Certification: Risk Based Inspection

Certification Full Name: Risk Based Inspection

Certification Provider: API

Exam Code: API-580

Exam Name: Risk Based Inspection

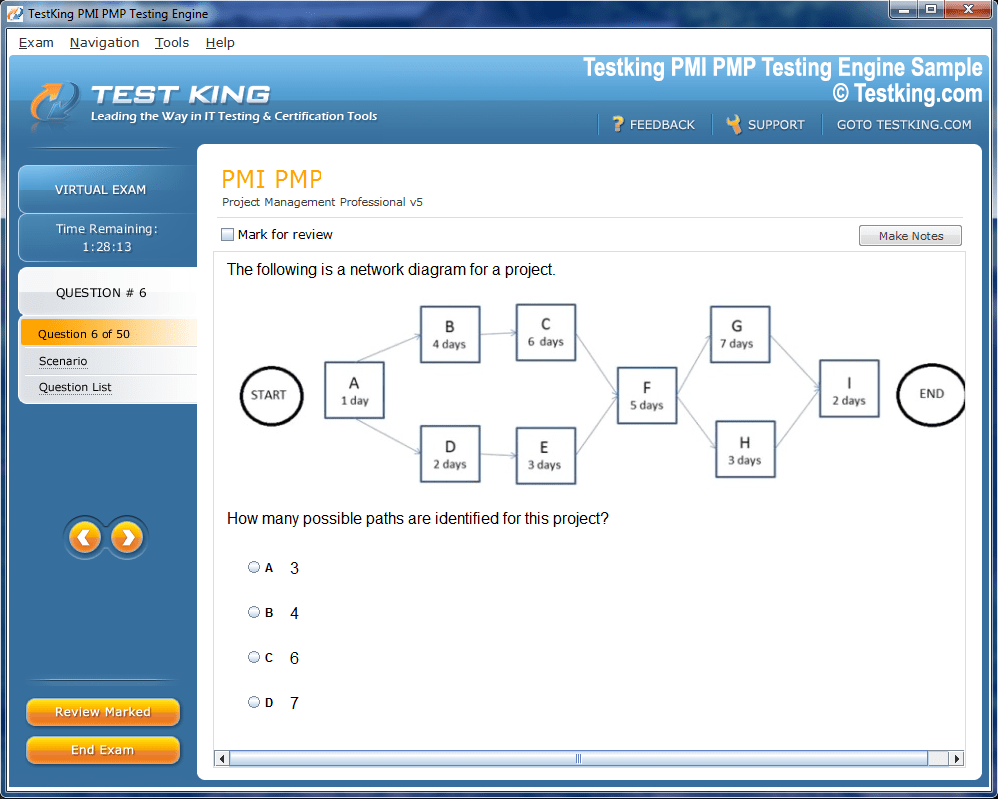

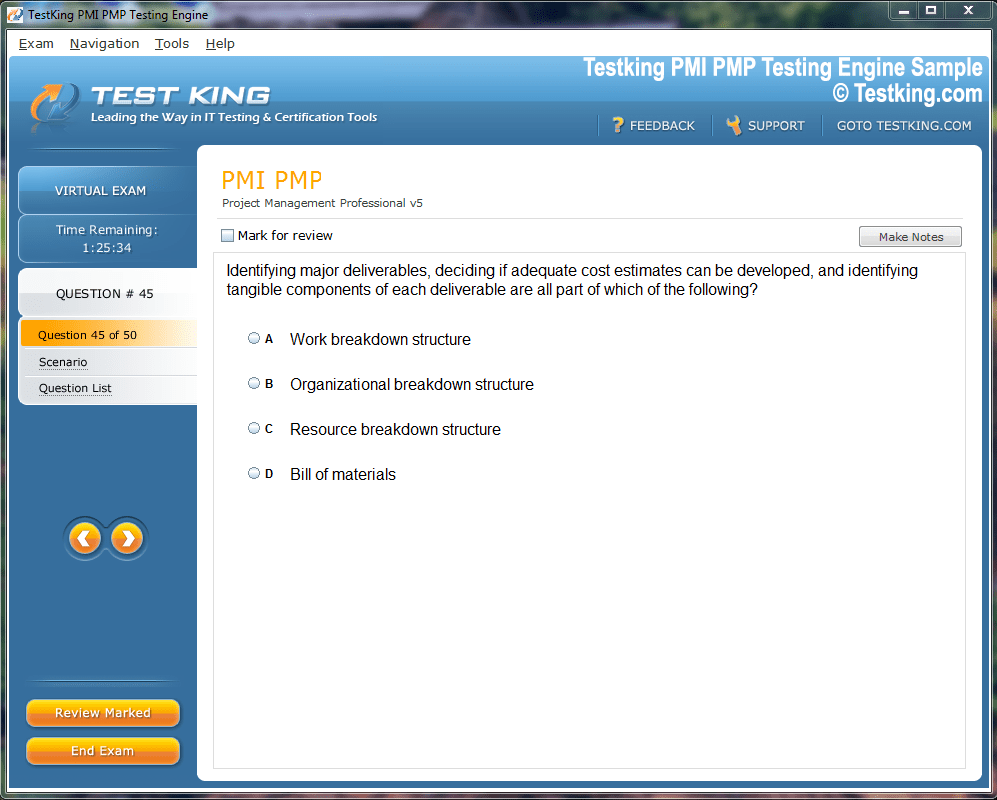

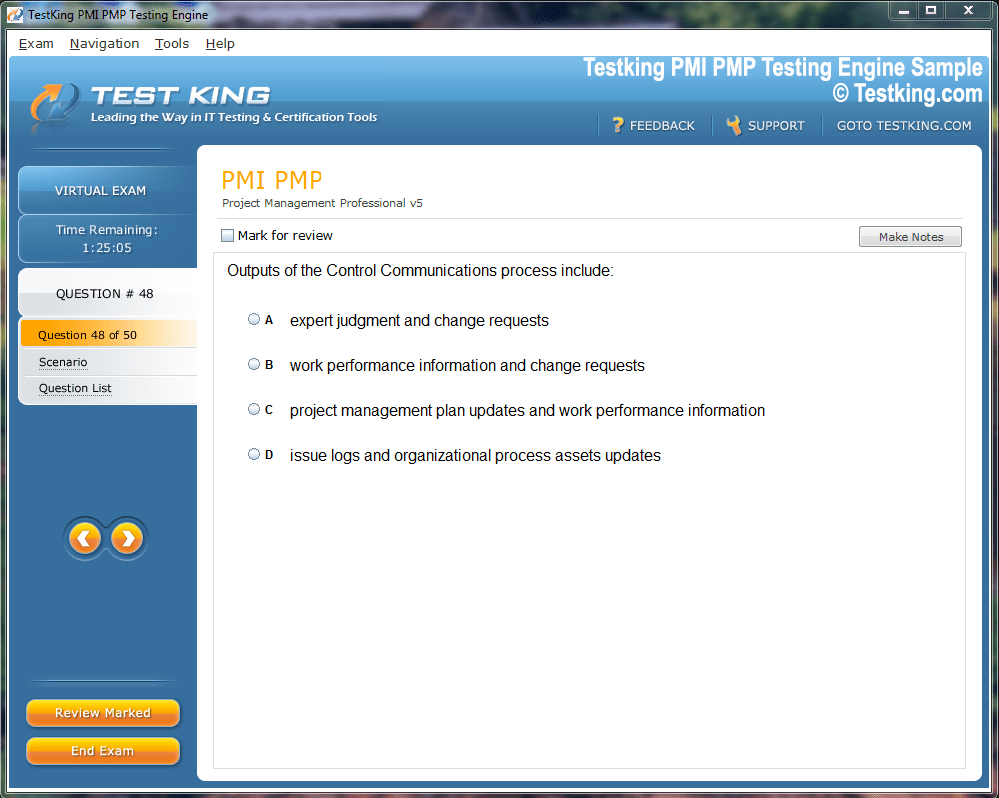

Product Screenshots

nop-1e =1

API 580 Risk Based Inspection: Essential Framework for Asset Integrity Management

The oil and gas sector demands rigorous protocols for maintaining equipment integrity and operational safety. Among the various methodologies available, API 580 stands out as a cornerstone framework that revolutionizes how organizations approach inspection strategies. This globally acknowledged standard provides a structured methodology for identifying, evaluating, and mitigating risks associated with equipment degradation and potential failures.

Risk Based Inspection represents a paradigm shift from traditional time-based inspection approaches to a more intelligent, data-driven strategy. Rather than inspecting all equipment at predetermined intervals regardless of actual risk levels, this methodology enables organizations to allocate resources where they are most needed. The framework helps companies optimize their maintenance budgets while simultaneously enhancing safety performance and operational reliability.

Organizations implementing this approach gain significant advantages in their asset management practices. The systematic evaluation of risk factors enables more informed decision-making regarding inspection priorities, resource allocation, and maintenance planning. Additionally, regulatory compliance becomes more manageable as the documented risk assessment process demonstrates due diligence to authorities and stakeholders.

Fundamental Principles of API 580 Risk Based Inspection

API 580 represents a comprehensive collection of recommendations developed by the American Petroleum Institute that outlines critical components necessary for establishing, implementing, and sustaining an effective Risk Based Inspection program. This framework has achieved widespread recognition as the benchmark standard for RBI processes across multiple industries beyond oil and gas.

The standard underwent rigorous development through the ANSI consensus procedure for establishing American National Standards. This process ensures that the guidelines reflect input from diverse stakeholders including industry practitioners, regulatory bodies, academic institutions, and safety organizations. The consensus-driven development process lends credibility and broad applicability to the standard.

Following this comprehensive vetting process, API 580 gained recognition as a Recognized and Generally Accepted Good Engineering Practice. This designation holds significant weight in regulatory compliance discussions and legal contexts. Organizations following RAGAGEP guidelines demonstrate their commitment to maintaining the highest industry standards.

Implementation of RBI methodologies using API 580 must align with requirements specified in related inspection codes. These include API 510 which governs Pressure Vessel Inspection procedures, API 570 addressing Piping Inspection protocols, and API 653 covering Tank Inspection, Repair, Alteration, and Reconstruction activities. The interplay between these standards ensures comprehensive coverage of different equipment types.

The initial publication of API 580 occurred in 2002, marking a significant milestone in the evolution of inspection methodologies. The standard has undergone multiple revisions since its inception, with the most substantial update released in early 2016. This third edition incorporated lessons learned from over a decade of industry implementation and addressed emerging challenges in asset integrity management.

Each revision cycle incorporates feedback from practitioners who have implemented the standard in diverse operating environments. The updates address technological advances, new damage mechanisms, evolving regulatory requirements, and improved risk assessment techniques. This continuous improvement process ensures the standard remains relevant and effective.

The philosophical foundation of API 580 rests on the principle that not all equipment presents equal risk. Some assets operate under more severe conditions, handle more hazardous materials, or serve more critical functions than others. Recognizing these differences allows organizations to tailor their inspection efforts accordingly.

Traditional inspection programs often treated all equipment similarly, resulting in over-inspection of low-risk items and potential under-inspection of high-risk components. The risk-based approach rectifies this imbalance by systematically evaluating each piece of equipment based on its unique risk profile. This targeted approach yields better outcomes with equivalent or reduced resources.

Core Components of API 580 Risk Based Inspection Framework

The effectiveness of any Risk Based Inspection program hinges on several foundational elements that must receive thorough attention during implementation. These components work synergistically to create a robust system for managing equipment integrity risks.

Management systems form the backbone of successful RBI implementation. These systems encompass documentation protocols that ensure all relevant information is captured, stored, and readily accessible. Proper documentation enables traceability of decisions, facilitates knowledge transfer, and supports continuous improvement efforts.

Personnel credentials represent another critical aspect of management systems. The complexity of risk assessment requires qualified individuals with appropriate technical backgrounds and experience. Organizations must establish clear qualification criteria for team members and ensure ongoing professional development to maintain competency levels.

Data requirements within management systems define what information must be collected, how frequently it should be updated, and quality standards it must meet. High-quality data forms the foundation for reliable risk assessments. Incomplete or inaccurate data can lead to flawed conclusions and inappropriate inspection priorities.

Analysis update protocols ensure that risk assessments remain current as conditions change. Equipment ages, operating conditions fluctuate, and new information becomes available over time. Regular reassessment cycles prevent risk evaluations from becoming outdated and maintain the relevance of inspection plans.

Program consistency across different facilities and units within an organization prevents gaps and redundancies. Standardized approaches facilitate benchmarking, enable efficient resource sharing, and simplify training programs. However, consistency must be balanced with flexibility to address site-specific conditions.

Documented techniques for probability of failure determination provide the analytical framework for evaluating likelihood of equipment failure. These methodologies may range from qualitative screening tools to sophisticated quantitative models. The chosen approach should match the complexity of the equipment and decisions being made.

Various damage mechanisms affect equipment differently, and the probability of failure analysis must account for all relevant degradation modes. Corrosion, erosion, cracking, creep, and other mechanisms progress at different rates under different conditions. Accurate prediction of failure likelihood requires understanding these mechanisms and their progression.

Historical failure data from similar equipment provides valuable input for probability assessments. Industry databases, internal records, and published research contribute to building statistical models. However, historical data must be applied carefully, considering differences between the reference population and specific equipment being assessed.

Consequence of failure evaluation complements probability analysis by estimating the potential impact if failure occurs. These documented methodologies assess multiple consequence categories including safety impacts on personnel, environmental damage, business interruption costs, and equipment repair or replacement expenses.

Safety consequences typically receive the highest priority in consequence assessments. Potential for injuries or fatalities drives many risk reduction decisions. The evaluation considers factors such as location, inventory volume, material toxicity, and potential ignition sources to estimate the severity of potential incidents.

Environmental consequences have gained increasing attention as regulatory requirements tighten and corporate responsibility expectations rise. Assessments consider the potential for soil contamination, water pollution, air emissions, and ecological damage. Cleanup costs and regulatory penalties factor into the economic impact calculations.

Business interruption represents a significant consequence

Business interruption represents a significant consequence category often overlooked in traditional safety-focused assessments. Lost production, contractual penalties, market share erosion, and reputation damage can far exceed direct repair costs. Comprehensive consequence evaluation captures these broader business impacts.

Documented methodologies for managing risk through various control measures extend beyond inspection activities. While inspection remains a primary risk management tool, the framework recognizes that process control modifications, equipment redesign, operating procedure changes, and emergency response planning also contribute to risk reduction.

Inspection strategies form the core of risk management in RBI programs. The timing, extent, and methods of inspection are tailored to address specific damage mechanisms and achieve target risk levels. High-risk equipment receives more frequent and intensive inspection, while low-risk items may have extended intervals.

Process control improvements can address root causes of degradation and reduce failure probability. Controlling corrosive contaminants, managing operating temperatures and pressures, and preventing flow-induced vibration exemplify process modifications that reduce damage rates. These proactive measures complement inspection efforts.

Emergency response capabilities influence consequence severity by determining how quickly and effectively an organization can respond to incidents. Well-trained response teams, appropriate equipment, effective communication systems, and practiced procedures can significantly reduce the impact of failures that do occur.

Inspection Planning Strategies According to API 580 Risk Based Inspection

Effective inspection planning under API 580 requires careful consideration of multiple interconnected factors. The planning process integrates technical analysis, operational requirements, resource constraints, and regulatory obligations into coherent inspection strategies.

Probability of failure analysis serves as a cornerstone of inspection planning. This analysis estimates the likelihood that equipment will fail within a specified timeframe. Understanding failure probability enables prioritization of inspection resources toward assets most likely to experience problems.

The probability of failure evolves throughout equipment lifecycle stages. Newly commissioned assets typically exhibit low failure probability due to pristine condition and absence of accumulated damage. As equipment ages and degrades, failure probability generally increases unless effective maintenance intervenes.

Various factors influence failure probability calculations. Material properties, design adequacy, fabrication quality, operating conditions, damage mechanisms, inspection history, and remaining life all contribute to the assessment. Sophisticated models incorporate multiple variables to produce nuanced probability estimates.

Equipment operating in harsh environments or handling corrosive materials naturally faces higher failure probabilities. Temperature extremes, pressure cycling, vibration, and chemical exposure accelerate degradation processes. The probability assessment must reflect these aggravating factors in determining inspection priorities.

Damage mechanism identification and characterization directly inform probability calculations. Each mechanism progresses at a characteristic rate depending on conditions. Corrosion rates, crack growth velocities, and creep accumulation follow predictable patterns that enable forecasting of future equipment condition.

Regular updates to probability assessments maintain their accuracy and relevance. As new inspection data becomes available, probability estimates should be revised to reflect current equipment condition. Changes in operating parameters, process chemistry, or materials of construction also trigger reassessment needs.

Failure analysis evaluates potential outcomes

Consequence of failure analysis evaluates potential outcomes if containment loss occurs. This assessment considers multiple impact categories to develop a comprehensive picture of potential losses. The consequence evaluation directly influences risk ranking and inspection planning decisions.

For qualitative consequence assessments, categorization schemes typically employ severity ratings. Common categories include insignificant, minor, significant, serious, major, and catastrophic. Each category represents a range of potential impacts across safety, environmental, and business dimensions.

These qualitative categories facilitate rapid screening of large equipment populations. The simplified approach enables initial prioritization without extensive data collection or complex modeling. However, qualitative assessments provide less precision than quantitative methods for critical decisions.

Risk matrices combine qualitative probability and consequence ratings to visualize risk levels. The matrix format intuitively displays which equipment combinations of likelihood and severity warrant priority attention. Color coding often highlights unacceptable risk levels requiring immediate action.

Quantitative consequence assessments provide greater precision for high-stakes decisions. These analyses calculate specific values for personnel injury risks, equipment damage costs, environmental remediation expenses, and business interruption losses. The detailed estimates support cost-benefit analyses of risk reduction options.

Personal injury consequences typically use metrics such as potential fatalities or injury rates. Consequence modeling considers release scenarios, dispersion patterns, ignition probability, and population exposure. Sophisticated software tools simulate various accident sequences to estimate casualty figures.

Equipment damage consequences encompass repair or replacement costs for the failed component and collateral damage to adjacent equipment. Secondary damage from fires, explosions, or chemical releases often exceeds primary failure costs. The assessment scope must extend beyond the immediate failure point.

Financial impact calculations include direct costs plus indirect business consequences. Lost production during repair periods, contractual penalties for missed deliveries, increased insurance premiums, and regulatory fines all factor into total financial impact. Market share losses and reputation damage represent harder-to-quantify but potentially significant consequences.

Damage mechanisms and failure modes represent the physical processes and outcomes that RBI programs aim to detect and prevent. Comprehensive understanding of these phenomena enables appropriate inspection technique selection and interpretation of findings.

Corrosion encompasses numerous specific mechanisms with distinct characteristics. General corrosion produces uniform material loss across surfaces, while localized corrosion creates pits, crevices, or selective attack. Understanding which corrosion type threatens specific equipment guides inspection method selection.

Cracking mechanisms include stress corrosion cracking, hydrogen-induced cracking, fatigue cracking, and creep cracking. Each mechanism requires specific conditions to progress and produces characteristic crack morphology. Detection methods must suit the expected crack characteristics.

Mechanical damage mechanisms such as erosion

Mechanical damage mechanisms such as erosion, cavitation, and fretting wear material through physical processes rather than chemical attack. These mechanisms often concentrate at specific locations such as flow direction changes, impingement points, or contact surfaces.

High-temperature damage mechanisms become relevant in elevated-temperature service. Creep produces time-dependent deformation under sustained stress. Thermal fatigue results from cyclic temperature changes. Oxidation and other high-temperature corrosion modes degrade material properties.

Failure modes describe how equipment can lose containment when damage mechanisms progress beyond critical thresholds. Common failure modes include through-wall holes, longitudinal or circumferential cracks, and catastrophic rupture. The likely failure mode influences consequence severity.

Small leaks from pinhole corrosion perforations or hairline cracks may allow detection and response before escalating. These relatively benign failure modes provide opportunities for intervention. Inspection programs should detect degradation before leaks develop.

Large ruptures release inventory rapidly and often produce more severe consequences. Brittle fracture, overpressure failure, or extensive corrosion thinning can lead to catastrophic failures. High-consequence equipment requires inspection strategies that detect conditions before rupture becomes likely.

Understanding which failure modes could result from identified damage mechanisms helps assess consequences more accurately. The progression from initial damage to eventual failure follows predictable paths. Inspection intervals should allow detection before critical damage states are reached.

Data and information inputs provide the raw material for risk assessments and inspection planning. The quality, completeness, and accessibility of data directly impact the reliability of RBI program outputs. Systematic data management practices underpin successful implementation.

Design and fabrication information establishes baseline equipment characteristics. Original specifications, material certifications, fabrication records, and quality control documentation describe the as-built condition. This information supports stress analysis, damage mechanism identification, and remaining life calculations.

Operating data characterizes the actual service conditions equipment experiences. Temperature, pressure, flow rates, chemical composition, and cycling patterns all influence degradation rates. Process historians and control systems provide rich data sources if properly configured and maintained.

Inspection history documents previous findings and equipment condition over time. Thickness measurements, non-destructive examination results, repairs, and modifications create a longitudinal record. Trending this data reveals degradation rates and validates damage mechanism predictions.

Maintenance records capture interventions that may affect equipment condition or failure probability. Repairs, replacements, cleaning operations, and protective coating applications alter the equipment state. The risk assessment must reflect these changes in failure probability.

Process safety information includes material safety data sheets, process flow diagrams, piping and instrumentation drawings, and equipment lists. This information supports consequence modeling by defining inventories, chemical properties, and interconnections.

Regulatory compliance records demonstrate adherence to applicable codes and standards. Inspection reports, pressure test certificates, and authority approvals provide assurance that equipment meets minimum requirements. Gaps in compliance documentation may indicate elevated risks.

Data quality significantly impacts risk assessment reliability

Data quality significantly impacts risk assessment reliability. Inaccurate measurements, transcription errors, or outdated information propagate through calculations and produce unreliable results. Quality assurance processes should validate data accuracy before use in risk assessments.

The qualification of personnel processing data affects reliability. Trained data collectors using calibrated instruments and proper techniques generate more trustworthy information than unqualified individuals. Investment in personnel competency pays dividends in data quality.

Data collection processes must ensure relevance and availability of information needed for decision-making. Systematic protocols identify what data to collect, when to collect it, and how to record it. Standardized forms and electronic data capture reduce errors and omissions.

Data storage systems must preserve information integrity while enabling efficient access. Electronic databases with appropriate backup and security measures provide advantages over paper records. However, the chosen system must match organizational capabilities and culture.

Data management encompasses the complete lifecycle from collection through analysis to archiving. Clear responsibilities for data entry, validation, updating, and retention prevent information gaps. Regular audits verify that management processes function as intended.

Risk Based Inspection requires collaboration among individuals with diverse expertise. The multidisciplinary nature of risk assessment and inspection planning necessitates effective teamwork. API 580 provides guidance for assembling and operating high-performing RBI teams.

The team leader coordinates activities, facilitates communication, resolves conflicts, and ensures progress toward program objectives. Leadership responsibilities include setting meeting agendas, tracking action items, and representing the team to management. The leader need not be the technical expert but must possess strong organizational skills.

Equipment inspectors or inspection specialists bring detailed knowledge of inspection techniques, equipment accessibility, and practical limitations. Their field experience grounds risk assessments in operational reality. Inspectors contribute historical knowledge of equipment condition and previous findings.

Corrosion specialists provide technical expertise regarding damage mechanisms, degradation rates, and mitigation methods. Their input proves critical for identifying applicable damage mechanisms, estimating damage progression rates, and recommending appropriate inspection techniques.

Process specialists understand the intended operation of equipment within the overall production system. They clarify operating conditions, explain process upsets, and identify operational changes that might affect equipment integrity. Process knowledge prevents unrealistic assumptions in risk assessments.

Operations and maintenance personnel offer frontline perspectives on equipment performance and condition. Operators observe equipment behavior daily and often detect early warning signs of problems. Maintenance technicians have intimate knowledge of equipment repair history and recurring issues.

Ensures alignment between RBI program activities

Management representation ensures alignment between RBI program activities and organizational objectives. Management input addresses resource availability, strategic priorities, and risk tolerance. Executive support proves essential when risk assessments identify needs that require significant investment.

Risk analysts specialize in probability and consequence assessment methodologies. Their expertise in statistical analysis, consequence modeling, and risk calculation techniques ensures technical rigor. Risk analysts often operate supporting software tools and interpret results for the broader team.

Environmental and safety personnel bring regulatory knowledge and expertise in consequence assessment. They identify applicable regulations, evaluate environmental release scenarios, and assess safety risks to personnel. Their input ensures comprehensive consequence evaluation.

Financial and business personnel contribute economic analysis capabilities. They help quantify business interruption costs, evaluate investment alternatives, and communicate risk in business terms. Financial perspectives balance technical considerations in decision-making.

Effective team functioning requires more than assembling qualified individuals. Team dynamics, communication patterns, and decision-making processes significantly influence outcomes. Regular meetings with structured agendas maintain focus and momentum.

Risk assessment and evaluation synthesize probability and consequence analyses into coherent risk rankings. This evaluation step enables comparison across diverse equipment types and prioritization of inspection resources. Multiple evaluation approaches exist, ranging from simple risk matrices to sophisticated quantitative methods.

Qualitative risk evaluation employs categorical scales for both probability and consequence. Combining these ordinal scales produces a risk ranking that supports preliminary prioritization. The simplicity and speed of qualitative methods enable screening of large equipment populations.

Semi-quantitative approaches introduce numerical scores while retaining some categorical aspects. These hybrid methods provide greater discrimination than purely qualitative tools while avoiding the data requirements of full quantitative analysis. Many organizations find semi-quantitative methods offer an optimal balance.

Quantitative risk assessment calculates numerical risk values by multiplying failure probability and consequence magnitude. The resulting risk metric enables direct comparison across equipment and supports cost-benefit analysis of risk reduction options. Quantitative methods require substantial data and sophisticated analysis.

Risk matrices visually display the distribution of equipment across probability-consequence space. The intuitive format facilitates communication with non-technical stakeholders. Color coding distinguishes acceptable from unacceptable risk levels and guides prioritization decisions.

Risk criteria define what constitutes acceptable versus unacceptable risk for an organization. These criteria reflect corporate risk tolerance, regulatory requirements, industry standards, and societal expectations. Establishing clear criteria before assessment prevents biased decision-making.

Target risk levels guide inspection planning and risk reduction efforts. Equipment with risk exceeding target levels requires action to reduce probability, mitigate consequences, or both. Inspection frequency and intensity increase for equipment above target risk until degradation is controlled.

Risk ranking produces a prioritized list of equipment ordered by risk level. This ranking directly informs resource allocation decisions. High-risk equipment receives priority attention while low-risk items may have extended inspection intervals or less intensive examination.

Constraints and Boundaries of API 580 Risk Based Inspection

While Risk Based Inspection offers powerful advantages, practitioners must recognize its limitations to avoid overreliance or misapplication. Understanding these boundaries enables realistic expectations and appropriate use of RBI within broader integrity management programs.

Inaccurate or missing information fundamentally compromises risk assessment validity. The analysis quality cannot exceed the quality of input data. Errors in operating conditions, material specifications, or inspection history propagate through calculations and produce unreliable risk estimates.

Data gaps force assumptions that introduce uncertainty. When key information is unavailable, analysts must make educated guesses about equipment characteristics or service conditions. Conservative assumptions provide safety margins but may overestimate risk and drive unnecessary inspection.

Detecting and correcting data errors requires vigilant quality assurance. Cross-checking information against multiple sources, validating calculations, and peer review of assessments help identify mistakes before they influence decisions. Systematic data validation protocols catch errors that individual reviewers might miss.

The consequence of data quality issues extends beyond individual assessments. Poor data quality erodes confidence in the entire RBI program. Stakeholders who discover errors become skeptical of all results. Building and maintaining data quality proves essential for program credibility.

Inadequate design or installation creates vulnerabilities that inspection cannot remedy. Fundamental flaws in equipment design, improper material selection, or installation errors require corrective action beyond the scope of inspection programs. RBI identifies these issues but cannot resolve them through monitoring alone.

Design deficiencies might include inadequate corrosion allowances, insufficient mechanical strength, or lack of access for inspection and maintenance. These shortcomings require engineering solutions such as equipment modification, replacement, or operating limit changes.

Installation errors such as misalignment, improper support, or contamination during construction compromise equipment integrity from initial startup. While inspection may detect resulting damage, correcting root causes requires revisiting construction practices.

Commissioning oversights such as inadequate system cleaning, improper startup procedures, or incomplete testing can introduce problems that persist throughout equipment life. RBI programs inherit the consequences of commissioning deficiencies without ability to prevent them retroactively.

Operating equipment beyond acceptable limits generates risks that inspection alone cannot manage adequately. Exceeding design pressures, temperatures, or corrosivity accelerates damage and may trigger failure mechanisms not considered in the original design. Operating discipline forms an essential complement to inspection.

Uncontrolled operating upsets subject equipment to conditions more severe than normal operation. Temperature spikes, pressure surges, or introduction of unexpected contaminants cause damage that may not become apparent until subsequent inspection. Real-time monitoring and upset prevention protect better than after-the-fact inspection.

Chronic operation outside design limits normalizes conditions that should be abnormal. Gradual acceptance of off-spec operation erodes safety margins and increases failure probability. RBI assessments should flag equipment operating beyond design conditions as requiring priority attention.

Process changes that alter equipment service may not receive proper evaluation before implementation. Introducing new chemicals, increasing throughput, or modifying operating sequences can activate damage mechanisms not present in original service. Management of change processes should trigger RBI updates.

Ineffective execution of recommended inspection plans undermines the entire RBI process. Deferred inspections, incomplete examination, or use of inappropriate techniques negate the benefit of thorough planning. Actual inspection practices must align with planned activities to achieve intended risk reduction.

Resource constraints sometimes prevent execution of planned inspections as scheduled. Budget limitations, personnel shortages, or equipment access restrictions may force compromises. When execution falls short of plans, risk levels increase above assumed values.

Quality of inspection execution significantly affects detection capability. Even appropriate techniques fail to find damage when inspectors lack training, use faulty equipment, or fail to examine critical locations. Inspection quality assurance ensures that performed examinations achieve their intended purpose.

Documentation of inspection findings and communication to decision-makers completes the inspection cycle. Undocumented findings or poor communication breaks the feedback loop that enables informed action. Systematic reporting processes ensure information reaches stakeholders who can act on it.

Absence of qualified personnel or effective teamwork hampers risk reduction regardless of assessment quality. Technical expertise in risk assessment, inspection, and engineering must combine with collaboration skills to produce results. Personnel development and team building deserve attention alongside technical aspects.

Qualification requirements for RBI team members ensure minimum competency levels. Training programs, experience requirements, and certification processes verify that individuals possess necessary knowledge and skills. However, formal qualifications alone do not guarantee effective performance.

Team dynamics strongly influence outcomes even among qualified individuals. Conflict, poor communication, or lack of psychological safety inhibit the frank discussion necessary for accurate risk assessment. Leaders must foster constructive team environments.

Organizational culture affects willingness to acknowledge risks and take corrective action. Cultures that shoot messengers or punish bearers of bad news drive problems underground. RBI programs thrive in cultures that value transparency and continuous improvement.

Knowledge management prevents loss of expertise as experienced personnel retire or transfer. Systematic capture of lessons learned, documentation of rationale for decisions, and mentoring of less experienced staff preserve institutional knowledge.

Lack of sound engineering and operational judgment undermines technical analysis. Numbers from risk models do not make decisions; people do. Experienced judgment must interpret analytical results, recognize unrealistic outputs, and make appropriate decisions considering factors beyond numerical risk values.

Engineering judgment encompasses technical knowledge applied

Engineering judgment encompasses technical knowledge applied to specific situations. Experienced engineers recognize when analytical results seem inconsistent with physical reality and investigate discrepancies. Blind acceptance of calculated values without sanity checking leads to poor decisions.

Operational judgment considers practical constraints and opportunities that pure analysis may overlook. Operators understand equipment idiosyncrasies, identify inspection timing opportunities, and recognize when theoretical plans prove impractical. Integrating operational perspectives improves plan effectiveness.

Risk models simplify complex reality through assumptions and approximations. Users must understand model limitations and interpret results accordingly. Sophisticated models may produce precise numbers that mask underlying uncertainty. Judgment distinguishes true precision from false precision.

Balancing competing objectives requires judgment beyond algorithmic decision rules. Risk reduction competes with production demands, capital investment opportunities, and other priorities. Leaders must weigh these tradeoffs using judgment informed by, but not dictated by, risk calculations.

Failure to follow up on inspection findings negates the value of detecting problems. Inspection discovers damage or degradation, but action prevents failures. Systematic processes for evaluating findings, determining appropriate responses, and implementing corrective measures complete the integrity loop.

Timely evaluation of inspection findings enables proactive response before conditions deteriorate further. Delays in reviewing results may allow continued degradation while data sits in files. Automated workflows route findings to responsible parties promptly.

Determining appropriate response to findings requires technical evaluation. Some findings warrant immediate shutdown and repair while others permit continued operation with monitoring. Decision criteria based on acceptance standards guide these determinations.

Implementing corrective actions addresses immediate equipment conditions and may reveal broader improvement opportunities. Recurring findings across multiple equipment items might indicate systematic issues requiring program-level changes. Learning from findings improves future performance.

Tracking corrective actions through completion ensures that intended fixes actually occur. Work order systems, action tracking databases, and management review meetings prevent items from falling through cracks. Verification that repairs achieved intended outcomes confirms effective resolution.

Construction and fabrication errors introduce defects that require correction outside normal RBI scope. Welding defects, improper heat treatment, dimensional errors, or material mix-ups compromise equipment integrity from the start. Quality control during fabrication prevents such errors more effectively than later inspection.

Fabrication codes specify quality requirements and inspection protocols for new construction. Compliance with codes like ASME Section VIII for pressure vessels provides assurance of initial integrity. However, enforcement varies and defects occasionally escape detection.

Vendor quality programs at fabrication shops should catch defects before equipment ships. Source inspection by owner representatives provides additional oversight. Despite these measures, some defects remain undetected until in-service inspection or failure reveals them.

Repairing fabrication defects often proves more expensive and disruptive than preventing them initially. Equipment may require removal from service for repair, affecting production schedules. Prevention through robust fabrication quality control provides superior outcomes.

Advantages and Strategic Value of Risk Based Inspection API 580

Organizations implementing Risk Based Inspection according to API 580 principles realize substantial benefits across safety, reliability, and economic dimensions. These advantages extend beyond simple cost reduction to fundamental improvements in how companies manage asset integrity.

The ability to prioritize inspection resources toward highest-risk equipment represents the most direct benefit of RBI implementation. Traditional approaches spread resources evenly across all equipment regardless of actual risk differences. This one-size-fits-all strategy wastes resources on low-risk equipment while potentially under-serving high-risk items.

Risk-based prioritization concentrates attention where it matters most. High-risk equipment receives more frequent inspection with more comprehensive techniques. This targeted approach detects problems before they escalate to failures. Meanwhile, low-risk equipment receives appropriate but less intensive monitoring.

Resource optimization extends beyond inspection activities to encompass the entire integrity program. Planning, analysis, and decision-making efforts focus on equipment where they provide greatest value. Organizations achieve better outcomes with equivalent or reduced resource expenditure.

The systematic nature of RBI enables defensible decision-making. Documented risk assessments provide clear rationale for inspection priorities and intervals. This transparency helps communicate decisions to regulators, management, and other stakeholders.

Equipment reliability improves when inspection programs detect and address degradation before failures occur. RBI programs, properly implemented, identify emerging problems while equipment remains operable. This early detection enables planned maintenance during convenient outages rather than forced shutdowns from failures.

Reduced failure rates directly impact plant availability. Unplanned shutdowns for emergency repairs disrupt production schedules and impose economic penalties. Preventing failures through proactive inspection maintains steady production flows.

Equipment operating without hidden defects performs more reliably and efficiently. Degradation such as fouling or corrosion often impairs performance before causing failure. Detection and correction through inspection restores design performance levels.

Reliability improvements accumulate over time as RBI programs mature. Initial implementation identifies and addresses backlog issues. Ongoing operation maintains equipment in better condition than traditional programs achieved. The compounding effect of incremental improvements yields substantial long-term gains.

Safety performance benefits from RBI's emphasis on consequence reduction. High-consequence equipment receives priority attention regardless of failure probability. This focus on worst-case scenarios aligns well with safety management objectives.

Preventing releases of hazardous materials protects workers, communities, and environment. RBI programs specifically target equipment whose failure could cause injuries, fatalities, or environmental damage. Reduced incident rates demonstrate safety improvements.

Near-miss events decline as equipment condition improves. Small leaks and minor incidents often precede catastrophic failures. RBI programs detect developing problems before they produce observable events. Fewer near-misses indicate that potential major incidents are being prevented.

Safety culture improves when organizations systematically address risks. Visible commitment to risk-based decision-making demonstrates management prioritization of safety. Workforce confidence increases when people see hazards being systematically managed.

Economic benefits flow from multiple sources including reduced maintenance costs, improved reliability, and optimized capital deployment. While safety provides the primary motivation for many organizations, economic advantages ensure sustained management support for RBI programs.

Maintenance cost reductions arise from better targeting of inspection activities and more effective repair planning. Over-inspection of low-risk equipment wastes resources without safety benefit. Redirecting those resources to high-risk equipment provides better return on investment.

Inspection technique selection based on damage mechanisms improves detection effectiveness. Using appropriate methods reduces both false positives that trigger unnecessary investigations and false negatives that miss actual problems. Better detection efficiency translates to cost savings.

Repair planning benefits from advance knowledge of equipment condition. Inspection findings enable procurement of materials and scheduling of resources before failures force reactive scrambling. Planned repairs cost less and cause less disruption than emergency responses.

Extended inspection intervals for low-risk equipment reduce direct inspection costs without compromising safety. When risk assessment demonstrates that longer intervals remain acceptable, organizations can reduce inspection frequency. These extensions must be technically justified and properly documented.

Production continuity improves when planned maintenance replaces reactive firefighting. Scheduling maintenance during planned outages avoids unplanned production interruptions. Coordinating inspection and maintenance activities during turnarounds maximizes equipment uptime between outages.

Capital investment optimization follows from improved understanding of equipment condition and remaining life. RBI assessments inform replacement timing decisions by clarifying when equipment approaches end of useful life. Premature replacement wastes capital while delayed replacement risks failures.

Budget allocation benefits from risk-based prioritization of capital projects. When multiple equipment items require investment, risk assessment identifies which improvements provide greatest risk reduction per dollar invested. This prioritization optimizes limited capital budgets.

Insurance costs may decrease as insurers recognize reduced risk from systematic integrity management. Demonstrating robust RBI programs provides evidence of responsible risk management. Some insurers offer premium reductions for certified programs.

Regulatory relationships improve when organizations demonstrate systematic approaches to compliance. Regulators appreciate documented decision processes and risk-based justification for activities. Productive relationships with authorities reduce compliance burden and may enable greater operational flexibility.

Compliance assurance increases through systematic tracking of inspection requirements. RBI programs incorporate regulatory mandates alongside risk-based priorities. Integration ensures that minimum requirements are met while optimizing activities beyond minimum standards.

Audit preparation becomes more straightforward when programs maintain comprehensive documentation. Risk assessments, inspection plans, findings documentation, and corrective action tracking provide clear evidence of compliance. Organized records facilitate efficient audits.

Variance requests gain credibility when supported by risk assessments. Occasionally, regulatory requirements prove impractical or excessive for specific equipment. Well-documented risk analyses support requests for alternative compliance approaches.

Stakeholder confidence grows when organizations demonstrate responsible asset management. Investors, customers, communities, and employees all have stakes in plant safety and reliability. Transparent risk management practices build trust with these constituencies.

Environmental stewardship improves through prevention of releases. RBI programs target equipment whose failure could cause environmental damage. Preventing these failures protects ecosystems and demonstrates corporate environmental responsibility.

Corporate reputation benefits from avoiding major incidents. High-profile failures generate negative publicity and damage brand value. Systematic prevention through RBI protects reputation alongside physical assets.

Operational knowledge deepens as RBI implementation forces systematic examination of equipment and processes. The analysis required for risk assessment develops organizational understanding of how equipment degrades and what factors matter most. This knowledge proves valuable beyond immediate RBI applications.

Cross-functional collaboration improves through RBI team interactions. Breaking down silos between operations, maintenance, engineering, and inspection creates relationships and mutual understanding. These improved working relationships benefit many activities beyond RBI.

Continuous improvement becomes embedded in organizational culture. RBI programs operate through cycles of assessment, inspection, analysis, and refinement. This cyclical process naturally incorporates lessons learned and drives ongoing enhancement of practices.

Professional Certification for API 580 Risk Based Inspection

Professional certification programs validate individual competency in Risk Based Inspection principles and practices. The American Petroleum Institute offers certification specifically for API 580, demonstrating that individuals possess knowledge necessary for effective RBI implementation.

Certification eligibility typically requires a combination of education, experience, and examination performance. Candidates must meet minimum qualifications before attempting the certification exam. These requirements ensure that certified individuals possess appropriate background for professional practice.

Educational prerequisites establish foundational technical knowledge. Engineering degrees or equivalent technical education provide the analytical skills necessary for risk assessment work. While specific educational paths may vary, all routes require substantial technical content.

Experience requirements ensure practical exposure to equipment integrity challenges. Years of relevant work experience complement academic knowledge with real-world perspective. The required experience duration varies based on educational level and specific work duties.

The certification examination comprehensively tests knowledge across all aspects of API 580. Question topics span risk assessment methodologies, damage mechanisms, inspection planning, and program management. Passing scores demonstrate mastery of core concepts.

Examination formats typically include multiple-choice questions that assess both theoretical understanding and practical application ability. Questions may present scenarios requiring candidates to apply principles to specific situations. This format tests judgment alongside factual knowledge.

Preparation for certification examinations requires thorough study of API 580 and related standards. Candidates benefit from formal training courses that systematically cover examination topics. Self-study using the standards documents and supporting references also proves effective for motivated learners.

Practice examinations help candidates assess readiness and identify knowledge gaps. Sample questions familiarize test-takers with question formats and difficulty levels. Working through practice problems under timed conditions builds test-taking skills.

Certification validity periods require periodic recertification to maintain credentials. API 580 certification remains valid for three years before renewal becomes necessary. Time limits ensure that certified individuals maintain current knowledge as standards evolve.

Recertification processes may involve continuing education, re-examination, or both. Requirements balance the need for currency verification against avoiding excessive burden on practitioners. The specific recertification path depends on the certifying organization's policies.

Conclusion

The implementation of API 580 Risk-Based Inspection (RBI) represents a transformative approach to asset integrity management, shifting the focus from routine, time-based inspections to a more analytical and strategic framework that prioritizes risk. By integrating probability of failure with consequence of failure, organizations are able to better allocate inspection resources, minimize downtime, and enhance safety performance across critical equipment. This framework not only provides a structured methodology for assessing and managing risks but also fosters a culture of proactive decision-making within asset-intensive industries.

One of the most significant advantages of API 580 is its ability to align inspection planning with actual risk exposure. Traditional inspection methods often result in either over-inspection of low-risk components or insufficient attention to high-risk assets, leading to inefficiencies and increased vulnerability. RBI, on the other hand, enables companies to focus resources on areas with the highest potential for safety, environmental, or financial consequences. This ensures that integrity management is not only technically robust but also economically optimized.

Equally important, API 580 emphasizes the integration of multidisciplinary expertise. Successful RBI implementation requires collaboration among engineers, inspectors, operations personnel, and risk specialists. This collective approach ensures that data, whether derived from equipment history, operating conditions, or material properties, is thoroughly analyzed and validated. In doing so, organizations strengthen the reliability of risk assessments and promote knowledge sharing across different functions. Moreover, the standard reinforces the value of maintaining high-quality data management systems, as reliable information is the backbone of any credible RBI program.

Another crucial outcome of adopting API 580 is its alignment with broader regulatory and corporate governance expectations. In an era of heightened scrutiny regarding safety, sustainability, and operational accountability, the framework provides a structured and internationally recognized methodology to demonstrate due diligence. By showing that inspection strategies are driven by quantifiable risk assessments, organizations can improve stakeholder confidence, reduce regulatory non-compliance, and strengthen their license to operate.

The long-term benefits of API 580 also extend to operational sustainability. As industries strive to optimize lifecycle performance of assets, RBI offers a pathway to extend equipment service life, reduce unplanned failures, and optimize maintenance budgets. In addition, by identifying high-risk scenarios early, organizations can implement mitigation strategies—such as material upgrades, process modifications, or enhanced monitoring systems—that prevent costly incidents and improve overall reliability.

API 580 serves as an essential framework for organizations seeking to balance safety, reliability, and economic performance in asset integrity management. By embedding risk-based thinking into inspection planning, industries are better positioned to address modern challenges, from regulatory compliance to cost efficiency and environmental stewardship. Ultimately, the adoption of API 580 is not merely a compliance exercise; it is a strategic investment in sustainable operations, organizational resilience, and stakeholder trust. As industries continue to evolve, those that embrace risk-based inspection principles will be best equipped to manage complexity, safeguard their assets, and achieve long-term operational excellence.

Frequently Asked Questions

Where can I download my products after I have completed the purchase?

Your products are available immediately after you have made the payment. You can download them from your Member's Area. Right after your purchase has been confirmed, the website will transfer you to Member's Area. All you will have to do is login and download the products you have purchased to your computer.

How long will my product be valid?

All Testking products are valid for 90 days from the date of purchase. These 90 days also cover updates that may come in during this time. This includes new questions, updates and changes by our editing team and more. These updates will be automatically downloaded to computer to make sure that you get the most updated version of your exam preparation materials.

How can I renew my products after the expiry date? Or do I need to purchase it again?

When your product expires after the 90 days, you don't need to purchase it again. Instead, you should head to your Member's Area, where there is an option of renewing your products with a 30% discount.

Please keep in mind that you need to renew your product to continue using it after the expiry date.

How often do you update the questions?

Testking strives to provide you with the latest questions in every exam pool. Therefore, updates in our exams/questions will depend on the changes provided by original vendors. We update our products as soon as we know of the change introduced, and have it confirmed by our team of experts.

How many computers I can download Testking software on?

You can download your Testking products on the maximum number of 2 (two) computers/devices. To use the software on more than 2 machines, you need to purchase an additional subscription which can be easily done on the website. Please email support@testking.com if you need to use more than 5 (five) computers.

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by all modern Windows editions, Android and iPhone/iPad versions. Mac and IOS versions of the software are now being developed. Please stay tuned for updates if you're interested in Mac and IOS versions of Testking software.