiency, including overproduction, excess inventory, and unnecessary motion. By systematically eliminating these sources of waste, Green Belts enhance the value delivered by organizational processes, improve resource utilization, and reduce costs. The integration of Lean techniques with Six Sigma analytics ensures that improvements are both precise and operationally meaningful.

Practical Application and Real-World Projects

Hands-on experience is critical for Green Belts to translate theoretical knowledge into practical skills. Participation in real-world projects allows candidates to apply Lean Six Sigma tools to tangible operational challenges. Through data collection, analysis, and implementation of solutions, Green Belts gain insights into the complexities of process improvement and develop the ability to deliver measurable results.

Project selection is often aligned with strategic organizational objectives, ensuring that improvement initiatives contribute meaningfully to performance goals. Green Belts work collaboratively with Black Belts and cross-functional teams, facilitating data-driven discussions, evaluating potential solutions, and monitoring outcomes. This practical engagement reinforces analytical skills, enhances problem-solving capabilities, and builds confidence in leading process improvement efforts.

Documentation and reporting are integral to project execution. Green Belts maintain detailed records of process analyses, corrective actions, and performance metrics. This documentation serves multiple purposes: it provides a reference for continuous improvement, enables knowledge transfer within the organization, and demonstrates accountability and methodological rigor to stakeholders.

Exam Preparation and Analytical Mastery

Preparing for the Lean Six Sigma Green Belt certification requires both conceptual understanding and analytical mastery. Candidates must be proficient in interpreting complex datasets, identifying trends, and applying statistical tools to solve practical problems. Study strategies include structured review of core concepts, practice examinations, and application of Lean Six Sigma methodologies to sample projects or case studies.

Time management and disciplined study routines are critical for comprehensive preparation. Candidates should allocate focused periods for reviewing topics such as DMAIC methodology, root cause analysis, process mapping, and statistical evaluation. Simulating exam conditions through timed practice tests enhances familiarity with question formats and reinforces the ability to apply analytical reasoning efficiently under time constraints.

Collaborative study approaches, including discussion groups and peer reviews, can further strengthen understanding. Sharing insights, debating problem-solving approaches, and analyzing case studies collectively deepen comprehension and foster a more nuanced grasp of Lean Six Sigma principles. By integrating theoretical study with practical exercises, candidates develop the competence and confidence required to succeed in the certification exam.

Certification Policies and Integrity

The Lean Six Sigma Green Belt examination is governed by policies designed to uphold integrity, standardization, and fairness. Candidates are required to present valid identification that matches their submitted application, and personal items are securely stored during the examination. Adherence to these policies ensures that all participants are assessed based solely on their knowledge and analytical skills.

Arriving at the testing center well before the scheduled exam time is essential to complete check-in procedures. Late arrivals may forfeit their exam opportunity, with fees non-refundable. Only non-programmable, battery-operated calculators are allowed, excluding devices capable of storing or graphing information. The exam is strictly closed-book, prohibiting reference materials, notes, or electronic devices.

Procedures for rescheduling, canceling, or addressing absence are clearly delineated by the IASSC. Candidates must comply with these protocols to maintain eligibility and preserve the integrity of the certification process. These measures ensure a controlled environment that facilitates accurate assessment of candidate competencies.

Application Process and Testing Options

Application for the Lean Six Sigma Green Belt certification is conducted through the official IASSC platform. Online applications are typically processed within one to two business days, while paper submissions may require three to five days. Eligibility is verified during the review, and applicants who do not meet criteria are refunded application fees.

Testing options provide flexibility and accessibility. Candidates may choose on-demand, web-based proctored exams that allow for remote completion at a secure location or opt for in-person testing at authorized Pearson-Vue centers. Once approved, candidates schedule their examination within the available testing window, selecting a date and time that accommodates their preparation and convenience.

The exam evaluates both theoretical knowledge and practical application of Lean Six Sigma principles. Questions span topics including DMAIC methodology, Lean tools, statistical analysis, project management, and process optimization. Achieving a minimum score of 70 percent ensures that certified Green Belts possess the analytical, operational, and problem-solving skills required for professional proficiency.

Professional Growth and Organizational Impact

Lean Six Sigma Green Belt certification enhances professional growth by validating expertise in process improvement, statistical analysis, and project execution. Certified practitioners are recognized for their ability to lead and support improvement initiatives, enhancing credibility and employability. This credential opens pathways for career advancement, enabling professionals to assume roles that require analytical rigor and operational insight.

Organizations benefit from the deployment of certified Green Belts through measurable improvements in efficiency, quality, and customer satisfaction. Green Belts optimize workflows, reduce defects, and implement data-driven solutions that enhance operational performance. Their contributions foster a culture of continuous improvement, embedding Lean Six Sigma principles into organizational practices and sustaining long-term gains.

Certified Green Belts also develop transferable competencies. Skills in analytical reasoning, structured problem-solving, and data-driven decision-making are applicable across industries and functional domains. These abilities empower practitioners to influence organizational strategy, drive innovation, and implement sustainable improvements that align with broader business objectives.

Continuous Improvement and Cultural Transformation

Lean Six Sigma Green Belts serve as catalysts for cultural transformation within organizations. By modeling analytical rigor, collaborative problem-solving, and evidence-based decision-making, they inspire colleagues to embrace continuous improvement as a core organizational value. Their participation in projects demonstrates the practical benefits of Lean Six Sigma methodologies, encouraging broader adoption and integration.

Through mentoring, knowledge sharing, and cross-functional engagement, Green Belts facilitate the dissemination of best practices. This systemic approach ensures that improvements are not confined to isolated projects but permeate organizational processes, creating a resilient, adaptable, and high-performing operational environment.

Organizations that leverage Lean Six Sigma principles and certified Green Belts achieve optimized resource utilization, reduced waste, and enhanced customer satisfaction. By embedding continuous improvement into the organizational fabric, companies maintain a competitive edge, adapt to evolving market conditions, and drive sustainable growth.

Sustaining Lean Six Sigma Improvements

Sustaining process improvements is a critical aspect of Lean Six Sigma methodology. Green Belts play a central role in ensuring that the gains achieved through process optimization are maintained over time. Without sustained application, improvements risk erosion, rendering previous efforts less impactful. Sustainability is achieved through continuous monitoring, rigorous control mechanisms, and proactive engagement with operational teams.

Control plans and monitoring systems are implemented to track key performance indicators (KPIs) and process metrics. Green Belts are responsible for setting thresholds, analyzing trends, and identifying deviations before they escalate into defects. By maintaining vigilance, they ensure that processes remain stable and deliver consistent quality outcomes, thereby reinforcing customer satisfaction and operational efficiency.

Sustainability also involves embedding Lean Six Sigma principles into organizational routines. Training team members, documenting procedures, and fostering a culture of accountability are essential for long-term success. Green Belts facilitate knowledge transfer, ensuring that the organization collectively understands the methodologies, tools, and strategies that underpin continuous improvement.

Advanced Analytical Techniques

Lean Six Sigma Green Belts employ advanced analytical techniques to diagnose complex operational challenges. Techniques such as regression analysis, design of experiments (DOE), and advanced statistical inference allow practitioners to evaluate multifaceted process interactions and identify high-impact improvement opportunities. Mastery of these techniques enhances decision-making and ensures that interventions are both effective and evidence-based.

Regression analysis, for instance, helps determine the relationship between multiple variables and process outcomes, allowing Green Belts to prioritize improvement efforts strategically. Design of experiments provides a structured approach to testing hypotheses and evaluating potential solutions under controlled conditions. By integrating these analytical methods with Lean tools, Green Belts optimize workflows while ensuring data-driven validation of improvements.

Advanced techniques also enable practitioners to predict process behavior and anticipate potential sources of variation. This predictive capability supports proactive decision-making, minimizes risk, and contributes to sustained operational excellence. Green Belts with proficiency in these analytical tools provide organizations with the ability to navigate complex process dynamics and achieve superior performance outcomes.

Lean Six Sigma Project Execution

Executing Lean Six Sigma projects requires meticulous planning, data analysis, and collaborative problem-solving. Green Belts contribute to each phase of project execution, from defining objectives and measuring performance to analyzing root causes, implementing solutions, and maintaining control. Their involvement ensures that projects are both analytically sound and operationally practical.

Project selection aligns with strategic organizational priorities, ensuring that improvements have meaningful impact. Green Belts collaborate with Black Belts and cross-functional teams, facilitating communication, managing project timelines, and monitoring progress. Their role extends to documenting findings, reporting outcomes, and making recommendations for further optimization.

Practical engagement in projects reinforces theoretical knowledge, enhancing proficiency in Lean and Six Sigma methodologies. By applying tools and techniques in real-world scenarios, Green Belts develop the confidence and capability to lead initiatives that drive measurable improvements. This experiential learning complements formal certification and fosters holistic professional development.

Exam Preparation and Mastery of Core Concepts

Preparing for the Lean Six Sigma Green Belt certification requires an integrated approach, combining conceptual understanding with practical application. Candidates focus on mastering DMAIC methodology, statistical tools, Lean techniques, and process optimization strategies. Structured study plans, practice examinations, and real-world exercises facilitate comprehensive preparation.

Self-assessment through diagnostic tests or practice exams helps candidates identify gaps in knowledge and prioritize areas for review. Collaborative learning, including group discussions, case study analysis, and peer feedback, enhances comprehension and provides exposure to diverse problem-solving approaches. By reinforcing theoretical knowledge through practical exercises, candidates gain the confidence to approach the certification exam effectively.

Time management is a key component of preparation. Candidates allocate dedicated periods for study, practice, and review, ensuring thorough coverage of all domains. Simulating exam conditions through timed practice tests builds familiarity with question formats and improves analytical efficiency, increasing the likelihood of achieving the required passing score.

Certification Policies and Examination Integrity

The Lean Six Sigma Green Belt exam is conducted under strict policies to maintain integrity, standardization, and fairness. Candidates must present a valid photo ID matching their application, with all personal items stored securely during the examination. Compliance ensures that assessments accurately reflect candidate knowledge and skills.

Permitted calculators are limited to non-programmable, battery-operated devices, prohibiting any capable of storing or graphing information. The examination is strictly closed-book, with reference materials, notes, or electronic devices not allowed. Candidates must also follow established protocols for rescheduling, cancellation, or absence, maintaining eligibility while preserving exam integrity.

Adherence to these policies ensures a controlled environment, providing a level playing field for all candidates. By upholding these standards, IASSC ensures that certification reflects genuine competency and proficiency in Lean Six Sigma methodologies.

Application and Scheduling

Candidates apply for the Lean Six Sigma Green Belt certification through the IASSC platform. Online applications are processed within one to two business days, while paper-based applications may require three to five days. During the review process, eligibility is verified, and applicants not meeting criteria are refunded application fees.

Testing options include on-demand, web-based proctored exams and in-person examinations at Pearson-Vue authorized centers. On-demand testing allows candidates to complete the exam remotely at a secure location, offering flexibility and convenience. In-person exams provide a traditional proctored environment, ensuring standardized administration.

Once approved, candidates schedule their examination within the designated testing window. Selecting an appropriate date allows for sufficient preparation, ensuring readiness to demonstrate knowledge, analytical skills, and practical understanding of Lean Six Sigma principles.

Professional Benefits and Career Advancement

Achieving Lean Six Sigma Green Belt certification offers substantial professional advantages. Certified practitioners are recognized for their expertise in process improvement, statistical analysis, and project management. This recognition enhances career prospects, opening opportunities in operational management, quality assurance, and continuous improvement roles.

Certification also cultivates transferable skills. Analytical reasoning, critical thinking, problem-solving, and data-driven decision-making are competencies applicable across industries and organizational functions. Green Belts gain the ability to influence decision-making, guide improvement initiatives, and implement sustainable solutions that enhance operational performance.

Organizations benefit from deploying certified Green Belts by achieving measurable improvements in efficiency, quality, and customer satisfaction. Green Belts optimize processes, reduce defects, and implement data-driven strategies that contribute to operational excellence. Their contributions foster a culture of continuous improvement, ensuring that Lean Six Sigma principles are embedded and sustained within organizational practices.

Continuous Improvement and Organizational Culture

Lean Six Sigma Green Belts play a crucial role in cultivating a culture of continuous improvement. By modeling data-driven decision-making, analytical rigor, and collaborative problem-solving, they inspire colleagues to embrace process optimization as a core organizational value. Their involvement in projects demonstrates the practical benefits of Lean Six Sigma methodologies, promoting wider adoption throughout the organization.

Mentoring, knowledge sharing, and cross-functional engagement are essential to cultural transformation. Green Belts facilitate the dissemination of best practices, encourage adherence to standardized procedures, and promote proactive identification of improvement opportunities. This systemic approach ensures that operational enhancements extend beyond individual projects, creating a resilient and high-performing organization.

Organizations leveraging Lean Six Sigma principles and certified Green Belts achieve optimized resource utilization, reduced waste, and improved customer satisfaction. Embedding continuous improvement into the organizational framework ensures sustainable growth, adaptability to market changes, and a competitive edge in increasingly dynamic environments.

Preparing for Future Opportunities

Lean Six Sigma Green Belt certification also lays the foundation for advanced professional development. Certified individuals may progress to Black Belt or Master Black Belt levels, gaining deeper analytical expertise, strategic project leadership skills, and broader organizational influence. These advanced roles involve overseeing complex projects, mentoring teams, and implementing enterprise-wide process improvements.

Beyond certification, Green Belts are well-positioned to contribute to cross-functional initiatives, operational strategy development, and innovation projects. Their analytical training, combined with practical experience, enables them to identify opportunities for cost reduction, efficiency enhancement, and quality improvement. This capability positions Green Belts as indispensable contributors to organizational growth and transformation.

Conclusion

The Lean Six Sigma Green Belt certification equips professionals with a comprehensive skill set designed to enhance process efficiency, reduce defects, and foster continuous improvement within organizations. Through mastery of the DMAIC methodology, statistical analysis, root cause identification, and Lean principles, Green Belts are empowered to analyze workflows, implement targeted interventions, and sustain measurable improvements. Their role bridges operational teams with strategic objectives, ensuring that improvement initiatives are both analytically sound and operationally effective.

Certified Green Belts contribute to organizational excellence by optimizing processes, minimizing variability, and enhancing overall quality. Their expertise in applying statistical tools, Lean techniques, and problem-solving methodologies allows organizations to achieve cost reductions, faster cycle times, and heightened customer satisfaction. Beyond individual projects, Green Belts promote a culture of continuous improvement, mentoring colleagues, sharing best practices, and fostering data-driven decision-making across departments.

The professional benefits of certification are equally significant. Green Belts gain recognition for their analytical acumen, project management abilities, and process improvement expertise, opening doors to career advancement and leadership opportunities. Their practical experience in executing Lean Six Sigma projects equips them to address complex operational challenges, drive innovation, and contribute to strategic initiatives.

Ultimately, the Lean Six Sigma Green Belt certification represents more than a credential—it embodies a commitment to operational excellence, efficiency, and sustainable growth. By integrating Lean and Six Sigma methodologies, professionals enhance both personal development and organizational performance, creating lasting value, resilience, and competitive advantage in a dynamic business environment.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.